ASTM D3836-13

(Practice)Standard Practice for Evaluation of Automotive Polish

Standard Practice for Evaluation of Automotive Polish

SIGNIFICANCE AND USE

4.1 This practice is intended to define the properties to be tested, the apparatus to use, and the comparisons of product performance. It is recognized that considerable discretion exists among formulators and marketers of automotive polish on what properties or performance characteristics are most important for their products. This practice is flexible enough to honor this fact within the confines of the automotive polish definition.

4.2 The methods of this practice are subjective and empirical in order to conform to the basic practices of the industry and to allow flexibility in testing.

SCOPE

1.1 This practice covers testing properties and apparatus used in evaluating the performance of automotive polishes. This practice is applicable to products that are commonly referred to as car/auto wax, cleaner wax, polish, etc.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3836 − 13

Standard Practice for Evaluation of

1

Automotive Polish

This standard is issued under the fixed designation D3836; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Apparatus and Materials

1.1 This practice covers testing properties and apparatus

5.1 Test Polish.

used in evaluating the performance of automotive polishes.

5.2 Control Polish—The control polish is selected for com-

This practice is applicable to products that are commonly

parison to the test polish. It may be a competitive product, a

referred to as car/auto wax, cleaner wax, polish, etc.

modified formulation of the test polish, etc. It should be

1.2 The values stated in SI units are to be regarded as

recognized that automotive polishes are formulated to perform

standard. No other units of measurement are included in this

different functions. This should be taken into account when

standard.

interpreting results and choosing the control polish.

1.3 This standard does not purport to address all of the

5.3 Test Substrates—The test substrate shall be one for

safety concerns, if any, associated with its use. It is the

whichthetestpolishisintended(Note1).Thetestsurfaceshall

responsibility of the user of this standard to establish appro-

be in good physical condition, not badly cracked, scratched, or

priate safety and health practices and determine the applica-

otherwise damaged so as to interfere with evaluation of polish

bility of regulatory limitations prior to use.

properties. The minimum test surface area for each sample

2

shall be 1290 cm .

2. Referenced Documents

NOTE 1—It is important to select a test substrate for which a particular

2.1 ASTM Standard:

polish is intended. For example, if a particular polish is intended for a

D1133 Test Method for Kauri-Butanol Value of Hydrocar-

certain make of car only, then the test substrate should reflect this.

bon Solvents

Standard paint panels that were previously available throughASTM have

been discontinued as of January 1, 1988. It became very difficult to

maintain paint panels that were representative of all current and past paint

3. Terminology

technologies used to manufacture automotive finishes. Since 5.3 requires

3.1 Definitions of Terms Specific to This Standard:

that the test substrate be one for which the test polish is intended, it is in

3.1.1 automotive polish—liquid or paste formulation for

the best interest of the user of this practice to determine and obtain the

appropriate test surface or coating, or both. ASTM Committee D21 on

cleaning and improving the appearance of automobile finishes.

Polishes suggests if further assistance is needed in determining or

obtaining appropriate test substrates that contact be made with automotive

4. Significance and Use

paint manufacturers, automobile manufacturers, or re-painting services.

4.1 This practice is intended to define the properties to be

5.4 Polishing Cloth—The same type and size of polishing

tested, the apparatus to use, and the comparisons of product

cloth shall be used with each sample tested. Separate cloths

performance. It is recognized that considerable discretion

shallbeusedforeachsample.Materialssuchaswashedcheese

exists among formulators and marketers of automotive polish

cloth, rumple cloth, flannel, cotton diaper cloth, and nonwoven

on what properties or performance characteristics are most

fabrics are suitable for this purpose. Felt or paper shall not be

important for their products. This practice is flexible enough to

used.

honor this fact within the confines of the automotive polish

definition.

5.5 Cleaning Solvent:

5.5.1 Aliphatic solvents with kauri butanol (Kb) values less

4.2 The methods of this practice are subjective and empiri-

than 38. (See Test Method D1133.)

cal in order to conform to the basic practices of the industry

and to allow flexibility in testing.

5.5.2 Water/isopropanol (70/30).

5.6 Eye Droppers and Distilled or Deionized Water.

1

This practice is under the jurisdiction of ASTM Committee D21 on Polishes

5.7 Masking Tape, with a 9.5-mm width.

and is the direct responsibility of Subcommittee D21.04 on Performance Tests.

Current edition approved Oct. 1, 2013. Published October 2013. Originally

5.8 Thermometer.

approved in 1979. Last previous edition approved in 2007 as D3836 – 94 (2007).

DOI: 10.1520/D3836-13. 5.9 Humidity Gage.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

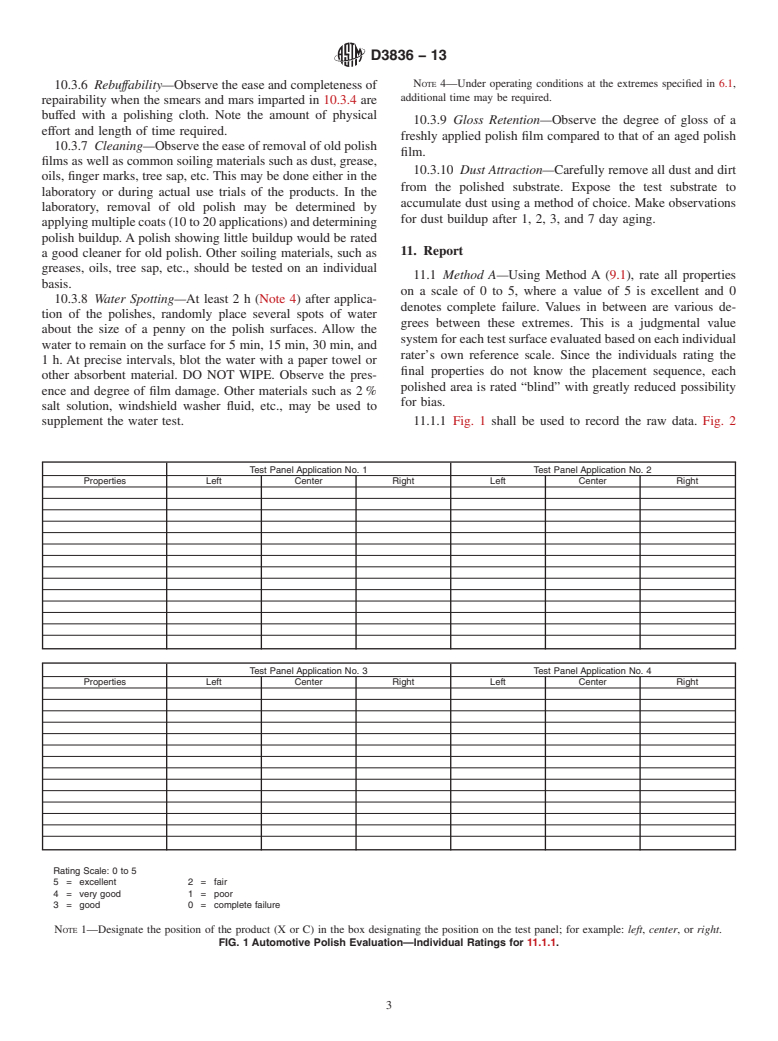

D3836 − 13

6. Test Conditions These four positionings should be written on tags and

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3836 − 94 (Reapproved 2007) D3836 − 13

Standard Practice for Evaluation of

1

Automotive Polish

This standard is issued under the fixed designation D3836; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers testing properties and apparatus used in evaluating the performance of automotive polishes. This

practice is applicable to products that are commonly referred to as car/auto wax, cleaner wax, polish, etc.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standard:

D1133 Test Method for Kauri-Butanol Value of Hydrocarbon Solvents

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 automotive polish—aids in liquid or paste formulation for cleaning and improving the appearance of automobile finishes.

4. Significance and Use

4.1 This practice is intended to define the properties to be tested, the apparatus to use, and the comparisons of product

performance. It is recognized that considerable discretion exists among formulators and marketers of automotive polish on what

properties or performance characteristics are best most important for their products. This practice is flexible enough to honor this

fact within the confines of the automotive polish definition below.definition.

4.2 The test methods methods of this practice are subjective and empirical in order to conform to the basic characteristicsprac-

tices of the industry and to allow flexibility in testing.

5. Apparatus and Materials

5.1 Sample of Polish Test Polish. to be tested.

5.2 Sample of Control Polish—The control polish is selected subjectively for comparison to the test polish. It may be a

competitive product, a modified formulation of the test polish, etc. It should be recognized that automotive polishes are formulated

to perform different functions. This should be taken into account when interpreting results and choosing the control polish.

5.3 Test Substrates—The test substrate shall be one for which the test polish is intended (Note 1). The test surface shall be in

good physical condition, not badly cracked, scratched, or otherwise damaged so as to interfere with evaluation of polish properties.

2 2

The minimum test surface area for each sample shall be 1290 cm (200 in. ).

NOTE 1—It is important to select a test substrate for which a particular polish is intended. For example, if a particular polish is intended for a certain

make of car only, then the test substrate should be similar.

NOTE 1—It is important to select a test substrate for which a particular polish is intended. For example, if a particular polish is intended for a certain

make of car only, then the test substrate should reflect this. Standard paint panels that were previously available through ASTM have been discontinued

as of January 1, 1988. It became very difficult to maintain paint panels that were representative of all current and past paint technologies used to

manufacture automotive finishes. Since 4.35.3 requires that the test substrate be one for which the test polish is intended, it is in the best interest of the

user of this practice to determine and obtain the appropriate test surface or coating, or both. ASTM Committee D-21D21 on Polishes suggests if further

assistance is needed in determining or obtaining appropriate test substrates that contact be made with automotive paint manufacturers, automobile

1

This practice is under the jurisdiction of ASTM Committee D21 on Polishes and is the direct responsibility of Subcommittee D21.04 on Performance Tests.

Current edition approved Feb. 1, 2007Oct. 1, 2013. Published March 2007October 2013. Originally approved in 1979. Last previous edition approved in 19992007 as

D3836 – 94 (1999).(2007). DOI: 10.1520/D3836-94R07.10.1520/D3836-13.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.