ASTM C806-12

(Test Method)Standard Test Method for Restrained Expansion of Expansive Cement Mortar

Standard Test Method for Restrained Expansion of Expansive Cement Mortar

ABSTRACT

This test method covers the standard procedure for determination of length changes of expansive cement mortar, while under restraint, due to the development of internal forces resulting from hydration of the cement. The test apparatus is comprised of the following: molds for casting test specimens; restraining cage which consists of a threaded steel rod with steel end plates held in place by cap nuts for corrosion prevention; length comparator; tamper which shall be made of nonabsorptive, nonabrasive material such as medium-hard rubber or seasoned oak wood; device for demolding specimens; weights and weighing devices; glass graduates to measure the mixing water in a single operation; an electrically driven mechanical mixer equipped with paddle and mixing bowl; and trowel which shall have a steel blade with straight edges. The sand to be used shall comply with the graded sand requirement and shall be handled in such a manner as to prevent segregation. Details on preparation and assembly of specimen molds and restraining cage, proportioning and mixing of mortars, molding, and curing of specimens are discussed. The expansion and shrinkage of the test specimens at any age shall be calculated and the length-change data, expressed as linear expansion or contraction based on the length of the specimen at any time of molding, shall be reported. Bias and precision in the batch, single, and multi-laboratory operation shall also be identified.

SCOPE

1.1 This test method covers the determination of length changes of expansive cement mortar, while under restraint, due to the development of internal forces resulting from hydration of the cement.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cement mixtures are caustic and may cause burns to skin and tissue upon prolonged exposure.2)

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C806 − 12

Standard Test Method for

1

Restrained Expansion of Expansive Cement Mortar

This standard is issued under the fixed designation C806; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C305Practice for Mechanical Mixing of Hydraulic Cement

Pastes and Mortars of Plastic Consistency

1.1 This test method covers the determination of length

C490PracticeforUseofApparatusfortheDeterminationof

changesofexpansivecementmortar,whileunderrestraint,due

Length Change of Hardened Cement Paste, Mortar, and

to the development of internal forces resulting from hydration

Concrete

of the cement.

C670Practice for Preparing Precision and Bias Statements

1.2 The values stated in inch-pound units are to be regarded

for Test Methods for Construction Materials

as standard. The values given in parentheses are mathematical

C778Specification for Standard Sand

conversions to SI units that are provided for information only

C1005Specification for Reference Masses and Devices for

and are not considered standard.

Determining Mass and Volume for Use in the Physical

1.3 This standard does not purport to address all of the

Testing of Hydraulic Cements

safety concerns, if any, associated with its use. It is the F606Test Methods for Determining the Mechanical Proper-

responsibility of the user of this standard to establish appro-

ties of Externally and Internally Threaded Fasteners,

priate safety and health practices and determine the applica- Washers, and Rivets (Metric) F0606_F0606M

bility of regulatory limitations prior to use. (Warning—Fresh

3. Terminology

hydraulic cement mixtures are caustic and may cause burns to

2

skin and tissue upon prolonged exposure. )

3.1 Definitionsoftermsusedinthistestmethodaregivenin

1.4 This international standard was developed in accor-

Terminology C219.

dance with internationally recognized principles on standard-

4. Apparatus

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4.1 Molds—The molds for casting test specimens, when

mendations issued by the World Trade Organization Technical

used in conjunction with the restraining cage described in 4.2,

Barriers to Trade (TBT) Committee.

shall provide for forming either 2 by 2 by 10-in. prisms having

a 10-in. gage length, or 50 by 50 by 250-mm prisms having a

2. Referenced Documents

250-mmgagelength.Themoldsshallotherwiseconformtothe

3

2.1 ASTM Standards:

requirements of Practice C490, except that the gage stud

A307Specification for Carbon Steel Bolts, Studs, and

holder, gage studs, and spacer screws described in that speci-

Threaded Rod 60000 PSI Tensile Strength

fication will not be used.

C109/C109MTest Method for Compressive Strength of

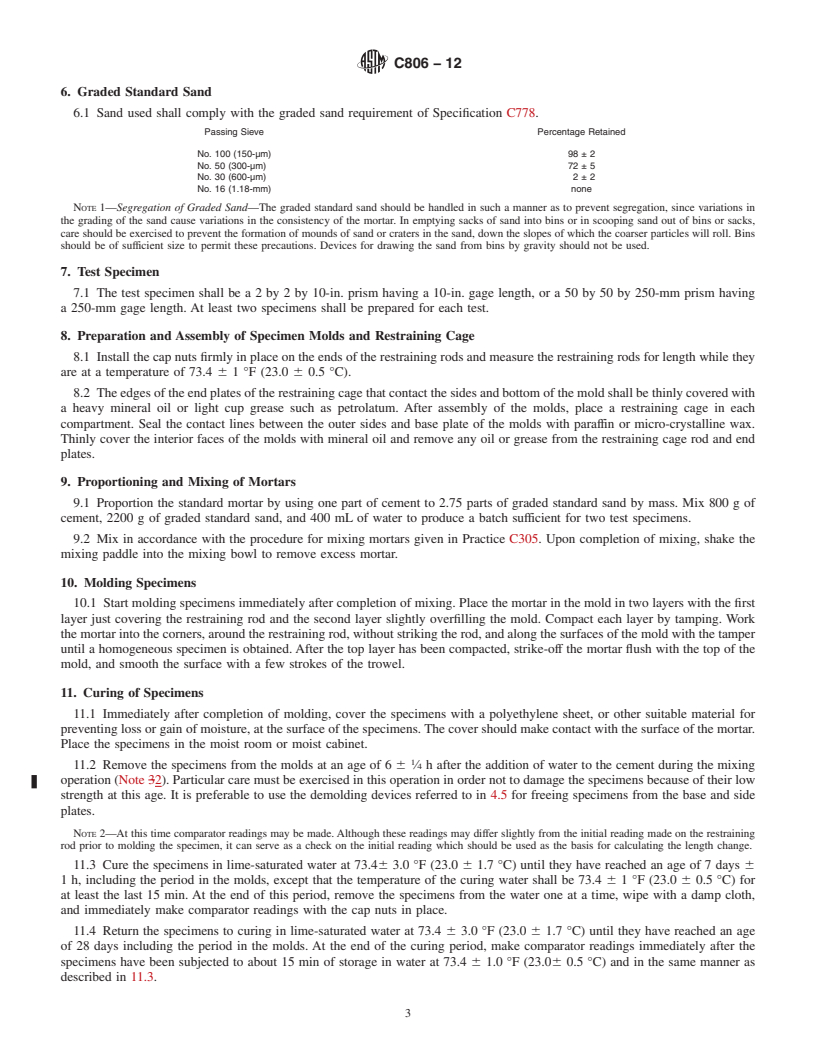

4.2 Restraining Cage, consisting of a threaded steel rod

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

with steel end plates held in place by nuts as shown in Fig. 1.

Specimens)

The rod shall be provided with cap nuts for prevention of

C157/C157MTest Method for Length Change of Hardened

corrosion. The rod shall conform to Specification A307 Grade

Hydraulic-Cement Mortar and Concrete

A except, it shall support 1180-lbf (5249 N) proof load when

C219Terminology Relating to Hydraulic Cement

tested in accordance with Method 1 of Test Methods F606.

4.3 Length Comparator—The length comparator for mea-

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC01onCement

suring length shall conform to and be used in accordance with

and is the direct responsibility of Subcommittee C01.13 on Special Cements.

the requirements of Practice C490. If the terminals of the

Current edition approved Dec. 15, 2012. Published February 2013. Originally

approved in 1975. Last previous edition approved in 2004 as C806–04. DOI:

comparator are fitted with collars, they shall be such that the

10.1520/C0806-12.

capnutsontheendsofthethreadedrodofthespecimendonot

2

SectionofSafety,ManualofCementTesting,AnnualBookofASTMStandards,

rest on the collar during measuring.

Vol 04.01.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.4 Tamper—The tamper shall be made of nonabsorptive,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

nonabrasive material such as medium-hard rubber or seasoned

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. oak wood, rendered nonabsorptive by immersion for 15 min in

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C80

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C806 − 04 C806 − 12

Standard Test Method for

1

Restrained Expansion of Expansive Cement Mortar

This standard is issued under the fixed designation C806; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of length changes of expansive cement mortar, while under restraint, due to the

development of internal forces resulting from hydration of the cement.

1.2 The values stated in non-SIinch-pound units are to be regarded as the standard. When both the inch-pound units and the SI

units are present, the non-SI units are to be regarded as the standard. The values in SI units are approximate, are listed for

information only, and will likely provide different values than the inch-pound units.standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (Warning—Fresh hydraulic cement mixtures are caustic and may cause burns to skin and tissue upon

2

prolonged exposure. )

2. Referenced Documents

3

2.1 ASTM Standards:

A307 Specification for Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile Strength

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C157/C157M Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete

C219 Terminology Relating to Hydraulic Cement

C305 Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

C490 Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

C778 Specification for Sand

C1005 Specification for Reference Masses and Devices for Determining Mass and Volume for Use in the Physical Testing of

Hydraulic Cements

F606 Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct

Tension Indicators, and Rivets

3. Terminology

3.1 Definitions of terms used in this test method are given in Terminology C219.

4. Apparatus

4.1 Molds—The molds for casting test specimens, when used in conjunction with the restraining cage described in 4.2, shall

provide for forming either 2 by 2 by 10-in. prisms having a 10-in. gage length, or 50 by 50 by 250-mm prisms having a 250-mm

gage length. The molds shall otherwise conform to the requirements of Practice C490, except that the gage stud holder, gage studs,

and spacer screws described in that specification will not be used.

4.2 Restraining Cage, consisting of a threaded steel rod with steel end plates held in place by nuts as shown in Fig. 1. The rod

shall be provided with cap nuts for prevention of corrosion. The rod shall conform to Specification A307 Grade A except, it shall

support 1180-lbf (5249 N) proof load when tested in accordance with Method 1 of Test Methods F606.

1

This test method is under the jurisdiction of ASTM Committee C01 on Cement and is the direct responsibility of Subcommittee C01.13 on Special Cements.

Current edition approved July 1, 2004Dec. 15, 2012. Published July 2004February 2013. Originally approved in 1975. Last previous edition approved in 19952004 as

C806 – 95.C806 – 04. DOI: 10.1520/C0806-04.10.1520/C0806-12.

2

Section of Safety, Manual of Cement Testing, Annual Book of ASTM Standards, Vol 04.01.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C806 − 12

Dimension, in. (mm) Tolerance, in. (mm)

3

A 11 ⁄4 (300) .

1

B 10 (250) ⁄8 (3)

C 2 (50) .

D 1 (25) .

31 1

E 1 ⁄32 (49) ⁄32 (1)

63

F ⁄64 (24

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.