ASTM E1002-05

(Test Method)Standard Test Method for Leaks Using Ultrasonics

Standard Test Method for Leaks Using Ultrasonics

SIGNIFICANCE AND USE

Test Method A—This test method is useful for locating and estimating the size of pressurized gas leaks, either as a quality control test or as a field inspection procedure. It is also valuable as a pretest before other more time consuming and more sensitive leak tests are employed. It should not be used exclusively to locate highly toxic or explosive gas leaks.

Test Method B—This test method is useful for locating leaks in systems that are not under pressure or vacuum as either a quality control or a field inspection procedure. It is not useful for estimating the size of a leak. It is also valuable as a pretest before leak tests using pressurized gas methods and more sensitive leak tests are employed.

SCOPE

1.1 Test Method A, Pressurization— This test method covers procedures for calibration of ultrasonic instruments, location, and estimated measurements of gas leakage to atmosphere by the airborne ultrasonic technique.²

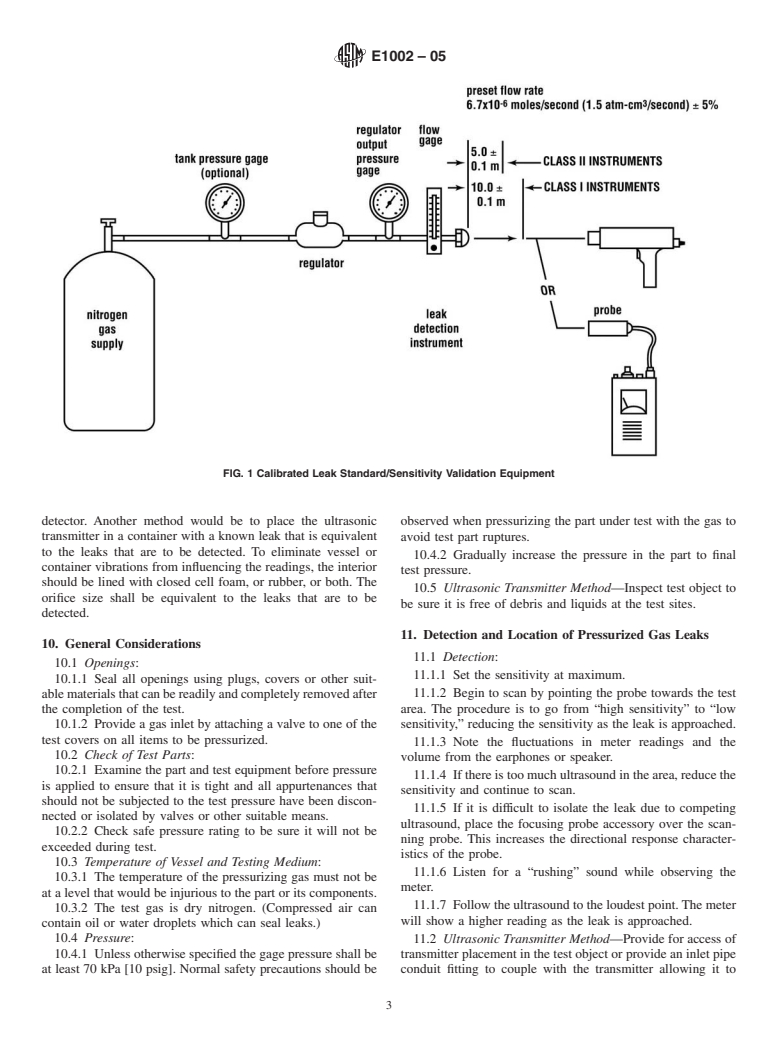

1.2 In general practice this should be limited to leaks detected by two classifications of instruments, Class I and Class II. Class I instruments should have a minimum detectable leak rate of 6.7 10 7 mol/s (1.5 10 2 std. cm3/s at 0C) or more for the pressure method of gas leakage to atmosphere. Class II instruments should have a minimal detectable leak rate of 6.7 106 mol/s (1.5 10 1 std. cm3/s at 0C) or more for the pressure method of gas leakage to atmosphere. Refer to Guide E 432 for additional information.

1.3 Test Method B, Ultrasonic TransmitterFor object under test not capable of being pressurized but capable of having ultrasonic tone placed/injected into the test area to act as an ultrasonic leak trace source.

1.3.1 This test method is limited to leaks producing leakage of 6.7 106 mol/s (1.5 10 1 std. cm3/s at 0C) or greater.

1.4 The values stated in SI units are to be regarded as the standard.

1.5This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1002–05

Standard Test Method for

1

Leaks Using Ultrasonics

This standard is issued under the fixed designation E1002; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Documents:

SNT-TC-1A Recommended Practice for Personnel Qualifi-

1.1 Test Method A, Pressurization—Thistestmethodcovers

4

cation and Certification in Nondestructive Testing

procedures for calibration of ultrasonic instruments, location,

ANSI/ASNT CP-189 ASNT Standard for Qualification and

and estimated measurements of gas leakage to atmosphere by

4

2

Certification of Nondestructive Testing Personnel

the airborne ultrasonic technique.

NAS-410 Certification and Qualification of Nondestructive

1.2 In general practice this should be limited to leaks

5

Personnel

detected by two classifications of instruments, Class I and

ClassII.ClassIinstrumentsshouldhaveaminimumdetectable

3. Terminology

−7 −2 3

leak rate of 6.7 310 mol/s (1.5 310 std. cm /s at 0°C) or

3.1 Definitions—For definitions of terms used in this test

more for the pressure method of gas leakage to atmosphere.

method, see Terminology E1316, Section E.

ClassIIinstrumentsshouldhaveaminimaldetectableleakrate

−6 −1 3

of 6.7 310 mol/s (1.5 310 std. cm /s at 0°C) or more for

4. Summary of Test Method

the pressure method of gas leakage to atmosphere. Refer to

4.1 Test MethodA—Thistestmethodsetsminimumrequire-

Guide E432 for additional information.

ments for an ultrasonic detector (Classifications I and II). It

1.3 Test Method B, Ultrasonic Transmitter—For object

provides for sensitivity validation of the detector and gives

under test not capable of being pressurized but capable of

procedures for pressurizing the test object, locating leaks, and

having ultrasonic tone placed/injected into the test area to act

estimating the leakage rates.

as an ultrasonic leak trace source.

4.2 Test Method B—Thistestmethodsetsminimumrequire-

1.3.1 This test method is limited to leaks producing leakage

−6 −1 3 ments for an ultrasonic detector used in conjunction with an

of 6.7 310 mol/s (1.5 310 std. cm /s at 0°C) or greater.

ultrasonic transmitter. It gives procedures for locating leaks

1.4 The values stated in SI units are to be regarded as the

using an electronically generated ultrasonic leak tracer source.

standard.

1.5 This standard does not purport to address all of the

5. Basis of Application

safety concerns, if any, associated with its use. It is the

5.1 The following items are subject to contractual agree-

responsibility of the user of this standard to consult and

ment between parties using or referencing this test method.

establish appropriate safety and health practices and deter-

5.2 Personnel Qualification

mine the applicability of regulatory limitations prior to use.

5.2.1 If specified in the contractual agreement, personnel

performing examinations to this test method shall be qualified

2. Referenced Documents

in accordance with a national or internationally recognized

3

2.1 ASTM Standards:

NDT personnel qualification practice or standard such as

E432 Guide for Selection of a Leak Testing Method

ANSI/ASNT-CP-189, SNT-TC-1A, NAS-410, or a similar

E543 Specification for Agencies Performing Nondestruc-

document and certified by the employer or certifying agency,

tive Testing

as applicable. The practice or standard used and its applicable

E1316 Terminology for Nondestructive Examinations

revision shall be identified in the contractual agreement be-

tween the using parties.

1

5.3 Qualification of Nondestructive Agencies—If specified

This test method is under the jurisdiction of ASTM Committee E07 on

Nondestructive Testing and is the direct responsibility of Subcommittee E07.08 on in the contractual agreement, NDT agencies shall be qualified

Leak Testing Method.

and evaluated as described in Practice E543. The applicable

Current edition approved April 1, 2005. Published May 2005. Originally

revisionofPracticeE543shallbeinthecontractualagreement.

approved in 1986. Last previous edition approved in 1996 as E1002-96. DOI:

10.1520/E1002-05.

2

This technique is sometimes called “ultrasonic translation.”

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromTheAmericanSocietyforNondestructiveTesting(ASNT),P.O.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Box 28518, 1711 Arlingate Lane, Columbus, OH 43228-0518.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1250

the ASTM website. Eye St., NW, Washington, DC 20005.

Copyright © ASTM I

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.