ASTM E929-83(1999)

(Test Method)Standard Test Method for Measuring Electrical Energy Requirements of Processing Equipment

Standard Test Method for Measuring Electrical Energy Requirements of Processing Equipment

SCOPE

1.1 This test method covers the determination of the energy and power requirements of processing equipment using an electrical metering system.

1.2 This test method can be used to measure energy and power requirements of processing equipment driven by an electrical motor operating on alternating current.

1.3 This test method includes instructions for installation and checkout of the energy metering system, procedures for measuring and recording energy usage, and methods for calculating the average gross power, average freewheeling power, and average net power requirements of processing equipment.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For hazard statements, see Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E929–83 (Reapproved 1999)

Standard Test Method for

Measuring Electrical Energy Requirements of Processing

Equipment

This standard is issued under the fixed designation E 929; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.6 loaded condition— equipment doing processing work

on solids, liquids, or gases, or all of these, (for example,

1.1 This test method covers the determination of the energy

moving material, changing its characteristics, or separating it

and power requirements of processing equipment using an

into different streams).

electrical metering system.

2.7 net power—the difference between gross power and

1.2 This test method can be used to measure energy and

freewheeling power; net power is the power required for

power requirements of processing equipment driven by an

processing.

electrical motor operating on alternating current.

2.8 specific energy— energy consumption expressed on the

1.3 This test method includes instructions for installation

basis of unit mass of throughput.

and checkout of the energy metering system, procedures for

2.9 unloaded condition—equipment not doing processing

measuring and recording energy usage, and methods for

work (for example, moving, changing the characteristics of, or

calculating the average gross power, average freewheeling

separating materials), but operating in a freewheeling, or

power, and average net power requirements of processing

idling, condition.

equipment.

1.4 This standard does not purport to address all of the

3. Summary of Test Method

safety concerns, if any, associated with its use. It is the

3.1 An electrical metering system is installed and checked.

responsibility of the user of this standard to establish appro-

3.2 Themeteringinstrumentationandprocessingequipment

priate safety and health practices and determine the applica-

is allowed to warmup.

bility of regulatory limitations prior to use. For hazard state-

3.3 Usingtheelectricalmeteringsystem,theenergyusedby

ments, see Section 6.

the processing equipment under no-load and loaded conditions

2. Terminology Definitions is measured and recorded.

3.4 The average gross power, average freewheeling power,

2.1 electrical metering system—a system composed of cur-

and average net power required by the equipment is calculated.

rent and potential transformers and a wattmeter electrically

connected in such a manner so as to measure the energy usage

4. Significance and Use

of a piece of equipment driven by an electric motor.

4.1 Energy usage and power requirements of processing

2.2 freewheeling condition—a piece of equipment under an

equipment are important from the standpoint of determining if

unloaded condition wherein the electrical energy is dissipated

equipment is operating within specification and meeting per-

due to friction and windage.

formance criteria.

2.3 freewheeling power—power requirement of a piece of

4.2 Having determined the energy usage and power require-

equipment under unloaded, or freewheeling, conditions.

ments of the processing equipment using this method, specific

2.4 gross energy— energy usage of a piece of equipment

energy may be calculated, with the use of system throughput,

operating under loaded conditions as measured using an

and used as one criterion to compare the performance of

electrical metering system.

similar pieces of equipment operating under similar operating

2.5 gross power— power requirement of a piece of equip-

conditions.

ment under loaded conditions.

4.3 Measurements of energy usage can be used for the

purposeofidentifyinginefficientelectricalmotorsandprocess-

This test method is under the jurisdiction of ASTM Committee D34 on Waste

ing equipment.

Management and is the direct responsibility of Subcommittee D34.03.02 on

Municipal Recovery and Reuse.

Current edition approved Feb. 25, 1983. Published May 1983.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E929–83 (1999)

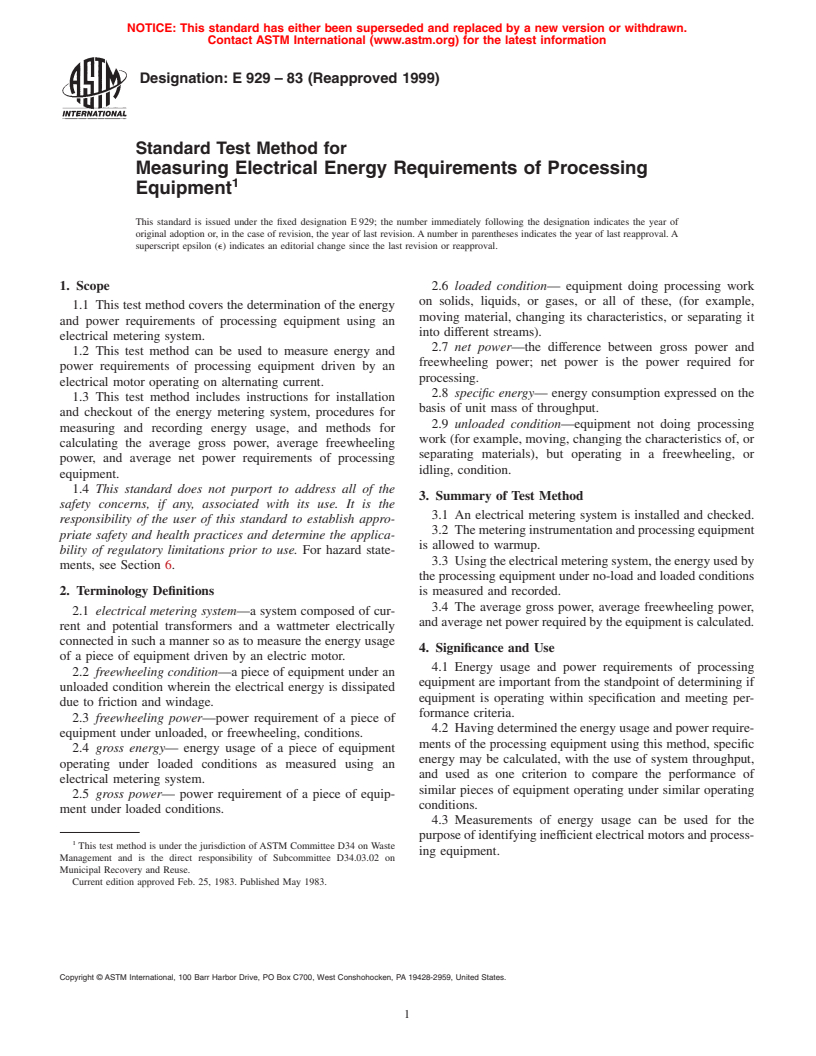

Watthour Meter Serial No. Type Class K Accuracy Date Calibrated

h

Current Transformer Serial No. Type Ratio Accuracy Class Date Calibrated

Potential Transformer Serial No. Type Ratio Accuracy Class Date Calibrated

FIG. 1 Electrical Metering System Installation Form

5. Apparatus 8.1.1 For the piece of equipment to be tested, determine the

type of electrical service (for example, single-phase two-wire,

5.1 Calibrated Watthour Meter.

three-phase three-wire), voltage requirements, full load power,

5.2 Volt-Ammeter.

and current rating of the motor from the motor nameplate or

5.3 Stopwatch, accurate to 0.1 s.

manufacturer’s specifications. For the purpose of meter selec-

5.4 Incandescent Lamps, for use as a known load.

tion and installation, it can be assumed that 1 hp = 1 kW = 1

5.5 Current Transformers (CTs).

kVA. Select the metering system that is compatible with the

5.6 Potential (Voltage) Transformers (PTs).

type of electrical service and with the load on the motor.

8.1.1.1 Self-contained single phase watthour meter can be

6. Hazards

used when the load is less than 48 kVA.

6.1 When installing metering equipment always de-energize

8.1.1.2 Self-contained polyphase meters can be used when

the load side of the processing equipment by locking out the

the load is less than 96 kVA (except 480 V delta).

main switch on the electrical control panel.

8.1.1.3 Above 48 or 96 kVA, respectively, for single and

6.2 Dangerous high voltage results from open current trans-

polyphase loads, use transformer type watthour meters.

formersecondaries.Therefore,toavoidequipmentdamageand

8.1.2 For any meter installation, do not exceed the meter’s

electrical shock, use circuit-closing devices or equipment to

overload capability listed as follows:

short circuit the secondaries of current transformers.

8.1.2.1 Class 10—Nominal 2.5-A meter, 10-A overload

6.3 Always observe the polarity markings of current and

capability.

potential transformers during their installations to ensure

8.1.2.2 Class 20—Nominal 2.5-A meter, 20-A overload

proper connection of the metering equipment. These polarity

capability.

markings are usually denoted on the transformers as white

8.1.2.3 Class 60—Nominal 15-A meter, 60-A overload

dots, blocks, or “HX” marks.

capability.

6.4 Closely observe polarities, and check connections of

8.1.2.4 Class 100—Nominal 15-A meter, 100-A overload

instrument transformers to the watthour meter.

capability.

8.1.2.5 Class 200—Nominal 30-A meter, 200-A overload

7. Equipment Calibration

capability.

7.1 Calibrate all meters and instrument transformers used

8.1.2.6 Class 320—Nominal 50-A meter, 320-A overload

for energy measurements in accordance with standard practice

capability.

, , ,

2 3 4 5

of calibration. The accuracy of the meters and trans

8.1.3 Instrument Transformers—For meter installations re-

formers shall be duly noted on the Electrical Metering Service

quiring instrument transformers (that is, when the primary

Installation Form, see Fig. 1.

current or voltage, or both, exceed the operating specifications

of the watthour meter), use current and potential (voltage)

8. Procedure

transformers. Select current and potential transformers with an

8.1 Meter Installation:

accuracy class rating of 0.3 (0.3 %) and compatibility with the

primary electrical service. If transformers with an accuracy

class of 0.3 are not available, substitute another accuracy class

and note on the Electrical Metering System Installation Form

Meter and Instrument Transformer Application Guide, 5th Edition, Westing-

(Fig. 1).

house Electric Company, Raleigh, NC.

Metermen’s Handbook, Duncan Electric Company, Lafayette, IN, No. 5M, 8.1.4 Current Transformers—Calculate the current trans-

April 1976.

former ratio (CTR) using the following definition.

Electrical Metermen’s Handbook, Edison Electric Institute, New York, NY.

CTR 5 Primary Current/Watthour Meter Nominal Current Rating

Guide for Installing General Electric Watthour Meters, General Electric

Company, Somersworth, NH, April 1976. (1)

E929–83 (1999)

Generally, current transformer ratios are denoted such that aftertheconclusionoftheloadtests,takeandrecordthreefinal

the secondary current will be 5 amperes when rated amperes disk timings of ten revolutions each. An Energy Measurement

are flowing in the primary circuit. Data Sheet for recording the freewheeling energy measure-

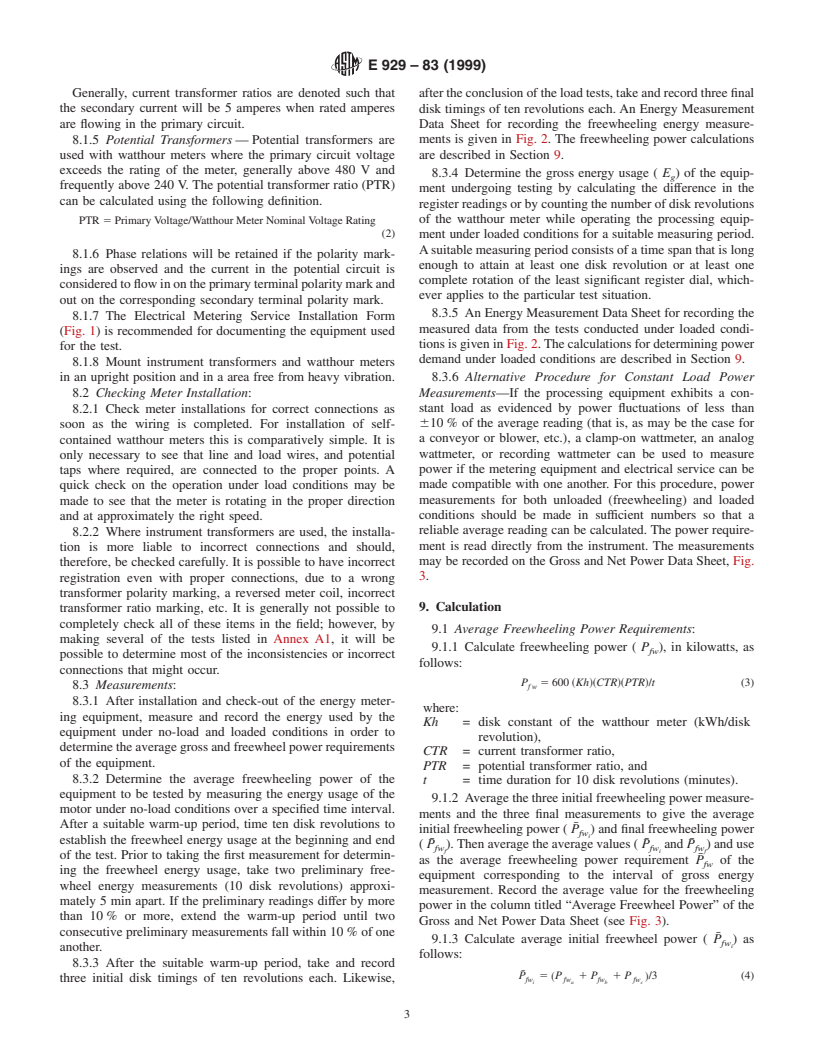

8.1.5 Potential Transformers — Potential transformers are ments is given in Fig. 2. The freewheeling power calculations

used with watthour meters where the primary circuit voltage are described in Section 9.

exceeds the rating of the meter, generally above 480 V and

8.3.4 Determine the gross energy usage ( E ) of the equip-

g

frequently above 240 V. The potential transformer ratio (PTR)

ment undergoing testing by calculating the difference in the

can be calculated using the following definition.

register readings or by counting the number of disk revolutions

PTR 5 Primary Voltage/Watthour Meter Nominal Voltage Rating of the watthour meter while operating the processing equip-

(2)

ment under loaded conditions for a suitable measuring period.

Asuitable measuring period consists of a time span that is long

8.1.6 Phase relations will be retained if the polarity mark-

enough to attain at least one disk revolution or at least one

ings are observed and the current in the potential circuit is

complete rotation of the least significant register dial, which-

consideredtoflowinontheprimaryterminalpolaritymarkand

ever applies to the particular test situation.

out on the corresponding secondary terminal polarity mark.

8.3.5 An Energy Measurement Data Sheet for recording the

8.1.7 The Electrical Metering Service Installation Form

measured data from the tests conducted under loaded condi-

(Fig. 1) is recommended for documenting the equipment used

tions is given in Fig. 2.The calculations for determining power

for the test.

demand under loaded conditions are described in Section 9.

8.1.8 Mount instrument transformers and watthour meters

in an upright position and in a area free from heavy vibration. 8.3.6 Alternative Procedure for Constant Load Power

8.2 Checking Meter Installation: Measurements—If the processing equipment exhibits a con-

stant load as evidenced by power fluctuations of less than

8.2.1 Check meter installations for correct connections as

610 % of the average reading (that is, as may be the case for

soon as the wiring is completed. For installation of self-

a conveyor or blower, etc.), a clamp-on wattmeter, an analog

contained watthour meters this is comparatively simple. It is

wattmeter, or recording wattmeter can be used to measure

only necessary to see that line and load wires, and potential

power if the metering equipment and electrical service can be

taps where required, are connected to the proper points. A

made compatible with one another. For this procedure, power

quick check on the operation under load conditions may be

measurements for both unloaded (freewheeling) and loaded

made to see that the meter is rotating in the proper direction

conditions should be made in sufficient numbers so that a

and at approximately the right speed.

reliable average reading can be calculated. The power require-

8.2.2 Where instrument transformers are used, the installa-

ment is read directly from the instrument. The measurements

tion is more liable to incorrect connections and should,

may be recorded on the Gross and Net Power Data Sheet, Fig.

therefore, be checked carefully. It is possible to have incorrect

3.

registration even with proper connections, due to a wrong

transformer polarity marking, a reversed meter coil, incorrect

9. Calculation

transformer ratio marking, etc. It is generally not possible to

completely check all of these items in the field; however, by

9.1 Average Freewheeling Power Requirements:

making several of the tests listed in Annex A1, it will be

9.1.1 Calculate freewheeling power ( P ), in kilowatts, as

fw

possible to determine most of the inconsistencies or incorrect

follows:

connections that might occur.

P 5 600 ~Kh!~CTR!~PTR!/t (3)

fw

8.3 Measurements:

8.3.1 After installation and check-out of the energy meter-

where:

ing equipment, measure and record the energy used by the

Kh = disk constant of the watthour meter (kWh/disk

equipment under no-load and loaded conditions in order to

revolution),

determine the average gross and freewheel power requirements

CTR = current transformer ratio,

of the equipment.

PTR = potential transformer ratio, and

8.3.2 Determine the average freewheeling power of the

t = time duration for 10 disk revolutions (minutes).

equipment to be tested by measuring the energy usage of the

9.1.2 Average the three initial freewheeling power measure-

motor under no-load conditions over a specified time interval.

ments and the three final measurements to give the average

After a suitable warm-up period, time ten disk revolutions to

¯

initial freewheeling power ( P ) and final freewheeling power

fw

i

establish the freewheel energy usage at the beginning and end

¯ ¯ ¯

( P ).Then average the average values ( P and P ) and use

fw fw fw

f i f

of the test. Prior to taking the first measurement for determin-

¯

as the average freewheeling power requirement P of the

fw

ing the freewheel energy usage, take two preliminary free-

equipment corresponding to the interval of gross energy

wheel energy measurements (10 disk revolutions) approxi-

measurement. Record the average value for the freewheeling

mately 5 min apart. If the preliminary readings differ by more

power in the column titled “Average Freewheel Power” of the

than 10 % or more, extend the warm-up period until two

Gross and Net Power Data Sheet (see Fig. 3).

consecutive preliminary measurements fall within 10 % of one

¯

9.1.3 Calculate average initial freewheel power ( P )as

fw

i

another.

follows:

8.3.3 After the suitable warm-up period, take and record

¯

P 5 ~P 1 P 1 P !/3 (4)

three initial disk timings of ten revolutions each. Likewise, fw fw fw fw

i a b c

E929–83 (1999)

CTR: ___ PTR: ___

Watthour Meter Reading

Test No. Time Interval (Min) Disk Revolutions (n) Kh (kWh/rev.) Gross Energy (kWh)

Initial (kWh) Final (kWh)

Loaded Condition

No-load Condition

(Freewheel)

Initial (P )

fwi

¯

Average Initial (P

fw)i

Final (P )

fwf

¯

Average Final (P )

fwf

Average of Average Initial and Average Final Freewheeling Power: ___

FIG. 2 Energy Measurement Data Sheet

wher

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.