ASTM C873/C873M-23

(Test Method)Standard Test Method for Compressive Strength of Concrete Cylinders Cast in Place in Cylindrical Molds

Standard Test Method for Compressive Strength of Concrete Cylinders Cast in Place in Cylindrical Molds

ABSTRACT

This test method covers the determination of strength of cylindrical concrete specimens that have been molded in place using special molds attached to formwork. A concrete cylinder mold assembly consisting of a mold and a tubular support member is fastened within the concrete formwork prior to placement of the concrete. The elevation of the mold upper edge is adjusted to correspond to the plane of the finished slab surface. The mold support prevents direct contact of the slab concrete with the outside of the mold and permits its easy removal from the hardened concrete. Strength of cast-in-place cylinders may be used for various purposes, such as estimating the load-bearing capacity of slabs, determining the time of form and shore removal, and determining the effectiveness of curing and protection. Consolidation of concrete in the mold may be varied to simulate the conditions of placement. Internal vibration of concrete in the mold is prohibited except under special circumstances.

SIGNIFICANCE AND USE

4.1 Cast-in-place cylinder strength relates to the strength of concrete in the structure due to the similarity of curing conditions because the cylinder is cured within the slab. However, due to differences in moisture condition, degree of consolidation, specimen size, and length-diameter ratio, there is not a unique relationship between the strength of cast-in-place cylinders and cores of the same age. When cores can be drilled undamaged and tested in the same moisture condition as the cast-in-place cylinders, the strength of the cylinders can be expected to be on average 10 % higher than the cores at ages up to 91 days for specimens of the same size and length-diameter ratio.4

4.2 Strength of cast-in-place cylinders may be used for various purposes, such as estimating the load-bearing capacity of slabs, determining the time of form and shore removal, and determining the effectiveness of curing and protection.

SCOPE

1.1 This test method covers the determination of strength of cylindrical concrete specimens that have been molded in place using special molds attached to formwork. This test method is limited to use in slabs where the depth of concrete is from 125 mm to 300 mm [5 in. to 12 in.].

1.2 The text of this standard refers to notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.2)

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C873/C873M − 23

Standard Test Method for

Compressive Strength of Concrete Cylinders Cast in Place

1

in Cylindrical Molds

This standard is issued under the fixed designation C873/C873M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 This test method covers the determination of strength of

C39/C39M Test Method for Compressive Strength of Cylin-

cylindrical concrete specimens that have been molded in place

drical Concrete Specimens

using special molds attached to formwork. This test method is

C42/C42M Test Method for Obtaining and Testing Drilled

limited to use in slabs where the depth of concrete is from

Cores and Sawed Beams of Concrete

125 mm to 300 mm [5 in. to 12 in.].

C470/C470M Specification for Molds for Forming Concrete

1.2 The text of this standard refers to notes and footnotes

Test Cylinders Vertically

that provide explanatory material. These notes and footnotes

C617/C617M Practice for Capping Cylindrical Concrete

(excluding those in tables and figures) shall not be considered

Specimens

as requirements of the standard.

C670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

1.3 Units—The values stated in either SI units or inch-

C1231/C1231M Practice for Use of Unbonded Caps in

pound units are to be regarded separately as standard. The

Determination of Compressive Strength of Hardened Cy-

values stated in each system are not necessarily exact equiva-

lindrical Concrete Specimens

lents; therefore, to ensure conformance with the standard, each

system shall be used independently of the other, and values

3. Summary of Test Method

from the two systems shall not be combined. Combining values

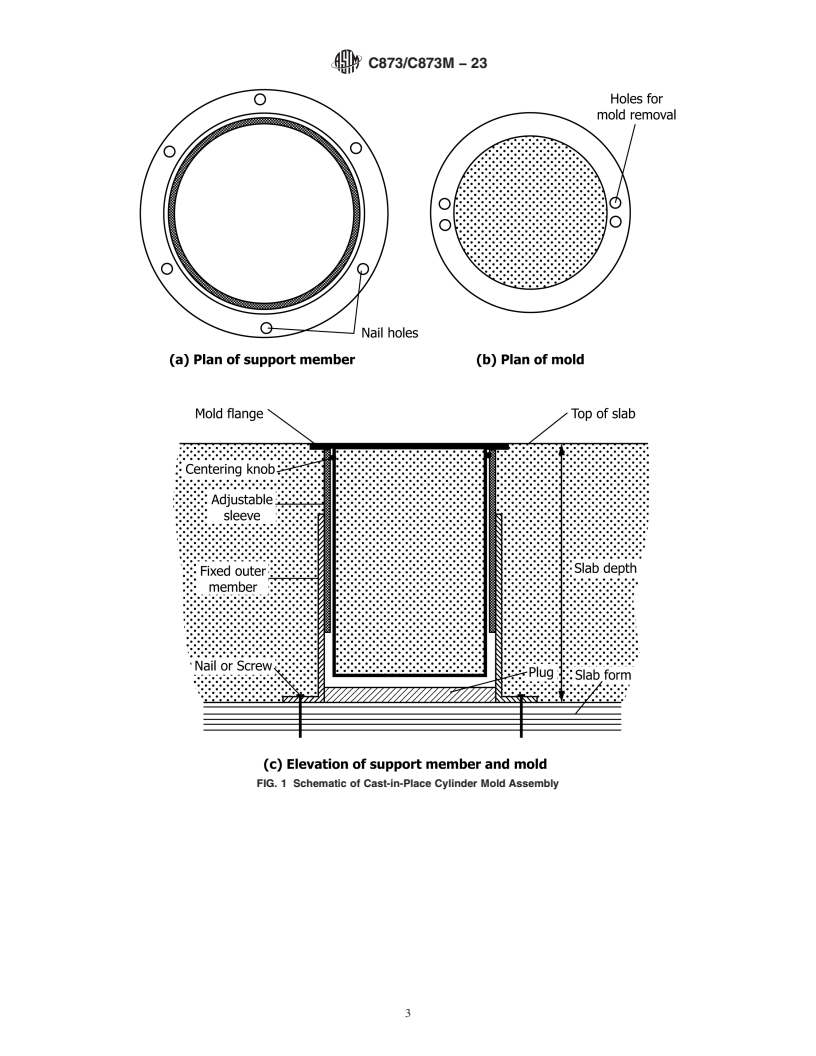

from the two systems may result in non-conformance with the 3.1 A concrete cylinder mold assembly consisting of a mold

standard.

and a tubular support member is fastened within the concrete

formwork prior to placement of the concrete as shown in Fig.

1.4 This standard does not purport to address all of the

1. The elevation of the mold upper edge is adjusted to

safety concerns, if any, associated with its use. It is the

correspond to the level of the finished slab surface. The mold

responsibility of the user of this standard to establish appro-

support prevents direct contact of the slab concrete with the

priate safety, health, and environmental practices and deter-

outside of the mold and permits easy removal of the mold from

mine the applicability of regulatory limitations prior to use.

the slab. The mold is filled at the time its location is reached in

(Warning—Fresh hydraulic cementitious mixtures are caustic

the normal course of concrete placement. The specimen in the

and may cause chemical burns to skin and tissue upon

2 “cured-in-place” condition is removed from its in-place loca-

prolonged exposure. )

tion immediately prior to de-molding, capping, and testing.

1.5 This international standard was developed in accor-

The reported compressive strength is corrected on the basis of

dance with internationally recognized principles on standard-

specimen length-diameter ratio using correction factors pro-

ization established in the Decision on Principles for the

vided in the section on calculation of Test Method C42/C42M.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Significance and Use

Barriers to Trade (TBT) Committee.

4.1 Cast-in-place cylinder strength relates to the strength of

concrete in the structure due to the similarity of curing

conditions because the cylinder is cured within the slab.

1

This test method is under the jurisdiction of ASTM Committee C09 on

However, due to differences in moisture condition, degree of

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

C09.61 on Testing for Strength.

Current edition approved Oct. 1, 2023. Published October 2023. Originally

3

approved in 1977. Last previous edition approved in 2015 as C873/C873M–15. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/C0873_C0873M-23. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Section on Safety Precautions, Manual of Aggregate and Concrete Testing, Standards volume information, refer to the standard’s Document Summary page on

Annual Book of ASTM Standards, Vol 04.02. the ASTM website.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C873/C873M − 15 C873/C873M − 23

Standard Test Method for

Compressive Strength of Concrete Cylinders Cast in Place

1

in Cylindrical Molds

This standard is issued under the fixed designation C873/C873M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of strength of cylindrical concrete specimens that have been molded in place using

special molds attached to formwork. This test method is limited to use in slabs where the depth of concrete is from 125125 mm

to 300 mm [5[5 in. to 12 in.].

1.2 The text of this standard refers to notes and footnotes that provide explanatory material. These notes and footnotes (excluding

those in tables and figures) shall not be considered as requirements of the standard.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in

each system may not beare not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall

be used independently of the other. other, and values from the two systems shall not be combined. Combining values from the two

systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to consult and establish appropriate safety and healthsafety, health, and environmental practices and

determine the applicability of regulatory limitations prior to use. (Warning—Fresh hydraulic cementitious mixtures are caustic

2

and may cause chemical burns to skin and tissue upon prolonged exposure. )

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

C39/C39M Test Method for Compressive Strength of Cylindrical Concrete Specimens

C42/C42M Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete

C470/C470M Specification for Molds for Forming Concrete Test Cylinders Vertically

C617C617/C617M Practice for Capping Cylindrical Concrete Specimens

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

1

This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.61 on

Testing for Strength.

Current edition approved Dec. 1, 2015Oct. 1, 2023. Published February 2016October 2023. Originally approved in 1977. Last previous edition approved in 20102015 as

C873/C873M–10a. DOI: 10.1520/C0873_C0873M-15.–15. DOI: 10.1520/C0873_C0873M-23.

2

Section on Safety Precautions, Manual of Aggregate and Concrete Testing, Annual Book of ASTM Standards, Vol 04.02.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C873/C873M − 23

C1231/C1231M Practice for Use of Unbonded Caps in Determination of Compressive Strength of Hardened Cylindrical

Concrete Specimens

3. Summary of Test Method

3.1 A concrete cylinder mold assembly consisting of a mold and a tubular support member is fastened within the concrete

formwork prior to placement of the concrete as shown in Fig. 1. The elevation of the mold upper edge is adjusted to correspond

to the level of the finished slab surface. The mold support prevents direct contact of the slab concrete with the outside of the mold

and permits easy removal of the mold from the slab. The mold is filled at the time its location is reached in the normal course of

concrete placement. The specimen in the “cured-in-place” condition is removed from its in-place location immedia

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.