ASTM D5547-95(2003)

(Test Method)Standard Test Method for Clay and Zeolite in Powdered Laundry Detergents by Atomic Absorption

Standard Test Method for Clay and Zeolite in Powdered Laundry Detergents by Atomic Absorption

ABSTRACT

This test method covers atomic absorption tests applicable to powdered laundry detergents containing clay and zeolite. The test sample is fused with lithium metaborate, dissolved in acid, its silicon and aluminum content measured by atomic absorption, and the silicon/aluminum (Si/Al) ratio calculated. The clay and zeolite content of the test sample is calculated from the Si/Al ratio of the test sample and the Si/Al ratio of the clay and zeolite expected in the test sample. This test method is based on the linear relationship between the relative composition (or ratio) of clay/zeolite in detergent powders and the Si/Al ratio of such detergents.

SCOPE

1.1 This test method covers atomic absorption tests applicable to powdered laundry detergents containing clay and zeolite.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D5547–95(Reapproved 2003)

Standard Test Method for

Clay and Zeolite in Powdered Laundry Detergents by Atomic

Absorption

This standard is issued under the fixed designation D5547; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Principle

1.1 This test method covers atomic absorption tests appli- 5.1 Clay and zeolite contain silicon and aluminum at differ-

cable to powdered laundry detergents containing clay and ent relative levels. The silicon/aluminum ratio is then a

zeolite. measure of the relative level of clay and zeolite in detergent

1.2 The values stated in SI units are to be regarded as the powders. That is, detergent powders with a Si/Al ratio match-

standard. ing clay or zeolite contain only clay or zeolite, respectively.

1.3 This standard does not purport to address all of the Detergent powders with Si/Al ratio falling between the Si/Al

safety concerns, if any, associated with its use. It is the ratio of clay and zeolite contain both clay and zeolite.

responsibility of the user of this standard to establish appro- 5.2 This test method is based on the linear relationship

priate safety and health practices and determine the applica- between the relative composition (or ratio) of clay/zeolite in

bility of regulatory limitations prior to use. detergent powders and the Si/Al ratio of such detergents.

5.3 A calibration equation is derivable, therefore, from just

2. Referenced Documents

two experimental points: the Si/Al ratio of the zeolite standard

2.1 ASTM Standards: (100 zeolite, 0 % clay) and the Si/Al ratio of the clay standard

E180 Practice for Determining the Precision of ASTM

(0 % zeolite, 100 % clay).

Methods for Analysis and Testing of Industrial and Spe-

6. Apparatus

cialty Chemicals

6.1 Suitable Atomic Absorption Spectrophotometers, fitted

3. Summary of Test Method

with a nitrous oxide-acetylene burner and aluminum and

3.1 The test sample is fused with lithium metaborate, silicon hollow cathode source lamps.

dissolved in acid, its silicon and aluminum content measured

6.2 Nitrous Oxide and Acetylene Tanks, with suitable regu-

by atomic absorption, and the silicon/aluminum (Si/Al) ratio lators.

calculated. The clay and zeolite content of the test sample is

6.3 Muffle Furnace, capable of reaching 1000°C.

calculated from the Si/Al ratio of the test sample and the Si/Al 6.4 Analytical Balance.

ratio of the clay and zeolite expected in the test sample.

6.5 Fisher Burner or Equivalent.

6.6 20-mL or Larger Platinum Crucibles.

4. Interferences

6.7 Platinum-tip Tongs.

4.1 Materials other than clay and zeolite that contain silicon

6.8 25-mL Buret.

or aluminum, or both, will interfere.

6.9 100-mL and 200-mL Polypropylene Volumetric Flasks.

6.10 10-mL and 25-mL Graduated Cylinders.

6.11 150-mL Plastic Beakers.

This test method is under the jurisdiction of ASTM Committee D12 on Soaps

6.12 Magnetic Stirrer and Magnetic Stirring Bars.

and Other Detergents and is the direct responsibility of Subcommittee D12.12 on

6 7

6.13 Blender, such as Waring or Osterizer or an industrial

Analysis of Soaps and Synthetic Detergents.

Current edition approved April 15, 1995. Published June 1995. Originally lab model, or a mortar and pestle, if a blender is not available.

published as D5547 – 94. Last previous edition D5547 – 94. DOI: 10.1520/D5547-

95R03.

7. Reagents

Silicon and aluminum measurements are by atomic absorption in this test

7.1 Purity of Reagents—Reagents grade chemicals shall be

method. ICP can be used to make such measurements as well.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

used in all tests. Unless otherwise indicated, it is intended that

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. The Si/Al ratio is usually about 1 in zeolites and about 3 in clays.

4 6

Withdrawn. The last approved version of this historical standard is referenced Waring blenders are available commercially.

on www.astm.org. Osterizer blenders are widely available commercially.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

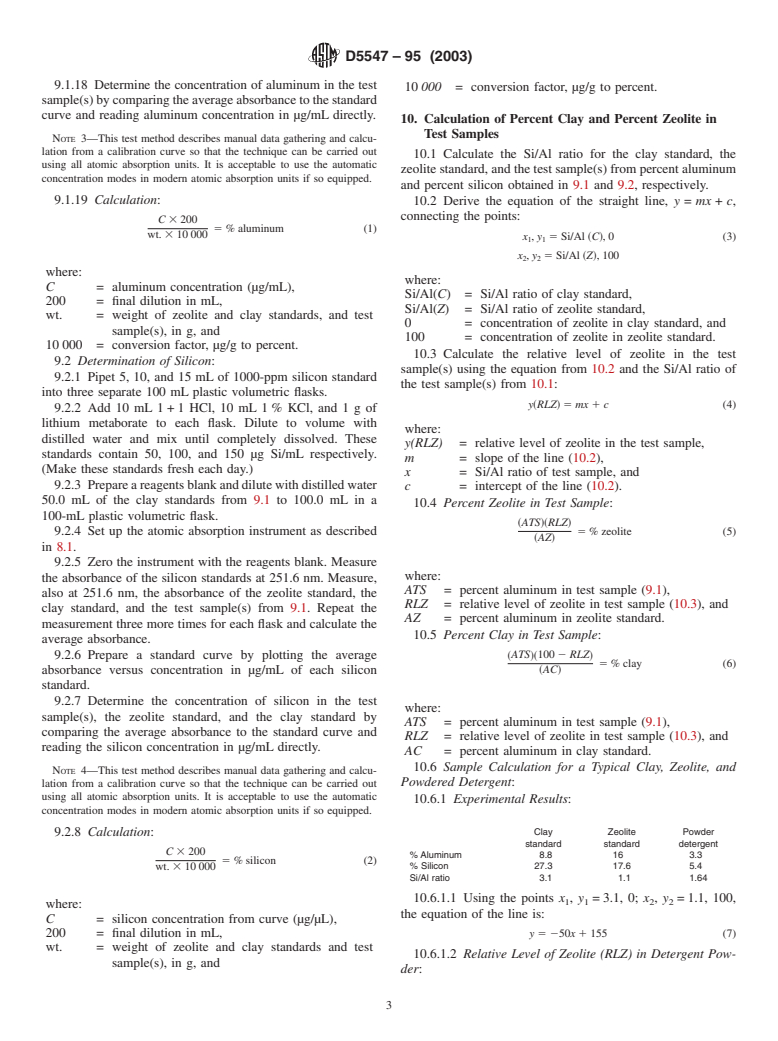

D5547–95 (2003)

all reagents conform to the specifications of the Committee on 9.1.3 Accurately weigh 0.3 g (to the nearest 0.1 mg) of the

Analytical Reagents of theAmerican Chemical Society, where ground test sample(s) into still another clean, dry, platinum

such specifications are available. Other grades may be used, crucible.

provided it is first ascertained that the reagent is of sufficiently

9.1.4 Add2g(60.1 g) of lithium metaborate to each

high purity to permit its use without lessening the accuracy of

platinum crucible, and mix the contents with a plastic rod.

the determination.

9.1.5 Place the crucibles containing the mixtures in a cool

7.2 Purity of Water—Unless otherwise indicated, reference

muffle furnace and turn on the heat. When the temperature

towatershallbeunderstoodtomeandistilledwaterorwaterof

reaches 1000°C, maintain heat for at least 5 additional min.

equal purity.

NOTE 1—The sample will ignite and splatter if placed in a hot furnace.

7.3 Aluminum Standard, 1000 µg Al/mL or equivalent.

Ifitisnotpossibletostartwithacoolfurnace,gentlycharthesamplewith

7.4 Silicon Standard, 1000 µg Si/mL.

a Fisher burner first, avoiding ignition, then place in the furnace.

7.5 Potassium Chloride, Baker-analyzed reagent or equiva-

lent.

9.1.6 Place 90 mL of distilled water into 150-mL plastic

7.6 Potassium Chloride Solution (1 %)—Dissolve1gof

beakers. (Use as many beakers as there are standards and

potassium chloride in 100 mL of distilled water. Mix well and

samples).

store in plastic container.

9.1.7 Add a magnetic stirring bar to each beaker, and place

7.7 Concentrated Hydrochloric Acid, Baker-analyzed re-

on a magnetic stirrer. Mix rapidly to make the water swirl in

agent or equivalent.

the beaker, but do not allow anything to splash out. This

7.8 Hydrochloric Acid Solution (1 + 1)—Mix equal parts of

apparatus should be near the furnace containing the ashed

concentrated HCl and distilled water by volume. Mix well and

standards and sample(s).

store in plastic container.

9.1.8 Using platinum-tip tongs, remove one crucible at a

7.9 Potassium Iodide, Baker-analyzed reagent or equiva-

time from the furnace, and immediately place over a Fisher

lent.

burner flame without allowing the melted sample to solidify.

7.10 Lithium Metaborate SPEX Grade, Special for Fu-

9.1.9 Add about 2 mg (a pinch on the end of a spatula) of

sions .

potassium iodide (KI) to the melted sample.Amolten ball will

7.11 Zeolite Standard—The same material expected in the

form. Roll the ball around the inside of the dish to pick up any

test sample, to be used as standard.

droplets or particles. The KI releasing agent is volatile, and it

7.12 Clay Standard—Thesamematerialexpectedinthetest

is necessary to carry out this step rather quickly (about 2 min).

sample, to be used as standard.

If the ball collapses and flows into the dish, start again by

adding fresh KI.

8. Instrumental Conditions

9.1.10 Dropeachmoltenballquicklyintotheswirlingwater

8.1 Following the instrument manufacturer’s instructions,

of each plastic beaker.

set up the atomic absorption instrument as follows:

To measure Aluminum To measure Silicon

NOTE 2—Precaution: Use face shield and protective clothing.

Wavelength, nm 309.3 251.6

9.1.11 Add 20 mL of 1 + 1 HCl and 20 mL of 1 %

Range UV UV

potassium chloride solution and mix until completely dis-

Slit, nm 0.2 0.2

Flame Nitrous oxide-acetylene. Nitrous oxide-acetylene.

solved. Quantitatively transfer to a 200-mL plastic volumetric

Rich, red. Strongly reducing red cone 2–3

flask with distilled water. Dilute to volume and mix well.

cm high with yellow outer

edge. 9.1.12 Using a buret, add 5, 7.5, and 10 mL of 1000-ppm

aluminum standard into 3 separate 100-mL plastic volumetric

9. Procedure

flasks. These standards contain 50, 75, and 100 µg Al/mL

9.1 Determination of Aluminum:

respectively. (Make these standards fresh each day).

9.1.1 Accurately weigh 0.1 g (to the nearest 0.1 mg) of

9.1.13 Add 10 mL 1 + 1 HCl, 10 mL 1 % KCl, and1gof

zeolitestandard(thesamematerialexpectedinthetestsample)

lithium metaborate to each flask. Dilute to volume with

into a clean, dry, platinum crucible.Also accurately weigh 0.2

distilled water and mix until completely dissolved.

g of clay standard (the same material expected in the test

9.1.14 Prepare a reagents blank.

sample) into another clean, dry, platinum crucible.

9.1.15 Set up the atomic absorption instrument as described

9.1.2 Grind a representative powdered detergent test sample

in 8.1.

in a blender to a fine, homogenous powder. (If a blender is not

9.1.16 Zerotheinstrumentwiththereagentsblank.Measure

available, use a mortar and pestle).

theabsorbanceofthealuminumstandards,thezeolitestandard,

the clay standard and the test sample at 309.3 nm. Repeat the

Reagent Chemicals, American Chemical Society Specifications, American

measurement three more times for each flask and calculate the

Chemical Society, Washington, DC. For suggestions on the testing of reagen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.