ASTM F1575-17

(Test Method)Standard Test Method for Determining Bending Yield Moment of Nails

Standard Test Method for Determining Bending Yield Moment of Nails

SIGNIFICANCE AND USE

5.1 Nails are a common mechanical fastener in wood structures. Engineering design procedures used to determine the capacities of laterally-loaded nailed connections currently use a yield theory to establish the nominal resistance for laterally-loaded nailed connections that are engineered. In order to develop the nominal resistance for laterally-loaded nailed connections, the bending yield moment must be known.

SCOPE

1.1 This test method covers procedures for determining the bending yield moment of nails when subjected to static loading. It is intended only for nails used in engineered connection applications, in which a required connection capacity is specified by the designer.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1575 − 17

Standard Test Method for

1

Determining Bending Yield Moment of Nails

This standard is issued under the fixed designation F1575; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* with a line represented by the initial tangent modulus offset

5 % of the fastener diameter.

1.1 This test method covers procedures for determining the

bending yield moment of nails when subjected to static

3.1.2 deformed shank—a nail shank that has been mechani-

loading. It is intended only for nails used in engineered

cally deformed with annular rings, barbs, helical flutes, etc. for

connection applications, in which a required connection capac-

the purpose of improved withdrawal capacity.

ity is specified by the designer.

3.1.2.1 fully deformed shank—a nail shank that has defor-

1.2 The values stated in inch-pound units are to be regarded

mation along the entire length.

as standard. No other units of measurement are included in this

3.1.2.2 partially deformed shank—a nail shank that that has

standard.

both smooth and deformed sections along the length.

1.3 This standard does not purport to address all of the

3.1.3 proportional limit load—is the load at which the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- load-deformation curve deviates from a straight line fitted to

the initial portion of the load-deformation curve. (See Fig. 1)

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

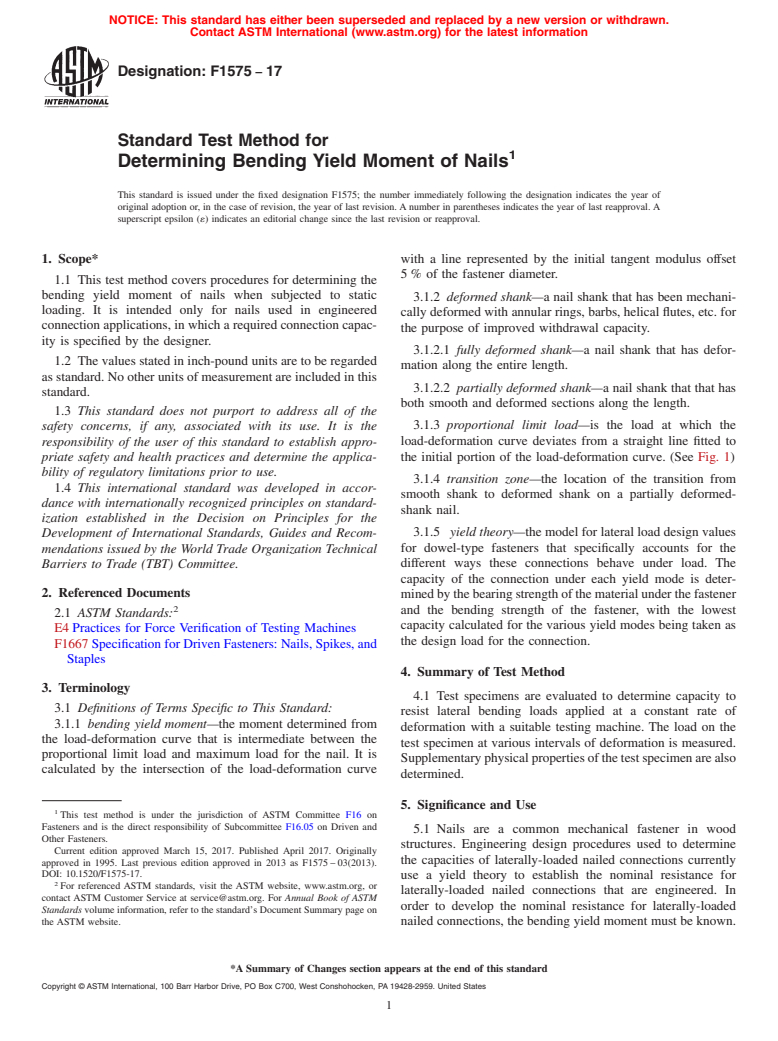

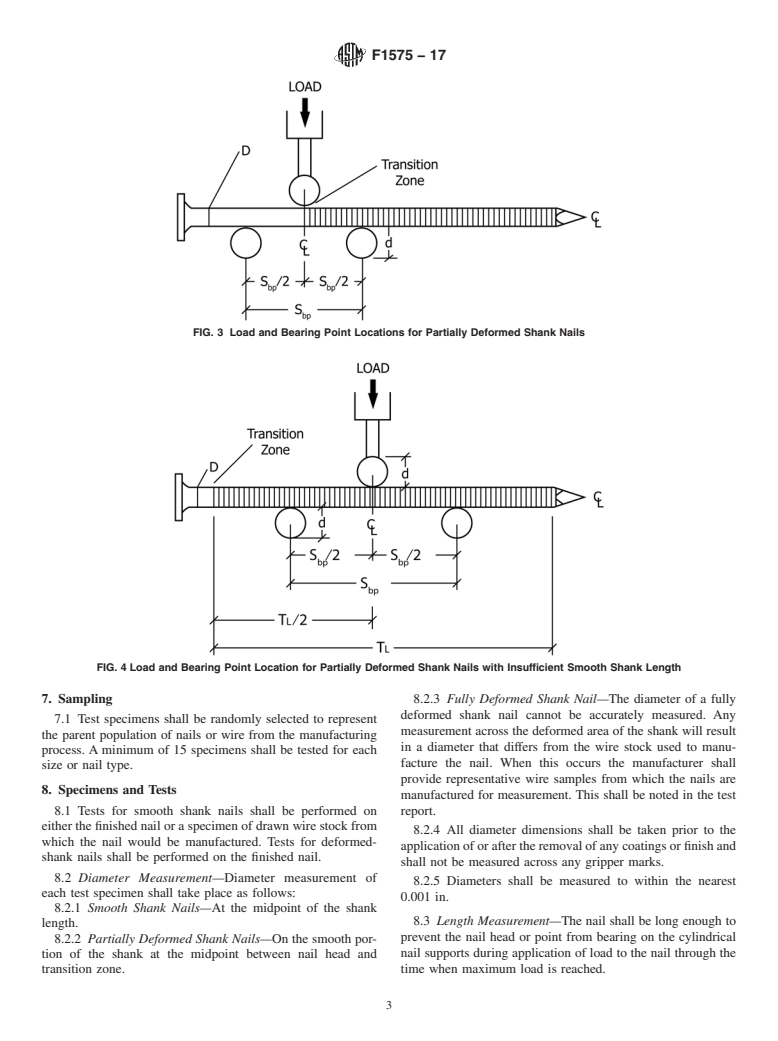

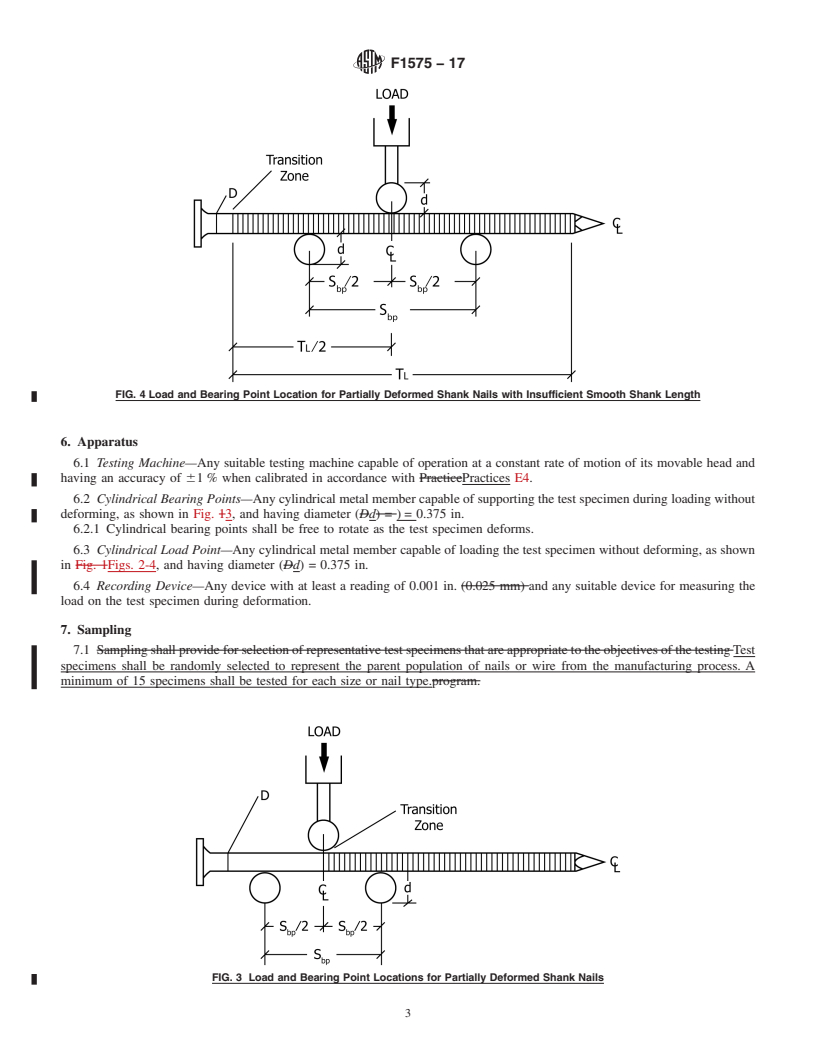

3.1.4 transition zone—the location of the transition from

1.4 This international standard was developed in accor-

smooth shank to deformed shank on a partially deformed-

dance with internationally recognized principles on standard-

shank nail.

ization established in the Decision on Principles for the

3.1.5 yield theory—the model for lateral load design values

Development of International Standards, Guides and Recom-

for dowel-type fasteners that specifically accounts for the

mendations issued by the World Trade Organization Technical

different ways these connections behave under load. The

Barriers to Trade (TBT) Committee.

capacity of the connection under each yield mode is deter-

2. Referenced Documents

minedbythebearingstrengthofthematerialunderthefastener

2

and the bending strength of the fastener, with the lowest

2.1 ASTM Standards:

capacity calculated for the various yield modes being taken as

E4 Practices for Force Verification of Testing Machines

the design load for the connection.

F1667 Specification for Driven Fasteners: Nails, Spikes, and

Staples

4. Summary of Test Method

3. Terminology

4.1 Test specimens are evaluated to determine capacity to

3.1 Definitions of Terms Specific to This Standard:

resist lateral bending loads applied at a constant rate of

3.1.1 bending yield moment—the moment determined from

deformation with a suitable testing machine. The load on the

the load-deformation curve that is intermediate between the

test specimen at various intervals of deformation is measured.

proportional limit load and maximum load for the nail. It is

Supplementaryphysicalpropertiesofthetestspecimenarealso

calculated by the intersection of the load-deformation curve

determined.

5. Significance and Use

1

This test method is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.05 on Driven and

5.1 Nails are a common mechanical fastener in wood

Other Fasteners.

structures. Engineering design procedures used to determine

Current edition approved March 15, 2017. Published April 2017. Originally

the capacities of laterally-loaded nailed connections currently

approved in 1995. Last previous edition approved in 2013 as F1575 – 03(2013).

DOI: 10.1520/F1575-17.

use a yield theory to establish the nominal resistance for

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

laterally-loaded nailed connections that are engineered. In

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

order to develop the nominal resistance for laterally-loaded

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. nailed connections, the bending yield moment must be known.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1575 − 17

FIG. 1 Example of Typical Load-Deformation Diagram f

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1575 − 03 (Reapproved 2013) F1575 − 17

Standard Test Method for

1

Determining Bending Yield Moment of Nails

This standard is issued under the fixed designation F1575; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers procedures for determining the bending yield moment of nails when subjected to static loading. It

is intended only for nails used in engineered connection applications, in which a required connection capacity is specified by the

designer.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this

standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

3

E1470 Test Method for Characterization of Proteins by Electrophoretic Mobility (Withdrawn 2014)

F1667 Specification for Driven Fasteners: Nails, Spikes, and Staples

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 bending yield moment—the moment determined from the load-deformation curve that is intermediate between the

proportional limit load and maximum load for the nail. It is calculated by the intersection of the load-deformation curve with a

line represented by the initial tangent modulus offset 5 % of the fastener diameter.

3.1.2 deformed shank—a nail shank that has been mechanically deformed with annular rings, barbs, helical flutes, etc. for the

purpose of improved withdrawal capacity.

3.1.2.1 fully deformed shank—a nail shank that has deformation along the entire length.

3.1.2.2 partially deformed shank—a nail shank that that has both smooth and deformed sections along the length.

3.1.3 proportional limit load—is the load at which the load-deformation curve deviates from a straight line fitted to the initial

portion of the load-deformation curve. (See Fig. 1)

3.1.4 transition zone—the location of the transition from smooth shank to threadeddeformed shank on a partially deformed-

shank nail.

3.1.5 yield theory—the model for lateral load design values for dowel-type fasteners that specifically accounts for the different

ways these connections behave under load. The capacity of the connection under each yield mode is determined by the bearing

strength of the material under the fastener and the bending strength of the fastener, with the lowest capacity calculated for the

various yield modes being taken as the design load for the connection.

1

This test method is under the jurisdiction of ASTM Committee F16 on Fasteners and is the direct responsibility of Subcommittee F16.05 on Driven and Other Fasteners.

Current edition approved Nov. 1, 2013March 15, 2017. Published March 2014April 2017. Originally approved in 1995. Last previous edition approved in 20082013 as

F1575 – 03(2008).(2013). DOI: 10.1520/F1575-03R13.10.1520/F1575-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1575 − 17

FIG. 21 Example of Typical Load-Deformation Diagram from Nail Bending Test

4. Summary of Test Method

4.1 Test specimens are evaluated to determine capacity to resist lateral bending loads applied at a constant rate of deformation

FIG. 12 Center-Point Bending Test for Load and Bearing Point Locations for Smooth Shank and Fully Deformed Shank Nails

with a suit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.