ASTM D5828-97(2011)e1

(Test Method)Standard Test Method for Compatibility of Supplemental Coolant Additives (SCAs) and Engine Coolant Concentrates

Standard Test Method for Compatibility of Supplemental Coolant Additives (SCAs) and Engine Coolant Concentrates

SIGNIFICANCE AND USE

This test was developed to mimic the formation of insolubles observed in some heavy-duty diesel cooling systems during the mid 1980s. It measures the compatibility of SCA and coolant concentrate solutions according to their tendency to form insolubles in service. Such insoluble materials may accumulate within a cooling system, restrict heat transfer through radiator cores, and contribute to the damage of components such as water pumps.

SCOPE

1.1 This test method covers determination of the compatibility of commercial SCA and commercial ethylene and propylene glycol engine coolant concentrates. This test method focuses on the solubility of specific chemical species formed in the engine coolant. The short duration of the test (24 h), among other restrictions, makes the test method of limited use for sorting out a variety of chemical compatibility problems in which a component of the SCA may react with a component of the coolant additive package. The test as currently written also does not deal with the issue of hard water compatibility, in which a component of the coolant or SCA additive package reacts with the hardness (Ca and Mg) to form a precipitate.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5828 − 97 (Reapproved 2011)

Standard Test Method for

Compatibility of Supplemental Coolant Additives (SCAs) and

Engine Coolant Concentrates

This standard is issued under the fixed designation D5828; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial corrections to Section 7 were made in June 2011.

INTRODUCTION

Supplemental coolant additives (SCAs) are used to impart special properties, usually resistance to

cavitation corrosion, to engine coolants used in diesel engines with replaceable cylinder liner sleeves.

Engines with this design require additives that are not normally found in commercial engine coolant

concentrates.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers determination of the compat-

D1193 Specification for Reagent Water

ibility of commercial SCA and commercial ethylene and

D1796 Test Method for Water and Sediment in Fuel Oils by

propylene glycol engine coolant concentrates.This test method

the Centrifuge Method (Laboratory Procedure)

focuses on the solubility of specific chemical species formed in

D3585 Specification forASTM Reference Fluid for Coolant

the engine coolant.The short duration of the test (24 h), among

Tests

other restrictions, makes the test method of limited use for

sorting out a variety of chemical compatibility problems in

3. Terminology

which a component of the SCAmay react with a component of

the coolant additive package. The test as currently written also

3.1 Definitions of Terms Specific to This Standard:

does not deal with the issue of hard water compatibility, in

3.1.1 engine coolant concentrate—an undiluted ethylene or

which a component of the coolant or SCA additive package

propylene glycol containing additives and only a small amount

reacts with the hardness (Ca and Mg) to form a precipitate.

of water, usually less than 5 %.

1.2 The values stated in SI units are to be regarded as the

3.1.2 reference engine coolant concentrate—a standard ma-

standard. The values given in parentheses are for information

terial prepared according to the formulary given in Annex A2

only.

of this test method. This material should not be confused with

1.3 This standard does not purport to address all of the

reference coolant in accordance with Specification D3585.

safety concerns, if any, associated with its use. It is the

3.1.3 reference supplemental coolant additive (SCA)—a

responsibility of the user of this standard to establish appro-

standard SCA prepared according to the formulary given in

priate safety and health practices and determine the applica-

Annex A1 of this test method.

bility of regulatory limitations prior to use.

3.1.4 supplemental coolant additive—a liquid or solid ma-

2. Referenced Documents

terial that is added to a coolant at a specified concentration.

2.1 ASTM Standards:

4. Summary of Test Method

This test method is under the jurisdiction ofASTM Committee D15 on Engine

4.1 A mixture of engine coolant concentrate and deionized

CoolantsandRelatedFluidsandisthedirectresponsibilityofSubcommitteeD15.11

water containing approximately twice the recommended con-

on Heavy Duty Coolants.

centration of SCA is heated to 88°C (190°F) for 24 h. The

CurrenteditionapprovedJan.1,2011.PublishedJune2011.Originallypublished

solution is centrifuged after returning to ambient temperature,

as D5828 – 95. Last previous edition approved in 2002 as D5828– 97 (2002). DOI:

10.1520/D5828-97R11.

and the amount of insoluble material is determined volumetri-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

cally and compared to the amount of insolubles obtained with

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

a mixture of standard reference SCA and reference engine

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. coolant.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5828 − 97 (2011)

5. Significance and Use 7.5 Nichrome Wire, or stainless steel wire.

5.1 This test was developed to mimic the formation of 7.6 Filter Paper, Whatman No. 4 or equivalent.

insolublesobservedinsomeheavy-dutydieselcoolingsystems

7.7 Plastic Containers, to store solutions. Polyethylene or

during the mid 1980s. It measures the compatibility of SCA

polypropylene containers with screw caps are satisfactory.

and coolant concentrate solutions according to their tendency

7.8 Acetone. WARNING: Acetone is flammable.

to form insolubles in service. Such insoluble materials may

accumulate within a cooling system, restrict heat transfer

7.9 Isopropyl Alcohol.

through radiator cores, and contribute to the damage of

8. Procedure

components such as water pumps.

8.1 Compatibility testing of SCAshall be conducted using a

6. Apparatus

ratio of 60 parts of coolant concentrate to 40 parts of a

6.1 Two-pan General Laboratory Balance, 1 to 2-kg capac-

water-SCA mixture. The level of SCA in the total 60:40

ity.

mixture will be approximately twice the SCA manufacturer’s

6.2 Centrifuge Tube, 100-mL capacity in accordance with recommended concentration.

Test Method D1796.

8.2 Fill a 100-mL centrifuge tube to the 60-mL mark with

6.3 Centrifuge, capable of maintaining 500 rcf, with trun- coolant concentrate.

nions and specimen holders suitable for the tube described in

8.3 Determine the volume of water to be added based on the

6.2.

physical state and the recommended concentration of SCA to

6.4 Constant Temperature Oil Bath, or equivalent, capable be evaluated. Add this volume of water to the centrifuge tube

of maintaining the test temperature at 88°C (190°F), within using a graduated cylinder. For example, if the SCAis a liquid

to be added at the recommended concentration of 3 % by

61°C (2°F).

volume, twice the recommended concentration is 6 % or 6 mL.

6.5 Condenser Tube, glass, approximately 5-mm outside

The volume of water to be added is 34 mL. This is 100 mL

diameter by 3-mm inside diameter by 300-mm long.

(volume of the centrifuge tube) less 60 mL(volume of coolant

6.6 Rubber Stoppers, to fit the centrifuge tube with a single

concentrate required) less 6 mL (volume of SCA required).

hole for the glass condenser tube.

NOTE1—Usinghardwaterwillgreatlyinfluencetheamountofsolubles

6.7 Rubber Stoppers, as above but without a hole.

formed. Testing the purity of the water with a conductivity meter is

recommended.

6.8 Graduated Cylinder, 100-mL capacity to deliver.

NOTE 2—If the SCA is a solid, prepare a sufficient volume of a

6.9 Pipette, to deliver volumes from 1 to 10 mL in 1-mL concentrated solution of the SCA in deionized water.

increments.

8.4 Pipette the required volume of SCA into the mixture of

coolantconcentrateandwater.Thesequenceofmixingmustbe

6.10 Analytical Balance, for preparing reference materials

as follows: coolant concentrate, water, SCAsolution. Cap with

and capable of weighing within an accuracy of 60.2 mg or

a solid rubber stopper and agitate thoroughly.

better.

NOTE 3—Glycol and water mixtures exhibit a volume contraction due

7. Reagents and Materials

to the partial molal volume effect. The final volume of the mixture should

7.1 Purity of Reagents—Regent grade chemicals shall be

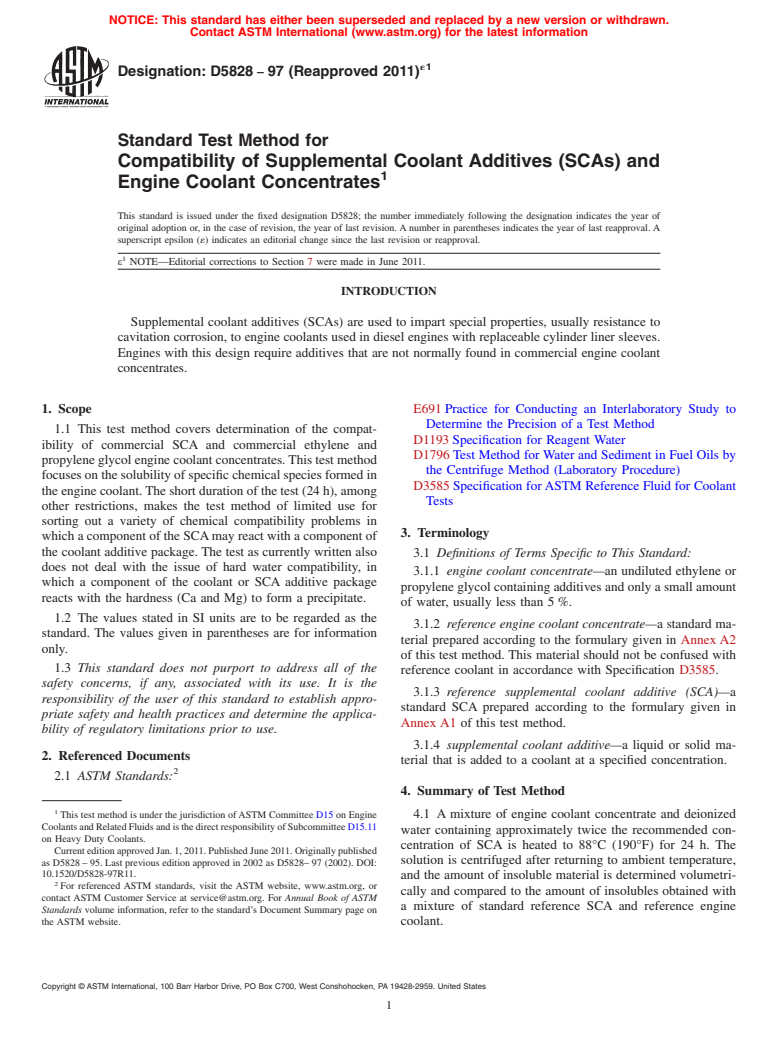

be less than 100 mL, as indicated in Fig. 1.

used in all tests. Unless otherwise indicated, it is intended that

8.5 In a similar manner, add 60 mL of reference coolant

all reagents conform to the specifications of the Committee on

concentrate, 34 mL of deionized water, and 6 mL of reference

Analytical Reagents of the American Chemical Society where

SCA solution to a second 100-mL centrifuge tube, and agitate

such specifications are available. Other grades may be used,

thoroughly. The reference coolant must be used within 30 days

provided it is first ascertained that the reagent is of sufficiently

of preparation. Discard and prepare a new reference if any

high purity to permit its use without lessening the accuracy of

insoluble material is observed.

the determination.

8.6 Replace the rubber stoppers with clean air condensers

7.2 Coolant Concentrate, and SCA for evaluation.

prepared by inserting a 300-mm (12-in.) length of glass tubing

7.3 Reference SCA, and coolant concentrate solutions (see through a properly sized one-hole stopper.

Annex A1 and Annex A2).

8.7 Insert a length of dry Nichrome or stainless steel wire

7.4 Deionized Water, in accordance with Specification into the condenser past the bottom of the condenser tube.

D1193. Immerse the centrifuge tube to the level of the solution in a

constanttemperaturebathat88°C(190°F)for24h(seeFig.1).

Hercamp and Hudgens, “Silicate Gelation in Heavy-Duty Engine Cooling

NOTE 4—The purpose of the wire is to provide a means of directing

Systems,” Paper No. 852327, Society of Automotive Engineers, December 1985.

condensate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.