ASTM D709-13

(Specification)Standard Specification for Laminated Thermosetting Materials

Standard Specification for Laminated Thermosetting Materials

ABSTRACT

This specification establishes the manufacture, property requirements, and testing of several grades of laminated thermosetting materials consisting of two or more plies or layers of reinforcing material such as cellulose paper, cotton fabric, glass fabric, and synthetic fiber fabrics, bonded by a thermosetting synthetic resin. These materials are available in the form of sheets, rolled and molded tubes, and molded rods.

SCOPE

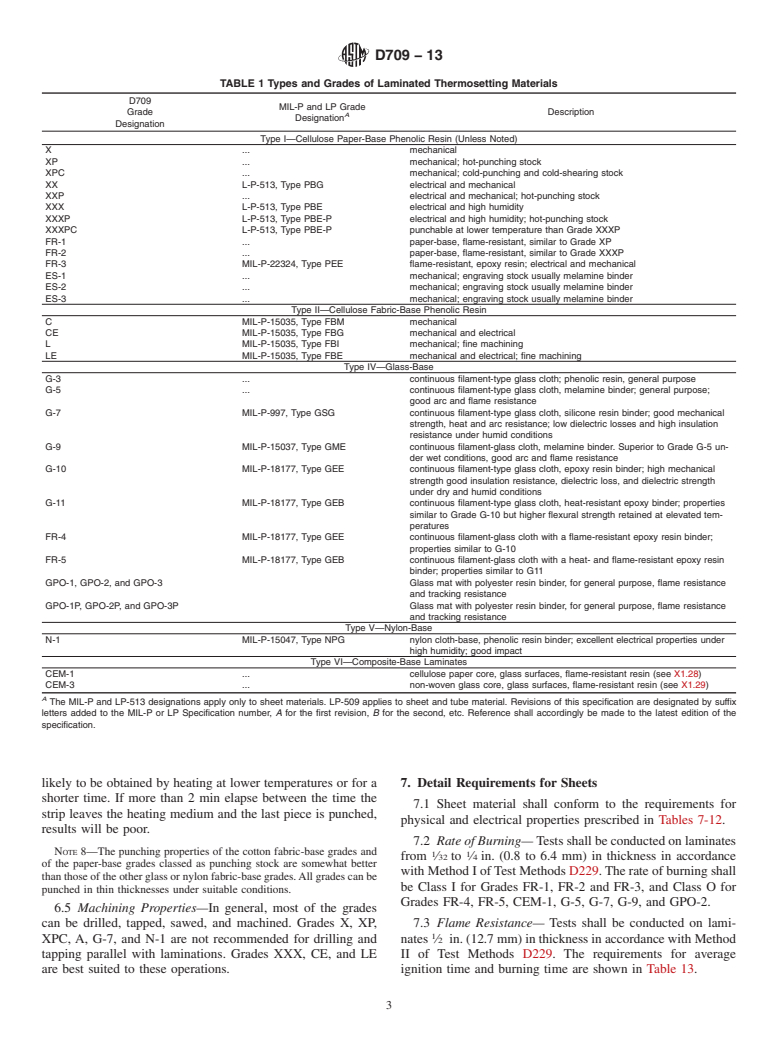

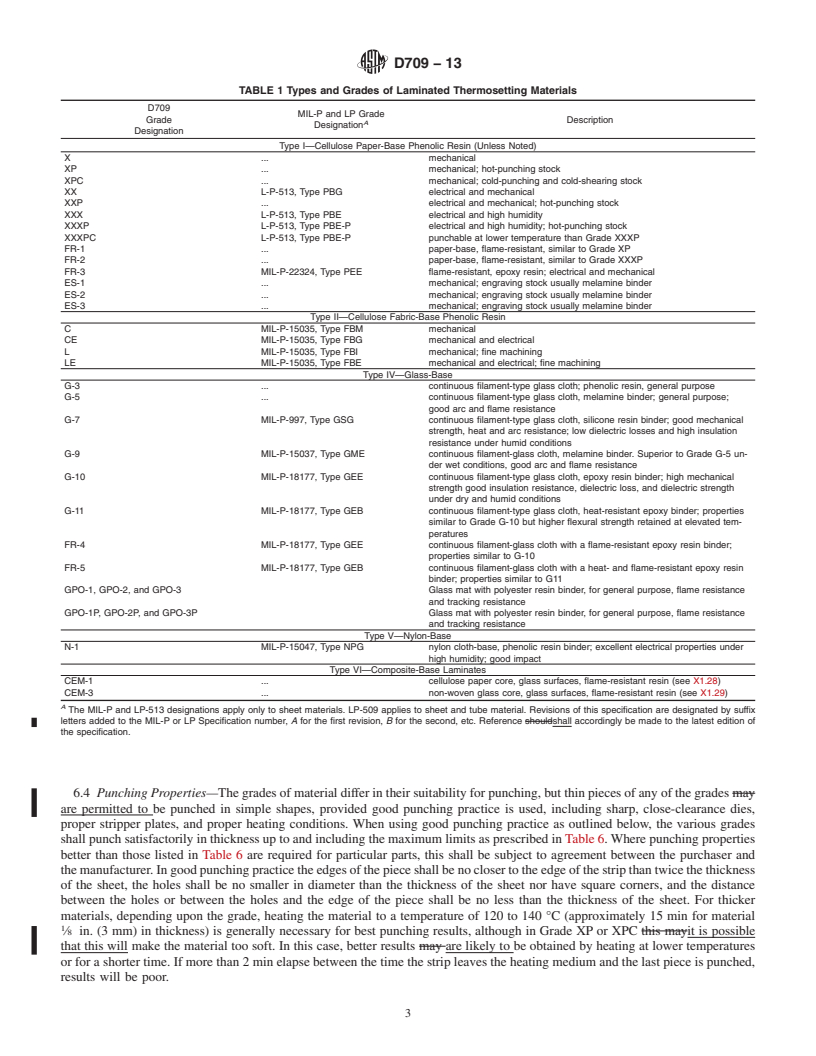

1.1 This specification covers laminated thermosetting materials consisting of two or more plies or layers of reinforcing material bonded by a thermosetting synthetic resin. Examples of such reinforcement are cellulose paper, cotton fabric, glass fabric, and synthetic fiber fabrics. These materials are available in the form of sheets, rolled and molded tubes, and molded rods.

1.2 The values stated in inch-pound units are to be regarded as the standard. Note 1—This specification resembles IEC 60893-3 in title only. The content is significantly different.

1.3 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D709 −13

StandardSpecification for

1

Laminated Thermosetting Materials

This standard is issued under the fixed designation D709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D495 Test Method for High-Voltage, Low-Current, DryArc

Resistance of Solid Electrical Insulation

1.1 This specification covers laminated thermosetting mate-

D621 Test Methods for Deformation of Plastics Under Load

rials consisting of two or more plies or layers of reinforcing

3

(Withdrawn 1994)

material bonded by a thermosetting synthetic resin. Examples

D668 TestMethodsofMeasuringDimensionsofRigidRods

of such reinforcement are cellulose paper, cotton fabric, glass

and Tubes Used for Electrical Insulation

fabric,andsyntheticfiberfabrics.Thesematerialsareavailable

D883 Terminology Relating to Plastics

in the form of sheets, rolled and molded tubes, and molded

D1180 Method of Test for Warpage of Sheet Plastics (With-

rods.

3

drawn 1988)

1.2 The values stated in inch-pound units are to be regarded

D1711 Terminology Relating to Electrical Insulation

as the standard.

D2303 Test Methods for Liquid-Contaminant, Inclined-

Plane Tracking and Erosion of Insulating Materials

NOTE 1—This specification resembles IEC 60893-3 in title only. The

content is significantly different.

D2304 Test Method for Thermal Endurance of Rigid Elec-

trical Insulating Materials

1.3 The following safety hazards caveat pertains only to the

D3636 Practice for Sampling and Judging Quality of Solid

test methods described in this specification. This standard does

Electrical Insulating Materials

not purport to address all of the safety concerns, if any,

D6054 Practice for Conditioning Electrical Insulating Mate-

associated with its use. It is the responsibility of the user of this

3

rials for Testing (Withdrawn 2012)

standard to establish appropriate safety and health practices

4

2.2 IEEE Standards:

and determine the applicability of regulatory limitations prior

1 General Principles forTemperature Limits in the Rating of

to use.

Electric Equipment

2. Referenced Documents

98 Guide for the Preparation of Test Procedures for the

2

Thermal Evaluation and Establishment of Temperature

2.1 ASTM Standards:

Indices of Solid Electrical Insulating Materials

D229 Test Methods for Rigid Sheet and Plate Materials

99 Guide for the Preparation of Test Procedures for the

Used for Electrical Insulation

Thermal Evaluation of Insulation Systems for Electric

D257 Test Methods for DC Resistance or Conductance of

Equipment

Insulating Materials

101 Guide for the Statistical Analysis of Thermal Life Test

D348 Test Methods for Rigid Tubes Used for Electrical

Data

Insulation

5

2.3 NEMA Standards:

D349 Test Methods for Laminated Round Rods Used for

LI 1-1971 Industrial Laminated Thermosetting Products

Electrical Insulation

LI 5-1969 Temperature Indices of Industrial Thermosetting

Laminates

1

This specification is under the jurisdiction of ASTM Committee D09 on

LI 3-1961 High-Temperature Properties of Industrial Ther-

Electrical and Electronic Insulating Materials and is the direct responsibility of

mosetting Laminates

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved Nov. 1, 2013. Published November 2013. Originally

3

approved in 1943. Last previous edition approved in 2007 as D709 – 01 (2007). The last approved version of this historical standard is referenced on

DOI: 10.1520/D0709-13. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from National Electrical Manufacturers Association (NEMA), 1300

the ASTM website. N. 17th St., Suite 1752, Rosslyn, VA 22209, http://www.nema.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D709−13

6

then ground to size. Molded rods are of two classes made by winding the

2.4 Military Specifications:

impregnated sheet convolutely before molding or by forming strips in the

MIL-P-997 Plastic Material, Laminated, Thermosetting,

molding operation.

Electric Insulation, Sheets,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D709 − 01 (Reapproved 2007) D709 − 13 An American National Standard

Standard Specification for

1

Laminated Thermosetting Materials

This standard is issued under the fixed designation D709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Scope*

1.1 This specification covers laminated thermosetting materials consisting of two or more plies or layers of reinforcing material

bonded by a thermosetting synthetic resin. Examples of such reinforcement are cellulose paper, cotton fabric, glass fabric, and

synthetic fiber fabrics. These materials are available in the form of sheets, rolled and molded tubes, and molded rods.

1.2 The values stated in inch-pound units are to be regarded as the standard.

NOTE 1—This specification resembles IEC 60893-3 in title only. The content is significantly different.

1.3 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D229 Test Methods for Rigid Sheet and Plate Materials Used for Electrical Insulation

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D348 Test Methods for Rigid Tubes Used for Electrical Insulation

D349 Test Methods for Laminated Round Rods Used for Electrical Insulation

3

D495 Test Method for High-Voltage, Low-Current, Dry Arc Resistance of Solid Electrical Insulation (Withdrawn 2013)

3

D621 Specification for Jute Rove and Plied Yarn for Electrical and Packing Purposes (Withdrawn 2000)

D668 Test Methods of Measuring Dimensions of Rigid Rods and Tubes Used for Electrical Insulation

D883 Terminology Relating to Plastics

3

D1180 Method of Test for Warpage of Sheet Plastics (Withdrawn 1988)

D1711 Terminology Relating to Electrical Insulation

D2303 Test Methods for Liquid-Contaminant, Inclined-Plane Tracking and Erosion of Insulating Materials

D2304 Test Method for Thermal Endurance of Rigid Electrical Insulating Materials

D3636 Practice for Sampling and Judging Quality of Solid Electrical Insulating Materials

3

D6054 Practice for Conditioning Electrical Insulating Materials for Testing (Withdrawn 2012)

4

2.2 IEEE Standards:

1 General Principles for Temperature Limits in the Rating of Electric Equipment

98 Guide for the Preparation of Test Procedures for the Thermal Evaluation and Establishment of Temperature Indices of Solid

Electrical Insulating Materials

99 Guide for the Preparation of Test Procedures for the Thermal Evaluation of Insulation Systems for Electric Equipment

101 Guide for the Statistical Analysis of Thermal Life Test Data

5

2.3 NEMA Standards:

LI 1-1971 Industrial Laminated Thermosetting Products

LI 5-1969 Temperature Indices of Industrial Thermosetting Laminates

1

This specification is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved May 1, 2007Nov. 1, 2013. Published June 2007November 2013. Originally approved in 1943. Last previous edition approved in 20012007 as

D709 – 01.D709 – 01 (2007). DOI: 10.1520/D0709-01R07.10.1520/D0709-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

5

Available from National Electrical Manufacturers Association (NEMA), 1300 N. 17th St., Suite 1752, Rosslyn, VA 22209, http://www.nema.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.