ASTM G172-03(2010)

(Guide)Standard Guide for Statistical Analysis of Accelerated Service Life Data

Standard Guide for Statistical Analysis of Accelerated Service Life Data

SIGNIFICANCE AND USE

The nature of accelerated service life estimation normally requires that stresses higher than those experienced during service conditions are applied to the material being evaluated. For non-constant use stress, such as experienced by time varying weather outdoors, it may in fact be useful to choose an accelerated stress fixed at a level slightly lower than (say 90 % of) the maximum experienced outdoors. By controlling all variables other than the one used for accelerating degradation, one may model the expected effect of that variable at normal, or usage conditions. If laboratory accelerated test devices are used, it is essential to provide precise control of the variables used in order to obtain useful information for service life prediction. It is assumed that the same failure mechanism operating at the higher stress is also the life determining mechanism at the usage stress. It must be noted that the validity of this assumption is crucial to the validity of the final estimate.

Accelerated service life test data often show different distribution shapes than many other types of data. This is due to the effects of measurement error (typically normally distributed), combined with those unique effects which skew service life data towards early failure time (infant mortality failures) or late failure times (aging or wear-out failures). Applications of the principles in this guide can be helpful in allowing investigators to interpret such data.

The choice and use of a particular acceleration model and life distribution model should be based primarily on how well it fits the data and whether it leads to reasonable projections when extrapolating beyond the range of data. Further justification for selecting models should be based on theoretical considerations.

Note 2—Accelerated service life or reliability data analysis packages are becoming more readily available in common computer software packages. This makes data reduction and analyses more directly accessible ...

SCOPE

1.1 This guide briefly presents some generally accepted methods of statistical analyses that are useful in the interpretation of accelerated service life data. It is intended to produce a common terminology as well as developing a common methodology and quantitative expressions relating to service life estimation.

1.2 This guide covers the application of the Arrhenius equation to service life data. It serves as a general model for determining rates at usage conditions, such as temperature. It serves as a general guide for determining service life distribution at usage condition. It also covers applications where more than one variable act simultaneously to affect the service life. For the purposes of this guide, the acceleration model used for multiple stress variables is the Eyring Model. This model was derived from the fundamental laws of thermodynamics and has been shown to be useful for modeling some two variable accelerated service life data. It can be extended to more than two variables.

1.3 Only those statistical methods that have found wide acceptance in service life data analyses have been considered in this guide.

1.4 The Weibull life distribution is emphasized in this guide and example calculations of situations commonly encountered in analysis of service life data are covered in detail. It is the intention of this guide that it be used in conjunction with Guide G166.

1.5 The accuracy of the model becomes more critical as the number of variables increases and/or the extent of extrapolation from the accelerated stress levels to the usage level increases. The models and methodology used in this guide are shown for the purpose of data analysis techniques only. The fundamental requirements of proper variable selection and measurement must still be met for a meaningful model to result.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G172 − 03 (Reapproved2010)

Standard Guide for

Statistical Analysis of Accelerated Service Life Data

This standard is issued under the fixed designation G172; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This guide briefly presents some generally accepted 2.1 ASTM Standards:

G166Guide for Statistical Analysis of Service Life Data

methods of statistical analyses that are useful in the interpre-

G169Guide for Application of Basic Statistical Methods to

tation of accelerated service life data. It is intended to produce

Weathering Tests

a common terminology as well as developing a common

methodology and quantitative expressions relating to service

3. Terminology

life estimation.

3.1 Terms Commonly Used in Service Life Estimation:

1.2 This guide covers the application of the Arrhenius

3.1.1 acceleratedstress,n—thatexperimentalvariable,such

equation to service life data. It serves as a general model for

as temperature, which is applied to the test material at levels

determining rates at usage conditions, such as temperature. It

higher than encountered in normal use.

serves as a general guide for determining service life distribu-

3.1.2 beginning of life, n—this is usually determined to be

tion at usage condition. It also covers applications where more

the time of delivery to the end user or installation into field

than one variable act simultaneously to affect the service life.

service. Exceptions may include time of manufacture, time of

For the purposes of this guide, the acceleration model used for

repair, or other agreed upon time.

multiple stress variables is the Eyring Model. This model was

derivedfromthefundamentallawsofthermodynamicsandhas

3.1.3 cdf, n—the cumulative distribution function (cdf),

been shown to be useful for modeling some two variable

denoted by F(t), represents the probability of failure (or the

accelerated service life data. It can be extended to more than

population fraction failing) by time = (t). See 3.1.7.

two variables.

3.1.4 completedata,n—acompletedatasetisonewhereall

1.3 Only those statistical methods that have found wide of the specimens placed on test fail by the end of the allocated

acceptance in service life data analyses have been considered

test time.

in this guide.

3.1.5 endoflife,n—occasionallythisissimpleandobvious,

such as the breaking of a chain or burning out of a light bulb

1.4 TheWeibulllifedistributionisemphasizedinthisguide

filament. In other instances, the end of life may not be so

and example calculations of situations commonly encountered

catastrophic or obvious. Examples may include fading,

in analysis of service life data are covered in detail. It is the

yellowing, cracking, crazing, etc. Such cases need quantitative

intentionofthisguidethatitbeusedinconjunctionwithGuide

measurements and agreement between evaluator and user as to

G166.

the precise definition of failure. For example, when some

1.5 The accuracy of the model becomes more critical as the

critical physical parameter (such as yellowing) reaches a

number of variables increases and/or the extent of extrapola-

pre-defined level. It is also possible to model more than one

tion from the accelerated stress levels to the usage level

failure mode for the same specimen (that is, the time to reach

increases. The models and methodology used in this guide are

a specified level of yellowing may be measured on the same

shown for the purpose of data analysis techniques only. The

specimen that is also tested for cracking).

fundamental requirements of proper variable selection and

3.1.6 f(t), n—the probability density function (pdf), equals

measurement must still be met for a meaningful model to

the probability of failure between any two points of time t

result. (1)

dF t

~ !

and t ; f~t!5 . For the normal distribution, the pdf is the

(2)

dt

“bell shape” curve.

This guide is under the jurisdiction of ASTM Committee G03 on Weathering

and Durability and is the direct responsibility of Subcommittee G03.08 on Service

Life Prediction. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJuly1,2010.PublishedJuly2010.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 2002. Last previous edition approved in 2002 as G172-03. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

G0172-03R10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G172 − 03 (2010)

3.1.7 F(t),n—theprobabilitythatarandomunitdrawnfrom where:

the population will fail by time (t). Also F(t) = the decimal

F(t) = probability of failure by time (t) as defined in 3.1.7,

fraction of units in the population that will fail by time (t).The

t = units of time used for service life,

decimal fraction multiplied by 100 is numerically equal to the c = scale parameter, and

percent failure by time (t). b = shape parameter.

3.1.8 incomplete data, n—an incomplete data set is one

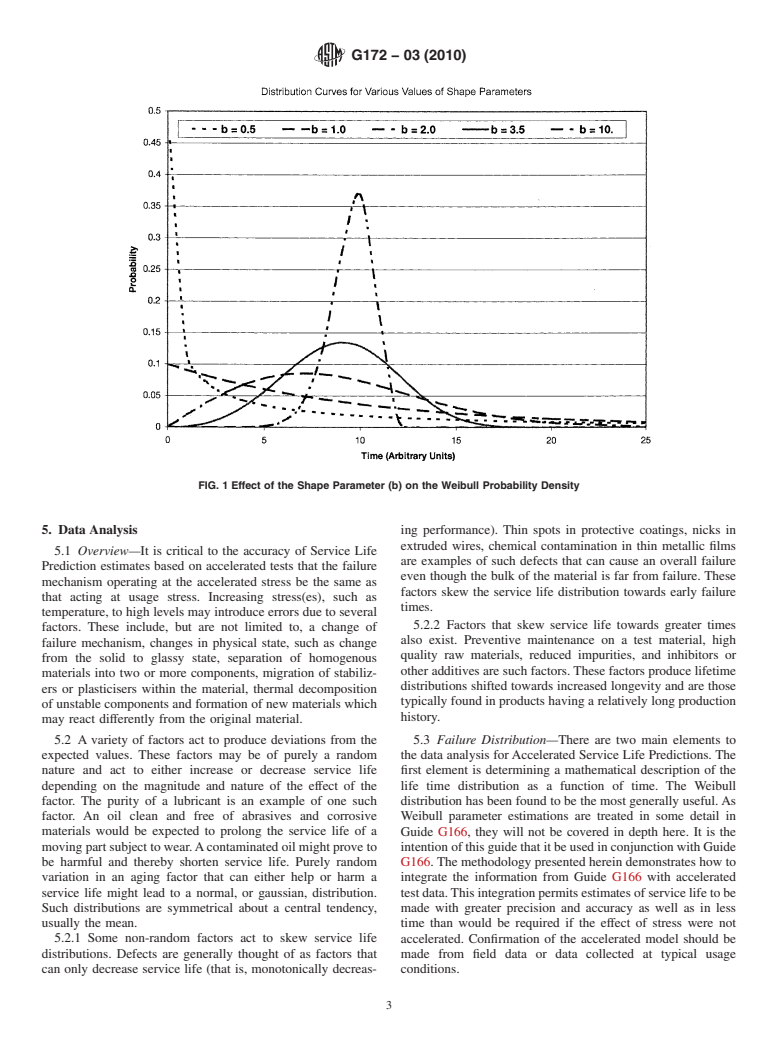

3.1.12.1 Discussion—The shape parameter (b), 3.1.12,isso

where (1) there are some specimens that are still surviving at

called because this parameter determines the overall shape of

the expiration of the allowed test time, or (2) where one or

the curve. Examples of the effect of this parameter on the

more specimens is removed from the test prior to expiration of

distribution curve are shown in Fig. 1.

the allocated test time. The shape and scale parameters of the

3.1.12.2 Discussion—The scale parameter (c), 3.1.12,isso

above distributions may be estimated even if some of the test

called because it positions the distribution along the scale of

specimensdidnotfail.Therearethreedistinctcaseswherethis

the time axis. It is equal to the time for 63.2% failure.

might occur.

NOTE 1—This is arrived at by allowing t to equal c in Eq 1. This then

3.1.8.1 multiple censored, n—specimens that were removed

-1

reduces to Failure Probability=1− e . which further reduces to equal 1

prior to the end of the test without failing are referred to as left

− 0.368 or 0.632.

censored or type II censored. Examples would include speci-

mens that were lost, dropped, mishandled, damaged or broken

4. Significance and Use

duetostressesnotpartofthetest.Adjustmentsoffailureorder

4.1 The nature of accelerated service life estimation nor-

can be made for those specimens actually failed.

mally requires that stresses higher than those experienced

3.1.8.2 specimen censored, n—specimens that were still

during service conditions are applied to the material being

surviving when the test was terminated after a set number of

evaluated. For non-constant use stress, such as experienced by

failures are considered to be specimen censored. This is

time varying weather outdoors, it may in fact be useful to

another case of right censored or type I censoring. See 3.1.8.3.

choose an accelerated stress fixed at a level slightly lower than

3.1.8.3 time censored, n—specimens that were still surviv- (say 90% of) the maximum experienced outdoors. By control-

ling all variables other than the one used for accelerating

ing when the test was terminated after elapse of a set time are

considered to be time censored. Examples would include degradation,onemaymodeltheexpectedeffectofthatvariable

at normal, or usage conditions. If laboratory accelerated test

experiments where exposures are conducted for a predeter-

mined length of time.At the end of the predetermined time, all devicesareused,itisessentialtoprovideprecisecontrolofthe

variables used in order to obtain useful information for service

specimens are removed from the test. Those that are still

surviving are said to be censored. This is also referred to as life prediction. It is assumed that the same failure mechanism

operating at the higher stress is also the life determining

rightcensoredortypeIcensoring.Graphicalsolutionscanstill

be used for parameter estimation.Aminimum of ten observed mechanismattheusagestress.Itmustbenotedthatthevalidity

ofthisassumptioniscrucialtothevalidityofthefinalestimate.

failuresshouldbeusedforestimatingparameters(thatis,slope

and intercept, shape and scale, etc.).

4.2 Accelerated service life test data often show different

3.1.9 material property, n—customarily, service life is con- distribution shapes than many other types of data. This is due

sidered to be the period of time during which a system meets

to the effects of measurement error (typically normally

critical specifications. Correct measurements are essential to distributed), combined with those unique effects which skew

produce meaningful and accurate service life estimates.

service life data towards early failure time (infant mortality

3.1.9.1 Discussion—There exists many ASTM recognized failures) or late failure times (aging or wear-out failures).

and standardized measurement procedures for determining

Applications of the principles in this guide can be helpful in

material properties. These practices have been developed allowing investigators to interpret such data.

within committees having appropriate expertise, therefore, no

4.3 The choice and use of a particular acceleration model

further elaboration will be provided.

and life distribution model should be based primarily on how

3.1.10 R(t), n—the probability that a random unit drawn

well it fits the data and whether it leads to reasonable

fromthepopulationwillsurviveatleastuntiltime(t).AlsoR(t)

projections when extrapolating beyond the range of data.

=thefractionofunitsinthepopulationthatwillsurviveatleast

Further justification for selecting models should be based on

until time (t); R(t)=1− F(t).

theoretical considerations.

NOTE 2—Accelerated service life or reliability data analysis packages

3.1.11 usage stress, n—the level of the experimental vari-

are becoming more readily available in common computer software

able that is considered to represent the stress occurring in

packages.Thismakesdatareductionandanalysesmoredirectlyaccessible

normal use. This value must be determined quantitatively for

to a growing number of investigators.This is not necessarily a good thing

accurate estimates to be made. In actual practice, usage stress

as the ability to perform the mathematical calculation, without the

may be highly variable, such as those encountered in outdoor fundamental understanding of the mechanics may produce some serious

errors. See Ref (1).

environments.

3.1.12 Weibull distribution, n—for the purposes of this

guide, the Weibull distribution is represented by the equation:

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

t b

S D

F t 51 2 e c (1) this standard.

~ !

G172 − 03 (2010)

FIG. 1 Effect of the Shape Parameter (b) on the Weibull Probability Density

5. Data Analysis ing performance). Thin spots in protective coatings, nicks in

extruded wires, chemical contamination in thin metallic films

5.1 Overview—It is critical to the accuracy of Service Life

are examples of such defects that can cause an overall failure

Prediction estimates based on accelerated tests that the failure

even though the bulk of the material is far from failure. These

mechanism operating at the accelerated stress be the same as

factors skew the service life distribution towards early failure

that acting at usage stress. Increasing stress(es), such as

times.

temperature, to high levels may introduce errors due to several

5.2.2 Factors that skew service life towards greater times

factors. These include, but are not limited to, a change of

also exist. Preventive maintenance on a test material, high

failure mechanism, changes in physical state, such as change

quality raw materials, reduced impurities, and inhibitors or

from the solid to glassy state, separation of homogenous

other additives are such factors.These factors produce lifetime

materials into two or more components, migration of stabiliz-

distributions shifted towards increased longevity and are those

ers or plasticisers within the material, thermal decomposition

typically found in products having a relatively long production

of unstable components and formation of new materials which

history.

may react differently from the original material.

5.2 A variety of factors act to produce deviations from the 5.3 Failure Distribution—There are two main elements to

expected values. These factors may be of purely a random the data analysis forAccelerated Service Life Predictions. The

nature and act to either increase or decrease service life first element is determining a mathematical description of the

depending on the magnitude and nature of the effect of the life time distribution as a function of time. The Weibull

factor. The purity of a lubricant is an example of one such distribution has been found to be the most generally useful.As

factor. An oil clean and free of abrasives and corrosive Weibull parameter estimations are treated in some detail in

materials would be expected to prolong the service life of a Guide G166, they will not be covered in depth here. It is the

movingpartsubjecttowear.Acontaminatedoilmightproveto intentionofthisguidethatitbeusedinconjunctionwithGuide

be harmful and thereby shorten service life. Purely random G166.Themethodologypresentedhereindemonstrateshowto

variation in an aging factor that can either help or harm a integrate the information from Guide G166 with accelerated

service life might lead to a normal, or gaussian, distribution. testdata.Thisintegrationpermitsestimatesofservicelifetobe

Such distributions are symmetrical about a central tendency, made with greater precision and accuracy as well as in less

usually the mean. time than would be required if the effect of stress were not

5.2.1 Some non-random factors act to skew service life accelerated. Confirmation of the accelerated model should be

distributions. Defects are generally thought of as factors that made from field data or data collected at typical usage

can only decrease service life (that is, monotonically decreas- conditions.

G172 − 03 (2010)

5.3.1 Establishing, in an accelerated time frame, a descrip- 5.4.5 The time element used in the Eq 3 is arbitrary. It can

tion of the distribution of frequency (or probability) of failure be the time for the first 5% failure, time for average failure,

time for 63.2% failure, time for 95% failure or any other

versus time in service is the objective o

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:G172–03 Designation: G172 – 03 (Reapproved 2010)

Standard Guide for

Statistical Analysis of Accelerated Service Life Data

This standard is issued under the fixed designation G172; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide briefly presents some generally accepted methods of statistical analyses that are useful in the interpretation of

accelerated service life data. It is intended to produce a common terminology as well as developing a common methodology and

quantitative expressions relating to service life estimation.

1.2 ThisguidecoverstheapplicationoftheArrheniusequationtoservicelifedata.Itservesasageneralmodelfordetermining

rates at usage conditions, such as temperature. It serves as a general guide for determining service life distribution at usage

condition. It also covers applications where more than one variable act simultaneously to affect the service life. For the purposes

of this guide, the acceleration model used for multiple stress variables is the Eyring Model. This model was derived from the

fundamental laws of thermodynamics and has been shown to be useful for modeling some two variable accelerated service life

data. It can be extended to more than two variables.

1.3 Only those statistical methods that have found wide acceptance in service life data analyses have been considered in this

guide.

1.4 The Weibull life distribution is emphasized in this guide and example calculations of situations commonly encountered in

analysis of service life data are covered in detail. It is the intention of this guide that it be used in conjunction with Guide G166.

1.5 The accuracy of the model becomes more critical as the number of variables increases and/or the extent of extrapolation

from the accelerated stress levels to the usage level increases. The models and methodology used in this guide are shown for the

purpose of data analysis techniques only. The fundamental requirements of proper variable selection and measurement must still

be met for a meaningful model to result.

2. Referenced Documents

2.1 ASTM Standards:

G166 Guide for Statistical Analysis of Service Life Data

G169 Guide for Application of Basic Statistical Methods to Weathering Tests

3. Terminology

3.1 Terms Commonly Used in Service Life Estimation:

3.1.1 accelerated stressaccelerated stress, n—that experimental variable, such as temperature, which is applied to the test

material at levels higher than encountered in normal use.

3.1.2 beginning of lifebeginning of life, n—this is usually determined to be the time of delivery to the end user or installation

into field service. Exceptions may include time of manufacture, time of repair, or other agreed upon time.

3.1.3 cdfcdf, n—the cumulative distribution function (cdf), denoted by F (t ), represents the probability of failure (or the

population fraction failing) by time = (t). See 3.1.7.

3.1.4 complete datacomplete data, n—a complete data set is one where all of the specimens placed on test fail by the end of

the allocated test time.

3.1.5 end of lifeend of life, n—occasionally this is simple and obvious, such as the breaking of a chain or burning out of a light

bulb filament. In other instances, the end of life may not be so catastrophic or obvious. Examples may include fading, yellowing,

cracking, crazing, etc. Such cases need quantitative measurements and agreement between evaluator and user as to the precise

definitionoffailure.Forexample,whensomecriticalphysicalparameter(suchasyellowing)reachesapre-definedlevel.Itisalso

possible to model more than one failure mode for the same specimen (that is, the time to reach a specified level of yellowing may

This guide is under the jurisdiction of ASTM Committee G03 on Weathering and Durability and is the direct responsibility of Subcommittee G03.08 on Service Life

Prediction.

Current edition approved Jan. 10, 2003. Published February 2003. DOI: 10.1520/G0172-03.

Current edition approved July 1, 2010. Published July 2010. Originally approved in 2002. Last previous edition approved in 2002 as G172-03. DOI:

10.1520/G0172-03R10.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G172 – 03 (2010)

be measured on the same specimen that is also tested for cracking).

3.1.6 f(t)f(t), n—the probability density function (pdf), equals the probability of failure between any two points of time t and

(1)

t ;f (t)= dF t! dt . For the normal distribution, the pdf is the “bell shape” curve.

~

(2)

/

3.1.7 F(t)F(t), n—the probability that a random unit drawn from the population will fail by time (t).Also F ( t) = the decimal

fraction of units in the population that will fail by time (t). The decimal fraction multiplied by 100 is numerically equal to the

percent failure by time (t).

3.1.8 incomplete dataincomplete data, n—an incomplete data set is one where (1) there are some specimens that are still

survivingattheexpirationoftheallowedtesttime,or(2)whereoneormorespecimensisremovedfromthetestpriortoexpiration

of the allocated test time. The shape and scale parameters of the above distributions may be estimated even if some of the test

specimens did not fail. There are three distinct cases where this might occur.

3.1.8.1 multiple censoredmultiple censored, n—specimens that were removed prior to the end of the test without failing are

referred to as left censored or type II censored. Examples would include specimens that were lost, dropped, mishandled, damaged

or broken due to stresses not part of the test. Adjustments of failure order can be made for those specimens actually failed.

3.1.8.2 specimen censoredspecimen censored, n—specimens that were still surviving when the test was terminated after a set

number of failures are considered to be specimen censored.This is another case of right censored or type I censoring. See 3.1.8.3.

3.1.8.3 time censoredtime censored, n—specimens that were still surviving when the test was terminated after elapse of a set

timeareconsideredtobetimecensored.Exampleswouldincludeexperimentswhereexposuresareconductedforapredetermined

length of time. At the end of the predetermined time, all specimens are removed from the test. Those that are still surviving are

saidtobecensored.ThisisalsoreferredtoasrightcensoredortypeIcensoring.Graphicalsolutionscanstillbeusedforparameter

estimation.Aminimum of ten observed failures should be used for estimating parameters (that is, slope and intercept, shape and

scale, etc.).

3.1.9 material propertymaterial property, n—customarily, service life is considered to be the period of time during which a

systemmeetscriticalspecifications.Correctmeasurementsareessentialtoproducemeaningfulandaccurateservicelifeestimates.

3.1.9.1 Discussion—There exists manyASTM recognized and standardized measurement procedures for determining material

properties.These practices have been developed within committees having appropriate expertise, therefore, no further elaboration

will be provided.

3.1.10 R(t)R(t), n—the probability that a random unit drawn from the population will survive at least until time (t).Also R (t)

= the fraction of units in the population that will survive at least until time (t); R (t)=1− F (t).

3.1.11 usage stressusage stress, n—the level of the experimental variable that is considered to represent the stress occurring in

normal use. This value must be determined quantitatively for accurate estimates to be made. In actual practice, usage stress may

be highly variable, such as those encountered in outdoor environments.

3.1.12 Weibull distributionWeibull distribution, n—for the purposes of this guide, theWeibull distribution is represented by the

equation:

t b

S D

F t! 51 2e c (1)

~

where:

F(t) = probability of failure by time (t) as defined in 3.1.7,

t = units of time used for service life,

c = scale parameter, and

b = shape parameter.

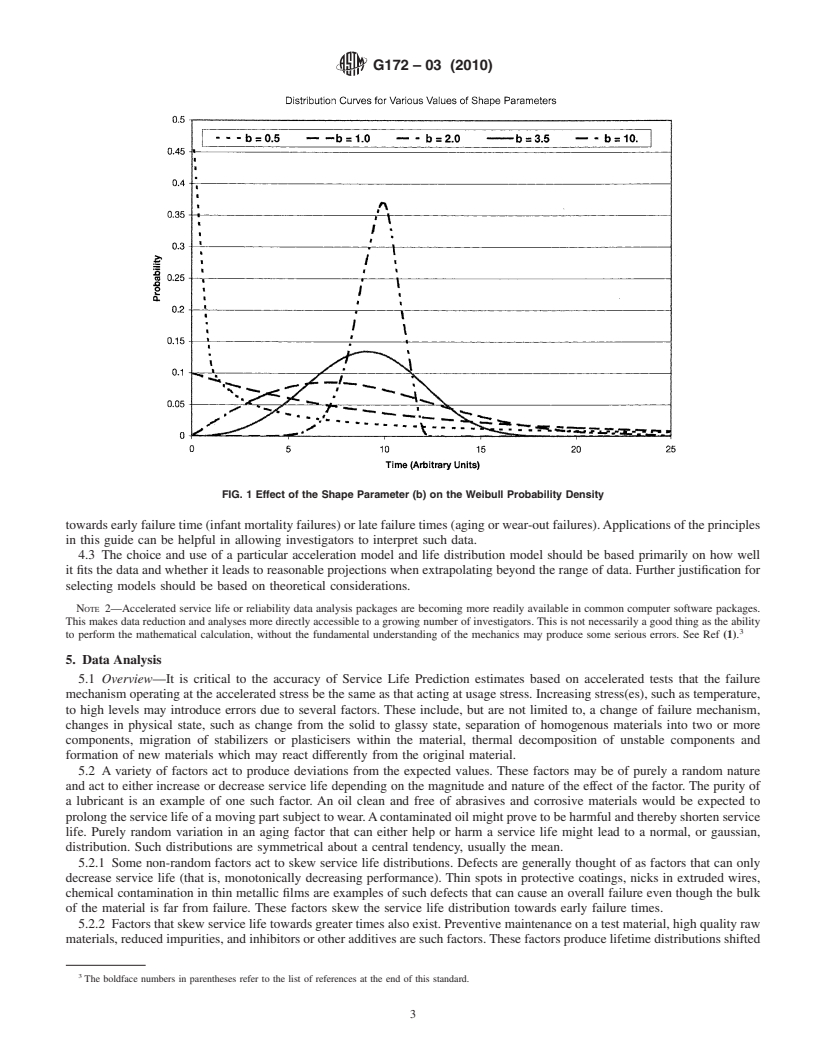

3.1.12.1 Discussion—The shape parameter (b), 3.1.12, is so called because this parameter determines the overall shape of the

curve. Examples of the effect of this parameter on the distribution curve are shown in Fig. 1.

3.1.12.2 Discussion—Thescaleparameter(c),3.1.12,issocalledbecauseitpositionsthedistributionalongthescaleofthetime

axis. It is equal to the time for 63.2% failure.

-1

NOTE 1—This is arrived at by allowing t to equal c in Eq 1. This then reduces to Failure Probability=1− e . which further reduces to equal 1 −

0.368 or 0.632.

4. Significance and Use

4.1 Thenatureofacceleratedservicelifeestimationnormallyrequiresthatstresseshigherthanthoseexperiencedduringservice

conditions are applied to the material being evaluated. For non-constant use stress, such as experienced by time varying weather

outdoors, it may in fact be useful to choose an accelerated stress fixed at a level slightly lower than (say 90% of) the maximum

experienced outdoors. By controlling all variables other than the one used for accelerating degradation, one may model the

expected effect of that variable at normal, or usage conditions. If laboratory accelerated test devices are used, it is essential to

provide precise control of the variables used in order to obtain useful information for service life prediction. It is assumed that the

same failure mechanism operating at the higher stress is also the life determining mechanism at the usage stress. It must be noted

that the validity of this assumption is crucial to the validity of the final estimate.

4.2 Accelerated service life test data often show different distribution shapes than many other types of data. This is due to the

effects of measurement error (typically normally distributed), combined with those unique effects which skew service life data

G172 – 03 (2010)

FIG. 1 Effect of the Shape Parameter (b) on the Weibull Probability Density

towardsearlyfailuretime(infantmortalityfailures)orlatefailuretimes(agingorwear-outfailures).Applicationsoftheprinciples

in this guide can be helpful in allowing investigators to interpret such data.

4.3 The choice and use of a particular acceleration model and life distribution model should be based primarily on how well

it fits the data and whether it leads to reasonable projections when extrapolating beyond the range of data. Further justification for

selecting models should be based on theoretical considerations.

NOTE 2—Accelerated service life or reliability data analysis packages are becoming more readily available in common computer software packages.

This makes data reduction and analyses more directly accessible to a growing number of investigators.This is not necessarily a good thing as the ability

to perform the mathematical calculation, without the fundamental understanding of the mechanics may produce some serious errors. See Ref (1).

5. Data Analysis

5.1 Overview—It is critical to the accuracy of Service Life Prediction estimates based on accelerated tests that the failure

mechanismoperatingattheacceleratedstressbethesameasthatactingatusagestress.Increasingstress(es),suchastemperature,

to high levels may introduce errors due to several factors. These include, but are not limited to, a change of failure mechanism,

changes in physical state, such as change from the solid to glassy state, separation of homogenous materials into two or more

components, migration of stabilizers or plasticisers within the material, thermal decomposition of unstable components and

formation of new materials which may react differently from the original material.

5.2 A variety of factors act to produce deviations from the expected values. These factors may be of purely a random nature

and act to either increase or decrease service life depending on the magnitude and nature of the effect of the factor. The purity of

a lubricant is an example of one such factor. An oil clean and free of abrasives and corrosive materials would be expected to

prolongtheservicelifeofamovingpartsubjecttowear.Acontaminatedoilmightprovetobeharmfulandtherebyshortenservice

life. Purely random variation in an aging factor that can either help or harm a service life might lead to a normal, or gaussian,

distribution. Such distributions are symmetrical about a central tendency, usually the mean.

5.2.1 Some non-random factors act to skew service life distributions. Defects are generally thought of as factors that can only

decrease service life (that is, monotonically decreasing performance). Thin spots in protective coatings, nicks in extruded wires,

chemical contamination in thin metallic films are examples of such defects that can cause an overall failure even though the bulk

of the material is far from failure. These factors skew the service life distribution towards early failure times.

5.2.2 Factorsthatskewservicelifetowardsgreatertimesalsoexist.Preventivemaintenanceonatestmaterial,highqualityraw

materials,reducedimpurities,andinhibitorsorotheradditivesaresuchfactors.Thesefactorsproducelifetimedistributionsshifted

The boldface numbers in parentheses refer to the list of references at the end of this standard.

G172 – 03 (2010)

towards increased longevity and are those typically found in products having a relatively long production history.

5.3 Failure Distribution—There are two main elements to the data analysis forAccelerated Service Life Predictions. The first

element is determining a mathematical description of the life time distribution as a function of time. The Weibull distribution has

been found to be the most generally useful.As Weibull parameter estimations are treated in some detail in Guide G166, they will

not be covered in depth here. It is the intention of this guide that it be used in conjunction with Guide G166. The methodology

presented herein demonstrates how to integrate the information from Guide G166 with accelerated test data. This integration

permits estimates of service life to be made with greater precision and accuracy as well as in less time than would

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.