ASTM D3404-15

(Guide)Standard Guide for Measuring Matric Potential in Vadose Zone Using Tensiometers (Withdrawn 2024)

Standard Guide for Measuring Matric Potential in Vadose Zone Using Tensiometers (Withdrawn 2024)

SIGNIFICANCE AND USE

5.1 Movement of water in the unsaturated zone is of considerable interest in studies of hazardous-waste sites (1, 2, 3, 4)3; recharge studies (5, 6); irrigation management (7, 8, 9); and civil-engineering projects (10, 11). Matric-potential data alone can be used to determine direction of flow (11) and, in some cases, quantity of water flux can be determined using multiple tensiometer installations. In theory, this technique can be applied to almost any unsaturated-flow situation whether it is recharge, discharge, lateral flow, or combinations of these situations.

5.2 If the moisture-characteristic curve is known for a soil, matric-potential data can be used to determine the approximate water content of the soil (10). The standard tensiometer is used to measure matric potential between the values of 0 and -867 cm of water; this range includes most values of saturation for many soils (12).

5.3 Tensiometers directly and effectively measure soil-water tension, but they require care and attention to detail. In particular, installation needs to establish a continuous hydraulic connection between the porous material and soil, and minimal disturbance of the natural infiltration pattern are necessary for successful installation. Avoidance of errors caused by air invasion, nonequilibrium of the instrument, or pressure-sensor inaccuracy will produce reliable values of matric potential.

5.4 Special tensiometer designs have extended the normal capabilities of tensiometers, allowing measurement in cold or remote areas, measurement of matric potential as low as -153 m of water (-15 bars), measurement at depths as deep as 6 m (recorded at land surface) for conventional tensiometers, depths up to 200 m and greater with advanced and portable versions (13, 14), and automatic measurement using as many as 22 tensiometers connected to a single pressure transducer, but these require a substantial investment of effort and money.

5.5 Pressure sensors commonly used in tensiomete...

SCOPE

1.1 This guide covers the measurement of matric potential in the vadose zone using tensiometers. The theoretical and practical considerations pertaining to successful onsite use of commercial and fabricated tensiometers are described. Measurement theory and onsite objectives are used to develop guidelines for tensiometer selection, installation, and operation.

1.2 Units—The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. The use of a mercury manometer has inherent safety concerns regarding the handling of and potential exposure to mercury. Mercury metal vapor poisoning has long been recognized as a hazard. When using equipment containing or requiring the use of mercury, take all precautions and care to avoid the escape of mercury vapor or the spillage of mercury. Maximum limits for mercury concentrations in industrial atmospheres are set by governmental agencies. These limits are usually based upon recommendations made by the American Conference of Governmental Industrial Hygienists*. It is possible for the concentration of mercury vapors accompanying spills from broken thermometers, barometers, and other instruments using mercury to exceed these limits. Mercury, being a heavy liquid with high surface tension, readily disperses into small droplets after spills, lodging in cracks and crevices. Resultant increased surface area of the mercury due to this dispersion promotes higher mercury concentrations in the surrounding air. Mercury vapor concentrations are readily measured using commercially available instrumentation. To monitor environmental hazards it is advisable to make periodic checks for mercury content at location...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3404 − 15

Standard Guide for

Measuring Matric Potential in Vadose Zone Using

1

Tensiometers

This standard is issued under the fixed designation D3404; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope locations where mercury is exposed to the atmosphere. Use a

spill kit for clean-up whenever spillage occurs. After spills and

1.1 This guide covers the measurement of matric potential

clean-up, make thorough checks for mercury vapor concentra-

in the vadose zone using tensiometers. The theoretical and

tions in the atmosphere. *In 1993, this Conference had

practical considerations pertaining to successful onsite use of

headquarters located in Building D-7 at 6500 Glenway Drive,

commercial and fabricated tensiometers are described. Mea-

Cincinnati, Ohio 45211.

surement theory and onsite objectives are used to develop

1.4 This guide offers an organized collection of information

guidelines for tensiometer selection, installation, and opera-

or a series of options and does not recommend a specific

tion.

course of action. This document cannot replace education or

1.2 Units—The values stated in SI units are to be regarded

experience and should be used in conjunction with professional

as the standard.

judgment. Not all aspects of this guide may be applicable in all

1.3 This standard does not purport to address all of the circumstances. This ASTM standard is not intended to repre-

safety concerns, if any, associated with its use. It is the

sent or replace the standard of care by which the adequacy of

responsibility of the user of this standard to establish appro- a given professional service must be judged, nor should this

priate safety and health practices and determine the applica-

document be applied without consideration of a project’s many

bility of regulatory limitations prior to use. The use of a unique aspects. The word“ Standard” in the title of this

mercury manometer has inherent safety concerns regarding the

document means only that the document has been approved

handling of and potential exposure to mercury. Mercury metal through the ASTM consensus process.

vapor poisoning has long been recognized as a hazard. When

2. Referenced Documents

using equipment containing or requiring the use of mercury,

take all precautions and care to avoid the escape of mercury 2

2.1 ASTM Standards:

vapor or the spillage of mercury. Maximum limits for mercury

D653Terminology Relating to Soil, Rock, and Contained

concentrations in industrial atmospheres are set by govern-

Fluids

mental agencies. These limits are usually based upon recom-

mendations made by the American Conference of Governmen-

3. Terminology

tal Industrial Hygienists*. It is possible for the concentration

3.1 For definitions of common technical terms in this

of mercury vapors accompanying spills from broken

standard, refer to Terminology D653.

thermometers, barometers, and other instruments using mer-

cury to exceed these limits. Mercury, being a heavy liquid with 3.2 Definitions of Terms Specific to This Standard:

high surface tension, readily disperses into small droplets after 3.2.1 accuracy of measurement—the difference between the

spills, lodging in cracks and crevices. Resultant increased value of the measurement and the true value.

surface area of the mercury due to this dispersion promotes

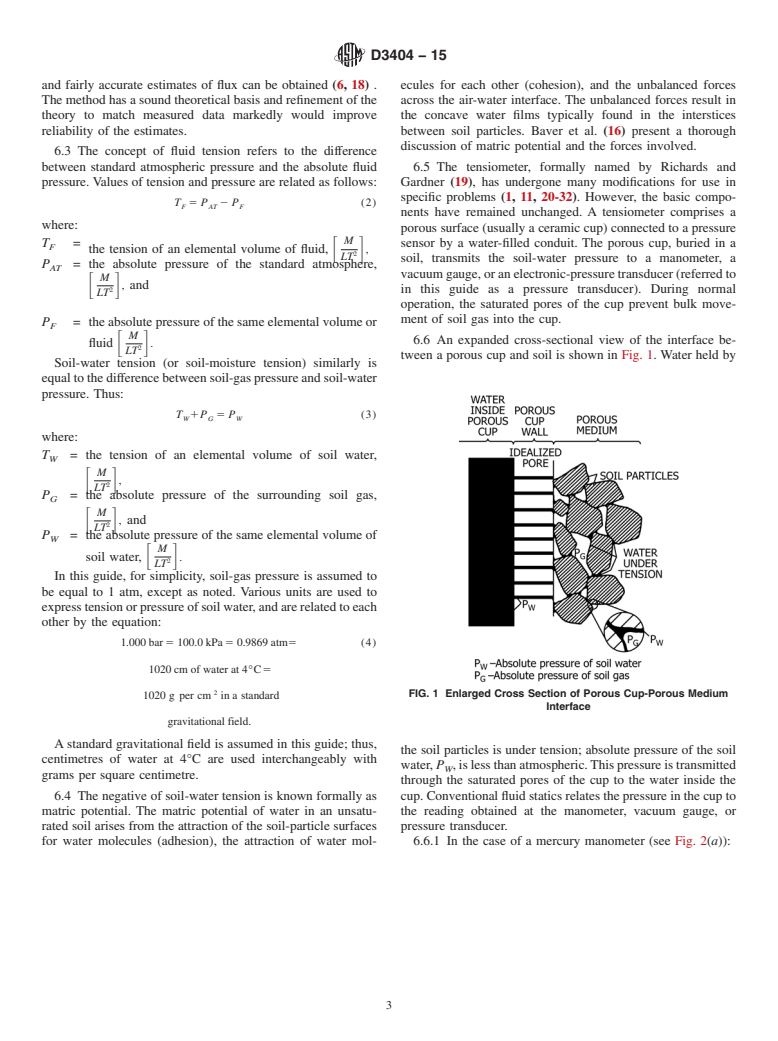

3.2.2 hysteresis—that part of inaccuracy attributable to the

higher mercury concentrations in the surrounding air. Mercury

tendency of a measurement device to lag in its response to

vapor concentrations are readily measured using commercially

environmental changes; parameters affecting pressure-sensor

available instrumentation. To monitor environmental hazards it

hysteresis are temperature and measured pressure.

is advisable to make periodic checks for mercury content at

3.2.3 precision (repeatability)—the variability among nu-

merous measurements of the same quantity.

1

ThisguideisunderthejurisdictionofASTMCommitteeD18onSoilandRock

and is the direct responsibility of Subcommittee D18.21 on Groundwater and

2

Vadose Zone Investigations. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 15, 2015. Published May 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2013 as D3404–91 (2013). Standards volume information, refer to the standard’s Document Summ

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3404 − 91 (Reapproved 2013) D3404 − 15

Standard Guide for

Measuring Matric Potential in Vadose Zone Using

1

Tensiometers

This standard is issued under the fixed designation D3404; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers the measurement of matric potential in the vadose zone using tensiometers. The theoretical and practical

considerations pertaining to successful onsite use of commercial and fabricated tensiometers are described. Measurement theory

and onsite objectives are used to develop guidelines for tensiometer selection, installation, and operation.

1.2 Units—The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for

information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. The use of a mercury manometer has inherent safety concerns regarding the handling of and potential

exposure to mercury. Mercury metal vapor poisoning has long been recognized as a hazard. When using equipment containing or

requiring the use of mercury, take all precautions and care to avoid the escape of mercury vapor or the spillage of mercury.

Maximum limits for mercury concentrations in industrial atmospheres are set by governmental agencies. These limits are usually

based upon recommendations made by the American Conference of Governmental Industrial Hygienists*. It is possible for the

concentration of mercury vapors accompanying spills from broken thermometers, barometers, and other instruments using

mercury to exceed these limits. Mercury, being a heavy liquid with high surface tension, readily disperses into small droplets after

spills, lodging in cracks and crevices. Resultant increased surface area of the mercury due to this dispersion promotes higher

mercury concentrations in the surrounding air. Mercury vapor concentrations are readily measured using commercially available

instrumentation. To monitor environmental hazards it is advisable to make periodic checks for mercury content at locations where

mercury is exposed to the atmosphere. Use a spill kit for clean-up whenever spillage occurs. After spills and clean-up, make

thorough checks for mercury vapor concentrations in the atmosphere. *In 1993, this Conference had headquarters located in

Building D-7 at 6500 Glenway Drive, Cincinnati, Ohio 45211.

1.4 This guide offers an organized collection of information or a series of options and does not recommend a specific course

of action. This document cannot replace education or experience and should be used in conjunction with professional judgment.

Not all aspects of this guide may be applicable in all circumstances. This ASTM standard is not intended to represent or replace

the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied

without consideration of a project’s many unique aspects. The word“ Standard” in the title of this document means only that the

document has been approved through the ASTM consensus process.

2. Referenced Documents

2

2.1 ASTM Standards:

D653 Terminology Relating to Soil, Rock, and Contained Fluids

3. Terminology

3.1 For definitions of common technical terms in this standard, refer to Terminology D653.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 accuracy of measurement—the difference between the value of the measurement and the true value.

1

This guide is under the jurisdiction of ASTM Committee D18 on Soil and Rock and is the direct responsibility of Subcommittee D18.21 on Groundwater and Vadose

Zone Investigations.

Current edition approved June 15, 2013April 15, 2015. Published June 2013May 2015. Originally approved in 1991. Last previous edition approved in 20042013 as

D3404 – 91 (2004).(2013). DOI: 10.1520/D3404-91R13.10.1520/D3404-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.