ASTM D6660-01(2014)e1

(Test Method)Standard Test Method for Freezing Point of Aqueous Ethylene Glycol Base Engine Coolants by Automatic Phase Transition Method

Standard Test Method for Freezing Point of Aqueous Ethylene Glycol Base Engine Coolants by Automatic Phase Transition Method

SIGNIFICANCE AND USE

5.1 The freezing point of an engine coolant indicates the coolant freeze protection.

5.2 The freezing point of an engine coolant may be used to determine the approximate glycol content, provided the glycol type is known.

5.3 Freezing point as measured by Test Method D1177 or approved alternative method is a requirement in Specifications D3306 and D6210.

5.4 This test method provides results that are equivalent to Test Method D1177 and expresses results to the nearest 0.1°C with improved reproducibility over Test Method D1177.

5.5 This test method determines the freezing point in a shorter period of time than Test Method D1177.

5.6 This test method removes most of the operator time and judgement required by Test Method D1177.

SCOPE

1.1 This test method covers the determination of the freezing point of an aqueous engine coolant solution.

1.2 This test method is designed to cover ethylene glycol base coolants up to a maximum concentration of 60 % (v/v) in water; however, the ASTM interlaboratory study mentioned in 12.2 has only demonstrated the test method with samples having a concentration range of 40 to 60 % (v/v) water.

Note 1: Where solutions of specific concentrations are to be tested, they shall be prepared from representative samples as directed in Test Method D1176. Secondary phases separating on dilution need not be separated.

Note 2: The products may also be marketed in a ready-to-use form (prediluted).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Some specific hazards statements are given in 7.3.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6660 − 01 (Reapproved 2014)

Standard Test Method for

Freezing Point of Aqueous Ethylene Glycol Base Engine

Coolants by Automatic Phase Transition Method

This standard is issued under the fixed designation D6660; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units information was corrected and Note 4 was changed to a warning statement and included in Section 7.3

editorially in July 2014.

1. Scope D3306 Specification for Glycol Base Engine Coolant for

Automobile and Light-Duty Service

1.1 This test method covers the determination of the freez-

D6210 Specification for Fully-Formulated Glycol Base En-

ing point of an aqueous engine coolant solution.

gine Coolant for Heavy-Duty Engines

1.2 This test method is designed to cover ethylene glycol

base coolants up to a maximum concentration of 60 % (v⁄v) in

3. Terminology

water; however, theASTM interlaboratory study mentioned in

3.1 Definitions of Terms Specific to This Standard:

12.2 has only demonstrated the test method with samples

3.1.1 automatic phase transition method, n—in this

having a concentration range of 40 to 60 % (v/v) water.

standard, the procedures of automatically cooling an engine

NOTE 1—Where solutions of specific concentrations are to be tested,

coolant sample until solid crystals appear, followed by con-

they shall be prepared from representative samples as directed in Test

trolled warming and recording the temperature at which the

Method D1176. Secondary phases separating on dilution need not be

crystals redissolve into the liquid phase.

separated.

NOTE 2—The products may also be marketed in a ready-to-use form

3.1.2 freezing point, n—the temperature at which crystalli-

(prediluted).

zation begins in the absence of supercooling, or the maximum

1.3 The values stated in SI units are to be regarded as temperature reached immediately after initial crystal formation

standard. No other units of measurement are included in this in the case of supercooling, or the temperature at which solid

standard. crystals, formed on cooling, disappear when the temperature of

the specimen is allowed to rise.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.3 peltier device, n—a solid state thermoelectric device

responsibility of the user of this standard to establish appro- constructed with dissimilar semiconductor materials, config-

priate safety and health practices and determine the applica-

ured in such a way that it will transfer heat to and away from

bility of regulatory limitations prior to use. Some specific a test specimen dependent on the direction of electric current

hazards statements are given in 7.3.

applied to the device.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

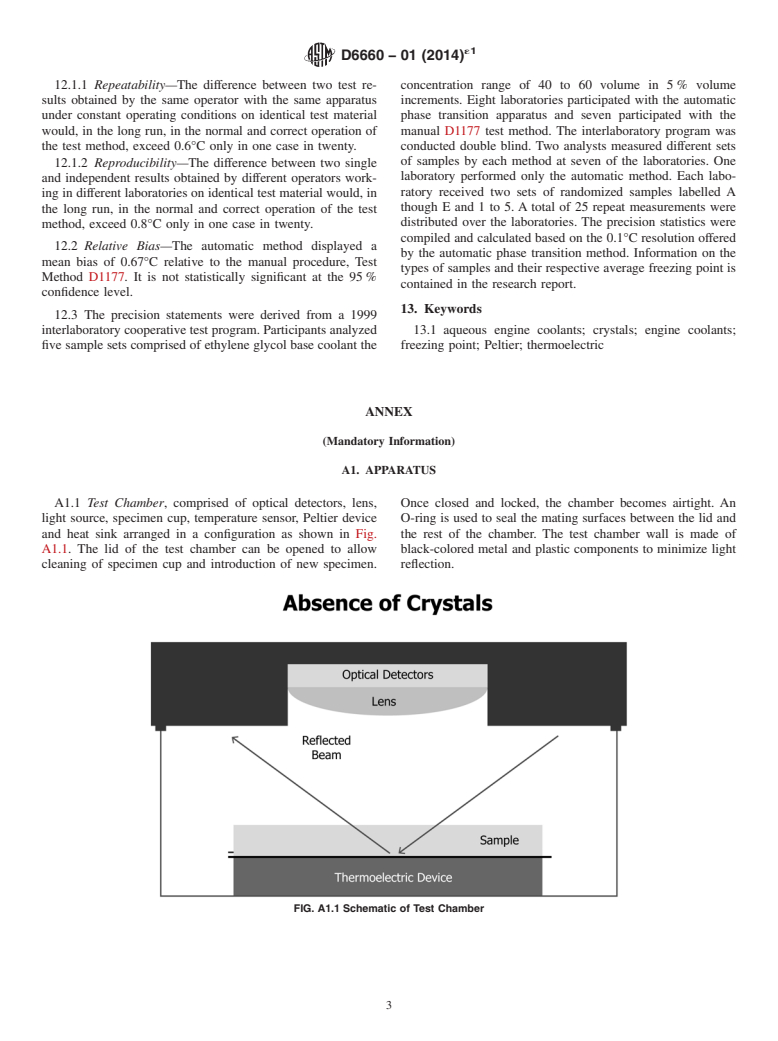

4.1 Aspecimen is cooled by a Peltier device while continu-

D1176 Practice for Sampling and Preparing Aqueous Solu-

ously being illuminated by a light source. The specimen is

tions of Engine Coolants orAntirusts forTesting Purposes

continuously monitored by an array of optical detectors for the

D1177 Test Method for Freezing Point of Aqueous Engine

first formation of crystals. Once the crystals are formed, the

Coolants

specimen is then warmed at controlled rates until all the

crystals return to the liquid phase. The detectors are sufficient

in number to ensure that any crystals are detected. The

This test method is under the jurisdiction ofASTM Committee D15 on Engine

Coolants and Related Fluids and is the direct responsibility of Subcommittee specimen temperature at which the crystals return to the liquid

D15.03 on Physical Properties.

phase is recorded by the temperature sensor as the freezing

Current edition approved July 1, 2014. Published July 2014. Originally approved

point.

in 2001. Last previous edition approved in 2007 as D6660 – 01(2007). DOI:

10.1520/D6660-01R14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5. Significance and Use

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 The freezing point of an engine coolant indicates the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. coolant freeze protection.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6660 − 01 (2014)

5.2 The freezing point of an engine coolant may be used to 8. Preparation of Apparatus

determine the approximate glycol content, provided the glycol

8.1 Install the analyzer for operation in accordance with

type is known.

manufacturer’s instructions.

5.3 Freezing point as measured by Test Method D1177 or

8.2 Make liquid cooling media connections and ensure that

approved alternative method is a requirement in Specifications

they do not leak.

D3306 and D6210.

8.3 Turn on the liquid cooling media.

5.4 This test method provides results that are equivalent to

8.4 Turnonthemainpowerswitchoftheanalyzer.Afterthe

Test Method D1177 and expresses results to the nearest 0.1°C

automatic self diagnostics start-up sequence is completed, the

with improved reproducibility over Test Method D1177.

instrument will display a “READY” message.

5.5 This test method determines the freezing point in a

shorter period of time than Test Method D1177.

9. Calibration and Standardization

5.6 This test method removes most of the operator time and

9.1 Ensure that all of the manufacturer’s instructions for

judgement required by Test Method D1177.

calibrating, checking and operating the apparatus are followed.

9.2 A sample with a mutually agreed upon freezing point

6. Apparatus

can be used to verify performance of the apparatus.

6.1 Automatic Apparatus —The apparatus described in this

method consists of a test chamber controlled by a micropro-

10. Procedure

cessor that is capable of cooling and heating the test specimen,

10.1 Open the test chamber lid and clean the specimen cup

optically observing the appearance and disappearance of solid

inside the test chamber with a cotton swab.

crystals and recording the temperature of the specimen.

10.2 Use the pipette to deliver 0.15 ml 6 0.01 ml of

6.2 The apparatus shall be equipped with a specimen cup,

specimen into the specimen cup. Clean the specimen out of the

optical detector array, light source, digital display, Peltier

cup by using a cotton swab. The cup should be cleaned to the

device and a specimen temperature measuring device.

point where no visible droplets of specimen remain in the cup.

6.3 The temperature measuring device in the specimen cup

10.3 Repeat step 10.2.

shall be capable of measuring the temperature of the test

10.4 Carefully measure 0.15 ml 6 0.01 ml of specimen into

specimen from -80°C to +50°C at a resolution of 0.1°C.

the specimen cup.

6.4 The apparatus shall be equipped with fittings to permit

10.5 Close and lock the test chamber lid.

the circulation of liquid cooling media to remove heat gener-

ated by the Peltier device and other electronic components of

10.6 Push the “RUN” button located on the front panel of

the apparatus.

the apparatus. The specimen is cooled by the Peltier device

while the appearance of solid crystals is continuously moni-

7. Reagents and Materials

tored by the optical detectors.The temperature of the specimen

7.1 Cooling Media—Liquid heat exchange media to remove is continuously monitored and displayed on the front panel of

the heat generated by the Peltier device and other electronic the apparatus. Once the crystals are detected, the specimen is

components from the apparatus. then warmed until all the crystals re-dissolve into the liquid

phase. The measurement is automatically terminated once the

NOTE 3—Some apparatus are designed to use tap water as cooling

freezing point is detected.

media to bring specimen temperature to -60°C. To achieve cooling of

specimento-80°C,providecirculationofliquidcoolingmediaat-30°Cor

10.7 When the measurement is complete the freezing point

lower to the apparatus. Refer to manufacturer’s operating instructions on

value per Test Method D6660 will be displayed on the front

the relationship between cooling media temperature and the minimum

panel of the apparatus.

specimen temperature.

10.8 Unlock and open the test chamber lid and clean the

7.2 Adjustable Volume Pipette, capable of dispensing 0.15

specimen out of the specimen cup with a cotton swab.

6 0.01 ml of sample.

7.3 Cotton Swabs —Plastic or paper shaft cotton swabs to

11. Report

clean the specimen cup. (Warning—The use of swabs with

11.1 Report the tempe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D6660 − 01 (Reapproved 2007) D6660 − 01 (Reapproved 2014)

Standard Test Method for

Freezing Point of Aqueous Ethylene Glycol Base Engine

Coolants by Automatic Phase Transition Method

This standard is issued under the fixed designation D6660; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units information was corrected and Note 4 was changed to a warning statement and included in Section 7.3

editorially in July 2014.

1. Scope

1.1 This test method covers the determination of the freezing point of an aqueous engine coolant solution.

1.2 This test method is designed to cover ethylene glycol base coolants up to a maximum concentration of 60 % (v/v) in water;

however, the ASTM interlaboratory study mentioned in 12.2 has only demonstrated the test method with samples having a

concentration range of 40 to 60 % (v/v) water.

NOTE 1—Where solutions of specific concentrations are to be tested, they shall be prepared from representative samples as directed in Test Method

D1176. Secondary phases separating on dilution need not be separated.

NOTE 2—The products may also be marketed in a ready-to-use form (prediluted).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parenthesis are for information

only.standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Some specific hazards statements are given in 7.3.

2. Referenced Documents

2.1 ASTM Standards:

D1176 Practice for Sampling and Preparing Aqueous Solutions of Engine Coolants or Antirusts for Testing Purposes

D1177 Test Method for Freezing Point of Aqueous Engine Coolants

D3306 Specification for Glycol Base Engine Coolant for Automobile and Light-Duty Service

D6210 Specification for Fully-Formulated Glycol Base Engine Coolant for Heavy-Duty Engines

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 automatic phase transition method, n—in this standard, the procedures of automatically cooling an engine coolant sample

until solid crystals appear, followed by controlled warming and recording the temperature at which the crystals redissolve into the

liquid phase.

3.1.2 freezing point, n—the temperature at which crystallization begins in the absence of supercooling, or the maximum

temperature reached immediately after initial crystal formation in the case of supercooling, or the temperature at which solid

crystals, formed on cooling, disappear when the temperature of the specimen is allowed to rise.

3.1.3 peltier device, n—a solid state thermoelectric device constructed with dissimilar semiconductor materials, configured in

such a way that it will transfer heat to and away from a test specimen dependent on the direction of electric current applied to the

device.

This test method is under the jurisdiction of ASTM Committee D15 on Engine Coolants and Related Fluids and is the direct responsibility of Subcommittee D15.03 on

Physical Properties.

Current edition approved April 1, 2007July 1, 2014. Published May 2007July 2014. Originally approved in 2001. Last previous edition approved in 20012007 as

ε1

D6660 - 01 .(2007). DOI: 10.1520/D6660-01R07.10.1520/D6660-01R14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6660 − 01 (2014)

4. Summary of Test Method

4.1 A specimen is cooled by a Peltier device while continuously being illuminated by a light source. The specimen is

continuously monitored by an array of optical detectors for the first formation of crystals. Once the crystals are formed, the

specimen is then warmed at controlled rates until all the crystals return to the liquid phase. The detectors are sufficient in number

to ensure that any crystals are detected. The specimen temperature at which the crystals return to the liquid phase is recorded by

the temperature sensor as the freezing point.

5. Significance and Use

5.1 The freezing point of an engine coolant indicates the coolant freeze protection.

5.2 The freezing point of an engine coolant may be used to determine the approximate glycol content, provided the glycol type

is known.

5.3 Freezing point as measured by Test Method D1177 or approved alternative method is a requirement in Specifications D3306

and D6210.

5.4 This test method provides results that are equivalent to Test Method D1177 and expresses results to the nearest 0.1°C with

improved reproducibility over Test Method D1177.

5.5 This test method determines the freezing point in a shorter period of time than Test Method D1177.

5.6 This test method removes most of the operator time and judgement required by Test Method D1177.

6. Apparatus

6.1 Automatic Apparatus —The apparatus described in this method consists of a test chamber controlled by a microprocessor

that is capable of cooling and heating the test specimen, optically observing the appearance and disappearance of solid crystals and

recording the temperature of the specimen.

6.2 The apparatus shall be equipped with a specimen cup, optical detector array, light source, digital display, Peltier device and

a specimen temperature measuring device.

6.3 The temperature measuring device in the specimen cup shall be capable of measuring the temperature of the test specimen

from -80°C to +50°C at a resolution of 0.1°C.

6.4 The apparatus shall be equipped with fittings to permit the circulation of liquid cooling media to remove heat generated by

the Peltier device and other electronic components of the apparatus.

7. Reagents and Materials

7.1 Cooling Media—Liquid heat exchange media to remove the heat generated by the Peltier device and other electronic

components from the apparatus.

NOTE 3—Some apparatus are designed to use tap water as cooling media to bring specimen temperature to -60°C. To achieve cooling of specimen to

-80°C, provide circulation of liquid cooling media at -30°C or lower to the apparatus. Refer to manufacturer’s operating instructions on the relationship

between cooling media temperature and the minimum specimen temperature.

7.2 Adjustable Volume Pipette, , capable capable of dispensing 0.15 6 0.01 ml of sample.

7.3 Cotton Swabs —Plastic or paper shaft cotton swabs to clean the specimen cup. (Warning—The use of swabs with wooden

shafts may damage the mirrored surface of the specimen cup.)

NOTE 4—Caution: The use of swabs with wooden shafts may damage the mirrored surface of the specimen cup.

8. Preparation of Apparatus

8.1 Install the analyzer for operation in accordance with manufacturer’s instructions.

8.2 Make liquid cooling media connections and ensure that they do not leak.

8.3 Turn on the liquid cooling media.

8.4 Turn on the main power switch of the analyzer. After the automatic self diagnostics start-up sequence is completed, the

instrument will display a “READY” message.

The following instrument has been found suitable for use in this test method: Phase Technology Freezing Point Analyzer model series 70 and 70V. The sole source of

supply of the apparatus known to the committee at this time is Phase Technology, i 1168 Hammersmith Gate, Richmond, B.C. Canada, V7A 5H8. If you are aware of

alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend.

A suitable pipette is an Eppendorf pipette.

Suitable cotton swabs are Q-tips or equivalent with paper or plastic shafts.

´1

D6660 − 01 (2014)

9. Calibration and Standardization

9.1 Ensure that all of the manufacturer’s instructions for calibrating, checking and operating the apparatus are followed.

9.2 A sample with a mutually agreed upon freezing point can be used to verify performance of the apparatus.

10. Procedure

10.1 Open the test chamber lid and clean the specimen cup inside the test chamber with a cotton swab.

10.2 Use the pipette to deliver 0.15 ml 6 0.01 ml of specimen into the specimen cup. Clean the specimen out of the cup by

using a cotton swab. The cup should be cleaned to the point where no visible droplets of specimen remain in the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.