ASTM E581-17A(2022)e1

(Test Method)Standard Test Methods for Chemical Analysis of Manganese-Copper Alloys

Standard Test Methods for Chemical Analysis of Manganese-Copper Alloys

SIGNIFICANCE AND USE

4.1 These test methods for the chemical analysis of metals and alloys are primarily intended to test such materials for compliance with compositional specifications. It is assumed that all who use these test methods will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

1.1 These test methods cover the chemical analysis of manganese-copper alloys having chemical compositions within the following limits:

Element

Range, %

Copper

68.0 to 72.0

Manganese

28.0 to 32.0

Carbon

0.03 max

Iron

0.01 max

Phosphorus

0.01 max

Silicon

0.05 max

Sulfur

0.01 max

1.2 The test methods appear in the following order:

Sections

Iron by the 1,10-Phenanthroline

Spectrophotometric Method

[0.003 % to 0.02 %]

11 – 20

Manganese by the (Ethylenedinitrilo)

Tetraacetic Acid (EDTA)—

Back-Titrimetric Method [28 % to 32 %]

21 – 27

Phosphorus by the

Molybdivanadophosphoric Acid

Extraction Spectrophotometric Method

[0.002 % to 0.014 %]

28 – 38

1.3 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: E581 − 17a (Reapproved 2022)

Standard Test Methods for

Chemical Analysis of Manganese-Copper Alloys

This standard is issued under the fixed designation E581; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in September 2022.

1. Scope 2. Referenced Documents

1.1 These test methods cover the chemical analysis of

2.1 ASTM Standards:

manganese-copper alloys having chemical compositions

D1193 Specification for Reagent Water

within the following limits:

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

Element Range, %

Copper 68.0 to 72.0

E50 Practices for Apparatus, Reagents, and Safety Consid-

Manganese 28.0 to 32.0

erations for Chemical Analysis of Metals, Ores, and

Carbon 0.03 max

Related Materials

Iron 0.01 max

Phosphorus 0.01 max

E55 Practice for Sampling Wrought Nonferrous Metals and

Silicon 0.05 max

Alloys for Determination of Chemical Composition

Sulfur 0.01 max

E60 Practice for Analysis of Metals, Ores, and Related

1.2 The test methods appear in the following order:

Materials by Spectrophotometry

Sections

E88 Practice for Sampling Nonferrous Metals and Alloys in

Iron by the 1,10-Phenanthroline 11–20

Cast Form for Determination of Chemical Composition

Spectrophotometric Method

[0.003 % to 0.02 %] E135 Terminology Relating to Analytical Chemistry for

Manganese by the (Ethylenedinitrilo)

Metals, Ores, and Related Materials

Tetraacetic Acid (EDTA)— 21–27

E173 Practice for Conducting Interlaboratory Studies of

Back-Titrimetric Method [28 % to 32 %]

Phosphorus by the

Methods for Chemical Analysis of Metals (Withdrawn

Molybdivanadophosphoric Acid 28–38 3

1997)

Extraction Spectrophotometric Method

E1601 Practice for Conducting an Interlaboratory Study to

[0.002 % to 0.014 %]

Evaluate the Performance of an Analytical Method

1.3 Units—The values stated in SI units are to be regarded

as standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions—For definitions of terms used in this test

1.4 This standard does not purport to address all of the

method, refer to Terminology E135.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.1 These test methods for the chemical analysis of metals

1.5 This international standard was developed in accor-

and alloys are primarily intended to test such materials for

dance with internationally recognized principles on standard-

compliance with compositional specifications. It is assumed

ization established in the Decision on Principles for the

that all who use these test methods will be trained analysts

Development of International Standards, Guides and Recom-

capable of performing common laboratory procedures skill-

mendations issued by the World Trade Organization Technical

fully and safely. It is expected that work will be performed in

Barriers to Trade (TBT) Committee.

a properly equipped laboratory.

These test methods are under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct For referenced ASTM standards, visit the ASTM website, www.astm.org, or

responsibility of Subcommittee E01.05 on Cu, Pb, Zn, Cd, Sn, Be, Precious Metals, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

their Alloys, and Related Metals. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Aug. 1, 2022. Published September 2022. Originally the ASTM website.

approved in 1976. Last previous edition approved in 2017 as E581 – 17a. DOI: The last approved version of this historical standard is referenced on

10.1520/E0581-17AR22E01. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E581 − 17a (2022)

5. Apparatus IRON BY THE 1,10-PHENANTHROLINE

SPECTROPHOTOMETRIC METHOD

5.1 Spectrophotometers shall conform to the requirements

prescribed in Practice E60.

11. Scope

11.1 This test method covers the determination of iron from

6. Reagents and Materials

0.003 % to 0.02 %.

6.1 Reagents required for each determination are listed in

separate sections of each test method. The standard solutions 12. Summary of Test Method

and certain other reagents used in more than one procedure

12.1 The sample is dissolved in HCl and hydrogen

shall conform to the requirements prescribed in Practices E50.

peroxide, and the excess oxidant removed by evaporation. The

6.2 Purity of Reagents—Reagent grade chemicals shall be iron is extracted with methyl isobutyl ketone-benzene mixture.

used in all tests. Unless otherwise indicated, all reagents shall The iron is extracted from the organic phase into a hydrox-

conform to the specifications of the Committee on Analytical ylamine hydrochloride solution and the red-colored 1,10-

Reagents of the American Chemical Society where such phenanthroline complex is formed. Spectrophotometric absor-

specifications are available. Other grades may be used, pro- bance measurement is made at 510 nm.

vided it is first ascertained that the reagent is of sufficiently

13. Iron Range

high purity to permit its use without lessening the accuracy of

13.1 Therecommendedrangeisfrom0.005 mgto0.125 mg

the determination.

of iron per 50 mL of solution using a 2 cm cell.

6.3 Purity of Water—Unless otherwise indicated, references

to water shall be understood to mean reagent water as defined NOTE1—Thistestmethodhasbeenwrittenforcellshavinga2 cmlight

path. Cells having other dimensions may be used, provided suitable

by Type I of Specification D1193.

adjustments can be made in the amounts of sample and reagents used.

7. Hazards

14. Stability of Color

7.1 For precautions to be observed in this method, refer to

14.1 The color develops within 5 min and is stable for at

Practices E50.

least 4 h.

7.2 A warning statement is given in 24.7.

15. Interferences

8. Sampling

15.1 Elements ordinarily present do not interfere if their

percentages are under the maximum limits shown in 1.1.

8.1 For procedures for sampling the material, refer to

Practices E55 and E88.

16. Reagents

16.1 Hydroxylamine Hydrochloride Solution (10 g/L)—

9. Rounding Calculated Values

Dissolve 5.0 g of hydroxylamine hydrochloride (NH OH·HCl)

9.1 Rounding of test results obtained using this test method

in 500 mL of water. Prepare fresh as needed.

shall be performed as directed in Practice E29, Rounding

16.2 Iron, Standard Solution A (1 mL = 0.125 mg Fe)—

Method, unless an alternative rounding method is specified by

Transfer 0.1250 g of iron (purity: 99.9 % min) to a 100 mL

the customer or applicable material specification.

beaker.Add 10 mLof HCl (1 + 1) and 1 mLof bromine water.

10. Interlaboratory Studies

Boil gently until the excess bromine is removed.Add 20 mLof

HCl, cool, transfer to a 1 L volumetric flask, dilute to volume,

10.1 These test methods have been evaluated in accordance

and mix.

with Practice E173, unless otherwise noted in the precision

section. The Reproducibility R of Practice E173 corresponds 16.3 Iron, Standard Solution B (1 mL = 0.00625 mg Fe)—

to the Reproducibility Index R of Practice E1601. The Repeat-

Using a pipet, transfer 50 mL of iron solution A

ability R of Practice E173 corresponds to the Repeatability (1 mL = 0.125 mg Fe) to a 1 L volumetric flask, dilute to

Index r of Practice E1601.

volume with HCl (1 + 49), and mix.

16.4 Methyl Isobutyl Ketone-Benzene Mixture—Mix

200 mL of methyl isobutyl ketone (MIBK) and 100 mL of

Reagent Chemicals, American Chemical Society Specifications, American benzene.

Chemical Society, Washington, DC, www.acs.org. For suggestions on the testing of

16.5 1,10-Phenanthroline-Ammonium Acetate Buffer

reagents not listed by the American Chemical Society, see the United States

Pharmacopeia and National Formulary, U.S. Pharmacopeial Convention, Inc. Solution—Dissolve 1.0 g of 1,10-phenanthroline monohydrate

(USPC), Rockville, MD, http://www.usp.org.

in 5 mLof HCl in a 600 mLbeaker.Add 215 mLof acetic acid

(CH COOH), and, while cooling, carefully add 265 mL of

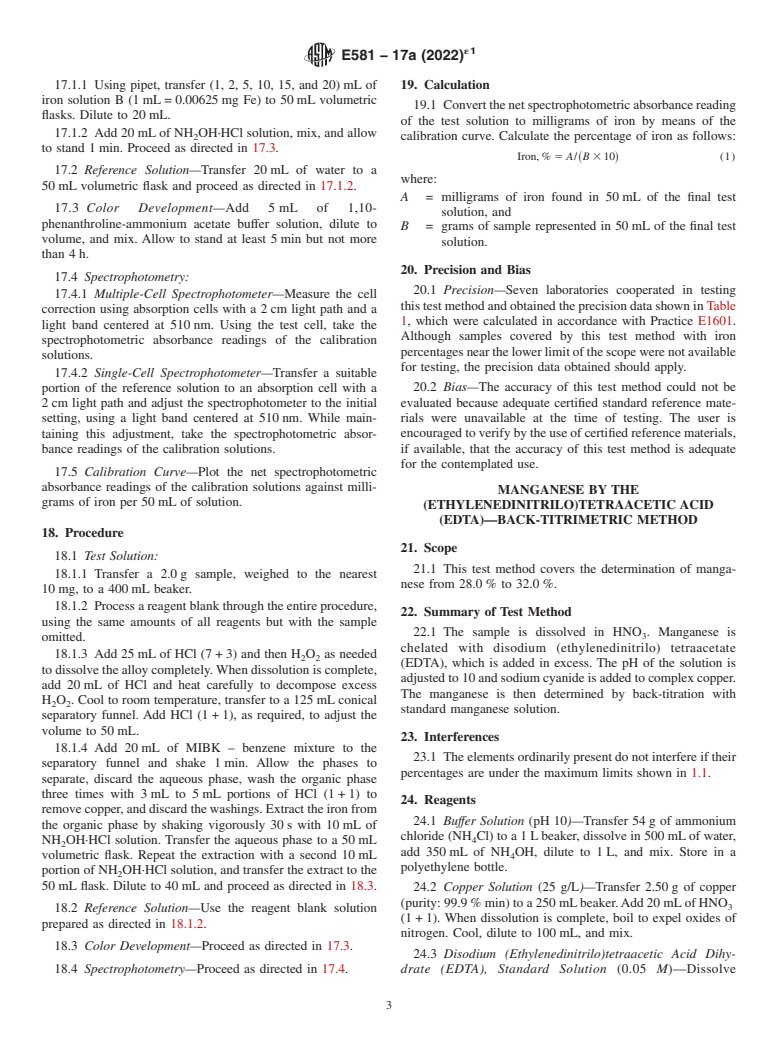

TABLE 1 Statistical Information

NH OH. Cool to room temperature. Using a pH meter, check

Iron Found, % Repeatability Reproducibility

the pH; if it is not between 6.0 and 6.5, adjust it to that range

Test Sample Labs (r, Practice (R, Practice

byaddingaceticacidorNH OHasrequired.Diluteto500 mL.

E1601) E1601)

Manganese 7 0.0137 0.0013 0.0028

17. Preparation of Calibration Curve

Copper

17.1 Calibration Solutions:

´1

E581 − 17a (2022)

17.1.1 Using pipet, transfer (1, 2, 5, 10, 15, and 20) mL of 19. Calculation

iron solution B (1 mL = 0.00625 mg Fe) to 50 mL volumetric

19.1 Convertthenetspectrophotometricabsorbancereading

flasks. Dilute to 20 mL.

of the test solution to milligrams of iron by means of the

17.1.2 Add 20 mL of NH OH·HCl solution, mix, and allow

calibration curve. Calculate the percentage of iron as follows:

to stand 1 min. Proceed as directed in 17.3.

Iron,% 5 A/ B 310 (1)

~ !

17.2 Reference Solution—Transfer 20 mL of water to a

where:

50 mL volumetric flask and proceed as directed in 17.1.2.

A = milligrams of iron found in 50 mL of the final test

17.3 Color Development—Add 5 mL of 1,10-

solution, and

phenanthroline-ammonium acetate buffer solution, dilute to

B = grams of sample represented in 50 mL of the final test

volume, and mix. Allow to stand at least 5 min but not more

solution.

than 4 h.

20. Precision and Bias

17.4 Spectrophotometry:

20.1 Precision—Seven laboratories cooperated in testing

17.4.1 Multiple-Cell Spectrophotometer—Measure the cell

thistestmethodandobtainedtheprecisiondatashowninTable

correction using absorption cells with a 2 cm light path and a

1, which were calculated in accordance with Practice E1601.

light band centered at 510 nm. Using the test cell, take the

Although samples covered by this test method with iron

spectrophotometric absorbance readings of the calibration

percentagesnearthelowerlimitofthescopewerenotavailable

solutions.

for testing, the precision data obtained should apply.

17.4.2 Single-Cell Spectrophotometer—Transfer a suitable

portion of the reference solution to an absorption cell with a 20.2 Bias—The accuracy of this test method could not be

2 cm light path and adjust the spectrophotometer to the initial evaluated because adequate certified standard reference mate-

rials were unavailable at the time of testing. The user is

setting, using a light band centered at 510 nm. While main-

taining this adjustment, take the spectrophotometric absor- encouragedtoverifybytheuseofcertifiedreferencematerials,

if available, that the accuracy of this test method is adequate

bance readings of the calibration solutions.

for the contemplated use.

17.5 Calibration Curve—Plot the net spectrophotometric

absorbance readings of the calibration solutions against milli-

MANGANESE BY THE

grams of iron per 50 mL of solution.

(ETHYLENEDINITRILO)TETRAACETIC ACID

(EDTA)—BACK-TITRIMETRIC METHOD

18. Procedure

21. Scope

18.1 Test Solution:

21.1 This test method covers the determination of manga-

18.1.1 Transfer a 2.0 g sample, weighed to the nearest

nese from 28.0 % to 32.0 %.

10 mg, to a 400 mL beaker.

18.1.2 Process a reagent blank through the entire procedure,

22. Summary of Test Method

using the same amounts of all reagents but with the sample

22.1 The sample is dissolved in HNO . Manganese is

omitted.

chelated with disodium (ethylenedinitrilo) tetraacetate

18.1.3 Add 25 mL of HCl (7 + 3) and then H O as needed

2 2

(EDTA), which is added in excess. The pH of the solution is

to dissolve the alloy completely.When dissolution is complete,

adjusted to 10 and sodium cyanide is added to complex copper.

add 20 mL of HCl and heat carefully to decompose excess

The manganese is then determined by back-titration with

H O . Cool to room temperature, transfer to a 125 mL conical

2 2

standard manganese solution.

separatory funnel. Add HCl (1 + 1), as required, to adjust the

volume to 50 mL.

23. Interferences

18.1.4 Add 20 mL of MIBK – benzene mixture to the

23.1 The elements ordinarily present do not interfere if their

separatory funnel and shake 1 min. Allow the phases to

percentages are under the maximum limits shown in 1.1.

separate, discard the aqueous phase, wash the organic phase

three times with 3 mL to 5 mL portions of HCl (1 + 1) to

24. Reagents

removecopper,anddiscardthewashings.Extracttheironfrom

24.1 Buffer Solution (pH 10)—Transfer 54 g of ammonium

the organic phase by shaking vigorously 30 s with 10 mL of

chloride (NH Cl) to a 1 Lbeaker, dissolve in 500 mLof water,

NH OH·HCl solution. Transfer the aqueous phase to a 50 mL 4

add 350 mL of NH OH, dilute to 1 L, and mix. Store in a

volumetric flask. Repeat the extraction with a second 10 mL

polyethylene bottle.

portion of NH OH·HCl solution, and transfer the extract to the

50 mL flask. Dilute to 40 mL and proceed as directed in 18.3.

24.2 Copper Solution (25 g/L)—Transfer 2.50 g of copper

(purity: 99.9 % min) to a 250 mLbeaker.Add 20 mLof HNO

18.2 Reference Solution—Use the reagent blank solution

(1 + 1). When dissolution is complete, boil to expel oxides of

prepared as directed in 18.1.2.

nitrogen. Cool, dilute to 100 mL, and mix.

18.3 Color Development—Proceed as directed in 17.3.

24.3 Disodium (Ethylenedinitrilo)tetraacetic Acid Dihy-

18.4 Spectrophotometry—Proceed as directed in 17.4. drate (EDTA), Standard Solution (0.05 M)—Dissolve

´1

E581 − 17a (2022)

18.6127 g of disodium (ethylenedinitrilo) tetraacetate dihy- 24.9 Sulfurous Acid (H SO ).

2 3

drate in water, transfer to a 1 L volumetric flask, dilute to

24.10 Zinc, Standard Solution (0.050 M)—Transfer

volume, and mix. The solution is stable for several months

3.2690 g of zinc (purity: 99.9 % min) to a 400 mL beaker, and

when stored in plastic or borosilicate glass bottles.

cover.Add 25 mL of HNO (1 + 1) and warm gently until the

24.3.1 Standardize the solution as follows: Using a pipet,

zinc is dissolved. Boil to expel oxides of nitrogen. Cool,

transfer 25 mL of zinc solution (0.050 M)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.