ISO/DIS 13628-14

(Main)Petroleum and natural gas industries -- Design and operation of subsea production systems

Petroleum and natural gas industries -- Design and operation of subsea production systems

Industries du pétrole et du gaz naturel -- Conception et exploitation des systèmes de production immergés

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 13628-14

ISO/TC 67/SC 4 Secretariat: ANSI

Voting begins on Voting terminates on

2011-10-13 2012-03-13

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ ORGANISATION INTERNATIONALE DE NORMALISATION

Petroleum and natural gas industries — Design and operationof subsea production systems —

Part 14:

Subsea high integrity pressure protection systems (HIPPS)

Industries du pétrole et du gaz naturel — Conception et exploitation des systèmes de production immergés —

Partie 14: Systèmes immergés de protection contre les pressions à haute intégrité

ICS 75.180.10ISO/CEN PARALLEL PROCESSING

This draft has been developed within the International Organization for Standardization (ISO), and

processed under the ISO-lead mode of collaboration as defined in the Vienna Agreement.

This draft is hereby submitted to the ISO member bodies and to the CEN member bodies for a parallel

five-month enquiry.Should this draft be accepted, a final draft, established on the basis of comments received, will be

submitted to a parallel two-month approval vote in ISO and formal vote in CEN.In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee

secretariat. ISO Central Secretariat work of editing and text composition will be undertaken at

publication stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME

STANDARDS TO WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.© International Organization for Standardization, 2011

---------------------- Page: 1 ----------------------

ISO/DIS 13628-14

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user’s country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic,

photocopying, recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO’s

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2011 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 13628-14

Contents Page

Foreword ............................................................................................................................................................. v

Introduction ....................................................................................................................................................... vii

1 Scope ...................................................................................................................................................... 1

2 Normative references ............................................................................................................................ 1

3 Terms, definitions, symbols and abbreviations ................................................................................. 2

3.1 Terms and definitions ........................................................................................................................... 2

3.2 Symbols and abbreviations .................................................................................................................. 5

4 General requirements ........................................................................................................................... 6

4.1 Principle.................................................................................................................................................. 6

4.2 Production characteristics ................................................................................................................... 8

4.3 Flowline rupture considerations .......................................................................................................... 8

4.4 Process hazard and risk analysis ........................................................................................................ 8

4.5 Selection and determination of SIL ..................................................................................................... 9

4.6 Safety requirement specification (SRS) .............................................................................................. 9

5 Procedure – Basic design................................................................................................................... 11

5.1 Principle - Design basis requirements .............................................................................................. 11

5.2 Modes of failure ................................................................................................................................... 14

5.3 Temperature ......................................................................................................................................... 14

5.4 Pressure ............................................................................................................................................... 14

5.5 Control system .................................................................................................................................... 15

5.6 Materials class rating .......................................................................................................................... 17

5.7 External hydrostatic pressure ............................................................................................................ 17

5.8 Transportation and installation conditions ...................................................................................... 18

5.9 Equipment design ............................................................................................................................... 18

5.10 Control systems .................................................................................................................................. 19

6 Materials and equipment .................................................................................................................... 22

6.1 HIPPS final element equipment ......................................................................................................... 22

6.2 HIPPS control system and final element-mounted control devices............................................... 24

6.3 Welding ................................................................................................................................................. 25

6.4 Coatings (external) .............................................................................................................................. 25

7 Quality control ..................................................................................................................................... 25

7.1 General ................................................................................................................................................. 25

7.2 HIPPS closure devices—PSL ............................................................................................................. 26

7.3 Structural components ....................................................................................................................... 27

7.4 Lifting devices ..................................................................................................................................... 27

7.5 Cathodic protection ............................................................................................................................. 27

7.6 Storing and shipping ........................................................................................................................... 27

8 Equipment marking ............................................................................................................................. 28

8.1 General ................................................................................................................................................. 28

8.2 Pad eyes and lift points ...................................................................................................................... 28

9 Validation.............................................................................................................................................. 28

9.1 General ................................................................................................................................................. 28

9.2 Validation for HIPPS closure devices (isolation valve) and actuator ............................................ 29

9.3 Validation for monitor/bleed, bypass, injection valves ................................................................... 29

9.4 Validation for DCV ............................................................................................................................... 29

9.5 Validation of sensors, logic solvers, and control system devices................................................. 30

9.6 Validation of HIPPS final element ...................................................................................................... 31

© ISO 2011 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 13628-14

9.7 Estimating SIL for HIPPS final element components...................................................................... 31

10 Commissioning and installation ....................................................................................................... 32

10.1 General ................................................................................................................................................. 32

10.2 Planning ............................................................................................................................................... 32

10.3 Installation ........................................................................................................................................... 34

10.4 Commissioning ................................................................................................................................... 34

iv © ISO 2011 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 13628-14

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 13628-14 was prepared by Technical Committee ISO/TC 67, Materials, equipment and offshore

structures for the petroleum, petrochemical and natural gas industries, Subcommittee SC 4, Drilling and

production equipment.This is the first edition of ISO 13628-14.

ISO 13628 consists of the following parts, under the general title Petroleum and natural gas industries —

Design and operation of subsea production systems: Part 1: General requirements and recommendations

Part 2: Flexible pipe systems for subsea and marine applications

Part 3: Through flowline (TFL) systems

Part 4: Subsea wellhead and tree equipment

Part 5: Subsea umbilicals

Part 6: Subsea production control sytems

Part 7: Completion/workover riser systems

Part 8: Remotely Operated Vehicle (ROV) interfaces on subsea production systems

Part 9 Remotely Operated Tool (ROT) intervention systems (combined into Part 8)

Part 10: Specification for bonded flexible pipe Part 11: Flexible pipe systems for subsea and marine applications

Part 12: Dynamic production risers (under preparation)

Part 13: Vacant

© ISO 2011 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/DIS 13628-14

Part 14: Subsea high integrity pressure protection systems (HIPPS)

Part 15: Subsea structures and man ifolds (under preparation)

Part 16 Recommended practice for flexib le pipe ancilliary equipment (under preparation)

Part 17: Specification for flexible pipe ancillary equipment (under preparation)

vi © ISO 2011 – All rights reserved---------------------- Page: 6 ----------------------

ISO/DIS 13628-14

Introduction

The part of International Standard ISO 13628 has been prepared to provide general recommendations and

overall guidance for the designa and operation of remotely operated tools comprising ROT and ROV tooling,

used on subsea production systems for the petroleum and natural gas indsutries worldwide.

Specific design requirements are used where a standard design or operating principle has been adopted in

the industry for a period of time. Requirements valid for certain geographic areas or environmental conditions,

are included where applicable.The functional recommendations for the tooling systems and interfaces on the subsea production system

allow alternative solutions to suite field specific requirements. The intention is to facilitate and complement the

decision process rather than replace individual engineering judgement and, where requirements are non-

mandatory, to provide positive guidance for hte selection of an optimum solution.

© ISO 2011 – All rights reserved vii---------------------- Page: 7 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 13628-14

Petroleum and natural gas industries — Design and operation

of subsea production systems —

Part 14:

Subsea high integrity pressure protection systems (HIPPS)

1 Scope

This part of the International Standard ISO 13628 series addresses the requirements for the use of high integrity

pressure protection systems (HIPPS) for subsea applications. ISO 10418, IEC 61508, and IEC 61511 specify

the requirements for onshore, topsides, and subsea safety instrumented systems (SIS’s) and are applicable to

HIPPS, which are designed to autonomously isolate downstream facilities from overpressure situations. This

International Standard integrates these requirements to address the specific needs of subsea production. These

requirements cover the HIPPS pressure sensors, logic solver, shutdown valves, and ancillary devices including

testing, communications, and monitoring subsystems.2 Normative references

The following referenced documents are indispensable for the application of this International Standard. For

dated references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.ISO 10418, Petroleum and natural gas industries – Offshore production installations – Basic surface safety

systemsISO 10423 , Petroleum and natural gas industries,

ISO 13628-1 , Petroleum and natural gas industries, Design and operation of subsea production systems,

General requirements and recommendationsISO 13628-3 , Petroleum and natural gas industries, Design and operation of subsea production systems,

Through flowline (TFL) systemsISO 13628-4 , Petroleum and natural gas industries, Design and operation of subsea production systems,

Subsea wellhead and Christmas tree equipmentISO 13628-6 , Petroleum and natural gas industries, Design and operation of subsea production systems,

Subsea Production Control Systems1) API 6A, Specification Wellhead and Christmas Tree Equipment, is equivalent to ISO 10423.

2) API 17A, Design and Operation of Subsea Production Systems—General Requirements and Recommendations, is

equivalent to ISO 13628-1.3) API 17C, Recommended Practice on TFL (Through Flowline) Systems, is equivalent to ISO 13628-3.

4) API 17D, Recommended Practice on Subsea Wellhead and Christmas Tree Equipment, is equivalent to ISO 13628-4.

5) API 17F, Specification for Subsea Production Control Systems, is equivalent to ISO13628-6.

© ISO 2011 – All rights reserved 1---------------------- Page: 8 ----------------------

ISO/DIS 13628-14

ISO 13628-8 , Petroleum and natural gas industries, Design and operation of subsea production systems,

Remotely operated vehicle (ROV) interfaces.NOTE ISO 13628-8 will be withdrawn and r eplaced by ISO 13628-13 when published. In this document, any

reference to ISO 13628-8 should be replaced with ISO 13628-13 when published and available.

IEC 61508, Part 1 to Part 4, Functional safety of electrical/electronic/programmable electronic safety-related

systemsIEC 61511, Part 1, Functional safety—Safety instrumented systems for the process industry sector

API Recommended Practice 6HT, Heat Treatment and Testing of Large Cross Section and Critical Section

ComponentsANSI/ASME B31.3, Process Piping

ANSI/ASME B31.8, Gas Transmission and Distribution Piping Systems

AWS D1.1, Structural Welding Code—Steel

ANSI/SAE J343, Test and Test Procedures for SAE 100R Series Hydraulic Hose and Hose Assemblies

ANSI/SAE J517, Hydraulic HoseSAE AS 4059, Aerospace Fluid Power—Cleanliness Classification for Hydraulic Fluids

3 Terms, definitions, symbols and abbreviations3.1 Terms and definitions

For the purposes of this document, the following definitions apply.

3.1.1

alternative pressure source

injection fluid used for valve seal test not to exceed the RWP of the HIPPS at its depth rating

NOTE Injection fluid can be any fluid that can be introduced into the system not only for testing but also for flushing

or preventing hydrates from forming.3.1.2

commissioning

functional validation of equipment and facilities prior to initiating operations

3.1.3

dangerous failure

failure which has potential to put safety-related system in a hazardous or fail-to-function state

6) API 17H, Recommended Practice for Remotely Operated Vehicle (ROV) Interfaces on Subsea Production Systems, is

equivalent to ISO 13628-8.2 © ISO 2011 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 13628-14

3.1.4

final element

part of a SIS which implements the physical action necessary to achieve a safe state

3.1.5fortified section

piping and equipment with an intermediate pressure rating somewhere between the SIP (high) and MAWP

(low) ratings3.1.6

hardware fault tolerance

HFT

ability of a functional unit to continue to perform a required function in the presence of faults or errors

NOTE In determining the HFT, no account is taken of other measures that may control the effects of faults such as

diagnostics, and where one fault directly leads to the occurrence of one or more subsequent faults, these are considered

as a single fault.3.1.7

high integrity pressure protection system

HIPPS

mechanical and electrical-hydraulic SIS used to protect production assets from high-pressure upsets

3.1.8maximum allowable operating pressure

MAOP

maximum pressure at which a system is allowed to operate that shall not be exceeded in steady state

conditions3.1.9

maximum operating pressure

maximum pressure predicted including deviations from normal operations, such as start-up/shutdown, process

flexibility, control requirements, and process upsets3.1.10

operating pressure

pressure in the equipment when the plant operates at steady state condition, subject to normal variation in

operating parameters3.1.11

overpressure source

one or a combination of sources which can create a pressure buildup beyond the RWP of hardware

downstreamNOTE Examples include the reservoir, pressure or boosting equipment (i.e. pump/compressor) manifolds, or other

fluid injection sources.3.1.12

pipeline

piping, risers, and appurtenances installed for transporting oil, gas, sulfur, and produced waters

3.1.13process hazard

process upset that could result in loss of life, injury to personnel, pollution, or damage to production assets

such as overpressure and the subsequent rupture or failure of the process equipment

© ISO 2011 – All rights reserved 3---------------------- Page: 10 ----------------------

ISO/DIS 13628-14

3.1.14

rated working pressure

RWP

maximum internal pressure that the equipment is designed to contain and/or control

3.1.15reliability

likelihood of a given piece of safety-related equipment to remain in operation for the expected duration

3.1.16risk analysis

determination of the frequency of the event (e.g. overpressure) and the ability of safeguards (e.g. HIPPS) to

reduce the frequency or the consequence such that the event becomes tolerable, either by being very rare

(unlikely) or lessening the impact3.1.17

safe failure

failure which does not have the potential to put the safety-related system in a hazardous or fail-to-function

state3.1.18

safe failure fraction

SFF

ratio of the average rate of safe failures plus dangerous detected failures of the subsystem to the total

average failure rate of the component, as defined by IEC 61508, Part 23.1.19

safety instrumented function

SIF

safety function with a specified SIL which is necessary to achieve functional safety and which can be either a

safety instrumented protection function or a safety instrumented control function

3.1.20safety integrity level

SIL

discrete level (one out of four) for specifying the safety integrity requirements of the SIFs to be allocated to the

SIS. SIL 4 has the highest level of safety integrity; SIL 1 has the lowest3.1.21

shut-in pressure

SIP

full internal product process pressure that shall be contained by the HIPPS at the seabed when the high-

pressure source is abruptly isolated to protect lower pressure hardware downstream of the spec break

3.1.22specification (spec) break

point at which equipment pressure rating changes from one RWP rating to a lower one (or vice versa)

downstreamNOTE These locations are defined by the normal operating conditions of a flow stream that allows the use of lower

design pressure equipment.3.1.23

subsea tieback

an offshore field developed with one or more wells completed on the seafloor, using subsea trees

NOTE The wells are connected by flowlines and umbilicals—the pathways for electrical and hydraulic signals—to a

production facility in another area.4 © ISO 2011 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/DIS 13628-14

3.1.24

systems integration test

SIT

a process conducted on land to verify the fit, form, and function between interfaces of all subsea equipment

and associated running tools prior to offshore installation3.1.25

systematic failure

failure related in a deterministic way to a certain cause, which can only be eliminated by a modification of the

design or of the manufacturing process, operational procedures, documentation, or other relevant factors

3.2 Symbols and abbreviationsC number of anticipated HIPPS final element closures per year

L expected design operating life of the HIPPS final element (years)

MTBF mean time (number of cycles) between failures

PFD average PFD

t defined as the planned testing interval of the entire HIPPS (sensors, logic solvers, and final

elements) while in-service to maintain the demonstrated SILλ dangerous undetectable failures

λ total failure rate

TOT

BSDV boarding shutdown valve

DCS distributed control system

DCV directional control valve

EPU electrical power unit

ESD emergency shutdown

FAT factory acceptance test

FIV flowline isolation valve

FMECA failure mode effects and criticality analysis

GOR gas-oil-ratio

HFT hardware fault tolerance

HIPPS high integrity pressure protection system

HPU hydraulic power unit

HSCM HIPPS subsea control module

LOPA layer of protection analysis

MAOP maximum allowable operating pressure

MAWP maximum allowable working pressure

MCS master control station

MOC management of change

MTBF mean time between failures

MTTF mean time to failure

NDE normally de-energized

NE normally energized

PCS production control system

PE programmable electronics

PES programmable electronic system

PFD probability of failure on demand

PLEM pipeline end manifold

PLET pipeline end termination

PR performance requirement

PSD production shutdown

PSH pressure switch high

PSL product specification level

PST partial stroke testing

PSV process safety valve

QRA quantitative risk analysis

QTC qualification test coupon

© ISO 2011 – All rights reserved 5

---------------------- Page: 12 ----------------------

ISO/DIS 13628-14

ROT remotely operated tool

ROV remotely operated vehicle

RWP rated working pressure

SAFE safety analysis function evaluation

SCM subsea control module

SCSSV surface controlled subsurface safety valve

SEM subsea electronics module

SFF safe failure fraction

SIF safety instrumented function

SIL safety integrity level

SIP shut-in pressure

SIS safety instrumented system

SIT systems integration test

SRS safety requirement specification

SWL safe working load

TFL through flowline

UPS uninterruptible power supply

USV underwater safety valve

4 General requirements

4.1 Principle

This clause covers system elements that shall be considered when designing a HIPPS. HIPPS is a SIS used

to protect downstream facilities and personnel, and prevent environmental release by containing high-

pressure excursions.The design and performance of the HIPPS, including all lifecycle activities, should be based on IEC 61511.

Hazard and risk assessments shall be conducted to determine requirements for risk reductions, allocate

safety integrity level (SIL) of the HIPPS, and demonstrate that the risk of overpressure has been adequately

mitigated. Appropriate regulatory agencies should be consulted for additional design and operating

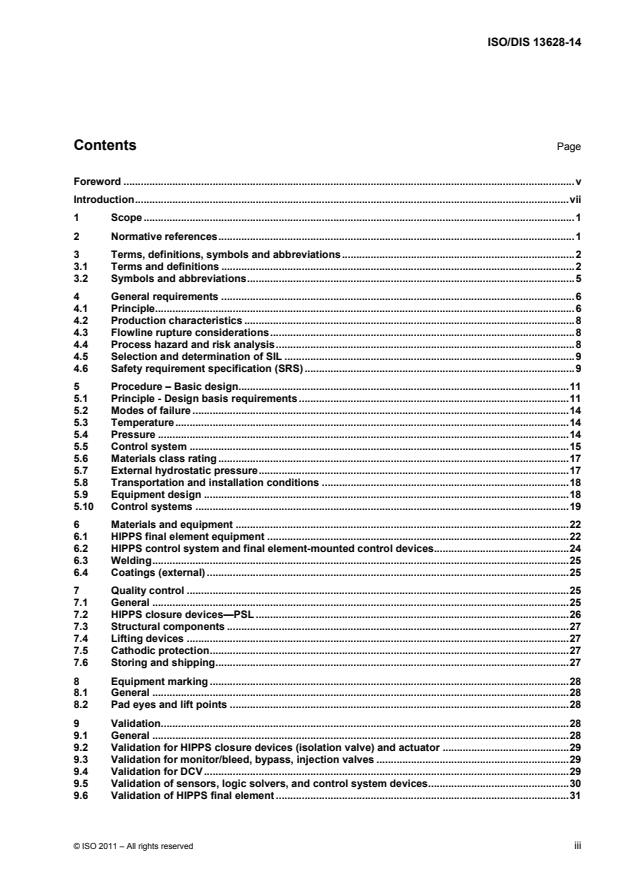

requirements.A typical HIPPS is shown in Figure 1.

6 © ISO 2011 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/DIS 13628-14

Figure 1 — Typical Subsea Production HIPPS Valve Diagram

4.1.1 Pressure Source

The overpressure to be mitigated by the HIPPS could originate from a number of sources. Examples include

but are not limited to high reservoir pressures, subsea pumps, and connection to higher pressure pipeline or

any combination thereof.The source could be gas, liquid, or multiphase fluid, which have different system response requirements. The

flow composition may change during the production life and may be dependent on topography. All of these

aspects, and any uncertainties associated with them, need to be considered as part of a full HIPPS analysis.

Before additional wells are tied into an existing system or any other change is made that could affect fluid

properties, a new flow analysis should be conducted to ensure that the system is designed to cover the new

configuration.4.1.2 HIPPS

SIS, defined by this document, provides pressure protection to downstream components.

4.1.3 Subsea fortified zoneA fortified section may be located downstream of the HIPPS isolation valves to allow time to respond to the

system closure determined by the pressure transient calculations. The response time to system closure will be

dependent on the nature of the flow for the specific system and would include consideration of the gas-oil-ratio

(GOR).The pressure rating of the fortified section will be project-specific and will range from the maximum allowable

operating pressure...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.