ASTM B611-13

(Test Method)Standard Test Method for Determining the High Stress Abrasion Resistance of Hard Materials

Standard Test Method for Determining the High Stress Abrasion Resistance of Hard Materials

SIGNIFICANCE AND USE

5.1 The extraction of minerals from the Earth’s mantle usually requires fracturing rock with tools made from metals, but clad, overlaid, or covered in some fashion with hard materials. Drilling, crushing, and moving rock involves high-stress abrasion on the surfaces that make contact with the rock. The stresses are high enough to crush/fracture the rock. This test method simulates this condition, and it is used to screen new materials for these types of applications. It can also be used as a quality control tool for materials destined for high-stress abrasion applications: slurry pumps, comminution equipment, recycling choppers, demolition equipment, etc.

5.2 Most abrasion tests use low-stress abrasion. The abrasive stays relatively intact during testing. High-stress abrasion simulates applications where the force between an abrasive substance and a tool/component will be high enough to crush the abrasive. If this describes an application under study, then this may be an appropriate test method to use.

SCOPE

1.1 This test method was developed for ranking the high-stress abrasion resistance of cemented carbides, but it has been successfully used on ceramics, cermets, and metal matrix hardfacings with a hardness over 55 HRC. The feature of this test method that discriminates it from other abrasion tests is that the abrasive is forced against the test specimen with a steel wheel with sufficient force to cause fracture of the abrasive particles. Some abrasion tests use rubber wheels to force abrasive against test surfaces (Test Methods G65, G105, G75). A rubber wheel produces low-stress abrasion while a steel wheel produces high-stress abrasion.

1.2 In summary, this is a high-stress laboratory abrasion test for hard materials using a water slurry of aluminum oxide particles as the abrasive medium and a rotating steel wheel to force the abrasive across a flat test specimen in line contact with the rotating wheel immersed in the slurry.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B611 − 13

Standard Test Method for

Determining the High Stress Abrasion Resistance of Hard

1

Materials

This standard is issued under the fixed designation B611; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G75 Test Method for Determination of Slurry Abrasivity

(Miller Number) and Slurry Abrasion Response of Mate-

1.1 This test method was developed for ranking the high-

rials (SAR Number)

stress abrasion resistance of cemented carbides, but it has been

G105 Test Method for Conducting Wet Sand/Rubber Wheel

successfully used on ceramics, cermets, and metal matrix

3

Abrasion Tests (Withdrawn 2016)

hardfacings with a hardness over 55 HRC. The feature of this

G40 Terminology Relating to Wear and Erosion

test method that discriminates it from other abrasion tests is

that the abrasive is forced against the test specimen with a steel

3. Terminology

wheel with sufficient force to cause fracture of the abrasive

3.1 Definitions: For definitions of terms found in this test

particles. Some abrasion tests use rubber wheels to force

method, please refer to Terminology G40.

abrasive against test surfaces (Test Methods G65, G105, G75).

3.2 Definitions of Terms Specific to This Standard:

A rubber wheel produces low-stress abrasion while a steel

3.2.1 abrasive wear, n—wear due to hard particles or hard

wheel produces high-stress abrasion.

protuberances forced against and moving along a solid surface.

1.2 In summary, this is a high-stress laboratory abrasion test

3.2.2 high-stress abrasion, n—progressive material removal

for hard materials using a water slurry of aluminum oxide

from a hard solid surface by the action of hard particles rolling

particles as the abrasive medium and a rotating steel wheel to

or sliding on that surface with sufficient force to cause fracture

force the abrasive across a flat test specimen in line contact

of the particles.

with the rotating wheel immersed in the slurry.

3.2.3 slurry, n—a suspension of solid material in liquid.

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Summary of Test Method

standard.

4.1 The test specimen is a flat that is held in a vertical

1.4 This standard does not purport to address all of the

position tangent to a rotating steel wheel immersed in water

safety concerns, if any, associated with its use. It is the

slurry of aluminum oxide particles.

responsibility of the user of this standard to establish appro-

4.2 The normal force holding the test specimen against the

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. wheelishighenoughtocausefractureofabrasiveparticlesthat

travel through the wheel/test specimen contact. The test metric

2. Referenced Documents

is the volume of material worn from the test specimen in

2

specified test duration and under specified test conditions.

2.1 ASTM Standards:

B311 Test Method for Density of Powder Metallurgy (PM)

4.3 The test specimen is weighed to determine mass loss

Materials Containing Less Than Two Percent Porosity

whichisconvertedtoavolumelossusingthedensityofthetest

G65 Test Method for Measuring Abrasion Using the Dry

material.

Sand/Rubber Wheel Apparatus

4.4 The slurry used in the test is composed of a specified

mass of 30-mesh aluminum oxide in a specified volume of

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

water.

and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive

4.5 There may be a corrosion component to the material

Wear.

Current edition approved Nov. 15, 2013. Published December 2013. Originally

removal, but it is considered to be negligible since the test time

approved in 1976. Last previous edition approved in 2005 as B611–85 (2005). DOI:

is only ten or twenty minutes (600 or 1200 seconds).

10.1520/B0611-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B611 − 13

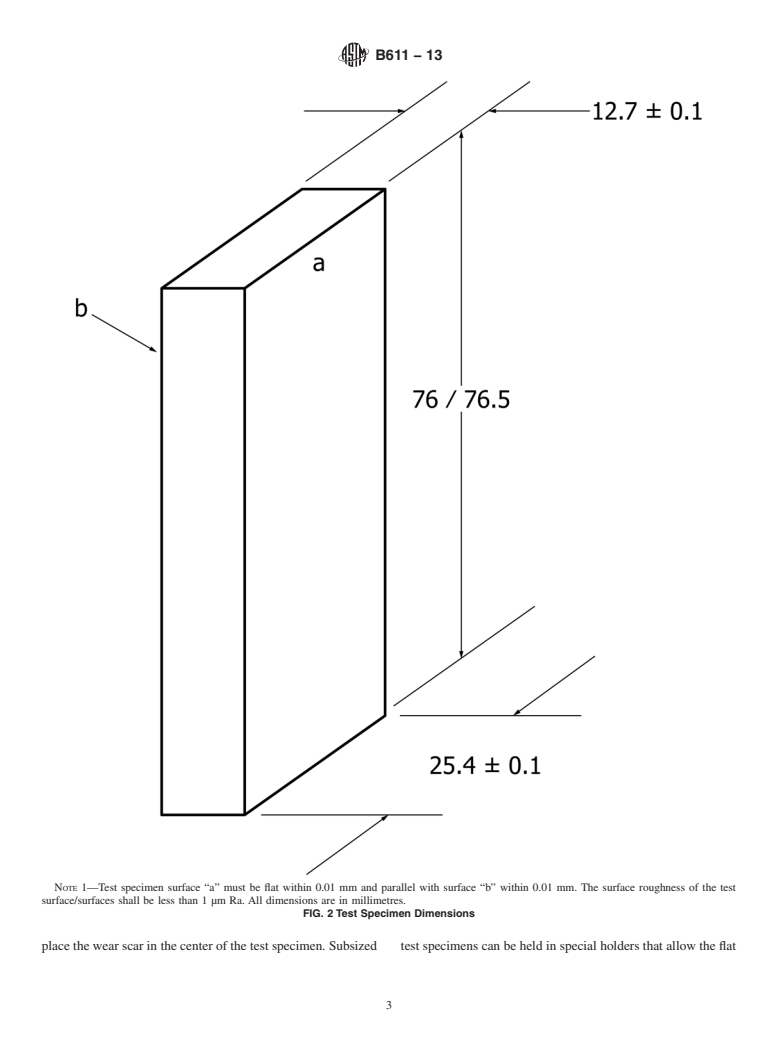

5. Significance and Use 6.2 Abrading Wheel—The wheel is made from AISI 1020

steel (80 to 95 HRB); the outside diameter is 169 6 0.1 mm

5.1 The extraction of minerals from the Earth’s mantle

when new a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B611 − 85 (Reapproved 2005) B611 − 13

Standard Test Method for

Abrasive Wear Determining the High Stress Abrasion

1

Resistance of Cemented CarbidesHard Materials

This standard is issued under the fixed designation B611; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of abrasive wear was developed for ranking the high-stress abrasion resistance

of cemented carbides.carbides, but it has been successfully used on ceramics, cermets, and metal matrix hardfacings with a

hardness over 55 HRC. The feature of this test method that discriminates it from other abrasion tests is that the abrasive is forced

against the test specimen with a steel wheel with sufficient force to cause fracture of the abrasive particles. Some abrasion tests

use rubber wheels to force abrasive against test surfaces (Test Methods G65, G105, G75). A rubber wheel produces low-stress

abrasion while a steel wheel produces high-stress abrasion.

1.2 In summary, this is a high-stress laboratory abrasion test for hard materials using a water slurry of aluminum oxide particles

as the abrasive medium and a rotating steel wheel to force the abrasive across a flat test specimen in line contact with the rotating

wheel immersed in the slurry.

1.3 The values stated in inch-poundSI units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered No other units of measurement are included

in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B311 Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity

G65 Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus

G75 Test Method for Determination of Slurry Abrasivity (Miller Number) and Slurry Abrasion Response of Materials (SAR

Number)

G105 Test Method for Conducting Wet Sand/Rubber Wheel Abrasion Tests

G40 Terminology Relating to Wear and Erosion

3. Terminology

3.1 Definitions: For definitions of terms found in this test method, please refer to Terminology G40.

3.2 Definitions:Definitions of Terms Specific to This Standard:

3.1.1 abrasion resistance, n—the specimen’s unit loss in volume per revolution of the steel wheel carrying the abrasive.

3.2.1 abrasive wear, n—that wear caused by a slurried abrasive on a rotating surface, contacting the specimen surface under

pressure.wear due to hard particles or hard protuberances forced against and moving along a solid surface.

3.2.2 wear number,high-stress abrasion, n—the reciprocal of the specimen’s total volume loss in units of cmprogressive

material removal from a hard solid surface by the action of hard particles rolling or sliding on that surface with sufficient force

−3

to cause fracture of the .particles.

3.2.3 slurry, n—a suspension of solid material in liquid.

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive Wear.

Current edition approved Oct. 1, 2005Nov. 15, 2013. Published October 2005XXX 2013. Originally approved in 1976. Last previous edition approved in 20002005 as

ε1

B611–85 (2000)(2005). . DOI: 10.1520/B0611-85R05.10.1520/B0611-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B611 − 13

4. Summary of Test Method

4.1 The test specimen is a flat that is held in a vertical position tangent to a rotating steel wheel immersed in water slurry of

aluminum oxide particles.

4.2 The normal force holding the test specimen against the wheel is high enough to cause fracture of abrasive p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.