ASTM A627-03(2011)

(Test Method)Standard Test Methods for Tool-Resisting Steel Bars, Flats, and Shapes for Detention and Correctional Facilities

Standard Test Methods for Tool-Resisting Steel Bars, Flats, and Shapes for Detention and Correctional Facilities

SIGNIFICANCE AND USE

Security barriers used in detention/correctional facilities are a major concern for their administrative officials. These test methods are designed to identify levels of physical security for openings such as fixed and operable exterior and interior windows, bar gratings, grilles for mechanical ducts, and so forth in walls that enclose or separate secure areas.

These test methods are intended to evaluate the resistance of these barriers to violent attacks using battering devices such as benches, bunks or tables, and so forth to bend or break the steel bars and to surreptitious attacks by cutting/abrading the steel bars over prolonged periods of time using handheld grit-type cutting/abrading media such as tungsten carbide rod saws. External attacks and attacks by corrosive agents and other means not typically available to inmates are not addressed in this standard.

The primary purpose or result of these test methods is to approximate the levels of abuse to which these physical security barriers will potentially be subjected in the correctional/detention facility. The desired result of its use is to help provide a degree of assurance of protection to the public, facility personnel, and inmates.

It is recommended that detention/correctional facility administrators provide for adequate training, supervision, regular inspection, and preventive maintenance programs to enable the barriers to function as intended throughout their expected service life.

SCOPE

1.1 These test methods cover requirements for simulated service tests and testing equipment for determining the performance characteristics of various types and shapes of steels designated for use in detention and correctional facilities as fixed barriers to prevent egress and to control passage.

1.2 It is the intent of these test methods to help ensure that opening assemblies such as detention security windows, grilles, bar grating, and other physical barriers incorporating steel bars perform at or above minimum acceptable levels for control of passage to unauthorized or secure areas, for confinement of inmates and to delay or frustrate escape attempts. To meet the intent of these test methods, opening assembles must perform to grade requirements shown in Tables X1.1 and X1.2 in Appendix X1.

1.3 These test methods apply primarily to the steels used as essential components of detention security windows, grilles, bar grating, and so forth, in opening assemblies enclosing or separating secure areas of detention/correctional facilities.

1.4 The values stated in inch-pound units are to be regarded as standard. The SI values given in parentheses are for information only.

1.5 This standard updates and combines two previous standards, ASTM Specifications A627-95 and A629-94, establishing new security grades and time durations.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A627 − 03 (Reapproved 2011)

Standard Test Methods for

Tool-Resisting Steel Bars, Flats, and Shapes for Detention

and Correctional Facilities

This standard is issued under the fixed designation A627; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 These test methods cover requirements for simulated

A629 Specification for Tool-Resisting Steel Flat Bars and

service tests and testing equipment for determining the perfor-

Shapes for Security Applications (Withdrawn 2004)

mance characteristics of various types and shapes of steels

C39/C39M Test Method for Compressive Strength of Cylin-

designated for use in detention and correctional facilities as

drical Concrete Specimens

fixed barriers to prevent egress and to control passage.

E4 Practices for Force Verification of Testing Machines

1.2 It is the intent of these test methods to help ensure that E18 Test Methods for Rockwell Hardness of Metallic Ma-

opening assemblies such as detention security windows, terials

E329 Specification for Agencies Engaged in Construction

grilles, bar grating, and other physical barriers incorporating

Inspection, Testing, or Special Inspection

steel bars perform at or above minimum acceptable levels for

control of passage to unauthorized or secure areas, for confine-

3. Terminology

ment of inmates and to delay or frustrate escape attempts. To

meet the intent of these test methods, opening assembles must 3.1 Definitions:

perform to grade requirements shown in Tables X1.1 and X1.2 3.1.1 bars, n—round, ribbed, hexagonal, or other shaped

bars that can be readily reduced to a round cross-sectional

in Appendix X1.

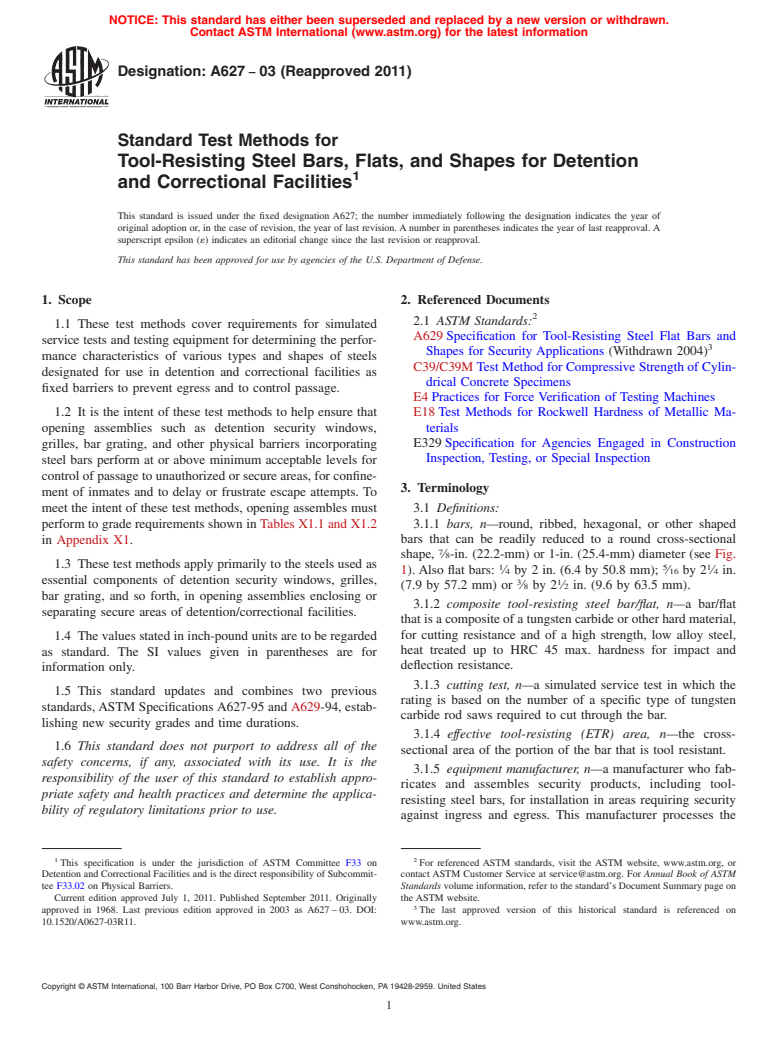

shape, ⁄8-in. (22.2-mm) or 1-in. (25.4-mm) diameter (see Fig.

1.3 These test methods apply primarily to the steels used as

1 5 1

1). Also flat bars: ⁄4 by 2 in. (6.4 by 50.8 mm); ⁄16 by 2 ⁄4 in.

essential components of detention security windows, grilles,

3 1

(7.9 by 57.2 mm) or ⁄8 by 2 ⁄2 in. (9.6 by 63.5 mm).

bar grating, and so forth, in opening assemblies enclosing or

3.1.2 composite tool-resisting steel bar/flat, n—a bar/flat

separating secure areas of detention/correctional facilities.

that is a composite of a tungsten carbide or other hard material,

for cutting resistance and of a high strength, low alloy steel,

1.4 The values stated in inch-pound units are to be regarded

heat treated up to HRC 45 max. hardness for impact and

as standard. The SI values given in parentheses are for

deflection resistance.

information only.

3.1.3 cutting test, n—a simulated service test in which the

1.5 This standard updates and combines two previous

rating is based on the number of a specific type of tungsten

standards,ASTM Specifications A627-95 and A629-94, estab-

carbide rod saws required to cut through the bar.

lishing new security grades and time durations.

3.1.4 effective tool-resisting (ETR) area, n—the cross-

1.6 This standard does not purport to address all of the

sectional area of the portion of the bar that is tool resistant.

safety concerns, if any, associated with its use. It is the

3.1.5 equipment manufacturer, n—a manufacturer who fab-

responsibility of the user of this standard to establish appro-

ricates and assembles security products, including tool-

priate safety and health practices and determine the applica-

resisting steel bars, for installation in areas requiring security

bility of regulatory limitations prior to use.

against ingress and egress. This manufacturer processes the

1 2

This specification is under the jurisdiction of ASTM Committee F33 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Detention and Correctional Facilities and is the direct responsibility of Subcommit- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tee F33.02 on Physical Barriers. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2011. Published September 2011. Originally the ASTM website.

approved in 1968. Last previous edition approved in 2003 as A627 – 03. DOI: The last approved version of this historical standard is referenced on

10.1520/A0627-03R11. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A627 − 03 (2011)

FIG. 1 Shaped Bars

semi-finished bar and fabricates finished products suitable for 4. Significance and Use

use in opening assemblies requiring these specified perfor-

4.1 Security barriers used in detention/correctional facilities

mance characteristics. This manufacturer is also responsible

are a major concern for their administrative officials.These test

forheattreating,fabricating,andassemblingallancillaryitems

methods are designed to identify levels of physical security for

so as not to impair the performance characteristics of the

openings such as fixed and operable exterior and interior

bar/flat.

windows, bar gratings, grilles for mechanical ducts, and so

3.1.6 hardness, n—indicated as HRC, refers to hardness

forth in walls that enclose or separate secure areas.

measured according to Test Methods E18 on the Rockwell C

4.2 These test methods are intended to evaluate the resis-

scale.

tanceofthesebarrierstoviolentattacksusingbatteringdevices

3.1.7 homogeneous tool-resisting bar/flat, n—a bar/flat that

such as benches, bunks or tables, and so forth to bend or break

is nominally of uniform chemistry throughout, usually high

the steel bars and to surreptitious attacks by cutting/abrading

strength,lowalloysteelheattreatedtoHRC61min.—HRC64

the steel bars over prolonged periods of time using handheld

max. hardness to a case depth of 0.150 in. min. for rounds and

grit-type cutting/abrading media such as tungsten carbide rod

each longitudinal edge hardened to 0.250-in. min. for flats.

saws. External attacks and attacks by corrosive agents and

3.1.8 lot, n—all bars/flats of the same nominal cross-

other means not typically available to inmates are not ad-

sectional dimensions from the same mill heat and production dressed in this standard.

lot.

4.3 The primary purpose or result of these test methods is to

3.1.9 performance characteristic, n—the response to any

approximate the levels of abuse to which these physical

one test (drop-weight, cutting, or deflection) shown in Tables

security barriers will potentially be subjected in the

X1.1 and X1.2.

correctional/detention facility.The desired result of its use is to

help provide a degree of assurance of protection to the public,

3.1.10 test completion, n—conduct one test sequence for

facility personnel, and inmates.

each lot of bars.

3.1.11 testing laboratory, n—approved third party testing

4.4 It is recommended that detention/correctional facility

laboratory, accredited to I.S.O. Standard 17025-99, selected by

administratorsprovideforadequatetraining,supervision,regu-

the equipment manufacturer.

lar inspection, and preventive maintenance programs to enable

the barriers to function as intended throughout their expected

3.1.12 test sequence:

service life.

3.1.12.1 round bars, n—conduct drop-weight test and cut-

ting test on one specimen bar and conduct deflection test on

5. Ordering Information

one additional specimen bar.

3.1.12.2 flat bar, n—conduct cutting test followed by hard- 5.1 Orders for material under this specification shall include

ness tests on the same flat bar. the following information:

A627 − 03 (2011)

5.1.1 Name of material (homogeneous tool-resisting steel or 6.1.2.6 All specimen bars used in all test sequences shall be

composite tool resisting steel), permanently marked for complete identification and held by

the equipment manufacturer for no less than three years after

5.1.2 Dimensions (nominal diameter or cross section),

the tests are completed.

5.1.3 Cross section (double-ribbed, round, hexagon, square,

rectangular, flat, or other shapes),

6.1.3 Procedure:

5.1.4 ASTM designation,

6.1.3.1 Conduct the test on one specimen bar selected as

5.1.5 Test reports (if required),

requiredin6.1.2.1–6.1.2.4inclusive;stopafter50consecutive

5.1.6 Certification (if required), and

blows, or sooner if the bar fails.

5.1.7 Special requirements (if any).

6.1.3.2 Drop the tup repeatedly so as to deliver 50 consecu-

tive blows at the same point on the specimen bar. It shall be

5.2 It is possible that bars of different nominal diameters/

properly weighted and guided so as to produce the required

shapes are specified or shown on drawings. Each bar of the

impact in foot-pounds for each blow.

nominal diameter/cross section shape tested shall meet or

exceed the minimum requirements of all tests for the diameter/

6.1.3.3 Apply each blow at the same point and on the same

shape shown in Tables X1.1 and X1.2. side of the specimen bar, perpendicular to the 14-in. (356-mm)

axis and at the midpoint (60.250 in. (66.4 mm)) between the

5.3 The minimum levels of performance per type of steel

supports of the specimen bar.

required in Tables X1.1 and X1.2 for each bar are not

6.1.3.4 To prevent an unmeasured secondary impact after

independent characteristics, but are interrelated to each other

each drop from the test height, make provisions in the testing

and though any one performance characteristic shall be per-

procedure to prevent the weighted tup from rebounding and

mitted to exceed the requirements, none of the other charac-

again striking the test specimen.

teristics shall be permitted to exhibit a performance lower than

6.1.3.5 The drop-weight machine is of simple design con-

the minimum performance levels shown.

structed from readily available rolled and shaped structural

steelproducts.Raisetheweightbyanymechanicalorelectrical

6. Mechanical Requirements

hoisting equipment or, alternatively, by hand. Provide a me-

6.1 Drop-Weight Test:

chanical or electrical mechanism to achieve quick release of

6.1.1 Requirements—The specimen bar shall not crack,

the weight. This testing machine shall conform to the require-

visibly fracture, or take a permanent set of more than 0.25 in.

ments of Sections 16 and 18 of Practices E4 as modified by the

(6.4 mm) at the midspan between support points under the

requirements of this specification or the manufacturer of the

impact of 50 consecutive blows of a force as specified in Table

testing machine, provided that modifications of this equipment

X1.1 under “Drop-Weight Test.”

or assembly details provide a functionally acceptable drop-

6.1.2 Number of Specimens:

weight machine.

6.1.2.1 The equipment manufacturer shall randomly select

6.1.3.6 For ⁄8-in. (22.2-mm) diameter bar, the drop-weight

three bars/flats no less than 4 ft (1.22 m) in length from the lot

machine shall drop a weight of 50 lb. (22.7 kg) from a height

for which the test is conducted. These 4-ft lengths shall be

of 2 ft (611 mm). For 1-in. (25.4-mm) diameter bar, the

permanently marked after production or heat treating for easy

drop-weight machine shall drop a weight of 50 lb. (22.7 kg)

identification of mill heat number, lot number, and individual

from a height of 3 ft (916 mm).

identification of the two specimen bars taken from each of the

6.1.3.7 The hardened tup that strikes the specimen bar shall

4-ft lengths.

be rounded initially to 0.250-in. (6.35-mm) radius and shall be

6.1.2.2 Two 14-in. (356-mm) specimen bars shall be cut

heat treated to a minimum hardness of HRC 50.

with a friction saw from each of the 4-ft lengths after heat

6.1.3.8 The entire tup and weight shall fall freely by gravity

treating. Each 14-in. specimen bar shall be permanently

when released and shall be inspected after each five blows to

marked for easy identification as to production, mill heat

determine that the original shape of the tup has not been

number, lot number, and identity of the longer bar from which

seriously deformed through repeated impact. If the 0.250-in.

it was taken.

radius is flattened to more than 0.312-in. radius, the test shall

6.1.2.3 The testing laboratory shall, as its own choice, select

be interrupted and the tup shall be restored to the 0.250-in.

two specimen bars taken from the same 4-ft length of bar for

radius before testing is continued.

conduct of each test sequence.

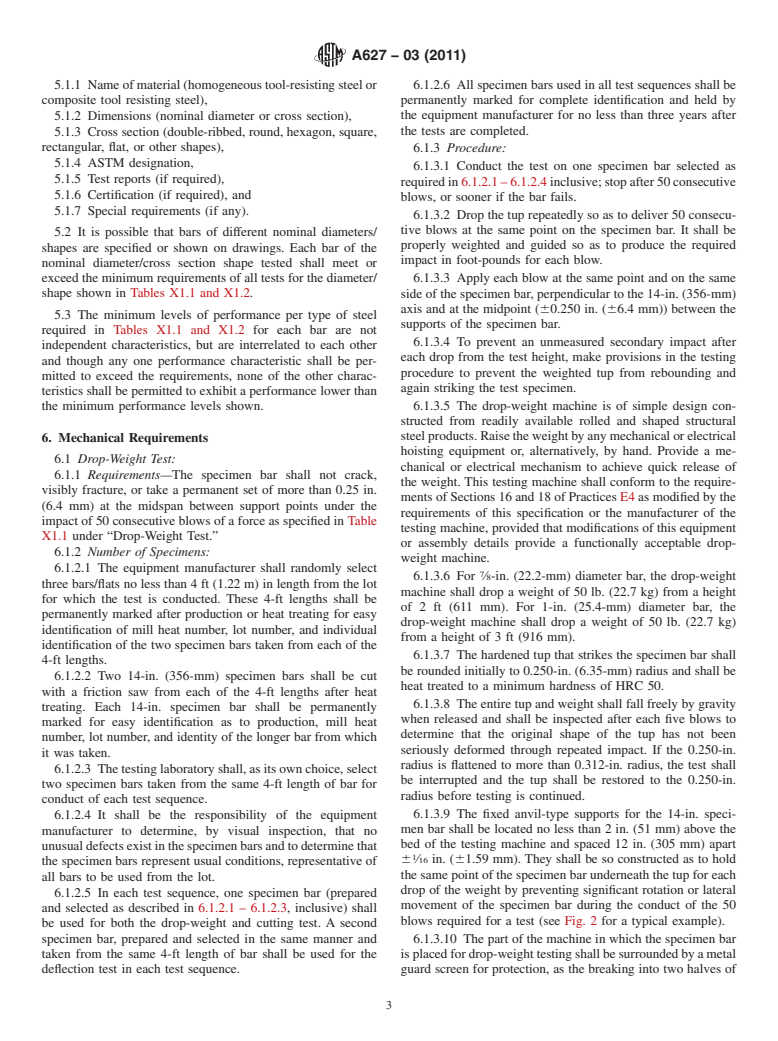

6.1.3.9 The fixed anvil-type supports for the 14-in. speci-

6.1.2.4 It shall be the responsibility of the equipment

men bar shall be located no less than 2 in. (51 mm) above the

manufacturer to determine, by visual inspection, that no

bed of the testing machine and spaced 12 in. (305 mm) apart

unusualdefectsexistinthespecimenbarsandtodeterminethat

6 ⁄16 in. (61.59 mm). They shall be so constructed as to hold

the specimen bars represent usual conditions, representative of

the same point of the specimen bar underneath the tup for each

all bars to be used from the lot.

drop of the weight by preventing significant rotation or lateral

6.1.2.5 In each test sequence, one specimen bar (prepared

movement of the specimen bar during the conduct of the 50

and selected as described in 6.1.2.1 – 6.1.2.3, inclusive) shall

blows required for a test (see Fig. 2 for a typical example).

be used for both the drop-weight and cutting test. A second

specimen bar, prepared and selected in the same manner and 6.1.3.10 The part of the machine in which the specimen bar

taken from the same 4-ft length of bar shall be used for the isplacedfordrop-weighttestingshallbesurroundedbyametal

deflection test in each test sequence. guard screen for protection, as the breaking into two halves of

A627 − 03 (2011)

FIG. 2 Typical Example of Drop-Weight Test Apparatus

the bar has the potential to cause them to be ejected laterally

60 = number of rod saws used in 18 000 cutting cycles

from the machine with projectile-like velocities (see Fig. 2 for

(300 cycles/rod saw).

a typical example).

6.2.1.2 Interpretation of Cutting Test Results—

6.1.3.11 The addition of other safety devices or features are

Homogeneous Tool-Resisting Bars/Flats—The cutting test

permitted provided that a functionally equivalent drop-weight

shall be performed with number of rod saws as required for

machine is maintained.

total severance.

6.1.3.12 The entire test machine shall be securely bolted to

6.2.1.3 Interpretation of Cutting Test Results--Composite

a rigid foundation, such as a concrete floor, so as to eliminate

Tool-Resisting Bars/Flats—The cutting test shall be performed

any possible cushioning effe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.