ASTM D5752-10(2017)

(Specification)Standard Specification for Supplemental Coolant Additives (SCAs) for Use in Precharging Coolants for Heavy-Duty Engines

Standard Specification for Supplemental Coolant Additives (SCAs) for Use in Precharging Coolants for Heavy-Duty Engines

ABSTRACT

This specification covers the general, physical, chemical, and performance requirements for supplemental coolant additives for use as precharging coolants in the cooling systems of heavy-duty engines. Test solutions shall be standard corrosive water, ethylene or propylene glycol in standard corrosive water, and NaCl dissolved in a solution of glycol in deionized water. These test solutions shall comply to the specific limits for the following requirements: corrosion in glassware mass loss; simulated service test mass loss; foaming; water pump cavitation erosion-corrosion rating; corrosion of cast aluminum alloys at heat-rejecting surfaces; ultrasonic cavitation resistance; supplemental coolant additive-glycol base coolant compatibility; hot surface scaling and deposits resistance; effect on nonmetals; storage stability; ash, chloride ion, and silicon contents; pH in distilled water; reserve alkalinity; and the effect on vehicle finish.

SCOPE

1.1 This specification covers the general, physical, chemical, and performance requirements for Supplemental Coolant Additives (SCAs) at a precharged level in the cooling systems of heavy-duty engines.

Note 1: After precharging, SCAs are customarily used periodically to service cooling systems at 1/4 to 1/3 the precharged dosage to compensate for additives lost through dilution and depletion.

1.2 The SCA products meeting this specification are intended for use with water, with recommended dilutions of coolant concentrates, with prediluted engine coolants, or to upgrade the performance of light-duty engine coolants to meet the heav-duty requirements of Specification D6210. Engine coolant products shall be of the low-silicate type and, if ethylene glycol based, shall meet Specification D4985. Propylene glycol base low-silicate type coolant products may also be used, if these materials meet the chemical and performance requirements of Specification D4985.

1.3 The SCA concentrate, before dissolution, may be in either liquid, solid, or slurry form. The form is as agreed upon between the manufacturer and the user.

1.4 The values stated in SI units are to be regarded as standard. The inch-pound units in parentheses are approximate equivalents provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D5752 −10 (Reapproved 2017)

Standard Specification for

Supplemental Coolant Additives (SCAs) for Use in

1,2

Precharging Coolants for Heavy-Duty Engines

This standard is issued under the fixed designation D5752; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This specification covers the general, physical,

chemical, and performance requirements for Supplemental

2. Referenced Documents

CoolantAdditives (SCAs) at a precharged level in the cooling

systems of heavy-duty engines. 2.1 ASTM Standards:

D512Test Methods for Chloride Ion In Water

NOTE 1—After precharging, SCAs are customarily used periodically to

D516Test Method for Sulfate Ion in Water

1 1

service cooling systems at ⁄4 to ⁄3 the precharged dosage to compensate

D1119Test Method for Percent Ash Content of Engine

for additives lost through dilution and depletion.

Coolants

1.2 The SCA products meeting this specification are in-

D1121Test Method for Reserve Alkalinity of Engine Cool-

tended for use with water, with recommended dilutions of

ants and Antirusts

coolant concentrates, with prediluted engine coolants, or to

D1126Test Method for Hardness in Water

upgrade the performance of light-duty engine coolants to meet

D1193Specification for Reagent Water

the heav-duty requirements of Specification D6210. Engine

D1287TestMethodforpHofEngineCoolantsandAntirusts

coolant products shall be of the low-silicate type and, if

D1293Test Methods for pH of Water

ethyleneglycolbased,shallmeetSpecificationD4985.Propyl-

D1384Test Method for Corrosion Test for Engine Coolants

ene glycol base low-silicate type coolant products may also be

in Glassware

used, if these materials meet the chemical and performance

D1881Test Method for Foaming Tendencies of Engine

requirements of Specification D4985.

Coolants in Glassware

1.3 The SCA concentrate, before dissolution, may be in

D1882Test Method for Effect of Cooling System Chemical

either liquid, solid, or slurry form. The form is as agreed upon

Solutions on Organic Finishes for Automotive Vehicles

between the manufacturer and the user.

D2570TestMethodforSimulatedServiceCorrosionTesting

of Engine Coolants

1.4 The values stated in SI units are to be regarded as

standard.The inch-pound units in parentheses are approximate D2809Test Method for Cavitation Corrosion and Erosion-

Corrosion Characteristics of Aluminum Pumps With En-

equivalents provided for information only.

gine Coolants

1.5 This standard does not purport to address all of the

D3634Test Method for Trace Chloride Ion in Engine Cool-

safety concerns, if any, associated with its use. It is the

ants

responsibility of the user of this standard to establish appro-

D4327Test Method forAnions in Water by Suppressed Ion

priate safety and health practices and determine the applica-

Chromatography

bility of regulatory limitations prior to use.

D4340Test Method for Corrosion of CastAluminumAlloys

1.6 This international standard was developed in accor-

in Engine Coolants Under Heat-Rejecting Conditions

dance with internationally recognized principles on standard-

D4985Specification for Low Silicate Ethylene Glycol Base

ization established in the Decision on Principles for the

Engine Coolant for Heavy Duty Engines Requiring a

Development of International Standards, Guides and Recom-

Pre-Charge of Supplemental Coolant Additive (SCA)

D5827Test Method for Analysis of Engine Coolant for

Chloride and Other Anions by Ion Chromatography

ThisspecificationisunderthejurisdictionofASTMCommitteeD15onEngine

Coolants and Related Fluids and is the direct responsibility of Subcommittee

D15.07 on Specifications.

Current edition approved April 1, 2017. Published April 2017. Originally

approved in 1995. Last previous edition approved in 2010 as D5752-10. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D5752-10R17. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Supporting data have been filed atASTM International Headquarters and may Standards volume information, refer to the standard’s Document Summary page on

be obtained by requesting Research Report: RR:D15-1024. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5752−10 (2017)

D5828Test Method for Compatibility of Supplemental SCAs be used only in conjunction with coolant products

Coolant Additives (SCAs) and Engine Coolant Concen- meeting Specification D4985.

trates

4. Preparation of Test Solutions

D6129Test Method for Silicon in Engine Coolant Concen-

4.1 The preparation of test solutions for this specification is

trates by Atomic Absorption Spectroscopy

listed in Table 1. The glycol used, either ethylene glycol or

D6130Test Method for Determination of Silicon and Other

propylene glycol, shall meet Specification E1177. Where

Elements in Engine Coolant by Inductively Coupled

distilled water is required, it shall conform to Type IV of

Plasma-Atomic Emission Spectroscopy

Specification D1193.

D6210Specification for Fully-Formulated Glycol Base En-

gine Coolant for Heavy-Duty Engines

4.2 The quantity of any freshly prepared test solution

D6471Specification for Recycled Prediluted Aqueous Gly-

required in this specification shall be sufficient to perform the

col Base Engine Coolant (50 Volume % Minimum) for

specific tests. However, no test solution shall be stored longer

Automobile and Light-Duty Service

than 96 h before initiation of a specific procedure.

D6472SpecificationforRecycledGlycolBaseEngineCool-

5. Detailed Requirements

ant Concentrate for Automobile and Light-Duty Service

E1177Specification for Engine Coolant Grade Glycol

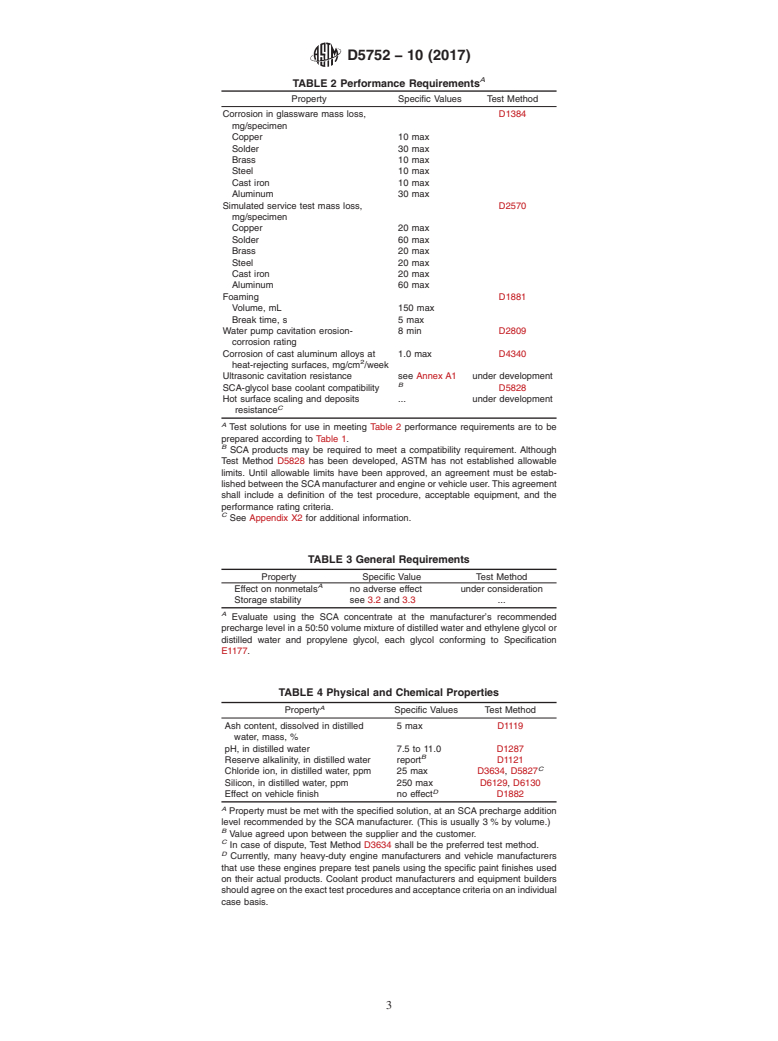

5.1 Test solutions prepared according to Table 1 shall meet

G32Test Method for Cavitation Erosion Using Vibratory

the performance requirements in Table 2, the general require-

Apparatus

ments in Table 3, and the physical and chemical requirements

2.2 Other Document:

in Table 4.

Federal Method 2540BTotal Dissolved Solids Dried at

5.2 TheSCAsshalladditionallyprovideaddedprotectionin

103–105°C

operating engines against cavitation corrosion (also termed

liner pitting) and against scaling of internal engine hot sur-

3. General Requirements

faces. Hot surfaces are typically within the engine head, head

3.1 The SCA concentrate upon addition to water or water/

spacer, or liquid-cooled exhaust manifold, oil coolers, after

glycol mixtures at the SCA manufacturer’s recommended

coolers, and exhaust gas recirculation (EGR) coolers. The

addition level shall provide the same performance as coolants

American Society for Testing and Materials has test methods

meeting Specification D6210, except for freeze and boil

under development for both cavitation corrosion and hot

protection.

surfaces scaling. Until these procedures are adopted asASTM

3.2 Liquid SCAconcentrates shall be storable in the manu- standards, the mandatory requirements of Annex A1 shall

facturer’soriginalcontainerattemperaturesfrom−7to+55°C apply.

(20 to 130°F) without chemical change. Any precipitation of

6. Keywords

ingredientsevidencedbythedropoutofsolidmaterialorliquid

6.1 heavy-duty engine coolants; precharging heavy-duty

turbidity shall disappear upon agitation and warming of the

engines; SCA; supplemental coolant additives

solution to a temperature exceeding 2°C (35°F).

3.3 Solid, slurry, and paste forms of SCA concentrate shall

TABLE 1 Composition of Test Solutions for Table 2 Performance

A

be so formulated and packaged as to prevent chemical or Requirements

physical change during storage before use. This requirement Test Method SCA Concentrate Solvent Mixture

B

applies to storage temperatures of −7 to+55°C (20 to 130°F), D1384 one-half manufacturer’s standard corrosive water

recommended precharged

regardless of humidity.

level

D1384 three times manufacturer’s 33 vol % glycol in standard

3.4 The SCA concentrates, when used according to the

B, C

recommended precharged corrosive water

manufacturer’s recommendations, shall dissolve totally in the

level

test solutions required in this specification. A light haze is

D1881 manufacturer’s recommended 33 vol % glycol in standard

B, C

precharge level corrosive water

permitted.

D2570 manufacturer’s recommended 44 vol % glycol in standard

B, C

3.5 If an engine, vehicle, or servicing organization recom- precharge level corrosive water

D2809 manufacturer’s recommended 16.7 vol % glycol in standard

mends adding a precharge dosage of an SCAproduct to a fully

B, C

precharge level corrosive water

formulated coolant governed by Specification D6210, that

D4340 manufacturer’s recommended 165-mg/L NaCl dissolved in a

organization assumes responsibility for determining the com- precharge level 1-L solution of 25 vol %

C, D

glycol in deionized water

patibilityandconductingsuitabletests.ASTMhasdevelopeda

A

Test solution to be prepared according to Section 4.

compatibility test (Test Method D5828), which may be used.

B

See Section 7 of Test Method D2570 for composition and method of preparation

At the present time, it is recommended that precharge doses of

of standard corrosive water.

C

The glycol used shall be ethylene glycol or propylene glycol and each shall meet

Specification E1177.

D

Standard Method for the Examination of Water and Wastewater, American Water conforming to Type IV of Specification D1193 is acceptable.

Public Health Association, et al, 1015 15th Street, N.W. Washington, DC 20005.

D5752−10 (2017)

A

TABLE 2 Performance Requirements

Property Specific Values Test Method

Corrosion in glassware mass loss, D1384

mg/specimen

Copper 10 max

Solder 30 max

Brass 10 max

Steel 10 max

Cast iron 10 max

Aluminum 30 max

Simulated service test mass loss, D2570

mg/specimen

Copper 20 max

Solder 60 max

Brass 20 max

Steel 20 max

Cast iron 20 max

Aluminum 60 max

Foaming D1881

Volume, mL 150 max

Break time, s 5 max

Water pump cavitation erosion- 8min D2809

corrosion rating

Corrosion of cast aluminum alloys at 1.0 max D4340

heat-rejecting surfaces, mg/cm /week

Ultrasonic cavitation resistance see Annex A1 under development

B

SCA-glycol base coolant compatibility D5828

Hot surface scaling and deposits . under development

C

resistance

A

Test solutions for use in meeting Table 2 performance requirements are to be

prepared according to Table 1.

B

SCA products may be required to meet a compatibility requirement. Although

Test Method D5828 has been developed, ASTM has not established allowable

limits. Until allowable limits have been approved, an agreement must be estab-

lished between the SCA manufacturer and engine or vehicle user. This agreement

shall include a definition of the test procedure, acceptable equipment, and the

performance rating criteria.

C

See Appendix X2 for additional information.

TABLE 3 General Requirements

Property Specific Value Test Method

A

Effect on nonmetals no adverse effect under consideration

Storage stability see 3.2 and 3.3 .

A

Evaluate using the SCA concentrate at the manufacturer’s recommended

precharge level in a 50:50 volume mixture of distilled water and ethylene glycol or

distilled water and propylene glycol, each glycol conforming to Specification

E1177.

TABLE 4 Physical and Chemical Properties

A

Property Specific Values Test Method

Ash content, dissolved in distilled 5 max D1119

water, mass, %

pH, in distilled water 7.5 to 11.0 D1287

B

Reserve alkalinity, in distilled water report D1121

C

Chloride ion, in distilled water, ppm 25 max D3634, D5827

Silicon, in distilled water, ppm 250 max D6129, D6130

D

Effect on vehicle finish no effect D1882

A

Property must be met with the specified solution, at an SCA precharge addition

level recommended by the SCA manufacturer. (This is usually 3 % by volume.)

B

Value agreed upon between the supplier and the customer.

C

In case of dispute, Test Method D3634 shall be the preferred test method.

D

Currently, many heavy-duty engine manufacturers and vehicle manufacturers

that use these engines prepare test panels using the specific paint finishes used

on their actual products. Coolant product manufacturers and equipment builders

should agree on the exact test procedures and acceptance criteria on an individual

case basis.

D5752−10 (2017)

ANNEX

(Mandatory Information)

A1. CHEMICAL REQUIREMENTS FOR SCAs

A1.1 Test methods to determine cavitation corrosion resis- A1.2.3 In-service qualification tests may consist of single-

tance are under development. Several chemical compositions ormultiple-cylinderenginetests.Attheoptionoftheengineor

of SCAs have been extensively tested by producers and users vehicle manufacturer, such testing may be conducted in “loose

andfoundtominimizesatisfactorilycylinderlinercavitationin engines” or in engines fully integrated into an application such

actual test engines. Until such time as an ASTM procedure is as a vehicle, a power boat, or a stationary power source. One

adopted that effectively evaluates cylinder liner cavitation such test has been developed.

corrosion, SCA formulations under this specification shall

A1.3 Chemical composition requirements for cavitation

provide the following when used at the SCA manufacturer’s

corrosion protection will be removed from this specification

recommended precharge addition level:

and replaced with anASTM test method when a test method is

−

A1.1.1 Aminimumconcentrationofnitriteas(NO )inthe

developed and adopted.

cooling system of 1200 ppm, or

A1.4 No specific chemical composition requirements for

A1.1.2 A minimum combined concentration of nitrite as

− −2

hot surface scaling and deposit resistance have been estab-

(NO ) plus molybdate as (MoO ) in the cooling system of

2 4

− −2

lished at this time. A test procedure for this property is under

780ppm.Atleast300ppmeachofNO andMoO mustbe

2 4

development and will be incorporated into Table 2 when a

present.

procedure is approved by ASTM.

A1.1.3 Concentrations below the minimums detailed in

A1.1.1 and A1.1.2 may not provide sufficient protection. (See

A1.5 Lack of compatibility between the coolant and SCA

X1.1.3.2 for further information.)

product’s chemistry results in chemical ingredient dropout

from solution, with potential ad

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.