ASTM C31/C31M-00e1

(Practice)Standard Practice for Making and Curing Concrete Test Specimens in the Field

Standard Practice for Making and Curing Concrete Test Specimens in the Field

SCOPE

1.1 This practice covers procedures for making and curing cylindrical and prismatic beam specimens from representative samples of fresh concrete for a construction project.

1.2 The concrete used to make the molded specimens shall be sampled after all on-site adjustments have been made to the mixture proportions, including the addition of mix water and admixtures. This practice is not satisfactory for making specimens from concrete not having a measurable slump or requiring other sizes and shapes of specimens.

1.3 The values stated in either inch-pound units or SI units shall be regarded separately as standard. The SI units are shown in brackets. The values stated may not be exact equivalents; therefore each system must be used independently of the other. Combining values from the two units may result in nonconformance.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 The text of this standard references notes which provide explanatory material. These notes shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: C 31/C 31M – 00

Standard Practice for

1

Making and Curing Concrete Test Specimens in the Field

This standard is issued under the fixed designation C 31/C 31M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Table number 2 was editorially corrected June 2001.

1. Scope C 173 Test Method for Air Content of Freshly Mixed

2

Concrete by the Volumetric Method

1.1 This practice covers procedures for making and curing

C 192/C 192M Practice for Making and Curing Concrete

cylinder and beam specimens from representative samples of

2

Test Specimens in the Laboratory

fresh concrete for a construction project.

C 231 Test Method for Air Content of Freshly Mixed

1.2 The concrete used to make the molded specimens shall

2

Concrete by the Pressure Method

be sampled after all on-site adjustments have been made to the

C 330 Specification for Lightweight Aggregate for Concrete

mixture proportions, including the addition of mix water and

2

Masonry Units

admixtures. This practice is not satisfactory for making speci-

C 403/C 403M Test Method for Time of Setting of Con-

mens from concrete not having measurable slump or requiring

2

crete Mixtures by Penetration Resistance

other sizes or shapes of specimens.

C 470/C 470M Specification for Molds for Forming Con-

1.3 The values stated in either inch-pound units or SI units

2

crete Test Cylinders Vertically

shall be regarded separately as standard. The SI units are

C 511 Specification for Moist Cabinets, Moist Rooms, and

shown in brackets. The values stated may not be exact

Water Storage Tanks Used in the Testing of Hydraulic

equivalents; therefore each system must be used independently

3

Cements and Concretes

of the other. Combining values from the two units may result

C 617 Practice for Capping Cylindrical Concrete Speci-

in nonconformance.

2

mens

1.4 This standard does not purport to address all of the

C 1064 Test Method for Temperature of Freshly Mixed

safety concerns, if any, associated with its use. It is the

2

Portland-Cement Concrete

responsibility of the user of this standard to establish appro-

4

2.2 American Concrete Institute Publication:

priate safety and health practices and determine the applica-

CP-1 Concrete Field Testing Technician, Grade I

bility of regulatory limitations prior to use.

309R Guide for Consolidation of Concrete

1.5 The text of this standard references notes which provide

explanatory material. These notes shall not be considered as

3. Significance and Use

requirements of the standard.

3.1 This practice provides standardized requirements for

2. Referenced Documents making, curing, protecting, and transporting concrete test

specimens under field conditions.

2.1 ASTM Standards:

3.2 If the specimens are made and standard cured, as

C 138 Test Method for Unit Weight, Yield, and Air Content

2

stipulated herein, the resulting strength test data when the

(Gravimetric) of Concrete

specimens are tested are able to be used for the following

C 143/C 143M Test Method for Slump of Hydraulic Ce-

2

purposes:

ment Concrete

2 3.2.1 Acceptance testing for specified strength,

C 172 Practice for Sampling Freshly Mixed Concrete

3.2.2 Checking adequacy of mixture proportions for

strength, and

3.2.3 Quality control.

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete

and Concrete Aggregatesand is the direct responsibility of Subcommittee C09.61 on

Testing Concrete for Strength.

3

Current edition approved Aug. 10, 2000. Published October 2000. Originally Annual Book of ASTM Standards, Vol 04.01.

4

published as C 31 – 20. Last previous edition C 31/C 31M – 98. Available from American Concrete Institute, P.O. Box 9094, Farmington Hills,

2

Annual Book of ASTM Standards, Vol 04.02. MI 48333-9094.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

C 31/C 31M – 00

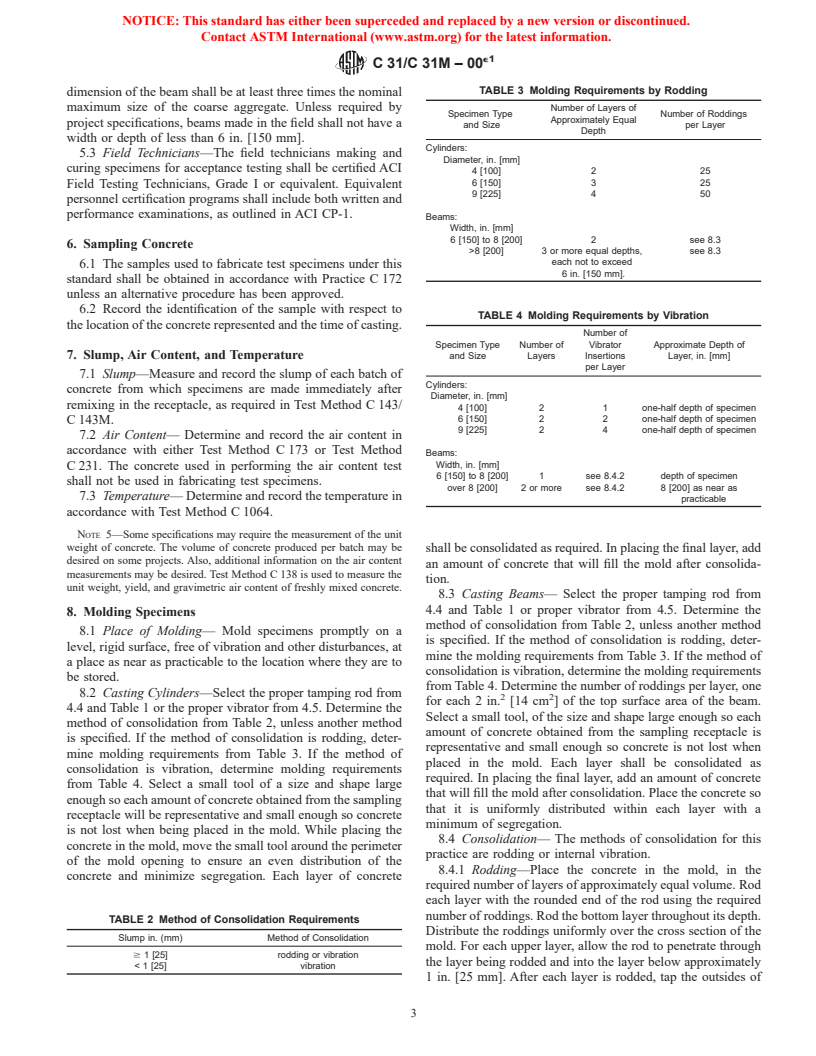

3.3 If the specimens are made and field cured, as stipulated length of the vibrator shaft and vibrating element shall exceed

herein, the resulting strength test data when the specimens are the depth of the section being vibrated by at least 3 in. [75

tested are able to be used for the following purposes: mm]. The vibrator frequency shall be checked periodically.

3.3.1 Determination of whether a stru

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.