SIST ISO 15767:2004

(Main)Workplace atmospheres -- Controlling and characterizing errors in weighing collected aerosols

Workplace atmospheres -- Controlling and characterizing errors in weighing collected aerosols

ISO 15767:2003 provides recommendations for controlling the analytical uncertainty associated with aerosol collection medium instability, where collection medium or substrate includes any article used to collect particles (e.g. filter or foam material) as well as those supporting elements which must be analysed by weighing.

ISO 15767:2003 is applicable to results compiled both from the literature and, if necessary and feasible, through laboratory experiment. Expected errors associated with given aerosol capture methods are quantified where possible. Recommendations as to materials to be used are given. Means of controlling or correcting errors arising from instability are provided. Recommendations for the weighing procedure are given. A procedure for estimating weighing errors is described. Finally, recommendations are given for the reporting of measured masses.

Atmosphères des lieux de travail -- Contrôle et caractérisation des erreurs de pesée des aérosols collectés

L'ISO 15767:2002 fournit des recommandations pour le contrôle des incertitudes analytiques liées à l'instabilité des supports de collecte d'aérosols, où le support ou substrat de collecte inclut tout objet utilisé pour recueillir des particules (par exemple un filtre ou un matériau en mousse), ainsi que les éléments connexes devant être soumis à l'analyse par pesée.

L'ISO 15767:2002 est applicable aux résultats compilés à la fois à partir de sources bibliographiques et, lorsque cela est nécessaire et faisable, à partir d'expériences en laboratoire. Les erreurs prévisibles liées aux méthodes de prélèvement d'aérosols sont quantifiées chaque fois que possible. Des recommandations sur les matériaux à utiliser sont indiquées. Des moyens de contrôle ou de correction des erreurs dues à l'instabilité sont fournis. Des recommandations sur le mode opératoire de pesée sont données. Une procédure d'estimation des erreurs de pesée est décrite. Enfin, des recommandations sont données pour établir des rapports des masses mesurées.

Zrak na delovnem mestu – Pregled in opis napak pri tehtanju zbranih aerosolov

General Information

Relations

Buy Standard

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15767

First edition

2003-02-15

Workplace atmospheres — Controlling

and characterizing errors in weighing

collected aerosols

Atmosphères des lieux de travail — Contrôle et caractérisation des

erreurs de pesée des aérosols collectés

Reference number

ISO 15767:2003(E)

©

ISO 2003

---------------------- Page: 1 ----------------------

ISO 15767:2003(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2003

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2003 — All rights reserved

---------------------- Page: 2 ----------------------

ISO 15767:2003(E)

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Normative references . 1

3 Terms and definitions. 1

4 Weight instability — Causes and minimization . 2

4.1 General. 2

4.2 Moisture sorption. 2

4.3 Electrostatic effects. 3

4.4 Effects of volatile compounds (other than water) . 3

4.5 Handling damage . 4

4.6 Buoyancy changes . 4

5 Correcting for weight instability by use of blanks . 4

5.1 General. 4

5.2 Minimum number of blanks . 4

5.3 Weighing times and sequence . 4

5.4 Conditioning times. 5

5.5 Storage stability . 5

6 Transport of samples to laboratory . 5

6.1 General. 5

6.2 Recommended packaging. 5

7 Weighing equipment and procedure. 6

7.1 The balance . 6

7.2 Recommended environmental controls . 6

7.3 Other equipment requirements. 6

7.4 Procedure. 7

8 Recommendations for the reporting of measured mass relative to LOD and LOQ. 7

Annex A (normative) Estimation of measurement errors . 8

Annex B (informative) Interpretation of LOD and LOQ. 12

Annex C (informative) Method evaluation example . 14

Annex D (normative) Test of transportation integrity. 15

Bibliography . 17

© ISO 2003 — All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 15767:2003(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 15767 was prepared by Technical Committee ISO/TC 146, Air quality, Subcommittee SC 2, Workplace

atmospheres.

iv © ISO 2003 — All rights reserved

---------------------- Page: 4 ----------------------

ISO 15767:2003(E)

Introduction

Assessment of airborne aerosol hazards in the occupational setting entails sampling onto a collection medium,

followed by analysis of the collected material. The result is generally an estimated concentration of a

hazardous material in the air. The accuracy of such estimates depends on several factors, one of which

relates to the specific type of analysis employed.

This International Standard deals with a specific type of analysis which finds the most general application in

the sampling of aerosols, namely the weighing of sampled material. Gravimetric analysis, though apparently

simple, is subject to errors from instability in the mass of the sampling medium and other elements which must

be weighed. An example is provided by aerosol samplers designed to collect particles so as to agree with the

inhalable aerosol sampling convention. For some sampler types, filter and cassette are weighed together to

make estimates. Therefore, if the cassette, for example, absorbs or loses water between the weighings

required for a concentration estimation, then errors may arise. This International Standard describes such

potential errors and provides solutions for their minimization.

© ISO 2003 — All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 15767:2003(E)

Workplace atmospheres — Controlling and characterizing

errors in weighing collected aerosols

1 Scope

This International Standard provides recommendations for controlling the analytical uncertainty associated

with aerosol collection medium instability, where collection medium or substrate includes any article used to

collect particles (e.g. filter or foam material) as well as those supporting elements which must be analysed by

weighing.

This International Standard is applicable to results compiled both from the literature and, if necessary and

feasible, through laboratory experiment. Expected errors associated with given aerosol capture methods are

quantified where possible. Recommendations as to materials to be used are given. Means of controlling or

correcting errors arising from instability are provided. Recommendations for the weighing procedure are given.

A procedure for estimating weighing errors is described. Finally, recommendations are given for the reporting

of measured masses.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 7708, Air quality — Particle size fraction definitions for health-related sampling

EN 482, Workplace atmospheres — General requirements for performance of procedures for the

measurement of chemical agents

EN 13205:2001, Workplace atmospheres — Assessment of performance of instruments for measurement of

airborne particle concentrations

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

substrate

aerosol sampling filter, foam, etc., together with whatever mounting is weighed as a single item

NOTE As an example of the converse, the 25-mm or 37-mm plastic filter cassette often used for “total dust” sampling

in either its closed-face or open-face version is not part of the substrate in the definition above, since it is not weighed.

© ISO 2003 — All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 15767:2003(E)

3.2

equilibration time

time constant characterizing an approximately exponentially damped approach of the mass of an aerosol

collection medium to a constant value

NOTE 1 The constant can be defined as the mean difference of the mass from equilibrium per mean mass loss or gain

rate as measured over a finite time interval.

NOTE 2 There may be important instances in which several time constants are required to describe the approach to

equilibrium.

NOTE 3 Equilibration time is expressed in seconds.

3.3

field blank

blank substrate that undergoes the same handling as the sample substrate, generally including conditioning

and, often, loading into the samplers or transport containers, as well as transportation between lab and

sampling site, but without being exposed to sampling

3.4

lab blank

blank substrate that undergoes the same handling as the sample substrate in the laboratory, including

conditioning and loading into the samplers or transport containers if this is done in the laboratory

3.5

blank substrate

collection medium or substrate taken from the same batch as the sampling medium, but unexposed to sampling

3.6

limit of detection

LOD

three times the estimated standard deviation of the mass of the sample, accounting for the double weighing

(exposed vs. unexposed) and for the uncertainty associated with any correction blanks used

NOTE The value LOD can be used as a threshhold value to assert the presence of a substance with confidence in

the method. Annex B describes how to estimate, on the basis of the method evaluation, the false positive rate in such

assertions.

3.7

limit of quantitation

LOQ

ten times the estimated standard deviation of the mass of the sample

NOTE The value LOQ can be used as a threshhold value to assure measurement of a substance accurately. For

details, see Annex B.

4 Weight instability — Causes and minimization

4.1 General

[1] to [11]

Weight instability of sampling substrates can be attributed to several causes . The following subclauses

address the more important of these.

4.2 Moisture sorption

4.2.1 Moisture sorption is the most common cause of weight instability. Water can be directly collected by

the filter or foam or other substrate material that is weighed. Water sorption by any part of the sampling

system which is weighed must be suspected as well. For example, the sampling cassette itself, if weighed,

[1]

can be the cause of significant error .

2 © ISO 2003 — All rights reserved

---------------------- Page: 7 ----------------------

ISO 15767:2003(E)

4.2.2 The effects of water sorption can be reduced by using non-sorptive materials. However, there may

exist specific sampling needs for which a hydrophobic material is not feasible. Table 1 presents a list of

common aerosol sampling substrates with different water adsorption features.

Table 1 — Water sorption characteristics of some aerosol sampling media

Water sorption

Substrate or cassette type

Very low Low High Very high

Cellulose fibre filter *

Glass fibre filter *

Quartz fibre filter *

Cellulose ester membrane filter *

Polytetrafluoroethylene filter *

PVC membrane filter * *

Polycarbonate filter *

Silver membrane filter *

Polyurethane foam *

Greased Mylar impaction substrate * *

Greased aluminium foil impaction substrate *

Carbon-filled resin *

Aluminium cassette * *

Stainless steel cassette *

NOTE 1 References [2] to [4] provide further details. Also, reference [5] reports that filters of evidently the same

material, but originating from different manufacturers, can have widely differing variabilities.

NOTE 2 There is generally a trade-off between hydrophobicity and conductivity in many materials [9]. Therefore, one

must be aware of the possibility of creating sampling problems when reducing hygroscopicity.

NOTE 3 Pre-treatments of substrates, such as greasing, can also affect water sorption.

4.3 Electrostatic effects

Electrostatic effects are a common source of weighing problems. These effects can usually be minimized by

discharging the substrate through the use of a plasma ion source or a radioactive source. Using conductive

materials may reduce such problems. See also reference [7].

4.4 Effects of volatile compounds (other than water)

[3]

4.4.1 Volatile compounds can be present in unused collection media , or can be adsorbed onto media

during sampling.

4.4.2 Desorption of volatiles from unused media can be controlled, for example, by heating or oxygen

plasma treatment prior to conditioning and weighing. Alternatively, losses may be compensated by the use of

blanks (see Clause 5).

4.4.3 When volatile materials collected during sampling form part of the intended sample, standardized

written procedures are required to ensure that any losses are minimized or at least controlled, for example by

conditioning under tightly specified conditions.

© ISO 2003 — All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 15767:2003(E)

4.4.4 When volatile materials collected during sampling are not part of the intended sample, it may be

difficult to eliminate them if weighing is the only form of analysis. Non-sorptive media should preferably be

used.

4.5 Handling damage

4.5.1 If friable substrates are used, procedures are needed to avoid mechanical damage.

4.5.2 The air-sampling equipment should be designed so that the substrate is not damaged during

assembly and disassembly.

4.5.3 Flat tipped forceps are recommended for handling filters. Non-oxidizing metal tins may be used to

weigh delicate substrates without direct handling.

4.5.4 Parts to be weighed shall not be touched with the hands, unless gloved.

4.5.5 Gloves, if used, shall leave no residue on what is weighed.

4.5.6 Handling shall take place in a clean environment, to avoid contamination.

4.6 Buoyancy changes

[8]

Corrections for air buoyancy , equal to the density of air multiplied by the air volume displaced, are not

necessary for small objects, such as a 37-mm diameter membrane filter. However, there may exist

circumstances (e.g. if an entire sampling cassette were weighed without the use of correcting blanks) in which

the object to be weighed is so large that buoyancy must be corrected. For example, if the volume weighed

3

exceeds 0,1 cm , then correction would be required in order to weigh down to 0,1 mg if pressure changes of

the order of 10 % between weighings are expected (e.g. at different altitudes). If such a correction is

necessary, the atmospheric pressure and temperature at the time of weighing should be recorded.

5 Correcting for weight instability by use of blanks

5.1 General

[12] to [20]

Many approaches to controlling weight instability exist . The use of blanks is the most important

practical tool for reducing errors due to weight instability. Correction for weight instability depends on the

specific application and should follow a written procedure. The general principles are as follows. Blank

sampling media are exposed, as closely as possible, to the same conditions as the active sampling media,

without actually drawing air through. Correction is effected by subtracting the average blank mass change

from the mass change of the active samples. Of course, if the atmosphere to be sampled contains water (or

other volatile) droplets, then the use of blanks alone cannot correct. Blanks shall be matched to samples, i.e. if

the sample consists of a filter within a cassette which is weighed, the blank shall be the same type of filter

within the same type of cassette.

NOTE The effect of filter variations due to their manufacture is generally eliminated through the use of blanks.

5.2 Minimum number of blanks

Generally, at least one blank is recommended for each 10 samples. Measurement schemes in current use

require between one and four blanks per batch. See Annex A for advantages of multiple blanks.

5.3 Weighing times and sequence

Blanks shall be interspersed with samples, before and after use, so as to detect systematic variations in mass

(e.g. due to sorption or evaporation of a contaminant during weighing).

4 © ISO 2003 — All rights reserved

---------------------- Page: 9 ----------------------

ISO 15767:2003(E)

5.4 Conditioning times

Conditioning times for reaching equilibrium with the weighing environment may vary from a few hours to

several weeks, depending on the specific sampling media. Typically, for workplace sampling applications,

overnight conditioning is satisfactory. For sampling media with longer conditioning times, error correction

through the use of blank substrates is particularly important.

5.5 Storage stability

Unused substrates shall be stored prior to weighing and conditioning in a clean laboratory, whose

environmental conditions do not differ too greatly from the environment of the balance. Pre-weighed

substrates shall be stored together with weighed blanks and used in any case within the assigned shelf-life.

The assigned shelf-life and storage requirements shall be documented as part of a written weighing procedure.

NOTE Shelf-life depends on substrate material, storage conditions, cassette material and required LOQ or LOD.

Archived samples shall be stored together with weighed blanks in a clean laboratory whose environmental

conditions do not differ too greatly from the environment of the balance. Note that transfers of mass between

filters and cassettes could occur where these media are stored together.

6 Transport of samples to laboratory

6.1 General

The transportation of samples shall form part of a written procedure. The transport procedure shall be

validated to ensure that significant losses do not occur. Follow the test method given in Annex D.

The main problems occurring during handling and transport of sampling media are described below.

With substrates designed to be separated from sampling cassettes, dust can migrate from substrate to

the transport container, and hence be lost.

On the other hand, contamination of the sampling cassette and cover lid (if supplied) can be a significant

source of error if the cassette (including cover lid) is part of the substrate.

If a cover lid is not supplied, dust can be lost from the cassette to the transport container.

Dust can migrate from sampling cassette to substrate.

NOTE Transportation losses are discussed in references [12] and [13].

6.2 Recommended packaging

6.2.1 Each substrate that is not mounted in a sampling cassette shall be transported in a Petri dish, tin or a

similar closed container.

6.2.2 Sampling cassettes (i.e. with mounted filters) should preferrably have cover lids during transport. If the

sample consists of all dust deposited inside the sampling cassette (with filter), then dust which migrates during

transport from cassette to cover lid shall also be weighed.

6.2.3 The sealed substrates shall be transported in a suitable container or package. The floor, ceiling and

walls of the container should be lined with a spongy material (preferably electrically conducting) which may

absorb some mechanical shock and thus protect the samples during transport.

6.2.4 The samples shall be protected from excessive heating or cooling during transport.

NOTE 1 Special procedures are generally used for the transport of unstable particles or biological materials.

© ISO 2003 — All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 15767:2003(E)

NOTE 2 If there is a possibility for dust to be lost from the substrate, the losses can be recovered by transporting the

substrate within a container that can itself be weighed.

7 Weighing equipment and procedure

7.1 The balance

The balance should be matched to the task. The choice of balance depends on the desired limits of

quantitation for the application (see Clause 8) and on the maximum tare masses of the samples to be weighed.

Workplace-air sampling typically requires a balance capable of weighing to an accuracy of either five or six

figures. The balance shall be regularly calibrated using reference masses traceable to International Standards.

NOTE The performance of different balances was compared and reported in reference [5]. In one experiment, repeat

weighings of 25-mm filters were made with filters stored between weighings in ventilated tins with conditions not strictly

controlled. A balance weighing to 1 µg (six figures) was compared to a balance weighing to 10 µg (five figures). It was

concluded that using a 1-µg balance vs. a 10-µg balance approximately halves the standard deviation of repeat weighing.

Intra-day standard deviation was smaller than the inter-day deviation and is expected to be of greater importance when

blanks are used to correct inter-day variation in the balance room. (See also reference [11].)

7.2 Recommended environmental controls

7.2.1 Equilibration and weighing shall be carried out under the same conditions, i.e. in the same room or

chamber. Environmental control can be achieved in different ways:

by means of a balance room containing balance, samples and the weighing personnel;

by means of an environmentally-controlled chamber containing balance and samples, sited within a clean

laboratory.

NOTE It may be possible to achieve an adequate level of environmental control without the need for active air

conditioning. However the quality of gravimetric analysis depends strongly on the quality of the environmental control.

7.2.2 For sensitive (i.e. hygroscopic) samples, temperature and humidity control in the weighing chamber or

balance room are important. In these cases, temperature should be maintained constant within ± 2 °C of the

set point, and humidity should be constant to within ± 5 % relative humidity (RH) at the target temperature.

The target temperature and humidity should be in the range of operating conditions recommended by the

manufacturer of the balance [e.g. (20 ± 2) °C and (50 ± 5) % RH]. Very dry atmospheres (e.g. < 20 % RH) are

to be avoided, as electrostatic buildup on the samples is more likely in such conditions. The environmental

controls shall be capable of compensating for heat and humidity sources, such as people working in the room

[3]

or electrically-powered instruments in the room .

NOTE Air conditioning in a weighing chamber is not necessary, e.g. filtered laboratory air can be fed into a positive-

pressure chamber.

7.2.3 The particulate content of the balance room or chamber air should be minimized by filtration [e.g. by

High Efficiency Particulate Air (HEPA) filtration].

7.2.4 Fresh air should be supplied consistent with the health and comfort requirements of personnel

working in the balance room or laboratory. Turbulent air movement generated by ventilation or humidity

control in the balance room or chamber should be minimal, so as not to affect the balance reading.

7.3 Other equipment requirements

The balance should be located in an area which is free from excessive vibration [e.g. due to lifts (elevators) or

rotating machinery]. A massive weighing table (e.g. one made of 200 kg of marble) is one means to dampen

ambient vibration. The area should be away from doors, windows, air ducts, and sources of radiant energy

6 © ISO 2003 — All rights reserved

---------------------- Page: 11 ----------------------

ISO 15767:2003(E)

such as direct sunlight or ovens. The electrical supply to the balance should be stable, and the balance should

not be located near sources of strong electromagnetic radiation.

7.4 Procedure

7.4.1 The weighing procedure shall be documented.

7.4.2 Equilibration of the sample to the temperature and humidity of the balance room or chamber shall take

place for a period appropriate to the sample. The samples shall be kept in clean containers but open to the

atmosphere so that equilibration can occur.

NOTE Desiccation prior to equilibration is sometimes used to remove excess water from the samples taken in a

humid environment. This only applies to samples with excess water. (See also references [21] to [23].)

7.4.3 Elimination (if possible) of static electricity from the sample is extremely important, and should be

done immediately prior to placement of the sample on the balance pan. Alternatively, a static eliminator can

be placed inside the balance chamber.

7.4.4 The balance reading shall not be recorded until after it has stabilized.

7.4.5 Re-zero the balance as determined necessary.

NOTE A defective substrate can sometimes be identified by an abnormal initial mass.

8 Recommendations for the reporting of measured mass relative to LOD and LOQ

8.1 If the measured mass is above the limit of quantitation (LOQ, Annexes A to C), then it is reported.

8.2 If the result falls between the limit of detection (LOD, Annexes A to C) and LOQ, then it is reported that

the measured mass is between the values of LOD and LOQ, and the measured mass is reported as well.

8.3 If the measured mass falls below the value of the LOD, it is reported that the estimate is below the value

of the LOD.

NOTE 1 If the value of the LOD is exceeded, then the false-positive error rate in asserting detection is < 1 % if the

method is evaluated with as many degrees of freedom (25) as specified in Annexes A to C.

NOTE 2 In some applications a series of measured masses, each below the the value of the LOD, may be of help, e.g.

in asserting the presence of mass over the entire series, even if the individual measurements are too small to assert

detection with confidence. Applications such as these employ actual measured values (even if negative).

8.4 LOD and LOQ values shall be determined and shall be given in the report. Annexes A to C contain

suitable procedures for these determinations.

© ISO 2003 — All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 15767:2003(E)

Annex A

(normative)

Estimation of measurement errors

A.1 Symbols (and abbreviated terms)

The following symbols and abbreviated terms are used in th

...

SLOVENSKI STANDARD

SIST ISO 15767:2004

01-junij-2004

Zrak na delovnem mestu – Pregled in opis napak pri tehtanju zbranih aerosolov

Workplace atmospheres -- Controlling and characterizing errors in weighing collected

aerosols

Atmosphères des lieux de travail -- Contrôle et caractérisation des erreurs de pesée des

aérosols collectés

Ta slovenski standard je istoveten z: ISO 15767:2003

ICS:

13.040.30 Kakovost zraka na delovnem Workplace atmospheres

mestu

SIST ISO 15767:2004 en

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

---------------------- Page: 1 ----------------------

SIST ISO 15767:2004

---------------------- Page: 2 ----------------------

SIST ISO 15767:2004

INTERNATIONAL ISO

STANDARD 15767

First edition

2003-02-15

Workplace atmospheres — Controlling

and characterizing errors in weighing

collected aerosols

Atmosphères des lieux de travail — Contrôle et caractérisation des

erreurs de pesée des aérosols collectés

Reference number

ISO 15767:2003(E)

©

ISO 2003

---------------------- Page: 3 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2003

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2003 — All rights reserved

---------------------- Page: 4 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Normative references . 1

3 Terms and definitions. 1

4 Weight instability — Causes and minimization . 2

4.1 General. 2

4.2 Moisture sorption. 2

4.3 Electrostatic effects. 3

4.4 Effects of volatile compounds (other than water) . 3

4.5 Handling damage . 4

4.6 Buoyancy changes . 4

5 Correcting for weight instability by use of blanks . 4

5.1 General. 4

5.2 Minimum number of blanks . 4

5.3 Weighing times and sequence . 4

5.4 Conditioning times. 5

5.5 Storage stability . 5

6 Transport of samples to laboratory . 5

6.1 General. 5

6.2 Recommended packaging. 5

7 Weighing equipment and procedure. 6

7.1 The balance . 6

7.2 Recommended environmental controls . 6

7.3 Other equipment requirements. 6

7.4 Procedure. 7

8 Recommendations for the reporting of measured mass relative to LOD and LOQ. 7

Annex A (normative) Estimation of measurement errors . 8

Annex B (informative) Interpretation of LOD and LOQ. 12

Annex C (informative) Method evaluation example . 14

Annex D (normative) Test of transportation integrity. 15

Bibliography . 17

© ISO 2003 — All rights reserved iii

---------------------- Page: 5 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 15767 was prepared by Technical Committee ISO/TC 146, Air quality, Subcommittee SC 2, Workplace

atmospheres.

iv © ISO 2003 — All rights reserved

---------------------- Page: 6 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

Introduction

Assessment of airborne aerosol hazards in the occupational setting entails sampling onto a collection medium,

followed by analysis of the collected material. The result is generally an estimated concentration of a

hazardous material in the air. The accuracy of such estimates depends on several factors, one of which

relates to the specific type of analysis employed.

This International Standard deals with a specific type of analysis which finds the most general application in

the sampling of aerosols, namely the weighing of sampled material. Gravimetric analysis, though apparently

simple, is subject to errors from instability in the mass of the sampling medium and other elements which must

be weighed. An example is provided by aerosol samplers designed to collect particles so as to agree with the

inhalable aerosol sampling convention. For some sampler types, filter and cassette are weighed together to

make estimates. Therefore, if the cassette, for example, absorbs or loses water between the weighings

required for a concentration estimation, then errors may arise. This International Standard describes such

potential errors and provides solutions for their minimization.

© ISO 2003 — All rights reserved v

---------------------- Page: 7 ----------------------

SIST ISO 15767:2004

---------------------- Page: 8 ----------------------

SIST ISO 15767:2004

INTERNATIONAL STANDARD ISO 15767:2003(E)

Workplace atmospheres — Controlling and characterizing

errors in weighing collected aerosols

1 Scope

This International Standard provides recommendations for controlling the analytical uncertainty associated

with aerosol collection medium instability, where collection medium or substrate includes any article used to

collect particles (e.g. filter or foam material) as well as those supporting elements which must be analysed by

weighing.

This International Standard is applicable to results compiled both from the literature and, if necessary and

feasible, through laboratory experiment. Expected errors associated with given aerosol capture methods are

quantified where possible. Recommendations as to materials to be used are given. Means of controlling or

correcting errors arising from instability are provided. Recommendations for the weighing procedure are given.

A procedure for estimating weighing errors is described. Finally, recommendations are given for the reporting

of measured masses.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 7708, Air quality — Particle size fraction definitions for health-related sampling

EN 482, Workplace atmospheres — General requirements for performance of procedures for the

measurement of chemical agents

EN 13205:2001, Workplace atmospheres — Assessment of performance of instruments for measurement of

airborne particle concentrations

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

substrate

aerosol sampling filter, foam, etc., together with whatever mounting is weighed as a single item

NOTE As an example of the converse, the 25-mm or 37-mm plastic filter cassette often used for “total dust” sampling

in either its closed-face or open-face version is not part of the substrate in the definition above, since it is not weighed.

© ISO 2003 — All rights reserved 1

---------------------- Page: 9 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

3.2

equilibration time

time constant characterizing an approximately exponentially damped approach of the mass of an aerosol

collection medium to a constant value

NOTE 1 The constant can be defined as the mean difference of the mass from equilibrium per mean mass loss or gain

rate as measured over a finite time interval.

NOTE 2 There may be important instances in which several time constants are required to describe the approach to

equilibrium.

NOTE 3 Equilibration time is expressed in seconds.

3.3

field blank

blank substrate that undergoes the same handling as the sample substrate, generally including conditioning

and, often, loading into the samplers or transport containers, as well as transportation between lab and

sampling site, but without being exposed to sampling

3.4

lab blank

blank substrate that undergoes the same handling as the sample substrate in the laboratory, including

conditioning and loading into the samplers or transport containers if this is done in the laboratory

3.5

blank substrate

collection medium or substrate taken from the same batch as the sampling medium, but unexposed to sampling

3.6

limit of detection

LOD

three times the estimated standard deviation of the mass of the sample, accounting for the double weighing

(exposed vs. unexposed) and for the uncertainty associated with any correction blanks used

NOTE The value LOD can be used as a threshhold value to assert the presence of a substance with confidence in

the method. Annex B describes how to estimate, on the basis of the method evaluation, the false positive rate in such

assertions.

3.7

limit of quantitation

LOQ

ten times the estimated standard deviation of the mass of the sample

NOTE The value LOQ can be used as a threshhold value to assure measurement of a substance accurately. For

details, see Annex B.

4 Weight instability — Causes and minimization

4.1 General

[1] to [11]

Weight instability of sampling substrates can be attributed to several causes . The following subclauses

address the more important of these.

4.2 Moisture sorption

4.2.1 Moisture sorption is the most common cause of weight instability. Water can be directly collected by

the filter or foam or other substrate material that is weighed. Water sorption by any part of the sampling

system which is weighed must be suspected as well. For example, the sampling cassette itself, if weighed,

[1]

can be the cause of significant error .

2 © ISO 2003 — All rights reserved

---------------------- Page: 10 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

4.2.2 The effects of water sorption can be reduced by using non-sorptive materials. However, there may

exist specific sampling needs for which a hydrophobic material is not feasible. Table 1 presents a list of

common aerosol sampling substrates with different water adsorption features.

Table 1 — Water sorption characteristics of some aerosol sampling media

Water sorption

Substrate or cassette type

Very low Low High Very high

Cellulose fibre filter *

Glass fibre filter *

Quartz fibre filter *

Cellulose ester membrane filter *

Polytetrafluoroethylene filter *

PVC membrane filter * *

Polycarbonate filter *

Silver membrane filter *

Polyurethane foam *

Greased Mylar impaction substrate * *

Greased aluminium foil impaction substrate *

Carbon-filled resin *

Aluminium cassette * *

Stainless steel cassette *

NOTE 1 References [2] to [4] provide further details. Also, reference [5] reports that filters of evidently the same

material, but originating from different manufacturers, can have widely differing variabilities.

NOTE 2 There is generally a trade-off between hydrophobicity and conductivity in many materials [9]. Therefore, one

must be aware of the possibility of creating sampling problems when reducing hygroscopicity.

NOTE 3 Pre-treatments of substrates, such as greasing, can also affect water sorption.

4.3 Electrostatic effects

Electrostatic effects are a common source of weighing problems. These effects can usually be minimized by

discharging the substrate through the use of a plasma ion source or a radioactive source. Using conductive

materials may reduce such problems. See also reference [7].

4.4 Effects of volatile compounds (other than water)

[3]

4.4.1 Volatile compounds can be present in unused collection media , or can be adsorbed onto media

during sampling.

4.4.2 Desorption of volatiles from unused media can be controlled, for example, by heating or oxygen

plasma treatment prior to conditioning and weighing. Alternatively, losses may be compensated by the use of

blanks (see Clause 5).

4.4.3 When volatile materials collected during sampling form part of the intended sample, standardized

written procedures are required to ensure that any losses are minimized or at least controlled, for example by

conditioning under tightly specified conditions.

© ISO 2003 — All rights reserved 3

---------------------- Page: 11 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

4.4.4 When volatile materials collected during sampling are not part of the intended sample, it may be

difficult to eliminate them if weighing is the only form of analysis. Non-sorptive media should preferably be

used.

4.5 Handling damage

4.5.1 If friable substrates are used, procedures are needed to avoid mechanical damage.

4.5.2 The air-sampling equipment should be designed so that the substrate is not damaged during

assembly and disassembly.

4.5.3 Flat tipped forceps are recommended for handling filters. Non-oxidizing metal tins may be used to

weigh delicate substrates without direct handling.

4.5.4 Parts to be weighed shall not be touched with the hands, unless gloved.

4.5.5 Gloves, if used, shall leave no residue on what is weighed.

4.5.6 Handling shall take place in a clean environment, to avoid contamination.

4.6 Buoyancy changes

[8]

Corrections for air buoyancy , equal to the density of air multiplied by the air volume displaced, are not

necessary for small objects, such as a 37-mm diameter membrane filter. However, there may exist

circumstances (e.g. if an entire sampling cassette were weighed without the use of correcting blanks) in which

the object to be weighed is so large that buoyancy must be corrected. For example, if the volume weighed

3

exceeds 0,1 cm , then correction would be required in order to weigh down to 0,1 mg if pressure changes of

the order of 10 % between weighings are expected (e.g. at different altitudes). If such a correction is

necessary, the atmospheric pressure and temperature at the time of weighing should be recorded.

5 Correcting for weight instability by use of blanks

5.1 General

[12] to [20]

Many approaches to controlling weight instability exist . The use of blanks is the most important

practical tool for reducing errors due to weight instability. Correction for weight instability depends on the

specific application and should follow a written procedure. The general principles are as follows. Blank

sampling media are exposed, as closely as possible, to the same conditions as the active sampling media,

without actually drawing air through. Correction is effected by subtracting the average blank mass change

from the mass change of the active samples. Of course, if the atmosphere to be sampled contains water (or

other volatile) droplets, then the use of blanks alone cannot correct. Blanks shall be matched to samples, i.e. if

the sample consists of a filter within a cassette which is weighed, the blank shall be the same type of filter

within the same type of cassette.

NOTE The effect of filter variations due to their manufacture is generally eliminated through the use of blanks.

5.2 Minimum number of blanks

Generally, at least one blank is recommended for each 10 samples. Measurement schemes in current use

require between one and four blanks per batch. See Annex A for advantages of multiple blanks.

5.3 Weighing times and sequence

Blanks shall be interspersed with samples, before and after use, so as to detect systematic variations in mass

(e.g. due to sorption or evaporation of a contaminant during weighing).

4 © ISO 2003 — All rights reserved

---------------------- Page: 12 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

5.4 Conditioning times

Conditioning times for reaching equilibrium with the weighing environment may vary from a few hours to

several weeks, depending on the specific sampling media. Typically, for workplace sampling applications,

overnight conditioning is satisfactory. For sampling media with longer conditioning times, error correction

through the use of blank substrates is particularly important.

5.5 Storage stability

Unused substrates shall be stored prior to weighing and conditioning in a clean laboratory, whose

environmental conditions do not differ too greatly from the environment of the balance. Pre-weighed

substrates shall be stored together with weighed blanks and used in any case within the assigned shelf-life.

The assigned shelf-life and storage requirements shall be documented as part of a written weighing procedure.

NOTE Shelf-life depends on substrate material, storage conditions, cassette material and required LOQ or LOD.

Archived samples shall be stored together with weighed blanks in a clean laboratory whose environmental

conditions do not differ too greatly from the environment of the balance. Note that transfers of mass between

filters and cassettes could occur where these media are stored together.

6 Transport of samples to laboratory

6.1 General

The transportation of samples shall form part of a written procedure. The transport procedure shall be

validated to ensure that significant losses do not occur. Follow the test method given in Annex D.

The main problems occurring during handling and transport of sampling media are described below.

With substrates designed to be separated from sampling cassettes, dust can migrate from substrate to

the transport container, and hence be lost.

On the other hand, contamination of the sampling cassette and cover lid (if supplied) can be a significant

source of error if the cassette (including cover lid) is part of the substrate.

If a cover lid is not supplied, dust can be lost from the cassette to the transport container.

Dust can migrate from sampling cassette to substrate.

NOTE Transportation losses are discussed in references [12] and [13].

6.2 Recommended packaging

6.2.1 Each substrate that is not mounted in a sampling cassette shall be transported in a Petri dish, tin or a

similar closed container.

6.2.2 Sampling cassettes (i.e. with mounted filters) should preferrably have cover lids during transport. If the

sample consists of all dust deposited inside the sampling cassette (with filter), then dust which migrates during

transport from cassette to cover lid shall also be weighed.

6.2.3 The sealed substrates shall be transported in a suitable container or package. The floor, ceiling and

walls of the container should be lined with a spongy material (preferably electrically conducting) which may

absorb some mechanical shock and thus protect the samples during transport.

6.2.4 The samples shall be protected from excessive heating or cooling during transport.

NOTE 1 Special procedures are generally used for the transport of unstable particles or biological materials.

© ISO 2003 — All rights reserved 5

---------------------- Page: 13 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

NOTE 2 If there is a possibility for dust to be lost from the substrate, the losses can be recovered by transporting the

substrate within a container that can itself be weighed.

7 Weighing equipment and procedure

7.1 The balance

The balance should be matched to the task. The choice of balance depends on the desired limits of

quantitation for the application (see Clause 8) and on the maximum tare masses of the samples to be weighed.

Workplace-air sampling typically requires a balance capable of weighing to an accuracy of either five or six

figures. The balance shall be regularly calibrated using reference masses traceable to International Standards.

NOTE The performance of different balances was compared and reported in reference [5]. In one experiment, repeat

weighings of 25-mm filters were made with filters stored between weighings in ventilated tins with conditions not strictly

controlled. A balance weighing to 1 µg (six figures) was compared to a balance weighing to 10 µg (five figures). It was

concluded that using a 1-µg balance vs. a 10-µg balance approximately halves the standard deviation of repeat weighing.

Intra-day standard deviation was smaller than the inter-day deviation and is expected to be of greater importance when

blanks are used to correct inter-day variation in the balance room. (See also reference [11].)

7.2 Recommended environmental controls

7.2.1 Equilibration and weighing shall be carried out under the same conditions, i.e. in the same room or

chamber. Environmental control can be achieved in different ways:

by means of a balance room containing balance, samples and the weighing personnel;

by means of an environmentally-controlled chamber containing balance and samples, sited within a clean

laboratory.

NOTE It may be possible to achieve an adequate level of environmental control without the need for active air

conditioning. However the quality of gravimetric analysis depends strongly on the quality of the environmental control.

7.2.2 For sensitive (i.e. hygroscopic) samples, temperature and humidity control in the weighing chamber or

balance room are important. In these cases, temperature should be maintained constant within ± 2 °C of the

set point, and humidity should be constant to within ± 5 % relative humidity (RH) at the target temperature.

The target temperature and humidity should be in the range of operating conditions recommended by the

manufacturer of the balance [e.g. (20 ± 2) °C and (50 ± 5) % RH]. Very dry atmospheres (e.g. < 20 % RH) are

to be avoided, as electrostatic buildup on the samples is more likely in such conditions. The environmental

controls shall be capable of compensating for heat and humidity sources, such as people working in the room

[3]

or electrically-powered instruments in the room .

NOTE Air conditioning in a weighing chamber is not necessary, e.g. filtered laboratory air can be fed into a positive-

pressure chamber.

7.2.3 The particulate content of the balance room or chamber air should be minimized by filtration [e.g. by

High Efficiency Particulate Air (HEPA) filtration].

7.2.4 Fresh air should be supplied consistent with the health and comfort requirements of personnel

working in the balance room or laboratory. Turbulent air movement generated by ventilation or humidity

control in the balance room or chamber should be minimal, so as not to affect the balance reading.

7.3 Other equipment requirements

The balance should be located in an area which is free from excessive vibration [e.g. due to lifts (elevators) or

rotating machinery]. A massive weighing table (e.g. one made of 200 kg of marble) is one means to dampen

ambient vibration. The area should be away from doors, windows, air ducts, and sources of radiant energy

6 © ISO 2003 — All rights reserved

---------------------- Page: 14 ----------------------

SIST ISO 15767:2004

ISO 15767:2003(E)

such as direct sunlight or ovens. The electrical supply to the balance should be stable, and the balance should

not be located near sources of strong electromagnetic radiation.

7.4 Procedure

7.4.1 The weighing procedure shall be documented.

7.4.2 Equilibration of the sample to the temperature and humidity of the balance room or chamber shall take

place for a period appropriate to the sample. The samples shall be kept in clean containers but open to the

atmosphere so that equilibration can occur.

NOTE Desiccation prior to equilibration is sometimes used to remove excess water from the samples taken in a

humid environment. This only applies to samples with excess water. (See also references [21] to [23].)

7.4.3 Elimination (if possible) of static electricity from the sample is extremely important, and should be

done immediately prior to placement of the sample on the balance pan. Alternatively, a static eliminator can

be placed inside the balance chamber.

7.4.4 The balance reading shall not be recorded until after it has stabilized.

7.4.5 Re-zero the balance as determined necessary.

NOTE A defective substrate can sometimes be identified by an abnormal initial mass.

8 Recommendations for the reporting of measured mass relative to LOD and LOQ

8.1 If the measured mass is above the limit of quantitation (LOQ, Annexes A to C), then it is reported.

8.2 If the result falls between the limit of detection (LOD, Annexes A to C) and LOQ, then it is reported that

the measured mass is between the values of LOD and LOQ, and the measured mass is reported as well.

8.3 If the m

...

NORME ISO

INTERNATIONALE 15767

Première édition

2003-02-15

Atmosphères des lieux de travail —

Contrôle et caractérisation des erreurs de

pesée des aérosols collectés

Workplace atmospheres — Controlling and characterizing errors in

weighing collected aerosols

Numéro de référence

ISO 15767:2003(F)

©

ISO 2003

---------------------- Page: 1 ----------------------

ISO 15767:2003(F)

PDF – Exonération de responsabilité

Le présent fichier PDF peut contenir des polices de caractères intégrées. Conformément aux conditions de licence d'Adobe, ce fichier

peut être imprimé ou visualisé, mais ne doit pas être modifié à moins que l'ordinateur employé à cet effet ne bénéficie d'une licence

autorisant l'utilisation de ces polices et que celles-ci y soient installées. Lors du téléchargement de ce fichier, les parties concernées

acceptent de fait la responsabilité de ne pas enfreindre les conditions de licence d'Adobe. Le Secrétariat central de l'ISO décline toute

responsabilité en la matière.

Adobe est une marque déposée d'Adobe Systems Incorporated.

Les détails relatifs aux produits logiciels utilisés pour la création du présent fichier PDF sont disponibles dans la rubrique General Info

du fichier; les paramètres de création PDF ont été optimisés pour l'impression. Toutes les mesures ont été prises pour garantir

l'exploitation de ce fichier par les comités membres de l'ISO. Dans le cas peu probable où surviendrait un problème d'utilisation,

veuillez en informer le Secrétariat central à l'adresse donnée ci-dessous.

© ISO 2003

Droits de reproduction réservés. Sauf prescription différente, aucune partie de cette publication ne peut être reproduite ni utilisée sous

quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les microfilms, sans l'accord écrit

de l'ISO à l'adresse ci-après ou du comité membre de l'ISO dans le pays du demandeur.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax. + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Publié en Suisse

ii © ISO 2003 — Tous droits réservés

---------------------- Page: 2 ----------------------

ISO 15767:2003(F)

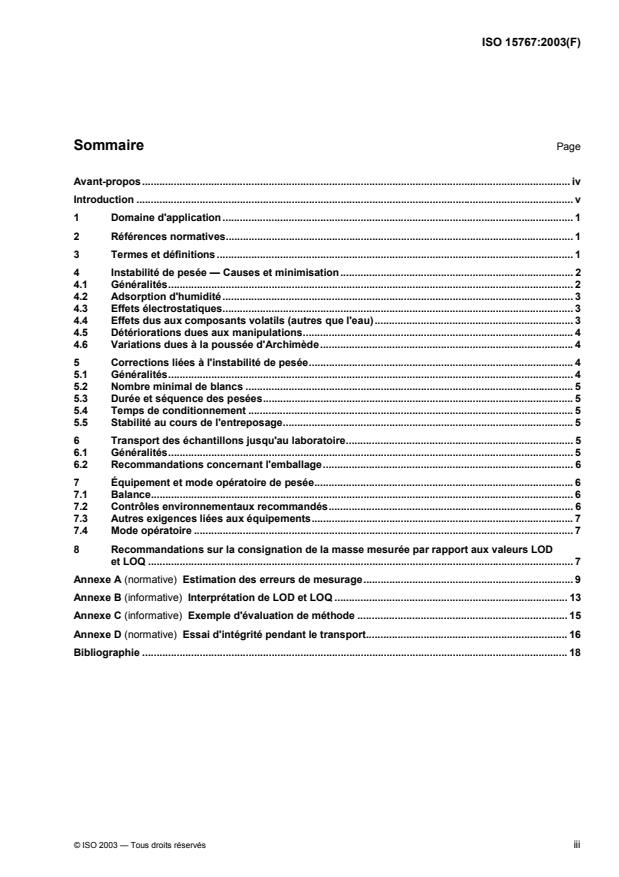

Sommaire Page

Avant-propos. iv

Introduction . v

1 Domaine d'application. 1

2 Références normatives. 1

3 Termes et définitions . 1

4 Instabilité de pesée — Causes et minimisation. 2

4.1 Généralités. 2

4.2 Adsorption d'humidité. 3

4.3 Effets électrostatiques. 3

4.4 Effets dus aux composants volatils (autres que l'eau). 3

4.5 Détériorations dues aux manipulations. 4

4.6 Variations dues à la poussée d'Archimède.4

5 Corrections liées à l'instabilité de pesée. 4

5.1 Généralités. 4

5.2 Nombre minimal de blancs . 5

5.3 Durée et séquence des pesées. 5

5.4 Temps de conditionnement . 5

5.5 Stabilité au cours de l'entreposage. 5

6 Transport des échantillons jusqu'au laboratoire. 5

6.1 Généralités. 5

6.2 Recommandations concernant l'emballage. 6

7 Équipement et mode opératoire de pesée.6

7.1 Balance. 6

7.2 Contrôles environnementaux recommandés. 6

7.3 Autres exigences liées aux équipements. 7

7.4 Mode opératoire . 7

8 Recommandations sur la consignation de la masse mesurée par rapport aux valeurs LOD

et LOQ . 7

Annexe A (normative) Estimation des erreurs de mesurage. 9

Annexe B (informative) Interprétation de LOD et LOQ . 13

Annexe C (informative) Exemple d'évaluation de méthode . 15

Annexe D (normative) Essai d'intégrité pendant le transport. 16

Bibliographie . 18

© ISO 2003 — Tous droits réservés iii

---------------------- Page: 3 ----------------------

ISO 15767:2003(F)

Avant-propos

L'ISO (Organisation internationale de normalisation) est une fédération mondiale d'organismes nationaux de

normalisation (comités membres de l'ISO). L'élaboration des Normes internationales est en général confiée

aux comités techniques de l'ISO. Chaque comité membre intéressé par une étude a le droit de faire partie du

comité technique créé à cet effet. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec l'ISO participent également aux travaux. L'ISO collabore étroitement avec

la Commission électrotechnique internationale (CEI) en ce qui concerne la normalisation électrotechnique.

Les Normes internationales sont rédigées conformément aux règles données dans les Directives ISO/CEI,

Partie 2.

La tâche principale des comités techniques est d'élaborer les Normes internationales. Les projets de Normes

internationales adoptés par les comités techniques sont soumis aux comités membres pour vote. Leur

publication comme Normes internationales requiert l'approbation de 75 % au moins des comités membres

votants.

L'attention est appelée sur le fait que certains des éléments du présent document peuvent faire l'objet de

droits de propriété intellectuelle ou de droits analogues. L'ISO ne saurait être tenue pour responsable de ne

pas avoir identifié de tels droits de propriété et averti de leur existence.

L'ISO 15767 a été élaborée par le comité technique ISO/TC 146, Qualité de l'air, sous-comité SC 2,

Atmosphères des lieux de travail.

iv © ISO 2003 — Tous droits réservés

---------------------- Page: 4 ----------------------

ISO 15767:2003(F)

Introduction

L'évaluation des risques liés aux aérosols en suspension dans l'air en milieu professionnel nécessite

l'échantillonnage sur un support de collecte, suivi d'une analyse des matières recueillies. Le résultat obtenu

permet généralement d'évaluer la concentration des matières nocives dans l'air. La précision de telles

estimations repose sur plusieurs facteurs, dont l'un est lié au type spécifique d'analyse employé.

La présente Norme internationale décrit un type d'analyse particulier, la pesée du matériau prélevé, qui est

appliqué de façon très générale dans le prélèvement des aérosols. L'analyse gravimétrique, bien que simple

en apparence, est propice aux erreurs en raison de l'instabilité de la masse du support de prélèvement

d'échantillonnage et des autres éléments à peser. Le cas se présente par exemple avec les échantillonneurs

d'aérosols conçus pour recueillir des particules conformément à la convention d'échantillonnage des aérosols

inhalables. Dans certains cas, les échantillonneurs comprennent un filtre et une cassette pesés ensemble

pour permettre les estimations. Ainsi, par exemple, l'absorption ou la déperdition d'eau dans la cassette entre

les différentes pesées requises pour estimer une concentration peuvent donner lieu à des erreurs. La

présente Norme internationale décrit les erreurs potentielles de ce type et fournit des solutions visant à les

minimiser.

© ISO 2003 — Tous droits réservés v

---------------------- Page: 5 ----------------------

NORME INTERNATIONALE ISO 15767:2003(F)

Atmosphères des lieux de travail — Contrôle et caractérisation

des erreurs de pesée des aérosols collectés

1 Domaine d'application

La présente Norme internationale fournit des recommandations pour le contrôle des incertitudes analytiques

liées à l'instabilité des supports de collecte d'aérosols, où le support ou substrat de collecte inclut tout objet

utilisé pour recueillir des particules (par exemple un filtre ou un matériau en mousse), ainsi que les éléments

connexes devant être soumis à l'analyse par pesée.

La présente Norme internationale est applicable aux résultats compilés à la fois à partir de sources

bibliographiques et, lorsque cela est nécessaire et faisable, à partir d'expériences en laboratoire. Les erreurs

prévisibles liées aux méthodes de prélèvement d'aérosols sont quantifiées chaque fois que possible. Des

recommandations sur les matériaux à utiliser sont indiquées. Des moyens de contrôle ou de correction des

erreurs dues à l'instabilité sont fournis. Des recommandations sur le mode opératoire de pesée sont données.

Une procédure d'estimation des erreurs de pesée est décrite. Enfin, des recommandations sont données pour

établir des rapports des masses mesurées.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent document. Pour les

références datées, seule l'édition citée s'applique. Pour les références non datées, la dernière édition du

document de référence s'applique (y compris les éventuels amendements).

ISO 7708, Qualité de l'air — Définitions des fractions de taille des particules pour l'échantillonnage lié aux

problèmes de santé

EN 482, Atmosphères des lieux de travail — Exigences générales concernant les performances des

procédures de mesurage des agents chimiques

EN 13205:2001, Atmosphères de lieux de travail — Évaluation des performances des instruments de

mesurage des concentrations d'aérosols

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s'appliquent.

3.1

substrat

filtre de prélèvement, mousse, etc. et tout accessoire de montage associé, pesés en tant qu'élément unique

NOTE À titre d'exemple contraire, la cassette en plastique servant de support aux filtres de 25 mm ou 37 mm

fréquemment utilisée pour échantillonner les «poussières totales», disponible en version à face fermée ou face ouverte,

ne fait pas partie du substrat défini ci-dessus, puisqu'elle n'est pas prise en compte dans la pesée.

© ISO 2003 — Tous droits réservés 1

---------------------- Page: 6 ----------------------

ISO 15767:2003(F)

3.2

temps d'équilibrage

constante temporelle qui caractérise une approche de la masse d'un support de collecte d'aérosols,

s'amortissant de façon approximativement exponentielle jusqu'à une valeur constante

NOTE 1 La constante peut être définie comme le rapport de la différence moyenne entre la masse obtenue à l'équilibre

et le rapport moyen de perte ou de gain de masse, sur une période déterminée.

NOTE 2 Dans certaines situations importantes, plusieurs constantes temporelles peuvent être requises pour décrire

une approche de l'équilibre.

NOTE 3 Le temps d'équilibrage est exprimé en secondes.

3.3

blanc de terrain

substrat à blanc soumis aux mêmes manipulations que le substrat de prélèvement, incluant généralement une

phase de conditionnement et nécessitant souvent une mise en place dans les échantillonneurs ou récipients

de transport, ainsi que l'acheminement entre le laboratoire et le site de prélèvement, mais sans être soumis

au prélèvement

3.4

blanc de laboratoire

substrat à blanc soumis aux mêmes manipulations de laboratoire que le substrat de prélèvement, incluant une

phase de conditionnement et une mise en place dans les échantillonneurs ou récipients de transport, si ces

opérations sont effectuées en laboratoire

3.5

substrat à blanc

support ou substrat de collecte provenant du même lot que le support de prélèvement, mais sans exposition

au prélèvement

3.6

limite de détection

LOD

trois fois l'écart type estimé de la masse de l'échantillon, avec la prise en compte de la double pesée

(exposée et non exposée) et de l'incertitude associée à la correction de blanc

NOTE La LOD peut être utilisée comme seuil de mise en évidence d'une substance présente, avec le niveau de

confiance qui caractérise la méthode. L'Annexe B décrit le mode d'estimation, sur la base de l'évaluation de la méthode,

du taux de faux positifs de ces mises en évidence.

3.7

limite de quantification

LOQ

dix fois l'écart type estimé de la masse de l'échantillon

NOTE La LOQ peut être utilisée comme seuil de garantie pour la précision du mesurage d'une substance. Voir les

détails à l'Annexe B.

4 Instabilité de pesée — Causes et minimisation

4.1 Généralités

[1] à [11]

L'instabilité de pesée des substrats de prélèvement peut être attribuée à plusieurs causes . Les plus

importantes sont décrites dans les paragraphes qui suivent.

2 © ISO 2003 — Tous droits réservés

---------------------- Page: 7 ----------------------

ISO 15767:2003(F)

4.2 Adsorption d'humidité

4.2.1 L'adsorption d'humidité est la cause la plus fréquente d'instabilité de pesée. L'eau peut être prélevée

directement sur le filtre, la mousse ou tout autre matériau de substrat pesé. L'adsorption d'eau dans une

partie quelconque du système de prélèvement pesé peut également être soupçonnée. Par exemple, la

[1]

cassette elle-même peut, lors de sa pesée, être à l'origine d'erreurs significatives .

4.2.2 Les effets de l'adsorption d'eau peuvent être réduits par l'emploi de matériaux non adsorbants.

Toutefois, les besoins liés à certains prélèvements ne permettent pas l'emploi de matériaux hydrophobes. Le

Tableau 1 présente une liste de substrats de prélèvement d'aérosols courants, ayant des propriétés

adsorbantes différentes vis-à-vis de l'eau.

Tableau 1 — Propriétés adsorbantes vis-à-vis de l'eau de quelques supports

de prélèvement d'aérosols

Type de substrat ou de cassette Très faible Faible Elevée Très élevée

Filtre en fibre de cellulose *

Filtre en fibre de verre *

Filtre en fibre de quartz *

Filtre à membrane en ester de cellulose *

Filtre en polytétrafluoroéthylène *

Filtre à membrane PVC * *

Filtre en polycarbonate *

Filtre à membrane argent *

Mousse de polyuréthanne *

Substrat d'impaction en mylar graissé * *

Substrat d'impaction à feuille d'aluminium graissée *

Résine au carbone *

Cassette en aluminium * *

Cassette en acier inoxydable *

NOTE 1 Les références [2] à [4] comportent des détails supplémentaires. Par ailleurs, la référence [5] établit que les

filtres réputés constitués du même matériau, mais provenant de fabricants divers, peuvent présenter des caractéristiques

très inégales.

NOTE 2 Pour de nombreux matériaux, il existe en général un compromis entre l'hydrophobicité et la conductivité [9].

Néanmoins, il doit être tenu compte du fait que la réduction de l'hygroscopicité peut engendrer des problèmes de

prélèvement.

NOTE 3 Le prétraitement des substrats, tel qu'un graissage, peut également influer sur l'adsorption d'eau.

4.3 Effets électrostatiques

Les effets électrostatiques sont une source fréquente de problèmes lors des pesées. Ces effets peuvent

généralement être minimisés par l'élimination des charges électriques du substrat, par l'emploi d'une source

ionique à plasma ou d'une source radioactive. Ces problèmes peuvent être réduits par l'usage de matériaux

conducteurs. Voir également la référence [7].

4.4 Effets dus aux composants volatils (autres que l'eau)

[3]

4.4.1 Des substances volatiles peuvent être présentes sur certains supports de collecte inutilisés , ou

introduites par adsorption sur le support pendant le prélèvement.

© ISO 2003 — Tous droits réservés 3

---------------------- Page: 8 ----------------------

ISO 15767:2003(F)

4.4.2 La désorption des substances volatiles du support inutilisé peut être contrôlée, par exemple, par un

traitement thermique ou un traitement par plasma à oxygène avant le conditionnement et la pesée. À l'opposé,

les pertes peuvent être compensées par l'usage de blancs (voir l'Article 5).

4.4.3 Lorsque les matières volatiles collectées lors du prélèvement font partie de l'échantillon, des

procédures normalisées écrites doivent être rédigées pour garantir que les pertes éventuelles sont

minimisées, ou au minimum contrôlées, par exemple grâce à un conditionnement rigoureusement défini.

4.4.4 Lorsque les matières volatiles recueillies lors du prélèvement ne font pas partie de l'échantillon, leur

élimination peut être difficile si la pesée constitue l'unique forme d'analyse. Il convient d'utiliser de préférence

des supports non adsorbants.

4.5 Détériorations dues aux manipulations

4.5.1 Si les substrats utilisés sont friables, des procédures sont requises pour éviter les détériorations

d'origine mécanique.

4.5.2 Il convient que l'équipement de prélèvement de l'air soit conçu pour que le substrat ne subisse

aucune détérioration lors de l'assemblage et du désassemblage.

4.5.3 L'utilisation de pinces à embouts plats est recommandée pour manipuler les filtres. Les substrats

délicats peuvent être pesés sans manipulation directe, dans des récipients en métal inoxydable.

4.5.4 Les éléments à peser ne doivent pas être manipulés avec les doigts, sauf si les mains sont gantées.

4.5.5 Si des gants sont utilisés, ils ne doivent laisser aucun résidu sur les éléments pesés.

4.5.6 La manipulation doit avoir lieu dans un environnement propre, pour éviter les contaminations.

4.6 Variations dues à la poussée d'Archimède

[8]

Les corrections liées à la poussée d'Archimède , égale à la masse volumique de l'air multipliée par le volume

d'air déplacé, ne sont pas nécessaires pour les objets de petite taille tels que les filtres à membrane de 37 mm.

Toutefois, dans certaines circonstances (par exemple pour peser une cassette de prélèvement entière sans

recourir à des blancs correcteurs), le volume de l'objet pesé est tel qu'une compensation de la poussée

3

atmosphérique est nécessaire. Si, par exemple, le volume pesé est supérieur à 0,1 cm , alors une correction

est requise pour permettre des pesées allant jusqu'à 0,1 mg, en cas de variation de pression prévue de l'ordre

de 10 % entre chaque pesée (par exemple à des altitudes différentes). Lorsqu'une telle correction est

nécessaire, il convient de consigner la pression atmosphérique et la température au moment de la pesée.

5 Corrections liées à l'instabilité de pesée

5.1 Généralités

[12] à [20]

Plusieurs approches pour contrôler l'instabilité de pesée existent . L'utilisation de blancs est la

principale solution pratique pour réduire les erreurs dues à l'instabilité de pesée. La correction de l'instabilité de

pesée dépendant de chaque application particulière, il convient qu'elle soit conforme à une procédure écrite. Le

principe général est le suivant. Des supports de prélèvement à blanc sont exposés à des conditions aussi

proches que possible de celles du support de prélèvement actif, sans toutefois procéder à un pompage d'air.

La correction est appliquée en soustrayant le changement de masse moyenne des échantillons à blanc du

changement de masse relevée sur les échantillons actifs. Bien entendu, dans le cas d'échantillons contenant

des gouttelettes d'eau (ou d'autres substances volatiles), l'usage de blancs seuls ne permet aucune correction.

Les blancs doivent être appariés aux échantillons: si l'échantillon comporte un filtre contenu dans la cassette

pesée, le blanc doit être constitué d'un filtre de même type contenu dans le même type de cassette.

NOTE Les effets des variations de l'état du filtre, qui résultent de leur fabrication, sont généralement éliminés par

l'usage de blancs.

4 © ISO 2003 — Tous droits réservés

---------------------- Page: 9 ----------------------

ISO 15767:2003(F)

5.2 Nombre minimal de blancs

Il est généralement conseillé d'utiliser au moins un blanc pour dix échantillons. Les procédures de mesurage

courantes nécessitent l'emploi d'un à quatre blancs par lot. Pour connaître les avantages liés à l'emploi de

plusieurs blancs, se reporter à l'Annexe A.

5.3 Durée et séquence des pesées

Des blancs doivent être intercalés entre les supports utilisés pour le prélèvement, avant et après utilisation,

afin de détecter les variations systématiques en masse (dues par exemple à l'adsorption ou à l'évaporation

d'un contaminant durant la pesée).

5.4 Temps de conditionnement

Le temps de conditionnement nécessaire à l'obtention d'un équilibre dans l'environnement de pesée peut varier