ASTM E478-08(2017)

(Test Method)Standard Test Methods for Chemical Analysis of Copper Alloys

Standard Test Methods for Chemical Analysis of Copper Alloys

SIGNIFICANCE AND USE

4.1 These test methods for the chemical analysis of metals and alloys are primarily intended as referee methods to test such materials for compliance with composition specifications. It is assumed that all who use these methods will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

1.1 These test methods cover the chemical analysis of copper alloys having chemical ranges within the following limits:2

Element

Composition, %

Aluminum

12.0 max

Antimony

1.0 max

Arsenic

1.0 max

Cadmium

1.5 max

Cobalt

1.0 max

Copper

40.0 min

Iron

6.0 max

Lead

27.0 max

Manganese

6.0 max

Nickel

50.0 max

Phosphorus

1.0 max

Silicon

5.0 max

Sulfur

0.1 max

Tin

20.0 max

Zinc

50.0 max

1.2 The test methods appear in the following order:

Sections

Aluminum by the Carbamate Extraction-Ethyl-

enedinitrilotetraacetate Titrimetric Test Method [2 % to 12 %]

71 – 78

Copper by the Combined Electrodeposition Gravimetric and Oxalyldihydrazide Spectrophotometric Test Method [50 %, minimum]

10 – 18

Iron by the 1,10-Phenanthroline Spectrophotometric Test Method [0.003 % to 1.25 %]

19 – 28

Lead by Atomic Absorption Spectrometry [0.002 % to 15 %]

90 – 100

Lead by the Ethylenedinitrilotetraacetic Acid (EDTA) Titrimetric Test Method [2.0 % to 30.0 %]

29 – 36

Nickel by the Dimethylglyoxime Extraction Sprectophotometric Test Method [0.03 % to 5.0 %]

37 – 46

Nickel by the Dimethylglyoxime Gravimetric Test Method [4 % to 50 %]

55 – 62

Silver in Silver-Bearing Copper by Atomic Absorption Spectrometry [0.01 % to 0.12 %]

101 – 112

Tin by the Iodotimetric Titration Test Method [0.5 % to 20 %]

63 – 70

Tin by the Phenylfluorone Spectrophotometric Test Method [0.01 % to 1.0 %]

113 – 123

Zinc by Atomic Absorption Spectrometry [0.2 % to 2 %]

79 – 89

Zinc by the Ethylenedinitrilotetraacetic Acid (EDTA) Titrimetric Test Method [2 % to 40 %]

47 – 54

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E478 − 08 (Reapproved 2017)

Standard Test Methods for

Chemical Analysis of Copper Alloys

This standard is issued under the fixed designation E478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

Tin by the Iodotimetric Titration Test Method

[0.5 % to 20 %] 63–70

1.1 These test methods cover the chemical analysis of

Tin by the Phenylfluorone Spectrophotometric

copper alloys having chemical ranges within the following Test Method [0.01 % to 1.0 %] 113 – 123

Zinc by Atomic Absorption Spectrometry [0.2 %

limits:

to 2 %] 79–89

Element Composition, % Zinc by the Ethylenedinitrilotetraacetic Acid

(EDTA) Titrimetric Test Method [2 % to 40 %] 47–54

Aluminum 12.0 max

1.3 The values stated in SI units are to be regarded as

Antimony 1.0 max

Arsenic 1.0 max standard. No other units of measurement are included in this

Cadmium 1.5 max

standard.

Cobalt 1.0 max

Copper 40.0 min 1.4 This standard does not purport to address all of the

Iron 6.0 max

safety concerns, if any, associated with its use. It is the

Lead 27.0 max

responsibility of the user of this standard to establish appro-

Manganese 6.0 max

Nickel 50.0 max priate safety and health practices and determine the applica-

Phosphorus 1.0 max

bility of regulatory limitations prior to use.

Silicon 5.0 max

1.5 This international standard was developed in accor-

Sulfur 0.1 max

Tin 20.0 max

dance with internationally recognized principles on standard-

Zinc 50.0 max

ization established in the Decision on Principles for the

1.2 The test methods appear in the following order:

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

Sections

Aluminum by the Carbamate Extraction-Ethyl-

Barriers to Trade (TBT) Committee.

enedinitrilotetraacetate Titrimetric Test

Method [2 % to 12 %] 71–78

2. Referenced Documents

Copper by the Combined Electrodeposition

Gravimetric and Oxalyldihydrazide Spectro-

2.1 ASTM Standards:

photometric Test Method [50 %, minimum] 10–18

Iron by the 1,10-Phenanthroline Spectrophoto- E29 Practice for Using Significant Digits in Test Data to

metric Test Method [0.003 % to 1.25 %] 19–28

Determine Conformance with Specifications

Lead by Atomic Absorption Spectrometry

E50 Practices for Apparatus, Reagents, and Safety Consid-

[0.002%to15%] 90 – 100

Lead by the Ethylenedinitrilotetraacetic Acid erations for Chemical Analysis of Metals, Ores, and

(EDTA) Titrimetric Test Method [2.0 % to

Related Materials

30.0 %] 29–36

E60 Practice for Analysis of Metals, Ores, and Related

Nickel by the Dimethylglyoxime Extraction

Sprectophotometric Test Method [0.03 % to

Materials by Spectrophotometry

5.0 %] 37–46

E135 Terminology Relating to Analytical Chemistry for

Nickel by the Dimethylglyoxime Gravimetric

Metals, Ores, and Related Materials

Test Method [4 % to 50 %] 55–62

Silver in Silver-Bearing Copper by Atomic Ab-

E173 Practice for Conducting Interlaboratory Studies of

sorption Spectrometry [0.01 % to 0.12 %] 101 – 112

Methods for Chemical Analysis of Metals (Withdrawn

1998)

These test methods are under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct

responsibility of Subcommittee E01.05 on Cu, Pb, Zn, Cd, Sn, Be, Precious Metals, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

their Alloys, and Related Metals. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Jan. 15, 2017. Published March 2017. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1973. Last previous edition approved in 2008 as E478 – 08. DOI: the ASTM website.

10.1520/E0478-08R17. The last approved version of this historical standard is referenced on

The actual limits of application of each test method are presented in 1.2. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E478 − 08 (2017)

E255 Practice for Sampling Copper and Copper Alloys for 10.2 This international standard was developed in accor-

the Determination of Chemical Composition dance with internationally recognized principles on standard-

E1601 Practice for Conducting an Interlaboratory Study to ization established in the Decision on Principles for the

Evaluate the Performance of an Analytical Method Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3. Terminology

Barriers to Trade (TBT) Committee.

3.1 For definitions of terms used in these test methods, refer

11. Summary of Test Method

to Terminology E135.

11.1 After dissolution of the sample in HNO and HF, the

4. Significance and Use

oxidesofnitrogenarereducedwithhydrogenperoxide,andthe

4.1 These test methods for the chemical analysis of metals copper deposited electrolytically. Loss of platinum from the

anode is minimized by the addition of lead. The copper

and alloys are primarily intended as referee methods to test

such materials for compliance with composition specifications. oxalyldihydrazide complex is formed with the copper remain-

ing in the electrolyte. Photometric measurement is made at

It is assumed that all who use these methods will be trained

approximately 540 nm.

analysts capable of performing common laboratory procedures

skillfully and safely. It is expected that work will be performed

12. Interferences

in a properly equipped laboratory.

12.1 The elements ordinarily present do not interfere if their

5. Apparatus, Reagents, and Spectrophotometric Practice

concentrations are under the maximum limits shown in 1.1.

5.1 Apparatus, standard solutions, and other reagents re-

13. Apparatus

quired for each determination are listed in separate sections

preceding the procedure. Spectrophotometers shall conform to 13.1 Polytetrafluoroethylene or Polypropylene Beakers,

250-mL capacity.

the requirements prescribed in Practice E60.

5.2 Spectrophotometric practice prescribed in these test 13.2 PolytetrafluoroethyleneorPolypropyleneSplitCovers.

methods shall conform to Practice E60.

13.3 Electrodes for Electroanalysis—Recommended sta-

tionary type platinum electrodes are described in 13.3.1 and

6. Hazards

13.3.2. The surface of the platinum electrode should be

6.1 Specific hazard statements are given in 33.7, 51.13, and

smooth, clean, and bright to promote uniform deposition and

107.1.

good adherence. Deviations from the exact size and shape are

6.2 Forotherprecautionstobeobservedintheuseofcertain allowable. In instances where it is desirable to decrease the

time of deposition and agitation of the electrolyte is

reagents in these test methods, refer to Practices E50.

permissible, a generally available rotating type of electrode

7. Sampling

may be employed. Cleaning of the electrode by sandblasting is

not recommended.

7.1 For procedures for sampling the material, refer to

13.3.1 Cathodes—Platinum cathodes may be either open or

Practice E255. However, this practice does not supersede any

closed cylinders formed from sheets that are plain or

sampling requirements specified in a specific ASTM material

perforated, or from gauze. Gauze cathodes are recommended;

specification.

preferably from 50-mesh gauze woven from approximately

8. Rounding Calculated Values

0.21-mm diameter wire. The top and bottom of gauze cathodes

should be reinforced by doubling the gauze about 3 mm onto

8.1 Calculated values shall be rounded to the desired num-

itself, or by the use of platinum bands or rings. The cylinder

ber of places as directed in Practice E29.

should be approximately 30 mm in diameter and 50 mm in

9. Interlaboratory Studies

height. The stem should be made from a platinum alloy wire

such as platinum-iridium, platinum-rhodium, or platinum-

9.1 These test methods were evaluated in accordance with

ruthenium, having a diameter of approximately 1.3 mm. It

Practice E173 unless otherwise noted in the precision section.

should be flattened and welded the entire length of the gauze.

Practice E173 has been replaced by Practice E1601. The

The overall height of the cathode should be approximately

Reproducibility R corresponds to the Reproducibility Index R

130 mm. A cathode of these dimensions will have a surface

of Practice E1601. The Repeatability R of Practice E173

area of 135 cm exclusive of the stem.

corresponds to the Repeatability Index r of Practice E1601.

13.3.2 Anodes—Platinum anodes may be a spiral type when

COPPER BY THE COMBINED

anodic deposits are not being determined, or if the deposits are

ELECTRODEPOSITION GRAVIMETRIC AND small (as in the electrolytic determination of lead when it is

OXALYLDIHYDRAZIDE SPECTROPHOTOMETRIC

present in compositions below 0.2 %). Spiral anodes should be

TEST METHOD

made from 1.0 mm or larger platinum wire formed into a spiral

of seven turns having a height of approximately 50 mm and a

10. Scope

diameter of 12 mm with an overall height of approximately

10.1 This test method covers the determination of copper in 130 mm.Aspiralanodeofthesedimensionswillhaveasurface

compositions greater than 50 %. area of 9 cm . When both cathode and anode plates are to be

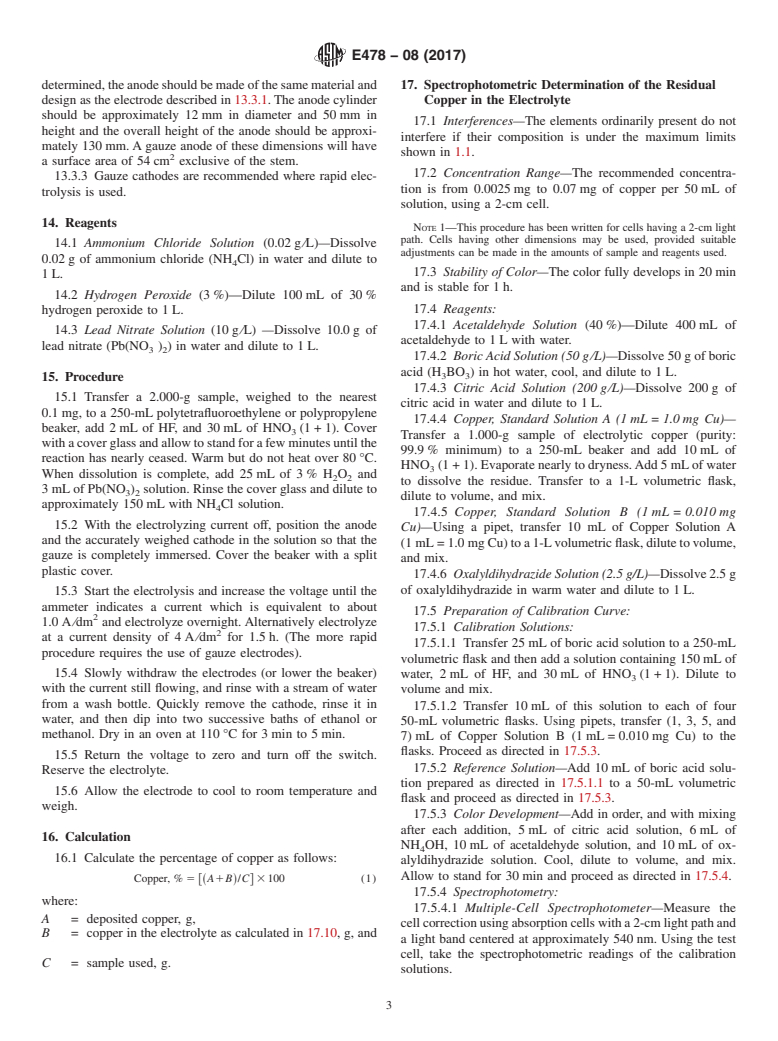

E478 − 08 (2017)

determined,theanodeshouldbemadeofthesamematerialand 17. Spectrophotometric Determination of the Residual

design as the electrode described in 13.3.1. The anode cylinder Copper in the Electrolyte

should be approximately 12 mm in diameter and 50 mm in

17.1 Interferences—The elements ordinarily present do not

height and the overall height of the anode should be approxi-

interfere if their composition is under the maximum limits

mately 130 mm. A gauze anode of these dimensions will have

shown in 1.1.

a surface area of 54 cm exclusive of the stem.

17.2 Concentration Range—The recommended concentra-

13.3.3 Gauze cathodes are recommended where rapid elec-

tion is from 0.0025 mg to 0.07 mg of copper per 50 mL of

trolysis is used.

solution, using a 2-cm cell.

14. Reagents

NOTE 1—This procedure has been written for cells having a 2-cm light

path. Cells having other dimensions may be used, provided suitable

14.1 Ammonium Chloride Solution (0.02 g⁄L)—Dissolve

adjustments can be made in the amounts of sample and reagents used.

0.02 g of ammonium chloride (NH Cl) in water and dilute to

17.3 Stability of Color—The color fully develops in 20 min

1L.

and is stable for 1 h.

14.2 Hydrogen Peroxide (3 %)—Dilute 100 mL of 30 %

17.4 Reagents:

hydrogen peroxide to 1 L.

17.4.1 Acetaldehyde Solution (40 %)—Dilute 400 mL of

14.3 Lead Nitrate Solution (10 g⁄L) —Dissolve 10.0 g of

acetaldehyde to 1 L with water.

lead nitrate (Pb(NO ) ) in water and dilute to 1 L.

3 2

17.4.2 BoricAcidSolution(50g⁄L)—Dissolve 50 g of boric

acid (H BO ) in hot water, cool, and dilute to 1 L.

3 3

15. Procedure

17.4.3 Citric Acid Solution (200g⁄L)—Dissolve 200 g of

15.1 Transfer a 2.000-g sample, weighed to the nearest

citric acid in water and dilute to 1 L.

0.1 mg, to a 250-mL polytetrafluoroethylene or polypropylene

17.4.4 Copper, Standard Solution A (1mL=1.0mg Cu)—

beaker, add 2 mL of HF, and 30 mL of HNO (1 + 1). Cover

Transfer a 1.000-g sample of electrolytic copper (purity:

withacoverglassandallowtostandforafewminutesuntilthe

99.9 % minimum) to a 250-mL beaker and add 10 mL of

reaction has nearly ceased. Warm but do not heat over 80 °C.

HNO (1 + 1). Evaporate nearly to dryness.Add 5 mLof water

When dissolution is complete, add 25 mL of 3 % H O and

2 2

to dissolve the residue. Transfer to a 1-L volumetric flask,

3 mLof Pb(NO ) solution. Rinse the cover glass and dilute to

3 2

dilute to volume, and mix.

approximately 150 mL with NH Cl solution.

17.4.5 Copper, Standard Solution B (1 mL = 0.010 mg

15.2 With the electrolyzing current off, position the anode

Cu)—Using a pipet, transfer 10 mL of Copper Solution A

and the accurately weighed cathode in the solution so that the

(1 mL = 1.0 mgCu)toa1-Lvolumetricflask,dilutetovolume,

gauze is completely immersed. Cover the beaker with a split

and mix.

plastic cover.

17.4.6 OxalyldihydrazideSolution(2.5g/L)—Dissolve2.5 g

of oxalyldihydrazide in warm water and dilute to 1 L.

15.3 Start the electrolysis and increase the voltage until the

ammeter indicates a current which is equivalent to about

17.5 Preparation of Calibration Curve:

1.0 A⁄dm and electrolyze overnight.Alternatively electrolyze

17.5.1 Calibration Solutions:

at a current density of 4 A⁄dm for 1.5 h. (The more rapid

17.5.1.1 Transfer 25 mL of boric acid solution to a 250-mL

procedure requires the use of gauze electrodes).

volumetric flask and then add a solution containing 150 mL of

15.4 Slowly withdraw the electrodes (or lower the beaker)

water, 2 mL of HF, and 30 mL of HNO (1 + 1). Dilute to

with the current still flowing, and rinse with a stream of water

volume and mix.

from a wash bottle. Quickly remove the cathode, rinse it in

17.5.1.2 Transfer 10 mL of this solution to each of four

water, and then dip into two successive baths of ethanol or

50-mL volumetric flasks. Using pipets, transfer (1, 3, 5, and

methanol. Dry in an oven at 110 °C for 3 min to 5 min.

7) mL of Copper Solution B (1 mL = 0.010 mg Cu) to the

flasks. Proceed as directed in 17.5.3.

15.5 Return the voltage to zero and turn off the switch.

17.5.2 Reference Solution—Add 10 mL of boric acid solu-

Reserve the electrolyte.

tion prepared as directed in 17.5.1.1 to a 50-mL volumetric

15.6 Allow the electrode to cool to room temperature and

flask and proceed as directed in 17.5.3.

weigh.

17.5.3 Color Development—Add in order, and with mixing

after each addition, 5 mL of citric acid solution, 6 mL of

16. Calculation

NH OH, 10 mL of acetaldehyde solution, and 10 mL of ox-

16.1 Calculate the percentage of copper as follows:

alyldihydrazide solution. Cool, dilute to volume, and mix.

Allow to stand for 30 min and proceed as directed in 17.5.4.

Copper, % 5 @~A1B!/C# 3100 (1)

17.5.4 Spectrophotometry:

where:

17.5.4.1 Multiple-Cell Spectrophotometer—Measure the

A = deposited copper, g,

cellcorrectionusingabsorptioncellswitha2-cmlightpathand

B = copper in the electrolyte as calculated in 17.10,g,and

a light band centered at approximately 540 nm. Using the test

cell, take the spectrophotometric readi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.