ASTM B373-00(2006)

(Specification)Standard Specification for Aluminum Foil for Capacitors (Withdrawn 2015)

Standard Specification for Aluminum Foil for Capacitors (Withdrawn 2015)

ABSTRACT

This specification covers nine thicknesses of annealed aluminum foil for use in manufacture of capacitors and includes UNS alloy designations A91145 and A91235. Foil to be used as anodes in electrolytic capacitors is beyond the scope of this specification. Requirements for quality assurance, chemical analysis, and tensile breaking load test are detailed. The foil shall conform to the chemical composition requirements prescribed for aluminum, silicon and iron, copper, manganese, magnesium, zinc, vanadium, and titanium, and shall meet the specified requirements for tensile breaking load, direct current electrical resistance, and area per unit weight. The foil shall be supplied with the finish bright on one side and matte on the other, in the dry or slick condition (dry annealed A, dry annealed B, dry annealed C, or slick annealed) and shall be tested for surface condition by water or water-alcohol test. Spooling requirements such as roll dimensions, roll winding, and roll covering are given. Foil splices shall be either welded or knurled and shall be free of splits, slivers, wrinkles, ragged edges, or excessive pinholes.

SCOPE

1.1 This specification covers nine thicknesses (0.00017 to 0.00050 in. (0.0043 to 0.0127 mm)) of annealed aluminum foil used in the manufacture of capacitors.

1.2 Foil to be used as anodes in electrolytic capacitors is beyond the scope of this specification.

1.3 Alloy designations are in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy designations are those of preceded by A9, for example, A91145 for Aluminum 1145 in accordance with Practice E 527.

1.4 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see .

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

WITHDRAWN RATIONALE

This specification covers nine thicknesses (0.00017 to 0.00050 in. (0.0043 to 0.0127 mm)) of annealed aluminum foil used in the manufacture of capacitors.

Formerly under the jurisdiction of Committee B07 on Light Metals and Alloys, this specification was withdrawn in January 2015 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B373 −00(Reapproved 2006)

Standard Specification for

1

Aluminum Foil for Capacitors

This standard is issued under the fixed designation B373; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

3

1. Scope Point-to-Plane Technique (Withdrawn 2002)

E252 Test Method for Thickness of Foil, Thin Sheet, and

1.1 This specification covers nine thicknesses (0.00017 to

Film by Mass Measurement

0.00050 in. (0.0043 to 0.0127 mm)) of annealed aluminum foil

E345 Test Methods of Tension Testing of Metallic Foil

used in the manufacture of capacitors.

E527 Practice for Numbering Metals and Alloys in the

1.2 Foil to be used as anodes in electrolytic capacitors is

Unified Numbering System (UNS)

beyond the scope of this specification.

E607 Test Method for Atomic Emission Spectrometric

Analysis Aluminum Alloys by the Point to Plane Tech-

1.3 Alloy designations are in accordance withANSI H35.1.

3

The equivalent Unified Numbering System alloy designations nique Nitrogen Atmosphere (Withdrawn 2011)

E716 Practices for Sampling and Sample Preparation of

are those of Table 1 preceded byA9, for example,A91145 for

Aluminum 1145 in accordance with Practice E527. Aluminum and Aluminum Alloys for Determination of

Chemical Composition by Spectrochemical Analysis

1.4 For acceptance criteria for inclusion of new aluminum

E1251 Test Method for Analysis of Aluminum and Alumi-

and aluminum alloys in this specification, see Annex A1.

num Alloys by Spark Atomic Emission Spectrometry

1.5 The values stated in inch-pound units are to be regarded

2.3 ANSI Standard:

as the standard. The values given in parentheses are for

H35.1 Alloy and Temper Designation Systems for Alumi-

4

information only.

num

2. Referenced Documents

3. Terminology

2.1 The following documents of the issue in effect on the

3.1 Definitions:

dateofmaterialpurchaseformapartofthisspecificationtothe

3.1.1 foil—a rolled product rectangular in cross section of

extent referenced herein.

thickness less than 0.006 in. (0.15 mm).

2

2.2 ASTM Standards:

3.1.2 matte one-side foil (M1S)—foil with a diffuse reflect-

B193 Test Method for Resistivity of Electrical Conductor ing finish (matte) on one side and bright specular finish on the

Materials

other (10.1).

E29 Practice for Using Significant Digits in Test Data to

3.1.3 dry annealed A—having a test dryness of 100/0, free

Determine Conformance with Specifications

from residual rolling oil, as determined by the water test

E34 Test Methods for Chemical Analysis of Aluminum and

(10.2.1).

Aluminum-Base Alloys

3.1.4 dry annealed B—having a test dryness of 90/10, a

E55 Practice for Sampling Wrought Nonferrous Metals and

slight film of residual rolling oil, as determined by the

Alloys for Determination of Chemical Composition

water-alcohol test (10.2.2).

E227 Test Method for Optical Emission Spectrometric

3.1.5 dry annealed C—having a test dryness of 80/20, a

Analysis of Aluminum and Aluminum Alloys by the

slight film of residual rolling oil, as determined by the

water-alcohol test (10.2.3).

1

This specification is under the jurisdiction of ASTM Committee B07 on Light

3.1.6 slick annealed—having a uniform film of residual

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

rolling oil or applied oil as determined by the water test

Aluminum Alloy Wrought Products.

Current edition approved Nov. 1, 2006. Published December 2006. Originally

(10.2.4).

approved in 1961. Last previous edition approved in 2000 as B373–00. DOI:

10.1520/B0373-00R06.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

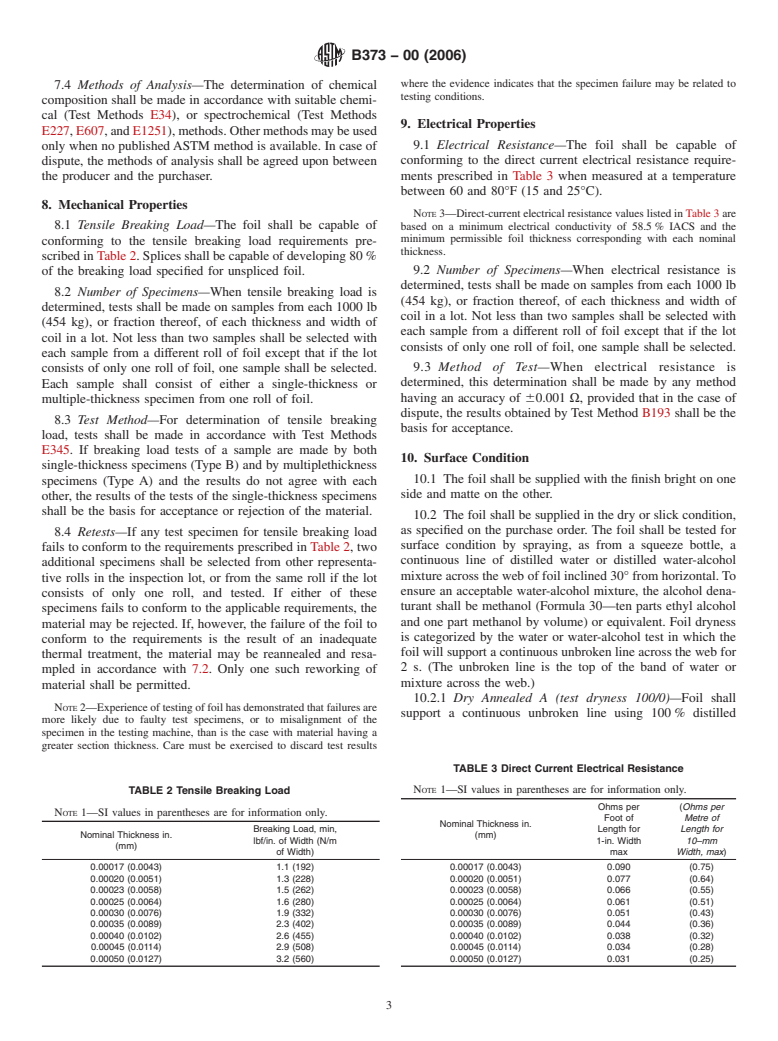

B373−00 (2006)

A,B,C

TABLE 1 Chemical Requirements

D

Aluminum Silicon Other Elements

Copper Manganese Magnesium Zinc Vanadium Titanium Aluminum

Designation plus Iron Each Total

E

1145 0.55 0.05 0.05 0.05 0.05 0.05 0.03 0.03 . 99.45 min

E

1235 0.65 0.05 0.05 0.05 0.10 0.05 0.06 0.03 . 99.35 min

A

Limits are in percent maximum unless stated otherwise.

B

Analysis shall be made fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.