ASTM D5957-98(2005)

(Guide)Standard Guide for Flood Testing Horizontal Waterproofing Installations

Standard Guide for Flood Testing Horizontal Waterproofing Installations

SCOPE

1.1 This guide provides the user with a method for testing the watertightness of waterproofing installations applied to horizontal surfaces having a slope not greater than 20 mm/m (2 % slope) (1/4 in. per ft).

1.2 This guide is intended for waterproofing installation on parking garages and plaza deck type applications over habitable spaces or on elevated structures, but is not intended for use on building roofing systems. Applicable waterproofing membrane installations that may be tested using this guide are fully adhered or bonded sheet membranes, liquid or fluid applied membranes, or loose laid sheet membranes.

1.3 The procedures presented here are not intended for use on those waterproofing installation applications that are for long-term water storage or continuously submerged environments, such as swimming pools, fountains, tank liners with hydrostatic pressure, or water storage units (storage period greater than 48 h).

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5957 −98(Reapproved 2005)

Standard Guide for

Flood Testing Horizontal Waterproofing Installations

This standard is issued under the fixed designation D5957; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ACI Document:

ACI 515 Guide to the Use of Waterproofing, Dampproofing,

1.1 This guide provides the user with a method for testing

Protective, and Decorative Barrier Systems for Concrete

the watertightness of waterproofing installations applied to

horizontal surfaces having a slope not greater than 20 mm/m

3. Terminology

(2 % slope) ( ⁄4 in. per ft).

3.1 For definitions of terms relating to roofing and

1.2 This guide is intended for waterproofing installation on

waterproofing, see Terminology D1079.

parking garages and plaza deck type applications over habit-

3.2 Definitions of Terms Specific to This Standard:

ablespacesoronelevatedstructures,butisnotintendedforuse

3.2.1 sacrificial sheet—a material used to form a temporary

on building roofing systems. Applicable waterproofing mem-

seal between a containment assembly and the waterproofing

brane installations that may be tested using this guide are fully

system. The material used for a sacrificial sheet shall not cause

adhered or bonded sheet membranes, liquid or fluid applied

damage nor be detrimental to the primary system.

membranes, or loose laid sheet membranes.

1.3 The procedures presented here are not intended for use

4. Summary of Guide

on those waterproofing installation applications that are for

4.1 This guide uses a series of temporary containment

long-term water storage or continuously submerged

assemblies of pond water on horizontal surfaces to determine

environments, such as swimming pools, fountains, tank liners

the watertightness of waterproofing installations.

with hydrostatic pressure, or water storage units (storage

period greater than 48 h). 4.2 The area to be tested is subdivided as required by the

containment assemblies, and drains within the subdivided area

1.4 The values stated in SI units are to be regarded as the

are temporarily blocked to prevent water leakage into the

standard. The values given in parentheses are for information

drainage system.

only.

4.3 Water is ponded in the subdivided area and maintained

1.5 This standard does not purport to address all of the

for a minimum period of 24 h. The space below the test

safety concerns, if any, associated with its use. It is the

location is monitored for leakage during the test period.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 This guide describes the techniques used to test for

2. Referenced Documents

watertightness of waterproofing installations on horizontal

services having a slope not greater than 20 mm/m (2 % slope)

2.1 ASTM Standards:

( ⁄4 in./ft). See also ACI 515.

D1079 Terminology Relating to Roofing and Waterproofing

5.2 The structural capacity of the substrate to which the

waterproofing system is to be installed should be reviewed by

a licensed structural engineer to verify that the loads associated

with the use of procedures described in this guide do not

exceed code and design restrictions. Lateral loads will be

This guide is under the jurisdiction of ASTM Committee D08 on Roofing and

imposed on curbs or walls used for containment of the water

Waterproofing and is the direct responsibility of Subcommittee D08.22 on Water-

proofing and Dampproofing Systems. during the test procedures and their effect should be accounted

Current edition approved July 1, 2005. Published July 2005. Originally approved

for. The effects of equipment, planters, or other movable

in 1996. Last previous edition approved in 1998 as D5957 – 98. DOI: 10.1520/

objects present within the test area should be considered.

D5957-98R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

the ASTM website. Hills, MI 48333.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5957−98 (2005)

NOTE1—Potablewaterweighsapproximately1000kg/cubicm(62.3lb

6.3 Vertical-Sided Shallow Pan .

2 2

per cubic ft) at 22°C (71.6°F) or 1 g/cm /cm depth (5.19 lbs/ft per in.

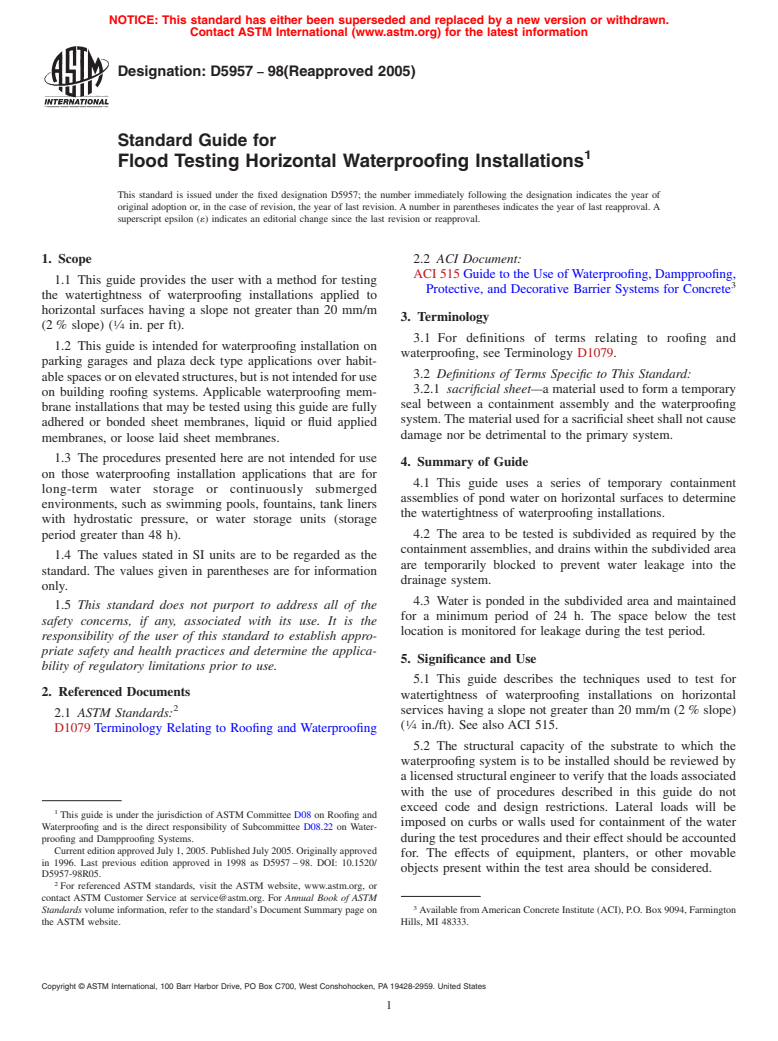

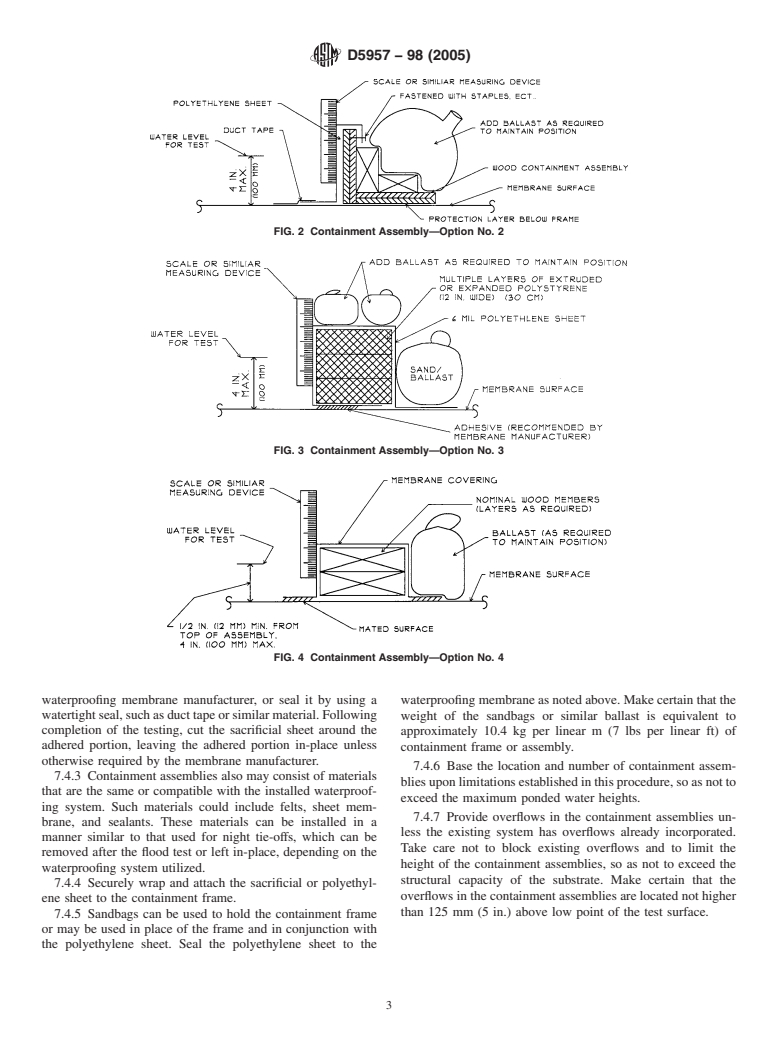

6.4 Containment Assemblies—Assemblies to form tempo-

depth).

rary dams can be constructed using one or more of the

5.3 This guide describes a procedure to test for watertight-

following materials. Refer to Figs. 1-4, for examples of

ness of waterproofing installations under ponded water with a

constructed containment assemblies.

short-term hydrostatic head measuring not more than 100 mm

6.4.1 Nominal 50-mm (2-in.) thick by 100 or 150-mm (4 or

(4 in.).

6-in.) wide wood members,

NOTE 2—Increasing the amount of water forming a hydrostatic head

6.4.2 Polyethylene film having a minimum thickness of 6

beyond 100 mm (4 in.) of water may be considered provided the impact

mils,

of increased loads on the substrate has been reviewed and approved by a

6.4.3 Sandbags,

licensed structural engineer.

6.4.4 Duct tape,

5.4 For the purposes of this guide, the installation of the

6.4.5 Waterproofing membrane materials,

waterproofingmembraneandflashingshouldbecompletedand

6.4.6 Adhesives and sealants,

the materials fully cured. Manufacturers should specify a

6.4.7 Scale or similar measuring device, and

minimum time period for materials to cure prior to performing

6.4.8 Extruded or expanded polystyrene insulation boards,

flood test, however, no testing should be performed during the

approximately 30 cm (12 in.) wide.

first 24 h following installation of system materials (48 h min

6.5 Garden Hoses or Firehoses—Standard size.

if materials are installed at a time when ambient temperatures

are below 10°C (50°F)).

NOTE 3—If firehoses are used, then set the hose of a flow disperser such

that the nozzle and initial flow are not in direct contact with the

5.5 The additional loads imposed upon the structure during

membrane.

the test period will affect the deflection of structural items. The

6.6 Plastic Bucket— Standard wash bucket with bottom

effects shall be analyzed by a licensed structural engineer prior

panal removed. Four holes measuring approximately 25.4 mm

to placement of additional loads. Critical locations shall be

(1 in.) diameter equally spaced around the bucket at approxi-

monitored during the duration of the test period.

mately 25.4 mm (1 in.) from the bottom.

5.6 This guide is not recommended to be used if freezing

temperatures are expected to occur during the test period.

7. Procedure

Ponded water can freeze and become adhered to the water-

7.1 Testing should be performed only after waterproofing

proofing system resulting in pulling or tearing of the flashings

membrane and flashings are inspected and any deficiencies

away from the substrate or may break interior corners.

repaired.

5.7 The intent of this guide is to provide a measure of

7.2 Testing prior to installation of drainage layer, protection

confidence of the waterproofing installation to remain water-

layer, pavers or overburden. (See also Appendix X1.)

tight for the service life of the system, based upon the observed

performance of the system under ponded water for a limited

7.3 If a protection layer is required prior to flood testing, it

period of time.

is recommended that a temporary protection layer be loose laid

and removed prior to testing of the waterproofing system.

6. Materials

7.4 Installation of Temporary Containment Assemblies:

6.1 Drain Plugs— Pneumatically inflatable devices consist-

7.4.1 Construct containment assemblies to be nondestruc-

ing of a rubber ball, draw chain and ring, and preset, built-in

tive, nonpenetrating of the waterproofing installation, and

pressure relief valve; compression plugs having a screw

easily removable.

mechanism; or other standard plumbing fixtures.

7.4.2 Containment assemblies consist of a sacrificial sheet

6.2 Standard Air Pressure Hand Pump with Hose—Pressure or a polyethylene sheet adhered to the surface of the water-

gage is optional. proofing membrane. Seal the sheet as recommended by the

FIG. 1 Containment Assembly—Option No. 1

D5957−98 (2005)

FIG. 2 Containment Assembly—Option No.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.