ASTM D5587-15(2019)

(Test Method)Standard Test Method for Tearing Strength of Fabrics by Trapezoid Procedure

Standard Test Method for Tearing Strength of Fabrics by Trapezoid Procedure

SIGNIFICANCE AND USE

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments because current estimates of between-laboratory precision are acceptable, and this test method is used extensively in the trade for acceptance testing.

5.2 If there are differences of practical significance between test results for two laboratories (or more), comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use the samples for such a comparative test that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing. Randomly assign the samples in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

5.3 The trapezoid tear produces tension along a reasonably defined course such that the tear propagates across the width of the specimen. It is useful for estimating the relative tear resistance of different fabrics or different directions in the same fabric.

5.4 Depending on the nature of the specimen, the data recording devices will show the tearing force in the form of a peak or peaks. The highest peaks appear to reflect the strength of the yarn components, individually or in combination, needed to stop a tear in fabrics of the same construction. The valleys recorded between the peaks have no specific significance. The minimum tearing force, however, is indicated to be above the lowest valleys.

5.5 Most textile fabrics can be tested by this test method. Some modification of clamping techniques may be necessary for a given fabric, depending upon its structure. Strong fabrics or fabrics...

SCOPE

1.1 This test method covers the measurement of the tearing strength of textile fabrics by the trapezoid procedure using a recording constant-rate-of-extension-type (CRE) tensile testing machine.

1.1.1 The CRE-type tensile testing machine has become the preferred test apparatus for determining trapezoid tearing strength. It is recognized that some constant-rate-of-traverse-type (CRT) tensile testing machines continue to be used. Consequently, these test instruments may be used when agreed upon between the purchaser and the supplier. The conditions for use of the CRT-type tensile tester are included in Appendix X1.

1.2 This test method applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knitted fabrics, layered fabrics, pile, and nonwoven fabrics. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing specimens with or without wetting.

1.3 Tearing strength, as measured in this test method, requires that the tear be initiated before testing. The reported value obtained is not directly related to the force required to initiate or start a tear.

1.4 Two calculations for trapezoid tearing strength are provided: the single-peak force and the average of five highest peak forces.

1.5 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound units may be approximate.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International ...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5587 − 15 (Reapproved 2019)

Standard Test Method for

Tearing Strength of Fabrics by Trapezoid Procedure

This standard is issued under the fixed designation D5587; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method covers the measurement of the tearing

mendations issued by the World Trade Organization Technical

strength of textile fabrics by the trapezoid procedure using a

Barriers to Trade (TBT) Committee.

recordingconstant-rate-of-extension-type(CRE)tensiletesting

machine.

2. Referenced Documents

1.1.1 The CRE-type tensile testing machine has become the

2.1 ASTM Standards:

preferred test apparatus for determining trapezoid tearing

D76 Specification for Tensile Testing Machines for Textiles

strength. It is recognized that some constant-rate-of-traverse-

D123 Terminology Relating to Textiles

type (CRT) tensile testing machines continue to be used.

D629 Test Methods for Quantitative Analysis of Textiles

Consequently, these test instruments may be used when agreed

D1776 Practice for Conditioning and Testing Textiles

upon between the purchaser and the supplier. The conditions

D2904 Practice for Interlaboratory Testing of a Textile Test

for use of the CRT-type tensile tester are included in Appendix

Method that Produces Normally Distributed Data (With-

X1.

drawn 2008)

1.2 This test method applies to most fabrics including

D2906 Practice for Statements on Precision and Bias for

wovenfabrics,airbagfabrics,blankets,nappedfabrics,knitted

Textiles (Withdrawn 2008)

fabrics, layered fabrics, pile, and nonwoven fabrics. The

D4850 Terminology Relating to Fabrics and Fabric Test

fabrics may be untreated, heavily sized, coated, resin-treated,

Methods

or otherwise treated. Instructions are provided for testing

specimens with or without wetting.

3. Terminology

1.3 Tearing strength, as measured in this test method,

3.1 For all terminology relating to D13.59, Fabric Test

requires that the tear be initiated before testing. The reported

methods, General, refer to Terminology D4850.

value obtained is not directly related to the force required to

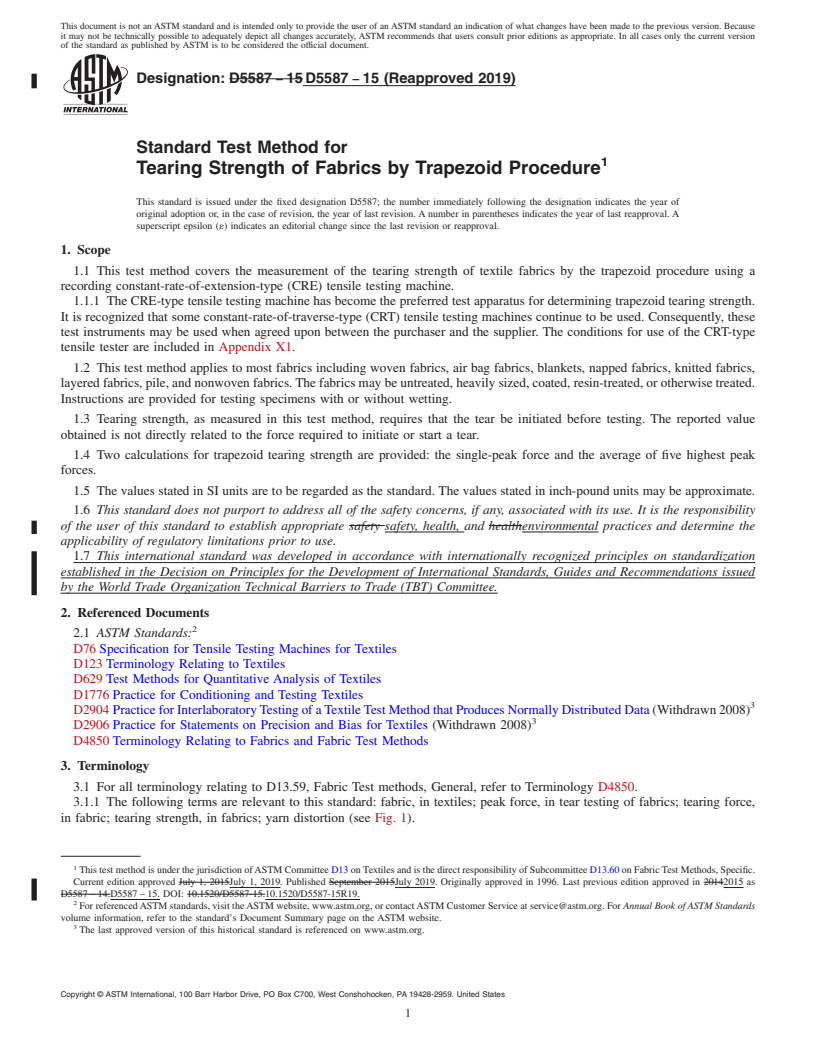

3.1.1 The following terms are relevant to this standard:

initiate or start a tear.

fabric, in textiles; peak force, in tear testing of fabrics; tearing

force, in fabric; tearing strength, in fabrics; yarn distortion (see

1.4 Two calculations for trapezoid tearing strength are

Fig. 1).

provided: the single-peak force and the average of five highest

peak forces.

3.2 For all other terms related to textiles, refer to Terminol-

ogy D123.

1.5 The values stated in SI units are to be regarded as the

standard. The values stated in inch-pound units may be

4. Summary of Test Method

approximate.

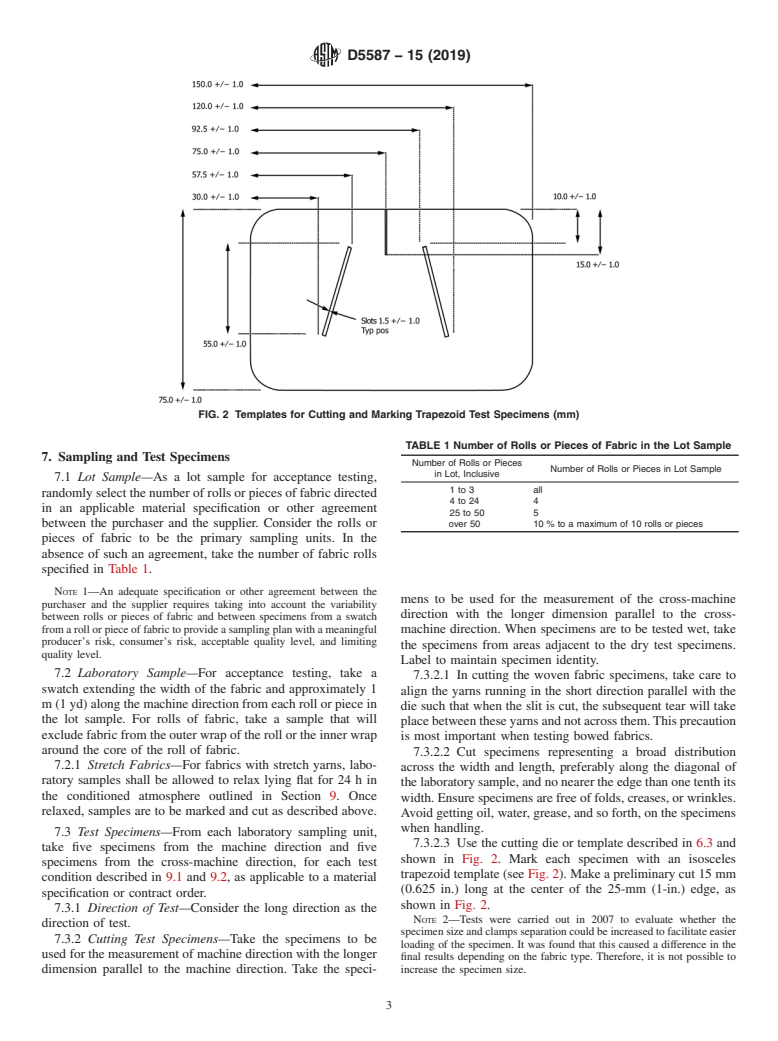

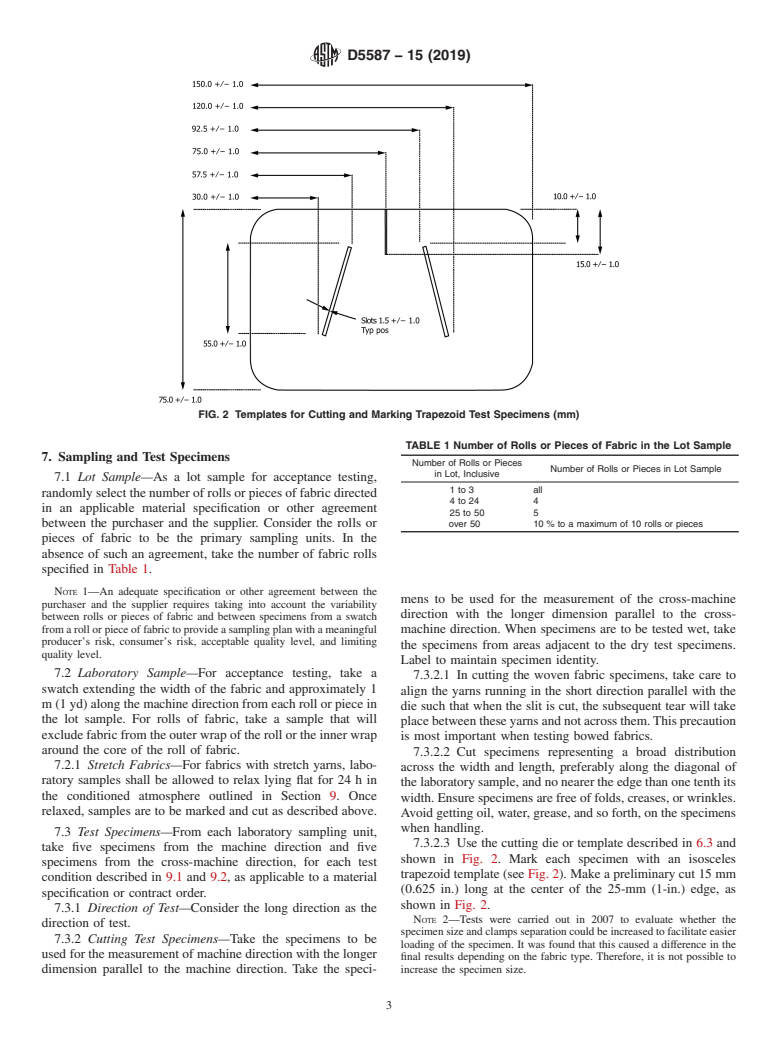

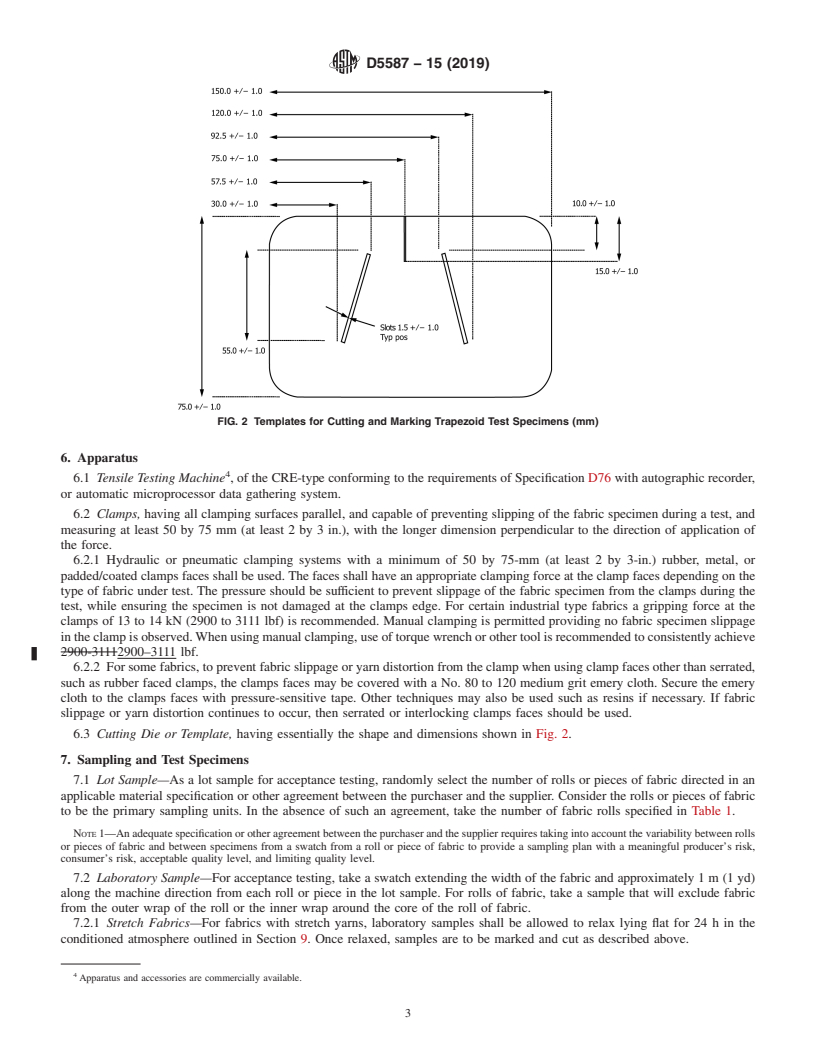

4.1 An outline of an isosceles trapezoid is marked on a

1.6 This standard does not purport to address all of the

rectangular specimen (see Fig. 2). The specimen is slit at the

safety concerns, if any, associated with its use. It is the

center of the smallest base of the trapezoid to start the tear.The

responsibility of the user of this standard to establish appro-

nonparallel sides of the marked trapezoid are clamped in

priate safety, health, and environmental practices and deter-

parallel clamps of a tensile testing machine. The separation of

mine the applicability of regulatory limitations prior to use.

the clamps is increased continuously to apply a force to

1.7 This international standard was developed in accor-

propagate the tear across the specimen. At the same time, the

dance with internationally recognized principles on standard-

1 2

This test method is under the jurisdiction ofASTM Committee D13 on Textiles For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Specific. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2019. Published July 2019. Originally approved the ASTM website.

in 1996. Last previous edition approved in 2015 as D5587 – 15. DOI: 10.1520/ The last approved version of this historical standard is referenced on

D5587-15R19. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5587 − 15 (2019)

5.5 Most textile fabrics can be tested by this test method.

Some modification of clamping techniques may be necessary

for a given fabric, depending upon its structure. Strong fabrics

or fabrics made from glass fibers require special adaptation to

prevent them from slipping in the clamps or being damaged as

a result of being gripped in the clamps. In some cases, due to

fabricconstructions,individualyarnsmaynotrupturebutshow

a high peak and yarn distortion within the test specimen.

Whereverpossible,thisshallbeprevented.Ifyouhavetriedall

of these steps and yarn distortion still occurs, this must be

included in the report.

5.6 The CRE-type is the preferred tensile testing machine.

This test method allows the use of the CRT-type tensile

machine when agreed upon between the purchaser and the

supplier. There may be no overall correlation, however, be-

tween the results obtained with the CRT-type machine and the

FIG. 1 Photograph Showing Yarn Distortion in a Modern Techni-

CRE-type machine. Consequently, these two tensile testers

cal Type Fabric

cannot be used interchangeably unless the degree of quantita-

tivecorrelationhasbeenestablishedbetweenthepurchaserand

the supplier. In any event, the CRE-type machine shall prevail.

force developed is recorded. The force to continue the tear is

6. Apparatus

calculated from autographic chart recorders or microprocessor

data collection systems.

6.1 Tensile Testing Machine , of the CRE-type conforming

to the requirements of Specification D76 with autographic

5. Significance and Use

recorder, or automatic microprocessor data gathering system.

5.1 This test method is considered satisfactory for accep-

6.2 Clamps, having all clamping surfaces parallel, and

tance testing of commercial shipments because current esti-

capable of preventing slipping of the fabric specimen during a

mates of between-laboratory precision are acceptable, and this

test, and measuring at least 50 by 75 mm (at least 2 by 3 in.),

test method is used extensively in the trade for acceptance

with the longer dimension perpendicular to the direction of

testing.

application of the force.

6.2.1 Hydraulic or pneumatic clamping systems with a

5.2 If there are differences of practical significance between

test results for two laboratories (or more), comparative test minimumof50by75-mm(atleast2by3-in.)rubber,metal,or

padded/coated clamps faces shall be used.The faces shall have

should be performed to determine if there is a statistical bias

between them, using competent statistical assistance. As a an appropriate clamping force at the clamp faces depending on

the type of fabric under test. The pressure should be sufficient

minimum, use the samples for such a comparative test that are

as homogeneous as possible, drawn from the same lot of to prevent slippage of the fabric specimen from the clamps

during the test, while ensuring the specimen is not damaged at

material as the samples that resulted in disparate results during

the clamps edge. For certain industrial type fabrics a gripping

initial testing. Randomly assign the samples in equal numbers

force at the clamps of 13 to 14 kN (2900 to 3111 lbf) is

to each laboratory. The test results from the laboratories

recommended. Manual clamping is permitted providing no

involved should be compared using a statistical test for

unpaired data, at a probability level chosen prior to the testing fabric specimen slippage in the clamp is observed.When using

manual clamping, use of torque wrench or other tool is

series. If bias is found, either its cause must be found and

corrected, or future test results for that material must be recommended to consistently achieve 2900–3111 lbf.

6.2.2 For some fabrics, to prevent fabric slippage or yarn

adjusted in consideration of the known bias.

distortion from the clamp when using clamp faces other than

5.3 The trapezoid tear produces tension along a reasonably

serrated, such as rubber faced clamps, the clamps faces may be

defined course such that the tear propagates across the width of

covered with a No. 80 to 120 medium grit emery cloth. Secure

the specimen. It is useful for estimating the relative tear

the emery cloth to the clamps faces with pressure-sensitive

resistanceofdifferentfabricsordifferentdirectionsinthesame

tape. Other techniques may also be used such as resins if

fabric.

necessary. If fabric slippage or yarn distortion continues to

5.4 Depending on the nature of the specimen, the data

occur, then serrated or interlocking clamps faces should be

recording devices will show the tearing force in the form of a

used.

peak or peaks. The highest peaks appear to reflect the strength

6.3 Cutting Die or Template, having essentially the shape

oftheyarncomponents,individuallyorincombination,needed

and dimensions shown in Fig. 2.

to stop a tear in fabrics of the same construction. The valleys

recorded between the peaks have no specific significance. The

minimum tearing force, however, is indicated to be above the

lowest valleys. Apparatus and accessories are commercially available.

D5587 − 15 (2019)

FIG. 2 Templates for Cutting and Marking Trapezoid Test Specimens (mm)

TABLE 1 Number of Rolls or Pieces of Fabric in the Lot Sample

7. Sampling and Test Specimens

Number of Rolls or Pieces

Number of Rolls or Pieces in Lot Sample

in Lot, Inclusive

7.1 Lot Sample—As a lot sample for acceptance testing,

1to3 all

randomly select the number of rolls or pieces of fabric directed

4to24 4

in an applicable material specification or other agreement

25 to 50 5

between the purchaser and the supplier. Consider the rolls or over 50 10 % to a maximum of 10 rolls or pieces

pieces of fabric to be the primary sampling units. In the

absence of such an agreement, take the number of fabric rolls

specified in Table 1.

NOTE 1—An adequate specification or other agreement between the

mens to be used for the measurement of the cross-machine

purchaser and the supplier requires taking into account the variability

direction with the longer dimension parallel to the cross-

between rolls or pieces of fabric and between specimens from a swatch

fromarollorpieceoffabrictoprovideasamplingplanwithameaningful machine direction. When specimens are to be tested wet, take

producer’s risk, consumer’s risk, acceptable quality level, and limiting

the specimens from areas adjacent to the dry test specimens.

quality level.

Label to maintain specimen identity.

7.2 Laboratory Sample—For acceptance testing, take a

7.3.2.1 In cutting the woven fabric specimens, take care to

swatch extending the width of the fabric and approximately 1

align the yarns running in the short direction parallel with the

m (1 yd) along the machine direction from each roll or piece in

die such that when the slit is cut, the subsequent tear will take

the lot sample. For rolls of fabric, take a sample that will

placebetweentheseyarnsandnotacrossthem.Thisprecaution

exclude fabric from the outer wrap of the roll or the inner wrap

is most important when testing bowed fabrics.

around the core of the roll of fabric.

7.3.2.2 Cut specimens representing a broad distribution

7.2.1 Stretch Fabrics—For fabrics with stretch yarns, labo-

across the width and length, preferably along the diagonal of

ratory samples shall be allowed to relax lying flat for 24 h in

thelaboratorysample,andnonearertheedgethanonetenthits

the conditioned atmosphere outlined in Section 9. Once

width. Ensure specimens are free of folds, creases, or wrinkles.

relaxed, samples are to be marked and cut as described above.

Avoid getting oil, water, grease, and so forth, on the specimens

when handling.

7.3 Test Specimens—From each laboratory sampling unit,

7.3.2.3 Use the cutting die or template described in 6.3 and

take five specimens from the machine direction and five

shown in Fig. 2. Mark each specimen with an isosceles

specimens from the cross-machine direction, for each test

trapezoid template (see Fig. 2). Make a preliminary cut 15 mm

condition described in 9.1 and 9.2, as applicable to a material

(0.625 in.) long at the center of the 25-mm (1-in.) edge, as

specification or contract order.

shown in Fig. 2.

7.3.1 Direction of Test—Consider the long direction as the

NOTE 2—Tests were carried out in 2007 to evaluate whether the

direction of test.

specimensizeandclampsseparationcouldbeincreasedtofacilitateeasier

7.3.2 Cutting Test Specimens—Take the specimens to be

loading of the specimen. It was found that this caused a difference in the

used for the measurement of machine direction with the longer

final results depending on the fabric type. Therefore, it is not possible to

dimension parallel to the machine direction. Take the speci- increase the specimen size.

D5587 − 15 (2019)

8. Preparation of Test Apparatus and Calibration

8.1 Set the distance between the clamps at the start of the

test at 25 61mm(1 6 0.05 in.).

8.2 Select the full-scale force range of the testing machine

such that the maximum force occurs between 15 and 85 % of

full-scale force.

8.3 Set the testing speed to 300 6 10 mm (12 6 0.5

in./min).

8.4 Verify calibration of the tensile testing machine as

specified in the manufacturer’s instructions and Specification

D76.

8.5 When using microprocessor automatic data gathering

systems, set the appropriate parameters as specified in the

manufacturer’s instructions.

9. Conditioning

FIG. 3 Positioning Specimen in Clamps

9.1 Condition 1, for Standard Testing:

9.1.1 Precondition the specimens by bringing them to ap-

10.2 Carefully position the specimen in the upper clamps of

proximate moisture equilibrium in the standard atmosphere for

the machine, aligning the lower edge of the clamps face with

preconditioning textiles as specified in Practice D1776, unless

lineAon the specimen. Carefully position the lower half of the

otherwisespecifiedinamaterialspecificatio

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5587 − 15 (Reapproved 2019)

Standard Test Method for

Tearing Strength of Fabrics by Trapezoid Procedure

This standard is issued under the fixed designation D5587; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method covers the measurement of the tearing

mendations issued by the World Trade Organization Technical

strength of textile fabrics by the trapezoid procedure using a

Barriers to Trade (TBT) Committee.

recording constant-rate-of-extension-type (CRE) tensile testing

machine.

2. Referenced Documents

1.1.1 The CRE-type tensile testing machine has become the

2.1 ASTM Standards:

preferred test apparatus for determining trapezoid tearing

D76 Specification for Tensile Testing Machines for Textiles

strength. It is recognized that some constant-rate-of-traverse-

D123 Terminology Relating to Textiles

type (CRT) tensile testing machines continue to be used.

D629 Test Methods for Quantitative Analysis of Textiles

Consequently, these test instruments may be used when agreed

D1776 Practice for Conditioning and Testing Textiles

upon between the purchaser and the supplier. The conditions

D2904 Practice for Interlaboratory Testing of a Textile Test

for use of the CRT-type tensile tester are included in Appendix

Method that Produces Normally Distributed Data (With-

X1.

drawn 2008)

1.2 This test method applies to most fabrics including

D2906 Practice for Statements on Precision and Bias for

woven fabrics, air bag fabrics, blankets, napped fabrics, knitted

Textiles (Withdrawn 2008)

fabrics, layered fabrics, pile, and nonwoven fabrics. The

D4850 Terminology Relating to Fabrics and Fabric Test

fabrics may be untreated, heavily sized, coated, resin-treated,

Methods

or otherwise treated. Instructions are provided for testing

specimens with or without wetting.

3. Terminology

1.3 Tearing strength, as measured in this test method,

3.1 For all terminology relating to D13.59, Fabric Test

requires that the tear be initiated before testing. The reported

methods, General, refer to Terminology D4850.

value obtained is not directly related to the force required to

3.1.1 The following terms are relevant to this standard:

initiate or start a tear.

fabric, in textiles; peak force, in tear testing of fabrics; tearing

force, in fabric; tearing strength, in fabrics; yarn distortion (see

1.4 Two calculations for trapezoid tearing strength are

Fig. 1).

provided: the single-peak force and the average of five highest

peak forces.

3.2 For all other terms related to textiles, refer to Terminol-

ogy D123.

1.5 The values stated in SI units are to be regarded as the

standard. The values stated in inch-pound units may be

4. Summary of Test Method

approximate.

4.1 An outline of an isosceles trapezoid is marked on a

1.6 This standard does not purport to address all of the

rectangular specimen (see Fig. 2). The specimen is slit at the

safety concerns, if any, associated with its use. It is the

center of the smallest base of the trapezoid to start the tear. The

responsibility of the user of this standard to establish appro-

nonparallel sides of the marked trapezoid are clamped in

priate safety, health, and environmental practices and deter-

parallel clamps of a tensile testing machine. The separation of

mine the applicability of regulatory limitations prior to use.

the clamps is increased continuously to apply a force to

1.7 This international standard was developed in accor-

propagate the tear across the specimen. At the same time, the

dance with internationally recognized principles on standard-

1 2

This test method is under the jurisdiction of ASTM Committee D13 on Textiles For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Specific. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2019. Published July 2019. Originally approved the ASTM website.

in 1996. Last previous edition approved in 2015 as D5587 – 15. DOI: 10.1520/ The last approved version of this historical standard is referenced on

D5587-15R19. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5587 − 15 (2019)

5.5 Most textile fabrics can be tested by this test method.

Some modification of clamping techniques may be necessary

for a given fabric, depending upon its structure. Strong fabrics

or fabrics made from glass fibers require special adaptation to

prevent them from slipping in the clamps or being damaged as

a result of being gripped in the clamps. In some cases, due to

fabric constructions, individual yarns may not rupture but show

a high peak and yarn distortion within the test specimen.

Wherever possible, this shall be prevented. If you have tried all

of these steps and yarn distortion still occurs, this must be

included in the report.

5.6 The CRE-type is the preferred tensile testing machine.

This test method allows the use of the CRT-type tensile

machine when agreed upon between the purchaser and the

supplier. There may be no overall correlation, however, be-

tween the results obtained with the CRT-type machine and the

FIG. 1 Photograph Showing Yarn Distortion in a Modern Techni-

CRE-type machine. Consequently, these two tensile testers

cal Type Fabric

cannot be used interchangeably unless the degree of quantita-

tive correlation has been established between the purchaser and

the supplier. In any event, the CRE-type machine shall prevail.

force developed is recorded. The force to continue the tear is

6. Apparatus

calculated from autographic chart recorders or microprocessor

data collection systems.

6.1 Tensile Testing Machine , of the CRE-type conforming

to the requirements of Specification D76 with autographic

5. Significance and Use

recorder, or automatic microprocessor data gathering system.

5.1 This test method is considered satisfactory for accep-

6.2 Clamps, having all clamping surfaces parallel, and

tance testing of commercial shipments because current esti-

capable of preventing slipping of the fabric specimen during a

mates of between-laboratory precision are acceptable, and this

test, and measuring at least 50 by 75 mm (at least 2 by 3 in.),

test method is used extensively in the trade for acceptance

with the longer dimension perpendicular to the direction of

testing.

application of the force.

5.2 If there are differences of practical significance between 6.2.1 Hydraulic or pneumatic clamping systems with a

minimum of 50 by 75-mm (at least 2 by 3-in.) rubber, metal, or

test results for two laboratories (or more), comparative test

should be performed to determine if there is a statistical bias padded/coated clamps faces shall be used. The faces shall have

an appropriate clamping force at the clamp faces depending on

between them, using competent statistical assistance. As a

minimum, use the samples for such a comparative test that are the type of fabric under test. The pressure should be sufficient

to prevent slippage of the fabric specimen from the clamps

as homogeneous as possible, drawn from the same lot of

during the test, while ensuring the specimen is not damaged at

material as the samples that resulted in disparate results during

the clamps edge. For certain industrial type fabrics a gripping

initial testing. Randomly assign the samples in equal numbers

force at the clamps of 13 to 14 kN (2900 to 3111 lbf) is

to each laboratory. The test results from the laboratories

involved should be compared using a statistical test for recommended. Manual clamping is permitted providing no

fabric specimen slippage in the clamp is observed. When using

unpaired data, at a probability level chosen prior to the testing

series. If bias is found, either its cause must be found and manual clamping, use of torque wrench or other tool is

recommended to consistently achieve 2900–3111 lbf.

corrected, or future test results for that material must be

adjusted in consideration of the known bias. 6.2.2 For some fabrics, to prevent fabric slippage or yarn

distortion from the clamp when using clamp faces other than

5.3 The trapezoid tear produces tension along a reasonably

serrated, such as rubber faced clamps, the clamps faces may be

defined course such that the tear propagates across the width of

covered with a No. 80 to 120 medium grit emery cloth. Secure

the specimen. It is useful for estimating the relative tear

the emery cloth to the clamps faces with pressure-sensitive

resistance of different fabrics or different directions in the same

tape. Other techniques may also be used such as resins if

fabric.

necessary. If fabric slippage or yarn distortion continues to

5.4 Depending on the nature of the specimen, the data

occur, then serrated or interlocking clamps faces should be

recording devices will show the tearing force in the form of a

used.

peak or peaks. The highest peaks appear to reflect the strength

6.3 Cutting Die or Template, having essentially the shape

of the yarn components, individually or in combination, needed

and dimensions shown in Fig. 2.

to stop a tear in fabrics of the same construction. The valleys

recorded between the peaks have no specific significance. The

minimum tearing force, however, is indicated to be above the

lowest valleys. Apparatus and accessories are commercially available.

D5587 − 15 (2019)

FIG. 2 Templates for Cutting and Marking Trapezoid Test Specimens (mm)

TABLE 1 Number of Rolls or Pieces of Fabric in the Lot Sample

7. Sampling and Test Specimens

Number of Rolls or Pieces

Number of Rolls or Pieces in Lot Sample

in Lot, Inclusive

7.1 Lot Sample—As a lot sample for acceptance testing,

1 to 3 all

randomly select the number of rolls or pieces of fabric directed

4 to 24 4

in an applicable material specification or other agreement

25 to 50 5

between the purchaser and the supplier. Consider the rolls or over 50 10 % to a maximum of 10 rolls or pieces

pieces of fabric to be the primary sampling units. In the

absence of such an agreement, take the number of fabric rolls

specified in Table 1.

NOTE 1—An adequate specification or other agreement between the

mens to be used for the measurement of the cross-machine

purchaser and the supplier requires taking into account the variability

direction with the longer dimension parallel to the cross-

between rolls or pieces of fabric and between specimens from a swatch

from a roll or piece of fabric to provide a sampling plan with a meaningful

machine direction. When specimens are to be tested wet, take

producer’s risk, consumer’s risk, acceptable quality level, and limiting

the specimens from areas adjacent to the dry test specimens.

quality level.

Label to maintain specimen identity.

7.2 Laboratory Sample—For acceptance testing, take a

7.3.2.1 In cutting the woven fabric specimens, take care to

swatch extending the width of the fabric and approximately 1

align the yarns running in the short direction parallel with the

m (1 yd) along the machine direction from each roll or piece in

die such that when the slit is cut, the subsequent tear will take

the lot sample. For rolls of fabric, take a sample that will

place between these yarns and not across them. This precaution

exclude fabric from the outer wrap of the roll or the inner wrap

is most important when testing bowed fabrics.

around the core of the roll of fabric.

7.3.2.2 Cut specimens representing a broad distribution

7.2.1 Stretch Fabrics—For fabrics with stretch yarns, labo-

across the width and length, preferably along the diagonal of

ratory samples shall be allowed to relax lying flat for 24 h in

the laboratory sample, and no nearer the edge than one tenth its

the conditioned atmosphere outlined in Section 9. Once

width. Ensure specimens are free of folds, creases, or wrinkles.

relaxed, samples are to be marked and cut as described above.

Avoid getting oil, water, grease, and so forth, on the specimens

when handling.

7.3 Test Specimens—From each laboratory sampling unit,

7.3.2.3 Use the cutting die or template described in 6.3 and

take five specimens from the machine direction and five

shown in Fig. 2. Mark each specimen with an isosceles

specimens from the cross-machine direction, for each test

trapezoid template (see Fig. 2). Make a preliminary cut 15 mm

condition described in 9.1 and 9.2, as applicable to a material

(0.625 in.) long at the center of the 25-mm (1-in.) edge, as

specification or contract order.

shown in Fig. 2.

7.3.1 Direction of Test—Consider the long direction as the

NOTE 2—Tests were carried out in 2007 to evaluate whether the

direction of test.

specimen size and clamps separation could be increased to facilitate easier

7.3.2 Cutting Test Specimens—Take the specimens to be

loading of the specimen. It was found that this caused a difference in the

used for the measurement of machine direction with the longer

final results depending on the fabric type. Therefore, it is not possible to

dimension parallel to the machine direction. Take the speci- increase the specimen size.

D5587 − 15 (2019)

8. Preparation of Test Apparatus and Calibration

8.1 Set the distance between the clamps at the start of the

test at 25 6 1 mm (1 6 0.05 in.).

8.2 Select the full-scale force range of the testing machine

such that the maximum force occurs between 15 and 85 % of

full-scale force.

8.3 Set the testing speed to 300 6 10 mm (12 6 0.5

in./min).

8.4 Verify calibration of the tensile testing machine as

specified in the manufacturer’s instructions and Specification

D76.

8.5 When using microprocessor automatic data gathering

systems, set the appropriate parameters as specified in the

manufacturer’s instructions.

9. Conditioning

FIG. 3 Positioning Specimen in Clamps

9.1 Condition 1, for Standard Testing:

9.1.1 Precondition the specimens by bringing them to ap-

10.2 Carefully position the specimen in the upper clamps of

proximate moisture equilibrium in the standard atmosphere for

the machine, aligning the lower edge of the clamps face with

preconditioning textiles as specified in Practice D1776, unless

line A on the specimen. Carefully position the lower half of the

otherwise specified in a material specification

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5587 − 15 D5587 − 15 (Reapproved 2019)

Standard Test Method for

Tearing Strength of Fabrics by Trapezoid Procedure

This standard is issued under the fixed designation D5587; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of the tearing strength of textile fabrics by the trapezoid procedure using a

recording constant-rate-of-extension-type (CRE) tensile testing machine.

1.1.1 The CRE-type tensile testing machine has become the preferred test apparatus for determining trapezoid tearing strength.

It is recognized that some constant-rate-of-traverse-type (CRT) tensile testing machines continue to be used. Consequently, these

test instruments may be used when agreed upon between the purchaser and the supplier. The conditions for use of the CRT-type

tensile tester are included in Appendix X1.

1.2 This test method applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knitted fabrics,

layered fabrics, pile, and nonwoven fabrics. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated.

Instructions are provided for testing specimens with or without wetting.

1.3 Tearing strength, as measured in this test method, requires that the tear be initiated before testing. The reported value

obtained is not directly related to the force required to initiate or start a tear.

1.4 Two calculations for trapezoid tearing strength are provided: the single-peak force and the average of five highest peak

forces.

1.5 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound units may be approximate.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D76 Specification for Tensile Testing Machines for Textiles

D123 Terminology Relating to Textiles

D629 Test Methods for Quantitative Analysis of Textiles

D1776 Practice for Conditioning and Testing Textiles

D2904 Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data (Withdrawn 2008)

D2906 Practice for Statements on Precision and Bias for Textiles (Withdrawn 2008)

D4850 Terminology Relating to Fabrics and Fabric Test Methods

3. Terminology

3.1 For all terminology relating to D13.59, Fabric Test methods, General, refer to Terminology D4850.

3.1.1 The following terms are relevant to this standard: fabric, in textiles; peak force, in tear testing of fabrics; tearing force,

in fabric; tearing strength, in fabrics; yarn distortion (see Fig. 1).

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, Specific.

Current edition approved July 1, 2015July 1, 2019. Published September 2015July 2019. Originally approved in 1996. Last previous edition approved in 20142015 as

D5587 – 14.D5587 – 15. DOI: 10.1520/D5587-15.10.1520/D5587-15R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5587 − 15 (2019)

FIG. 1 Photograph Showing Yarn Distortion in a Modern Technical Type Fabric

3.2 For all other terms related to textiles, refer to Terminology D123.

4. Summary of Test Method

4.1 An outline of an isosceles trapezoid is marked on a rectangular specimen (see Fig. 2). The specimen is slit at the center of

the smallest base of the trapezoid to start the tear. The nonparallel sides of the marked trapezoid are clamped in parallel clamps

of a tensile testing machine. The separation of the clamps is increased continuously to apply a force to propagate the tear across

the specimen. At the same time, the force developed is recorded. The force to continue the tear is calculated from autographic chart

recorders or microprocessor data collection systems.

5. Significance and Use

5.1 This test method is considered satisfactory for acceptance testing of commercial shipments because current estimates of

between-laboratory precision are acceptable, and this test method is used extensively in the trade for acceptance testing.

5.2 If there are differences of practical significance between test results for two laboratories (or more), comparative test should

be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use

the samples for such a comparative test that are as homogeneous as possible, drawn from the same lot of material as the samples

that resulted in disparate results during initial testing. Randomly assign the samples in equal numbers to each laboratory. The test

results from the laboratories involved should be compared using a statistical test for unpaired data, at a probability level chosen

prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must

be adjusted in consideration of the known bias.

5.3 The trapezoid tear produces tension along a reasonably defined course such that the tear propagates across the width of the

specimen. It is useful for estimating the relative tear resistance of different fabrics or different directions in the same fabric.

5.4 Depending on the nature of the specimen, the data recording devices will show the tearing force in the form of a peak or

peaks. The highest peaks appear to reflect the strength of the yarn components, individually or in combination, needed to stop a

tear in fabrics of the same construction. The valleys recorded between the peaks have no specific significance. The minimum

tearing force, however, is indicated to be above the lowest valleys.

5.5 Most textile fabrics can be tested by this test method. Some modification of clamping techniques may be necessary for a

given fabric, depending upon its structure. Strong fabrics or fabrics made from glass fibers require special adaptation to prevent

them from slipping in the clamps or being damaged as a result of being gripped in the clamps. In some cases, due to fabric

constructions, individual yarns may not rupture but show a high peak and yarn distortion within the test specimen. Wherever

possible, this shall be prevented. If you have tried all of these steps and yarn distortion still occurs, this must be included in the

report.

5.6 The CRE-type is the preferred tensile testing machine. This test method allows the use of the CRT-type tensile machine

when agreed upon between the purchaser and the supplier. There may be no overall correlation, however, between the results

obtained with the CRT-type machine and the CRE-type machine. Consequently, these two tensile testers cannot be used

interchangeably unless the degree of quantitative correlation has been established between the purchaser and the supplier. In any

event, the CRE-type machine shall prevail.

D5587 − 15 (2019)

FIG. 2 Templates for Cutting and Marking Trapezoid Test Specimens (mm)

6. Apparatus

6.1 Tensile Testing Machine , of the CRE-type conforming to the requirements of Specification D76 with autographic recorder,

or automatic microprocessor data gathering system.

6.2 Clamps, having all clamping surfaces parallel, and capable of preventing slipping of the fabric specimen during a test, and

measuring at least 50 by 75 mm (at least 2 by 3 in.), with the longer dimension perpendicular to the direction of application of

the force.

6.2.1 Hydraulic or pneumatic clamping systems with a minimum of 50 by 75-mm (at least 2 by 3-in.) rubber, metal, or

padded/coated clamps faces shall be used. The faces shall have an appropriate clamping force at the clamp faces depending on the

type of fabric under test. The pressure should be sufficient to prevent slippage of the fabric specimen from the clamps during the

test, while ensuring the specimen is not damaged at the clamps edge. For certain industrial type fabrics a gripping force at the

clamps of 13 to 14 kN (2900 to 3111 lbf) is recommended. Manual clamping is permitted providing no fabric specimen slippage

in the clamp is observed. When using manual clamping, use of torque wrench or other tool is recommended to consistently achieve

2900-31112900–3111 lbf.

6.2.2 For some fabrics, to prevent fabric slippage or yarn distortion from the clamp when using clamp faces other than serrated,

such as rubber faced clamps, the clamps faces may be covered with a No. 80 to 120 medium grit emery cloth. Secure the emery

cloth to the clamps faces with pressure-sensitive tape. Other techniques may also be used such as resins if necessary. If fabric

slippage or yarn distortion continues to occur, then serrated or interlocking clamps faces should be used.

6.3 Cutting Die or Template, having essentially the shape and dimensions shown in Fig. 2.

7. Sampling and Test Specimens

7.1 Lot Sample—As a lot sample for acceptance testing, randomly select the number of rolls or pieces of fabric directed in an

applicable material specification or other agreement between the purchaser and the supplier. Consider the rolls or pieces of fabric

to be the primary sampling units. In the absence of such an agreement, take the number of fabric rolls specified in Table 1.

NOTE 1—An adequate specification or other agreement between the purchaser and the supplier requires taking into account the variability between rolls

or pieces of fabric and between specimens from a swatch from a roll or piece of fabric to provide a sampling plan with a meaningful producer’s risk,

consumer’s risk, acceptable quality level, and limiting quality level.

7.2 Laboratory Sample—For acceptance testing, take a swatch extending the width of the fabric and approximately 1 m (1 yd)

along the machine direction from each roll or piece in the lot sample. For rolls of fabric, take a sample that will exclude fabric

from the outer wrap of the roll or the inner wrap around the core of the roll of fabric.

7.2.1 Stretch Fabrics—For fabrics with stretch yarns, laboratory samples shall be allowed to relax lying flat for 24 h in the

conditioned atmosphere outlined in Section 9. Once relaxed, samples are to be marked and cut as described above.

Apparatus and accessories are commercially available.

D5587 − 15 (2019)

TABLE 1 Number of Rolls or Pieces of Fabric in the Lot Sample

Number of Rolls or Pieces

Number of Rolls or Pieces in Lot Sample

in Lot, Inclusive

1 to 3 all

4 to 24 4

25 to 50 5

over 50 10 % to a maximum of 10 rolls or pieces

7.3 Test Specimens—From each laboratory sampling unit, take five specimens from the machine direction and five specimens

from the cross-machine direction, for each test condition described in 9.1 and 9.2, as applicable to a material specification or

contract order.

7.3.1 Direction of Test—Consider the long direction as the direction of test.

7.3.2 Cutting Test Specimens—Take the specimens to be used for the measurement of machine direction with the longer

dimension parallel to the machine direction. Take the specimens to be used for the measurement of the cross-machine direction

with the longer dimension parallel to the cross-machine direction. When specimens are to be tested wet, take the specimens from

areas adjacent to the dry test specimens. Label to maintain specimen identity.

7.3.2.1 In cutting the woven fabric specimens, take care to align the yarns running in the short direction parallel with the die

such that when the slit is cut, the subsequent tear will take place between these yarns and not across them. This precaution is most

important when testing bowed fabrics.

7.3.2.2 Cut specimens representing a broad distribution across the width and length, preferably along the diagonal of the

laboratory sample, and no nearer the edge than one tenth its width. Ensure specimens are free of folds, creases, or wrinkles. Avoid

getting oil, water, grease, and so forth, on the specimens when handling.

7.3.2.3 Use the cutting die or template described in 6.3 and shown in Fig. 2. Mark each specimen with an isosceles trapezoid

template (see Fig. 2). Make a preliminary cut 15 mm (0.625 in.) long at the center of the 25-mm (1-in.) edge, as shown in Fig.

2.

NOTE 2—Tests were carried out in 2007 to evaluate whether the specimen size and clamps separation could be increased to facilitate easier loading

of the specimen. It was found that this caused a difference in the final results depending on the fabric type. Therefore, it is not possible to increase the

specimen size.

8. Preparation of Test Apparatus and Calibration

8.1 Set the distance between the clamps at the start of the test at 25 6 1 mm (1 6 0.05 in.).

8.2 Select the full-scale force range of the testing machine such that the maximum force occurs between 15 and 85 % of

full-scale force.

8.3 Set the testing speed to 300 6 10 mm (12 6 0.5 in./min).

8.4 Verify calibration of the tensile testing machine as specified in the manufacturer’s instructions and Specification D76.

8.5 When using microprocessor automatic data gathering systems, set the appropriate parameters as specified in the

manufacturer’s instructions.

9. Conditioning

9.1 Condition 1, for Standard Testing:

9.1.1 Precondition the specimens by bringing them to approximate moisture equilibrium in the standard atmosphere for

preconditioning textil

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.