ASTM F680-20

(Test Method)Standard Test Methods for Nails

Standard Test Methods for Nails

SIGNIFICANCE AND USE

4.1 When specified, the tests selected for application shall be performed to assure conformance with requirements stipulated in the product specification.

SCOPE

1.1 These test methods cover procedures for the testing of nails. The test or tests selected, and the requirements for compliance, will be as specified in the applicable product standard. Performance tests for nail withdrawal and lateral load capability are not included as they are covered by Test Methods D1761.

1.2 The tests described are as follows:

Section

Dimensional tests

5

Tension test

6

Conventional bend test

7

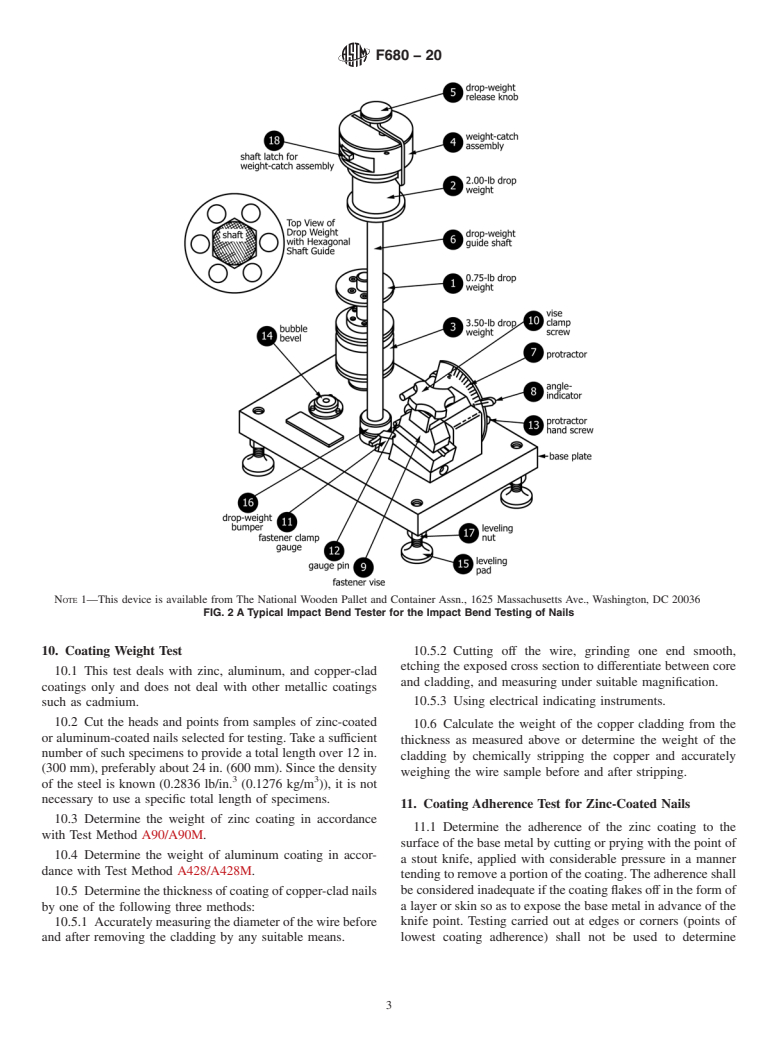

Impact bend test

8

Rockwell hardness test

9

Coating weight test

10

Coating adherence test for zinc-coated nails

11

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F680 − 20

Standard Test Methods for

1

Nails

ThisstandardisissuedunderthefixeddesignationF680;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A90/A90M Test Method for Weight [Mass] of Coating on

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

1.1 These test methods cover procedures for the testing of

A370 Test Methods and Definitions for Mechanical Testing

nails. The test or tests selected, and the requirements for

of Steel Products

compliance, will be as specified in the applicable product

A428/A428M Test Method for Weight [Mass] of Coating on

standard.Performancetestsfornailwithdrawalandlateralload

Aluminum-Coated Iron or Steel Articles

capabilityarenotincludedastheyarecoveredbyTestMethods

D1761 Test Methods for Mechanical Fasteners in Wood and

D1761.

Wood-Based Materials

1.2 The tests described are as follows:

E18 Test Methods for Rockwell Hardness of Metallic Ma-

Section

terials

Dimensional tests 5

F547 Terminology of Nails for Use with Wood and Wood-

Tension test 6

Base Materials

Conventional bend test 7

Impact bend test 8

Rockwell hardness test 9

3. Terminology

Coating weight test 10

Coating adherence test for zinc-coated nails 11

3.1 Definitions—For definitions of terms used in this test

1.3 The values stated in inch-pound units are to be regarded method, refer to Terminology F547.

as standard. The values given in parentheses are mathematical

4. Significance and Use

conversions to SI units that are provided for information only

and are not considered standard.

4.1 When specified, the tests selected for application shall

be performed to assure conformance with requirements stipu-

1.4 This standard does not purport to address all of the

lated in the product specification.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Dimensional Tests

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5.1 Dimensions to be evaluated include, but shall not be

1.5 This international standard was developed in accor-

limited to length, shank diameter, diameter or major dimen-

dance with internationally recognized principles on standard-

sions of head, straightness, head concentricity to shank, and

ization established in the Decision on Principles for the

length of point. For mechanically deformed nails, angle, depth,

Development of International Standards, Guides and Recom-

and configuration of deformations and other dimensional

mendations issued by the World Trade Organization Technical characteristics shall be measured when required. Unless

Barriers to Trade (TBT) Committee.

specified, any suitable measuring means as identified in these

test methods may be applied.

2. Referenced Documents

5.2 Measurement of smooth shank nails:

2

2.1 ASTM Standards: 5.2.1 Smooth shank nails shall be measured at the approxi-

mated mid-point of the shank length. Additional locations

along the shank may be selected as required.

5.2.2 Measurements shall not be taken across the gripper

1

These test methods are under the jurisdiction of ASTM Committee F16 on

marks.

Fasteners and are the direct responsibilities of Subcommittee F16.05 on Driven and

Other Fasteners.

5.2.3 Average of two measurements taken approximately

Current edition approved Dec. 15, 2020. Published January 2021. Originally

90° apart shall constitute the diameter measurement.

approved in 1980. Last previous edition approved in 2017 as F680-17. DOI:

10.1520/F0680-20.

5.3 Measurement of deformed shank nails diameters (See

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Note 1.)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.3.1 For deformed shank nails where the deformation

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. exists along the entire length of the shank.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F680 − 20

5.3.1.1 Measure at the approximate mid-point of the shank specified in the product specification. The cold bending shall

length.Additional locations along the shank may be selected as be performed by any hand or power device that will deform the

requi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F680 − 17 F680 − 20

Standard Test Methods for

1

Nails

This standard is issued under the fixed designation F680; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 These test methods cover procedures for the testing of nails. The test or tests selected, and the requirements for compliance,

will be as specified in the applicable product standard. Performance tests for nail withdrawal and lateral load capability are not

included as they are covered by Test Methods D1761.

1.2 The tests described are as follows:

Section

Dimensional tests 5

Tension test 6

Conventional bend test 7

Impact bend test 8

Rockwell hardness test 9

Coating weight test 10

Coating adherence test for zinc-coated nails 11

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and

determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A90/A90M Test Method for Weight [Mass] of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A428/A428M Test Method for Weight [Mass] of Coating on Aluminum-Coated Iron or Steel Articles

D1761 Test Methods for Mechanical Fasteners in Wood and Wood-Based Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

1

These test methods are under the jurisdiction of ASTM Committee F16 on Fasteners and are the direct responsibilities of Subcommittee F16.05 on Driven and Other

Fasteners.

Current edition approved June 1, 2017Dec. 15, 2020. Published June 2017January 2021. Originally approved in 1980. Last previous edition approved in 20122017 as

F680-80(2012).F680-17. DOI: 10.1520/F0680-17.10.1520/F0680-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F680 − 20

F547 Terminology of Nails for Use with Wood and Wood-Base Materials

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology F547.

4. Significance and Use

4.1 When specified, the tests selected for application shall be performed to assure conformance with requirements stipulated in

the product specification.

5. Dimensional Tests

5.1 Dimensions to be evaluated include, but shall not be limited to length, stockshank diameter, diameter or major dimensions of

head, straightness, head concentricity to shank, and length of point. For mechanically deformed nails, angle, depth, and

configuration of deformations shall be measured as specified. Other and other dimensional characteristics shall be measured when

required. Any Unless specified, any suitable measuring means as identified in these test methods may be applied.

5.2 Measurement of smooth shank nails:

5.2.1 Smooth shank nails shall be measured at the approximated mid-point of the shank length. Additional locations along the

shank may be selected as required.

5.2.2 Measurements shall not be taken across the gripper marks.

5.2.3 Average of two measurements taken approximately 90° apart shall constitute the diameter measurement.

5.3 Measurement of deformed shank nails diameters (See Note 1.)

5.3.1 For deformed shank nails where the deformation exists along the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.