ASTM F2132-01(2008)e1

(Specification)Standard Specification for Puncture Resistance of Materials Used in Containers for Discarded Medical Needles and Other Sharps (Withdrawn 2017)

Standard Specification for Puncture Resistance of Materials Used in Containers for Discarded Medical Needles and Other Sharps (Withdrawn 2017)

ABSTRACT

This specification provides the performance requirements and associated test procedures for the puncture resistance of materials used in the construction of containers for discarded medical needles and other sharps. It shall establish the average and minimum value of puncture force that the container materials must withstand under controlled laboratory conditions and normal room temperature when following the test procedure described herein. Materials meeting the specified performance requirements will be considered puncture resistant, but this specification will not evaluate the construction of, or provide pass/fail criteria for, sharps containers.

SCOPE

1.1 The purpose of this specification is to provide a test procedure and performance requirement for the puncture resistance of materials used in the construction of containers for discarded medical needles and other sharps. This test specification will establish (1) the average puncture force and (2) a minimum value of puncture force that container material(s) must withstand when following the test procedure described in Section 6. This specification shall be applicable to regions of uniform material and thickness, and needle contact areas as defined in 3.1.7 and 3.1.9. Materials meeting the performance requirements of Section 4 shall be considered “puncture-resistant.” This specification does not evaluate the construction of, or provide pass/fail criteria for, a sharps container.

1.2 This specification provides a test procedure to determine if all regions of one container meet the material puncture resistance requirements. It does not define the number of additional test containers required to achieve a statistically valid sample of a manufacturing lot or process. An appropriate sampling plan shall be determined by the test requester, as this depends upon the manufacturing process variability, manufacturing lot size, and other factors, such as end-user requirements.

1.3 This specification is intended to evaluate the performance of materials used in the construction or manufacture of sharps containers under controlled laboratory conditions, and at normal room temperature (see 6.1). (Warning—This specification only characterizes material puncture resistance at normal room temperatures. Applications of sharps containers outside the range of 23 ± 2°C (such as usage in emergency vehicles) require further material characterization by the product specifier to determine suitable use.)

1.4 The values stated in inch/pound are to be regarded as the standard. The SI values given in parentheses are for information only.

1.5 The following hazard caveat pertains only to the test procedure portion, Section 6, of this specification.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This specification provided a test procedure and performance requirement for the puncture resistance of materials used in the construction of containers for discarded medical needles and other sharps.

Formerly under the jurisdiction of Committee F04 on Medical and Surgical Materials and Devices, this specification was withdrawn in July 2017 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F2132 −01 (Reapproved 2008)

Standard Specification for

Puncture Resistance of Materials Used in Containers for

Discarded Medical Needles and Other Sharps

This standard is issued under the fixed designation F2132; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in June 2008.

1. Scope 1.4 Thevaluesstatedininch/poundaretoberegardedasthe

standard. The SI values given in parentheses are for informa-

1.1 The purpose of this specification is to provide a test

tion only.

procedure and performance requirement for the puncture

resistance of materials used in the construction of containers 1.5 The following hazard caveat pertains only to the test

for discarded medical needles and other sharps. This test procedure portion, Section 6, of this specification.

specification will establish (1) the average puncture force and

1.6 This standard does not purport to address all of the

(2) a minimum value of puncture force that container materi-

safety concerns, if any, associated with its use. It is the

al(s) must withstand when following the test procedure de-

responsibility of the user of this standard to establish appro-

scribed in Section 6. This specification shall be applicable to

priate safety and health practices and determine the applica-

regions of uniform material and thickness, and needle contact

bility of regulatory limitations prior to use.

areas as defined in 3.1.7 and 3.1.9. Materials meeting the

performance requirements of Section 4 shall be considered

2. Referenced Documents

“puncture-resistant.” This specification does not evaluate the

2.1 ASTM Standards:

construction of, or provide pass/fail criteria for, a sharps

E691 Practice for Conducting an Interlaboratory Study to

container.

Determine the Precision of a Test Method

1.2 Thisspecificationprovidesatestproceduretodetermine

2.2 ISO Standards:

if all regions of one container meet the material puncture

ISO 7864 Sterile Hypodermic Needles for Single Use

resistance requirements. It does not define the number of

ISO 594 Luer Fittings

additional test containers required to achieve a statistically

valid sample of a manufacturing lot or process.An appropriate 2.3 Other Standards:

sampling plan shall be determined by the test requester, as this AS4031:1992 Non-reusableContainersfortheCollectionof

Sharp Medical Items Used in Health Care Areas

depends upon the manufacturing process variability, manufac-

turing lot size, and other factors, such as end-user require- BSI 7320:1990 Specification for Sharps Containers

CSA Z316.6-95 Evaluation of Single Use Medical Sharps

ments.

Containers for Biohazardous and Cytotoxic Waste

1.3 This specification is intended to evaluate the perfor-

DHHS (NIOSH) Publication No. 97-111 Selecting,

mance of materials used in the construction or manufacture of

Evaluating, and Using Sharps Disposal Containers

sharps containers under controlled laboratory conditions, and

at normal room temperature (see 6.1). (Warning—This speci-

fication only characterizes material puncture resistance at

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

normal room temperatures. Applications of sharps containers

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

outside the range of 23 6 2°C (such as usage in emergency

Standards volume information, refer to the standard’s Document Summary page on

vehicles) require further material characterization by the prod-

the ASTM website.

uct specifier to determine suitable use.)

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

Available from StandardsAustralia International Ltd., 286 Sussex St., Sydney,

Australia NSW 2000.

1 5

This specification is under the jurisdiction of ASTM Committee F04 on Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

Medical and Surgical Materials and Devices and is the direct responsibility of London W4 4AL, U.K., http://www.bsi-global.com.

Subcommittee F04.33 on Medical/Surgical Instruments. Available from Canadian Standards Association, Andre Wisaksana, 178

Current edition approved Feb. 1, 2008. Published March 2008. Originally Rexdale Blvd., Etobicoke, ON Canada M9W 1R3.

approved in 2001. Last previous edition approved in 2001 as F2132 – 01. DOI: Available from Publications Dissemination, EID National Institute for Occu-

10.1520/F2132-01R08E01. pational Safety and Health, 4676 Columbus Pkwy., Cincinnati, OH 45226-1998.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2132−01 (2008)

3. Terminology tested as configured in actual use and shall meet the puncture

resistancespecificationofthisstandardtobedeemedpuncture-

3.1 Definitions:

resistant. If a container is designed to use a removable liner

3.1.1 container—a product used for the containment of

enclosed by the container, the material used in the removable

discarded medical needles and other sharps.

liner must meet the puncture resistance specification of this

3.1.2 material—the substance(s) used in the construction of

standard to be deemed puncture-resistant.

a sharps container.

For example, layered materials must be tested with the same

3.1.3 puncture force—the minimum force applied to the

spacing as configured in the actual application.

representative sharp object that causes its tip to penetrate (exit)

the opposite side of the test specimen from the side that it

5. Sampling and Specimen Preparation

entered when tested in accordance with the test procedure

5.1 Direct Versus Indirect Method—Either of two testing

portion, Section 6, of this specification.

procedures may be used to demonstrate that the material is

3.1.4 puncture resistant—a region of uniform material and

puncture-resistant under this specification. The direct method

thickness is defined as puncture resistant if it meets Section 4

shall be used if the material being evaluated has unknown

of this specification when tested in accordance with Section 6

characteristics. The indirect method may be used only if the

of this specification.

material being evaluated has been previously characterized by

3.1.5 test specimen—a sample of material being evaluated

a puncture force versus thickness relationship (see 7.2.2).

for puncture resistance that is taken from the actual container

5.1.1 Direct Method Specimen Preparation:

(direct method) or a representative example of the material and

5.1.1.1 One sharps container shall be selected at random to

thickness having the same characteristics as the actual con-

represent the material(s) to be tested. If it is not possible to

tainer (indirect method). Refer to Section 5.

obtain the required number of test specimens from one

container, additional randomly selected containers shall be

3.1.6 puncture test specimen—a test specimen that has been

sampled until the required number of test specimens is ob-

punctured using the puncture test described in 6.3, and subse-

tained.

quently evaluated using the direct or indirect methods de-

5.1.1.2 Identify each region of uniform material and thick-

scribed in 7.1 and 7.2 of this specification.

ness(see3.1.7and3.1.9).Markeachregionwithagridof1-in.

3.1.7 region of uniform material and thickness—sharps-

(25.4-mm) squares until the entire region has been covered. If

contactareasofthecontainer,inaggregate,thataremadeofthe

it is not possible to fit a 1-in. grid over certain areas of the

same homogeneous, composite, or laminated material, and, as

container, a smaller grid may be used; however, it shall be no

a consequence of fabrication or design or both, are expected to

less than 0.5 in. (12.7 mm) on a side.

have the same material and thickness as other areas of the

5.1.1.3 Number every square of the grid so that each region

container. For example, in molded containers, the corners

of uniform material and thickness has consecutive numbers,

couldbeexpectedtobeofdifferentthicknessthanthesidesand

starting with No. 1 in each region.

bottom, resulting in different regions of uniform material and

5.1.1.4 Using a random-number generator or table, select a

thickness. Labels, tabs, membranes, or thin films covering

quantity of 1-in. (or 0.5-in.) square specimens equal to 10 % of

openings in the container are considered separate regions of

the surface area of each region of the container as defined in

uniform material and thickness.

3.1.7 or no less than twelve specimens from each region. If at

3.1.8 sharps—items used in medical treatment, diagnoses,

least twelve specimens cannot be obtained from one container,

or research that may cause puncture wounds, cuts, or tears in

refer to 5.1.1.1. Remove the specimens identified by the

skin or mucous membranes, including, but not limited to:

random number selection from each region of the test con-

hypodermic, surgical, suture, and IV needles; Pasteur pipets,

tainer. Mark the test specimen as it is removed to identify the

lancets, razors, scalpels, and other blades and sharp objects.

inside of the container, as the puncture is required from the

3.1.9 sharps-contact areas—the material of a container that

inside of the container outward.

represents those surfaces that enclose sharps within the

5.1.1.5 Measure, mark, and record the thickness at the

container, when in its final closure configuration (that is,

center of each selected test specimen using a thickness-

disposal) configuration.

measuring device capable of measuring in 0.001-in. (0.025-

mm) increments, with an accuracy of 2 % of the thickness

4. Performance Requirements

measured, for example, a ball micrometer with a ball diameter

4.1 Puncture Resistance Specification—When tested in ac-

of 0.06 to 0.125 in. (1.6 to 3.2 mm). If the test specimen

cordance with Section 6, the average puncture force to pen-

includes a radius, corner, edge, or other design feature, find the

etrate material test specimens representing any regions of

minimum thickness and mark the location, if not in the center

uniform material and thickness and sharps-contact areas, as

of the specimen. Identify the specimen as to material and

defined in Section 3, shall not be less than 3.4 lbf (15 N), with

thickness represented.

no one value from any region of material tested less than 2.8

5.1.1.6 Proceed to Section 6.

lbf (12.5 N).

5.1.2 Indirect Method Specimen Preparation:

4.2 Layered Materials and Liners—If a container is de- 5.1.2.1 Obtainfabricatedormoldedtestspecimens(referred

signed to use nonlaminated layers of material in sharps-contact to as plaques within the indirect section) representing each

areas, the combination of these layered materials must be material, range of thickness, and equivalent manufacturing

´1

F2132−01 (2008)

process used to represent the sharps container. These plaques

shall not be from the container itself, but shall be used to

correlate the measured thickness of an actual container to the

puncture resistance value of plaques having the same charac-

teristics.

5.1.2.2 Produce a minimum of nine test plaques to represent

a minimum of four different thicknesses that span the range of

thicknesses expected for each region of uniform material and

thickness of the representative container. Select nine test

plaques from a minimum of four thickness ranges for a

minimum of 36 specimens. The size of each prepared plaque

shall be determined as in 5.1.1.2.

5.1.2.3 Measure and record the thickness at the center of

each selected test plaque, using the same thickness measuring

device as in 5.1.1.5, and identify the plaque as to material and

thickness represented.

5.1.2.4 Proceed to Section 6.

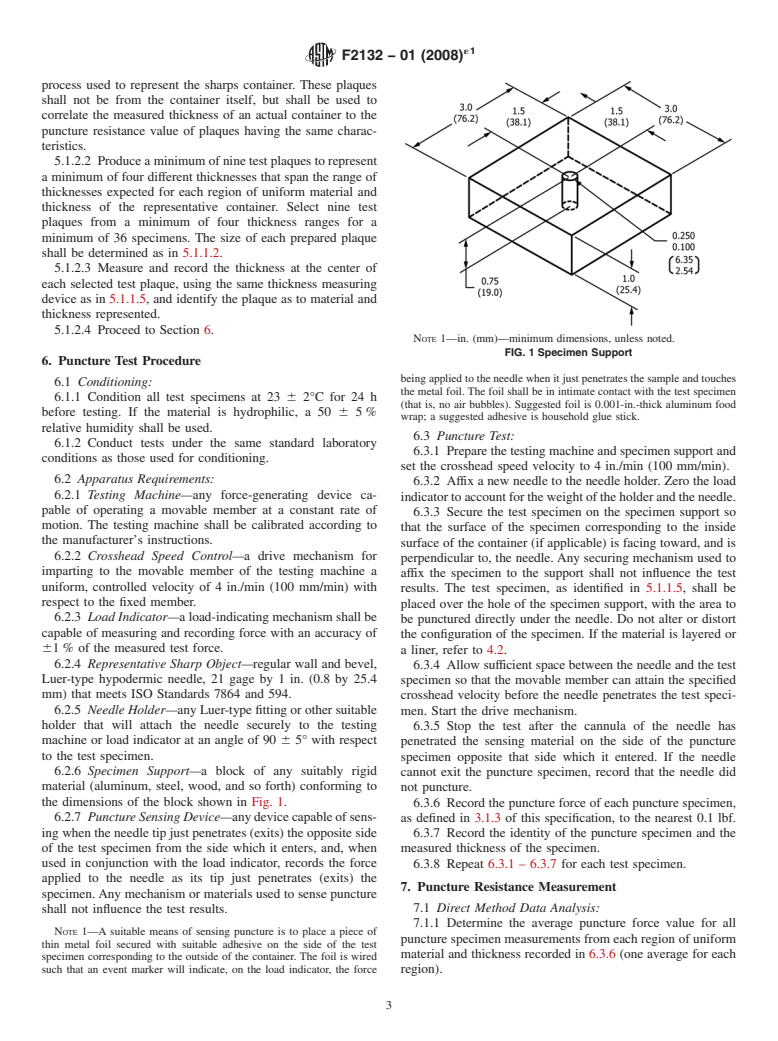

NOTE 1—in. (mm)—minimum dimensions, unless noted.

FIG. 1Specimen Support

6. Puncture Test Procedure

being applied to the needle when it just penetrates the sample and touches

6.1 Conditioning:

the metal foil. The foil shall be in intimate contact with the test specimen

6.1.1 Condition all test specimens at 23 6 2°C for 24 h

(that is, no air bubbles). Suggested foil is 0.001-in.-thick aluminum food

before testing. If the material is hydrophilic, a 50 6 5%

wrap; a suggested adhesive is household glue stick.

relative humidity shall be used.

6.3 Puncture Test:

6.1.2 Conduct tests under the same standard laboratory

6.3.1 Prepare the testing machine and specimen support and

conditions as those used for conditioning.

set the crosshead speed velocity to 4 in./min (100 mm/min).

6.2 Apparatus Requirements:

6.3.2 Affix a new needle to the needle holder. Zero the load

6.2.1 Testing Machine—any force-generating device ca-

indicatortoaccountfortheweightoftheholderandtheneedle.

pable of operating a movable member at a constant rate of

6.3.3 Secure the test specimen on the specimen support so

motion. The testing machine shall be calibrated according to

that the surface of the specimen corresponding to the inside

the manufacturer’s instructions.

surface of the container (if applicable) is facing toward, and is

6.2.2 Crosshead Speed Control—a drive mechanism for

perpendicular to, the needle. Any securing mechanism used to

imparting to the movable member of the testing machine a

affix the specimen to the support shall not influence the test

uniform, controlled velocity of 4 in./min (100 mm/min) with

results. The test specimen, as identified in 5.1.1.5, shall be

respect to the fixed member.

placed over the hole of the specimen support, with the area to

6.2.3 Load Indicator—aload-indicatingmechanismshallbe

be punctured directly under the needle. Do not alter or distort

capable of measuring and recording force with an accuracy of

the configuration of the specimen. If the material is layered or

61 % of the measured test force.

a liner, refer to 4.2.

6.2.4 Representative Sharp Object—regular wall and bevel,

6.3.4 Allow sufficient space between the needle and the test

Luer-type hypodermic needle, 21 gage by 1 in. (0.8 by 25.4

specimen so that the movable member can attain the specified

mm) that meets ISO Standards 7864 and 594.

crosshead velocity before the needle penetrates the test speci-

6.2.5 Needle Holder—any Luer-type fitting or other suitable

men. Start the drive mechanism.

holder that will attach the needle securely to the testing

6.3.5 Stop the test after the cannula of the needle has

machine or load indicator at an angle of 90 6 5° with respect

penetrated the sensing material on the side of the puncture

to the test specimen.

specimen opposite that side which it entered. If the needle

6.2.6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.