ASTM E73-83(2002)

(Practice)Standard Practice for Static Load Testing of Truss Assemblies

Standard Practice for Static Load Testing of Truss Assemblies

SCOPE

1.1 This practice is intended as a guide for use in the testing of truss assemblies fabricated from all types of construction materials. While the practice may be used for the testing of a variety of assemblies, it is primarily intended to be used in the testing of those trusses designed to be spaced at 1.2 m (48 in.) centers or greater. It can be used, but it is not normally intended, for the testing of wood residential trussed rafters. Either proof tests or tests to destruction may be run.

1.2 Limitations—It is not intended that this practice be used for routine quality control testing.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E73–83 (Reapproved 2002)

Standard Practice for

Static Load Testing of Truss Assemblies

ThisstandardisissuedunderthefixeddesignationE 73;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.3 For other definitions in this practice, see Terminology

E 631.

1.1 This practice is intended as a guide for use in the testing

of truss assemblies fabricated from all types of construction

4. Summary of Practice

materials. While the practice may be used for the testing of a

4.1 This practice outlines the procedures to be followed in

variety of assemblies, it is primarily intended to be used in the

the static load testing of major load carrying truss assemblies.

testing of those trusses designed to be spaced at 1.2 m (48 in.)

While the procedure tells what to do, it does not tell the testing

centers or greater. It can be used, but it is not normally

agency how to do it.This leaves the selection of the test fixture

intended, for the testing of wood residential trussed rafters.

and loading medium to the discretion of the testing agency.

Either proof tests or tests to destruction may be run.

Materials selection, sampling, conditioning, fabrication, test

1.2 Limitations—It is not intended that this practice be used

procedures, and report requirements are covered.

for routine quality control testing.

4.2 Two types of tests may be conducted using this practice:

1.3 This standard does not purport to address all of the

4.2.1 Proof Tests—A proof test is frequently made to

safety concerns, if any, associated with its use. It is the

provide assurance that the truss will support a stated load or to

responsibility of the user of this standard to establish appro-

determine the deformations and structural response under a

priate safety and health practices and determine the applica-

specified loading.

bility of regulatory limitations prior to use. For specific hazard

4.2.2 Test to Failure—In testing to failure, more detailed

statements, see Section 7.

information is generally desired such as ultimate load carrying

2. Referenced Documents capacity, total load-deflection history, yield point, connection

performance, factor of safety, etc.

2.1 ASTM Standards:

4.2.3 If desired, either type of test may be extended to

E 196 Practice for Gravity Load Testing of FloorsAnd Flat

2 include a determination of the magnitude and distribution of

Roofs

the stresses in the members and connections in order to permit

E 575 Practice for Reporting Data from Structural Tests of

a more comprehensive analysis of the truss performance.

Building Constructions, Elements, Connections, and As-

semblies

5. Significance and Use

E 631 Terminology of Building Constructions

5.1 This practice provides a guide to any individual, group,

3. Terminology agency, or code body on the methods of test for truss

assemblies fabricated from all types of construction materials.

3.1 truss—a coplanar system of structural elements joined

Sample size is generally kept to a minimum to reduce costs.

together at their ends usually to construct a series of triangles

The methods may be used to apply proof loads to an assembly

that form a stable beam-like framework.

or to test it to failure. Information obtained includes strength

3.2 static load—a load or series of loads that are supported

and stiffness data, and if assemblies are tested to their ultimate

by or are applied to a structure so gradually that forces caused

loadcarryingcapacity,thefailuremethodormechanismcanbe

by change in momentum of the load and structural elements

observed.

can be neglected and all parts of the system at any instant are

essentially in equilibrium.

6. Test Apparatus

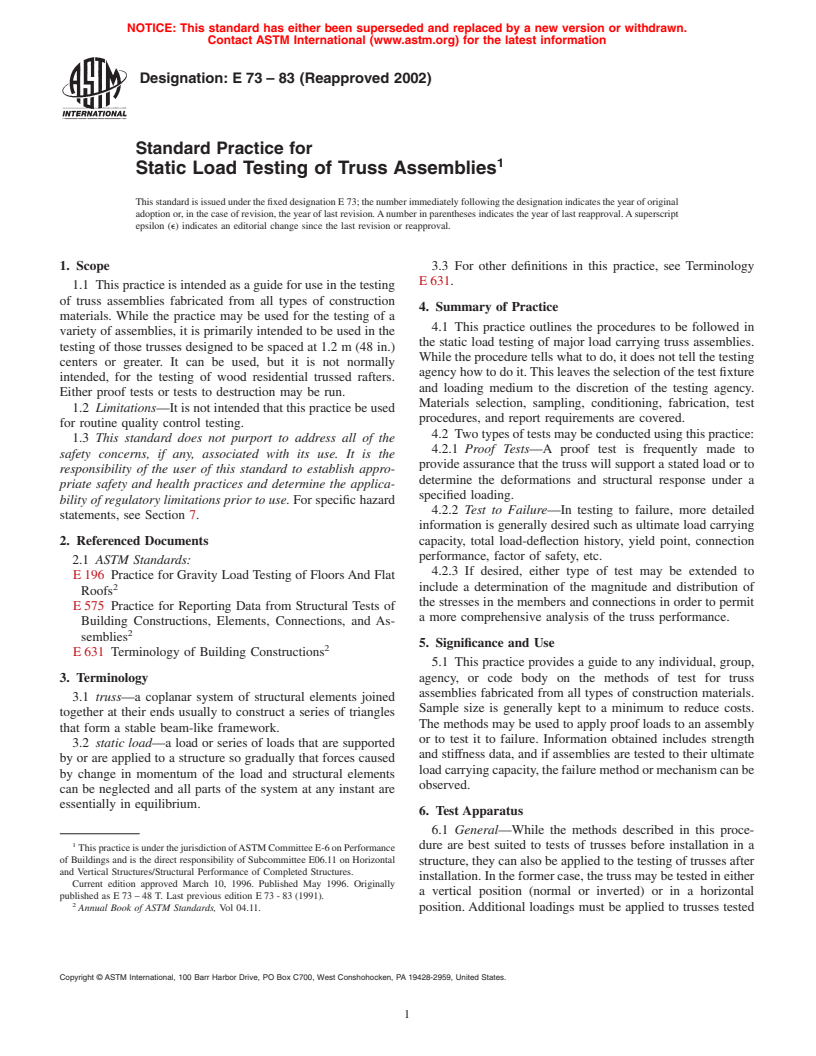

6.1 General—While the methods described in this proce-

dure are best suited to tests of trusses before installation in a

ThispracticeisunderthejurisdictionofASTMCommitteeE-6onPerformance

of Buildings and is the direct responsibility of Subcommittee E06.11 on Horizontal

structure, they can also be applied to the testing of trusses after

and Vertical Structures/Structural Performance of Completed Structures.

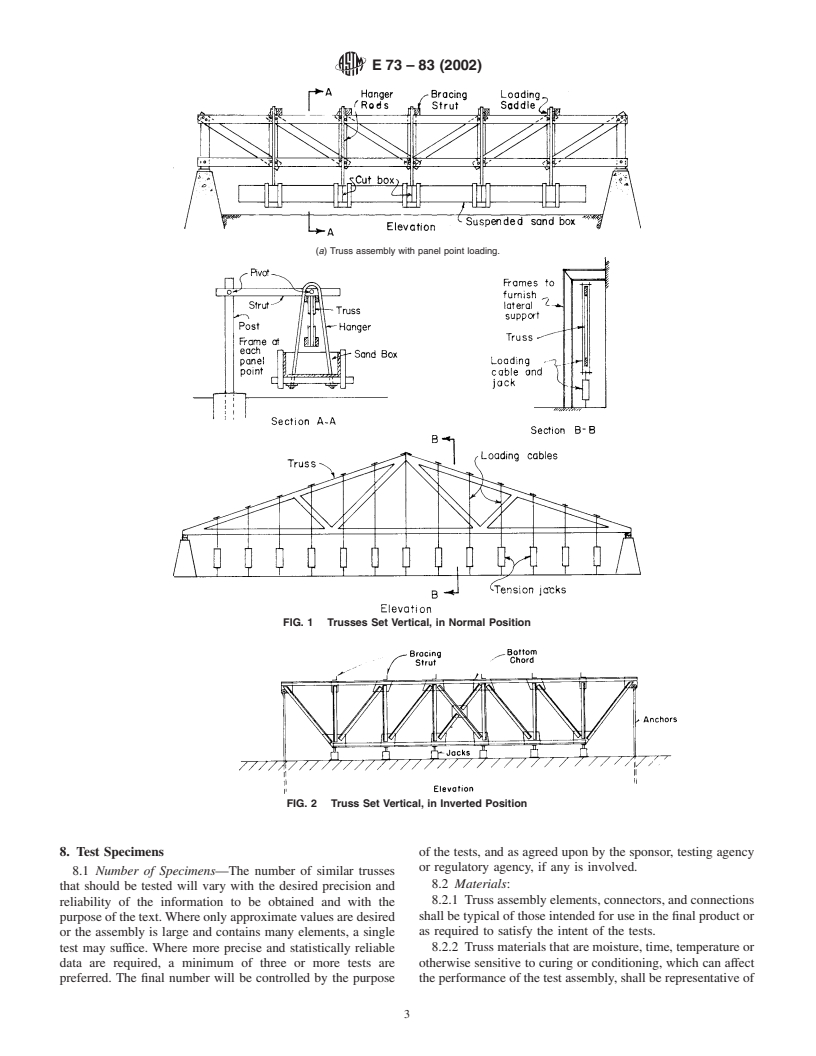

installation. In the former case, the truss may be tested in either

Current edition approved March 10, 1996. Published May 1996. Originally

a vertical position (normal or inverted) or in a horizontal

published as E 73 – 48 T. Last previous edition E 73 - 83 (1991).

Annual Book of ASTM Standards, Vol 04.11. position. Additional loadings must be applied to trusses tested

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E73–83 (2002)

in an inverted or horizontal position to compensate for the used, care shall be taken to compartmentalize the water in cells

effect of dead loads and gravity. Regardless of the orientation topreventanon-uniformloadasthetrussandelementsdeflect.

of the truss in the test fixture, the fixture and load application

Air bags reacting against restraint frames have also been used.

means shall be designed with an ample margin of safety to

6.4 Load and Deflection Measuring Devices

ensure that it is the test specimen that is being tested and not

6.4.1 Load Measuring Devices—Loads may be measured

the test fixture. More information on the testing of components

using one or more of the following devices. Pressure gages or

in existing structures is contained in Practice E 196.

hydraulic load cells can be incorporated into a hydraulic

6.2 Supports and Reactions:

loading system. These devices must be calibrated with the

6.2.1 The reaction supports shall provide sufficient clear-

jacks or cylinders at different positions of piston travel to

ance above the ground or restraint frame to allow for normal

ensure a true loading history. Spring dynamometers, electronic

displacements, ease of loading, instrumentation, and provide

load cells, or the weighing tables of universal testing machines

room for observations and measurements. Supports shall have

havealsobeensuccessfullyused.Theloadmeasuringdeviceor

adequate strength and stiffness to resist deformations during

devices used shall be capable of measuring loads to an

tests.

accuracy of 6 2 % of design load.

6.2.2 Support reaction hardware shall be typical of that

6.4.2 Deflection Measuring Devices:

planned for use in the completed structure or as required to

6.4.2.1 Deflection readings may be taken in a variety of

satisfy the intent of the tests. In a single truss test, frequently

ways. One of the simplest methods is by the use of a taut wire

the support at one end will allow rotation but not translation (a

or mono-filament line stretched between supports in combina-

rocker) and the other will allow both rotation and translation (a

tion with a mirror-scale located at the desired deflection

roller) so as not to induce additional unintentional secondary

measuring points. Such a device avoids any magnification of

stresses into the test truss as it deforms under load.

deflection readings due to a settlement of supports during

6.2.3 Where lateral support is used, it shall not interfere

loading.When the taut wire method is used, care must be taken

with the free in-plane displacement of the truss assembly. The

to ensure that the wire will remain under tension during the

testtrussesshallnotbelaterallysupportedinamannerthatwill

entire test. This can be accomplished by incorporating a spring

exceed that intended in a typical installation. Trusses tested in

into the line or by letting one end run over a pulley with a

pairs shall be laterally braced and sheathed in a typical manner.

Lateralbracingbetweentrussestestedinpairsshallbeinstalled weight attached to the line. Deflections are read on a scale with

a mirror backing.The mirror-scale deflection measuring device

in a manner to prevent both trusses from buckling together.

Care shall be taken when testing trusses horizontally to keep is read by visually lining up the top of the wire with its image

the test truss flat to minimize any adverse lateral displacement on the mirror and then reading the scale.

caused by gravity.

6.4.2.2 Other commonly used devices are such things as

6.3 Loading Devices:

direct reading micrometer dial gages, optical levels used to

6.3.1 The loading devices shall result in the desired truss read scales attached to the truss, linearly variable differential

loading situation regardless of whether uniform, concentrated, transformers (LVDT), or a combination of flexible wire at-

or a combination of both. The system shall be such as to allow tached at deflection points and monitored remotely through a

the application of loads during the test to approximate the

system of pulleys attached to dial gages. Deflection readings

overall intended in-service load distribution. Care should be and measuring devices shall have an accuracy of 6 2% of

taken to avoid eccentrically applied loads unless this type of

design load deflection.

loading is desired.

6.4.3 Strain Measurements—Strain measurements may be

6.3.2 Vertical loads may be applied in the form of dead

taken on truss elements using electrical or mechanical strain

weight through bearing, suspension, or jacking arrangements.

gages. Approximate stress distribution and magnitude may be

Horizontal loads are usually applied by some form of jacking

observed by the application of special brittle lacquers to the

arrangement directly in-plane or by using a system of cables

areas of interest.All of these measurements should be made by

and pulleys with dead weights or hydraulic cylinders. The

personnel experienced in the application and operation of the

loading system should have provisions for applying unbal-

methods employed on the material being tested.

anced loads when this type of loading can be critical to truss

6.5 Typical Setups—Some suggested setups for running

performance (see 9.4). Uplift forces such as those caused by

truss tests are shown in Figs. 1-3.

wind loads may be simulated by reversing the direction of the

applied gravity loads; or if the fixture will permit it, testing the

7. Hazards

truss upside down. It is preferable to test the truss in its

7.1 Full-scale load tests of any large size specimen such as

normally installed orientation in order to more typically allow

for the uplift forces working against gravity forces. a truss can be hazardous to the individuals performing or

observing the tests, and also damage the testin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.