ASTM C1139-90(1996)e1

(Specification)Standard Specification for Fibrous Glass Thermal Insulation and Sound Absorbing Blanket and Board for Military Applications

Standard Specification for Fibrous Glass Thermal Insulation and Sound Absorbing Blanket and Board for Military Applications

SCOPE

1.1 This specification covers unfaced flexible fibrous glass blanket and faced board used for thermal and sound absorbing insulation at temperatures up to 450°F (232°C) for military applications as a replacement for MIL-I-22023D.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following hazard caveat pertains only to the test method section of this specification. This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

e1

Designation: C 1139 – 90 (Reapproved 1996)

Standard Specification for

Fibrous Glass Thermal Insulation and Sound Absorbing

Blanket and Board for Military Applications

This standard is issued under the fixed designation C 1139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—A Keywords section and precision statements were added in August 1996.

1. Scope C 612 Specification for Mineral Fiber Block and Board

Thermal Insulation

1.1 This specification covers unfaced flexible fibrous glass

C 665 Specification for Mineral Fiber Blanket Thermal

blanket and faced board used for thermal and sound absorbing

Insulation for Light Frame Construction and Manufactured

insulation at temperatures up to 450°F (232°C) for military

Housing

applications as a replacement for MIL-I-22023D.

C 1101/C1101M Test Method for Classifying the Flexibility

1.2 The values stated in inch-pound units are to be regarded

or Rigidity of Mineral Fiber Blanket and Board Insulation

as the standard. The values given in parentheses are for

E 84 Test Method for Surface Burning Characteristics of

information only.

Building Materials

1.3 The following hazard caveat pertains only to the test

2.2 U.S. Military Standards:

method section of this specification. This standard does not

MIL-STD-167-1 Mechanical Vibrations of Shipboard

purport to address all of the safety concerns, if any, associated

Equipment (Type 1 Environmental and Type II Internally

with its use. It is the responsibility of the user of this standard

Excited)

to establish appropriate safety and health practices and

MIL-Y-1140 Yarn, Cord, Sleeving, Cloth and Tape-Glass

determine the applicability of regulatory limitations prior to

MIL-A-3316 Adhesives, Fire Resistant, Thermal Insula-

use.

tion

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions—Terminology C 168 shall apply to the

C 167 Test Methods for Thickness and Density of Blankets

terms used in this specification.

or Batt Thermal Insulations

C 168 Terminology Relating to Thermal Insulating Materi-

4. Classification

als

4.1 The fibrous glass felt shall be of the following types and

C 177 Test Method for Steady-State Heat Flux Measure-

grades:

ments and Thermal Transmission Properties by Means of

3 3

Type I, Unfaced Thermal Blanket Nominal Density, lb/ft (kg/m )

the Guarded-Hot-Plate Apparatus

Grade 1 0.75 (12)

C 390 Criteria for Sampling and Acceptance of Preformed

Grade 2 1.00 (16)

Thermal Insulation Lots Grade 3 1.50 (24)

Grade 4 2.00 (32)

C 411 Test Method for Hot-Surface Performance of High

Grade 5 2.50 (40)

Temperature Thermal Insulation

Grade 6 3.00 (48)

C 423 Test Method for Sound Absorption and Sound Ab- Type II, Unfaced Sound Absorbing

3 3

Blanket Nominal Density, lb/ft (kg/m )

sorption Coefficients by the Reverberation Room Method

Grade 1 0.75 (12)

C 518 Test Method for Steady-State Heat Flux Measure-

Grade 2 1.00 (16)

ments and Thermal Transmission Properties by Means of Grade 3 1.50 (24)

2 Grade 4 2.00 (32)

the Heat Flow Meter Apparatus

Grade 5 2.50 (40)

Grade 6 3.00 (48)

This specification is under the jurisdiction of ASTM Committee C-16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on

Blanket and Loose Fill Insulation. Annual Book of ASTM Standards, Vol 04.07.

Current edition approved Feb. 23, 1990. Published August 1990. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 04.06. Robbins Ave., Philadelphia, PA 19111-5094.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 1139

7.9 Apparent Thermal Conductivity—The thermal conduc-

Type III, Faced, Thermal and Sound Density shall be 2.8 (45)

3 3

Absorbing Board lb/ft (kg/m )

tivities for Type I, Grade 1 through 6 and Type III materials

shall not exceed the values shown in Table 1. Thermal

5. Ordering Information

conductivity shall be determined by Test Methods C 177 or

5.1 The type, dimensions, density, maximum use tempera-

C 518.

ture, and facing (if required) shall be specified by the pur-

7.10 Vibration Resistance of Type II Materials—There shall

chaser. A product certification may be specified in the purchase

be a maximum of 0.50 % weight loss and the insulation shall

order.

not settle and lose thickness when subjected to the vibration

test described in 11.9.

6. Materials and Manufacture

7.11 Acoustical Performance of Type II Materials—The

6.1 Composition:

coefficients of absorption shall be not less than those shown in

6.1.1 The insulation shall be composed of glass, processed

Table 2 when Type II material is tested in accordance with

from a molten state into a fibrous form, bonded with a chemical

11.8.

binder. Asbestos shall not be used as an ingredient or compo-

7.12 Kerfing—Type III panels shall be capable of being

nent part of the product.

kerfed with a 90° V-groove to facilitate bending when the panel

6.1.2 The facing shall be a polyester film reinforced with

is folded to a right angle. The facing material shall be flexible

glass yarns (MIL-I-1140). The laminating adhesive shall con-

to form a neat square corner at the kerfed joint (see 11.11).

form to the requirements of MIL-A-3316. Asbestos shall not be

7.13 Flashover Time—Flashover time shall not occur within

used as an ingredient or component part of the product.

10 min when tested in accordance with 11.12.4.5.

8. Dimensions and Permissible Variations

7. Physical Requirements

8.1 The standard sizes and tolerances of Types I, II, and III

7.1 A 1-in. (25-mm) thick sample of the insulation shall be

materials are listed in Table 3.

flexible when tested in accordance with 11.1.

7.2 The insulation shall be of the nominal density specified

9. Workmanship, Finish, and Appearance

for its grade with a tolerance of 610 %. Density shall be

9.1 The insulation units shall indicate good workmanship

determined in accordance with 11.2.

and shall not have defects that adversely affect their installation

7.3 Maximum Temperature of Use—When tested in accor-

and service qualities.

dance with 11.10 at the insulation’s maximum use temperature

of 450°F (232°C), the insulation shall not crack, warp, flame, 10. Sampling

glow, smolder, or show evidence of fused fibers.

10.1 Inspection and qualification shall be in accordance

7.4 The nonfibrous material (shot) content shall not be

with Criteria C390. Other provisions for sampling can be

greater than 1.5 % by weight when tested in accordance with

agreed upon between the purchaser, seller, and manufacturer.

11.3.

11. Test Methods

7.5 Binder Content—When tested in accordance with 11.4,

the binder content shall not exceed 30 % by weight. 11.1 Flexibility—Rigidity—Test in accordance with Test

7.6 Corrosiveness to Steel—When tested in accordance with Method C 1101/C 1101M.

11.6, steel plates in contact with the insulation shall show no 11.2 Density—Test in accordance with Test Methods C 167.

corrosion greater than comparative plates in contact with sterile 11.3 Nonfibrous Shot Content—Test in accordance with the

cotton. Annex in Specification C 612.

7.7 Surface Burning Characteristics Type I and II—The 11.4 Test Method for Determining Binder Content:

insulation shall have a flame spread index not greater than 25

11.4.1 Scope—This test method provides a test to determine

and a smoke developed index not greater than 50 when tested the amount of organic binder present in the insulation.

in accordance with Test Method E 84. 11.4.2 Summary of Test Method—The percent binder by

7.8 Quarter Scale Room Fire Test of Type III—Type III shall weight is measured by determining the weight lost by the

meet the requirements of the Quarter-Scale Room-Fire Test insulation after it is placed in a 1000°F (538°C) furnace for 1

Method described in 11.12. h.

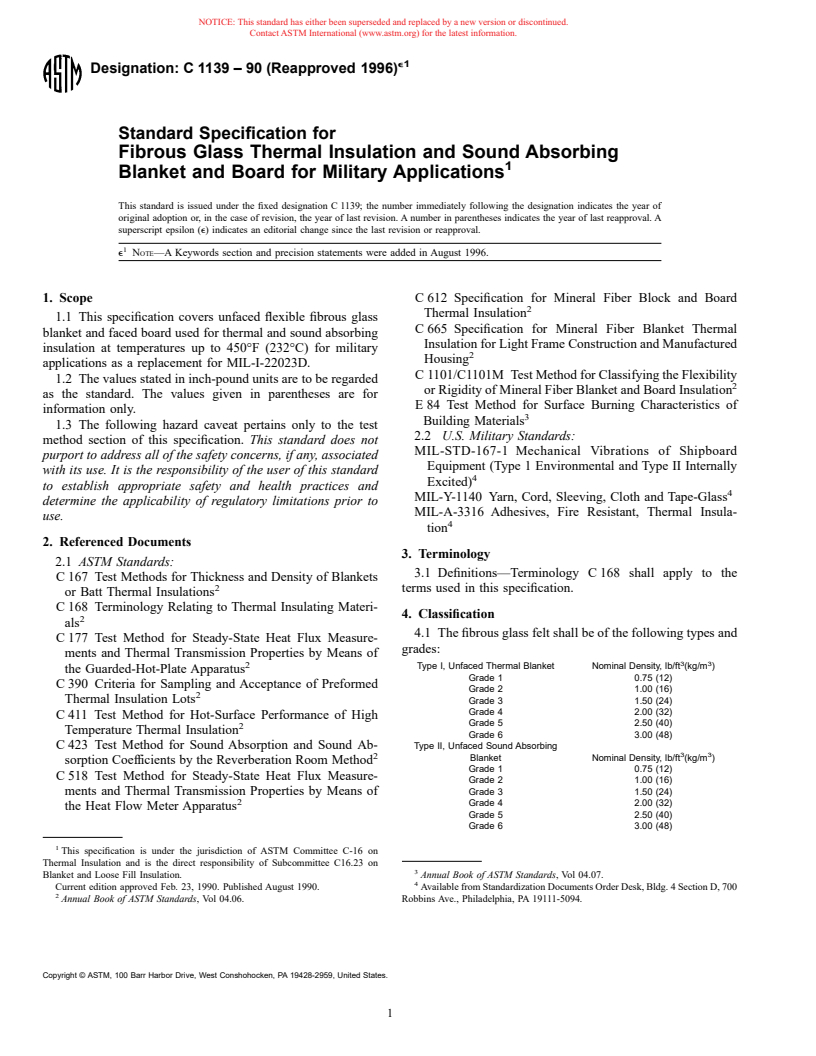

TABLE 1 Type I and Type III Thermal Insulation Blanket Physical Requirements

Type I Type I Type I Type I Type I Type I

Type I Type III

Grade 1 Grade 2 Grade 3 Grade 4 Grade 5 Grade 6

Nominal Density (lb/ft ) 0.75 1.0 1.5 2.0 2.5 3.0 2.8

Thermal Conductivity, max Btu·in./h ft ·°F (W/m·K)

Mean Temperature,° F (°C)

25 (−4) 0.27 (0.039) 0.26 (0.037) 0.24 (0.035) 0.22 (0.032) 0.22 (0.032) 0.22 (0.032) 0.22 (0.032)

50 (10) 0.29 (0.042) 0.28 (0.040) 0.26 (0.037) 0.24 (0.035) 0.23 (0.033) 0.23 (0.033) 0.23 (0.033)

75 (24) 0.32 (0.046) 0.30 (0.043) 0.27 (0.039) 0.25 (0.036) 0.24 (0.035) 0.24 (0.035) 0.24 (0.035)

100 (38) 0.35 (0.050) 0.32 (0.046) 0.29 (0.042) 0.27 (0.039) 0.26 (0.037) 0.25 (0.036) 0.26 (0.037)

200 (93) 0.49 (0.071) 0.43 (0.062) 0.38 (0.055) 0.34 (0.049) 0.31 (0.045) 0.30 (0.043) 0.31 (0.045)

300 (149) 0.70 (0.101) 0.58 (0.083) 0.50 (0.072) 0.44 (0.063) 0.38 (0.055) 0.37 (0.053) 0.38 (0.055)

C 1139

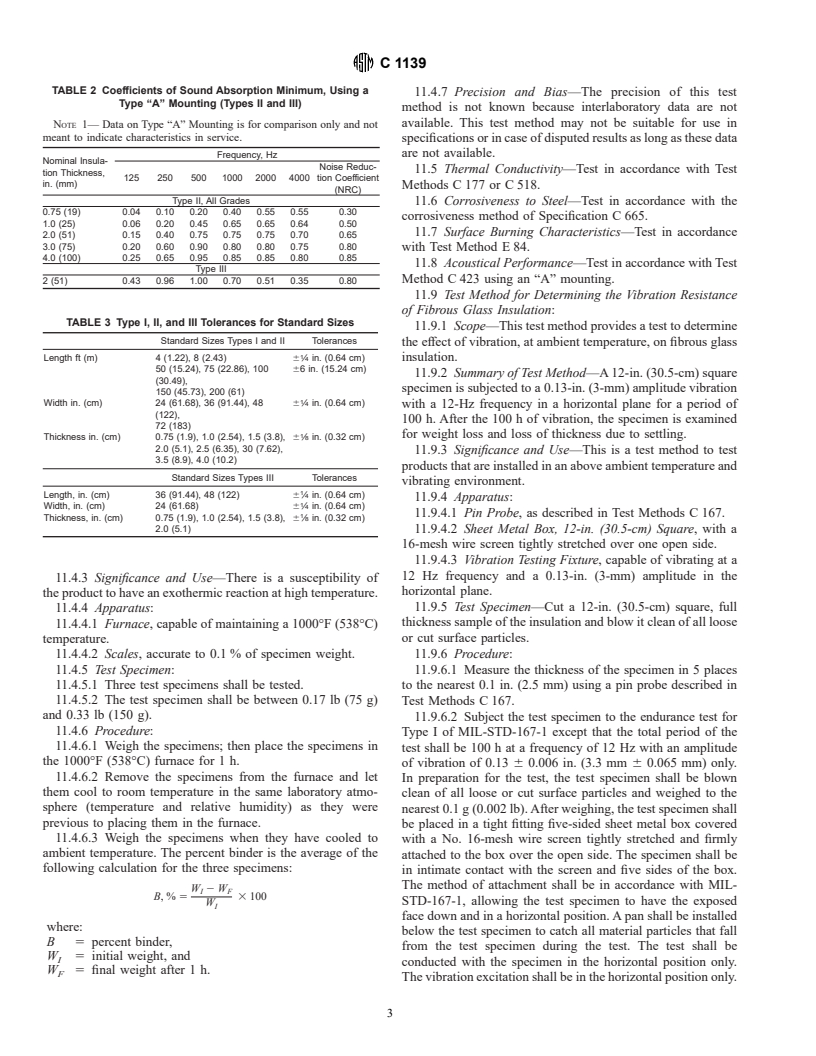

TABLE 2 Coefficients of Sound Absorption Minimum, Using a

11.4.7 Precision and Bias—The precision of this test

Type “A” Mounting (Types II and III)

method is not known because interlaboratory data are not

available. This test method may not be suitable for use in

NOTE 1— Data on Type “A” Mounting is for comparison only and not

meant to indicate characteristics in service.

specifications or in case of disputed results as long as these data

are not available.

Frequency, Hz

Nominal Insula-

Noise Reduc-

11.5 Thermal Conductivity—Test in accordance with Test

tion Thickness,

125 250 500 1000 2000 4000 tion Coefficient

in. (mm)

Methods C 177 or C 518.

(NRC)

Type II, All Grades

11.6 Corrosiveness to Steel—Test in accordance with the

0.75 (19) 0.04 0.10 0.20 0.40 0.55 0.55 0.30

corrosiveness method of Specification C 665.

1.0 (25) 0.06 0.20 0.45 0.65 0.65 0.64 0.50

11.7 Surface Burning Characteristics—Test in accordance

2.0 (51) 0.15 0.40 0.75 0.75 0.75 0.70 0.65

3.0 (75) 0.20 0.60 0.90 0.80 0.80 0.75 0.80

with Test Method E 84.

4.0 (100) 0.25 0.65 0.95 0.85 0.85 0.80 0.85

11.8 Acoustical Performance—Test in accordance with Test

Type III

2 (51) 0.43 0.96 1.00 0.70 0.51 0.35 0.80 Method C 423 using an “A” mounting.

11.9 Test Method for Determining the Vibration Resistance

of Fibrous Glass Insulation:

TABLE 3 Type I, II, and III Tolerances for Standard Sizes

11.9.1 Scope—This test method provides a test to determine

Standard Sizes Types I and II Tolerances

the effect of vibration, at ambient temperature, on fibrous glass

Length ft (m) 4 (1.22), 8 (2.43) 6 ⁄4 in. (0.64 cm) insulation.

50 (15.24), 75 (22.86), 100 66 in. (15.24 cm)

11.9.2 Summary of Test Method—A 12-in. (30.5-cm) square

(30.49),

specimen is subjected to a 0.13-in. (3-mm) amplitude vibration

150 (45.73), 200 (61)

Width in. (cm) 24 (61.68), 36 (91.44), 48 6 ⁄4 in. (0.64 cm)

with a 12-Hz frequency in a horizontal plane for a period of

(122),

100 h. After the 100 h of vibration, the specimen is examined

72 (183)

1 for weight loss and loss of thickness due to settling.

Thickness in. (cm) 0.75 (1.9), 1.0 (2.54), 1.5 (3.8), 6 ⁄8 in. (0.32 cm)

2.0 (5.1), 2.5 (6.35), 30 (7.62),

11.9.3 Significance and Use—This is a test method to test

3.5 (8.9), 4.0 (10.2)

products that are installed in an above ambient temperature and

Standard Sizes Types III Tolerances

vibrating environment.

Length, in. (cm) 36 (91.44), 48 (122) 6 ⁄4 in. (0.64 cm)

11.9.4 Apparatus:

Width, in. (cm) 24 (61.68) 6 ⁄4 in. (0.64 cm)

11.9.4.1 Pin Probe, as described in Test Methods C 167.

Thickness, in. (cm) 0.75 (1.9), 1.0 (2.54), 1.5 (3.8), 6 ⁄8 in. (0.32 cm)

2.0 (5.1) 11.9.4.2 Sheet Metal Box, 12-in. (30.5-cm) Square, with a

16-mesh wire screen tightly stretched over one open side.

11.9.4.3 Vibration Testing Fixture, capable of vibrating at a

12 Hz frequency and a 0.13-in. (3-mm) amplitude in the

11.4.3 Significance and Use—There is a susceptibility of

horizontal plane.

the product to have an exothermic reaction at high temperature.

11.9.5 Test Specimen—Cut a 12-in. (30.5-cm) square, full

11.4.4 Apparatus:

thickness sample of the insulation and blow it clean of all loose

11.4.4.1 Furnace, capable of maintaining a 1000°F (538°C)

or cut surface particles.

temperature.

11.4.4.2 Scales, accurate to 0.1 % of specimen weight. 11.9.6 Procedure:

11.4.5 Test Specimen: 11.9.6.1 Measure the thickness of the specimen in 5 places

11.4.5.1 Three test specimens shall be tested.

to the nearest 0.1 in. (2.5 mm) using a pin probe described in

11.4.5.2 The test specimen shall be between 0.17 lb (75 g) Test Methods C 167.

and 0.33 lb (150 g).

11.9.6.2 Subject the test specimen to the endurance test for

11.4.6 Procedure:

Type I of MIL-STD-167-1 except that the total period of the

11.4.6.1 Weigh the specimens; then place the specimens in

test shall be 100 h at a frequency of 12 Hz with an amplitude

the 1000°F (538°C) furnace for 1 h.

of vibration of 0.13 6 0.006 in. (3.3 mm 6 0.065 mm) only.

11.4.6.2 Remove the specimens from the furnace and let

In preparation for the test, the test specimen shall be blown

them cool to room temperature in the same laboratory atmo-

clean of all loose or cut surface particles and weighed to the

sphere (temperature and relative humidity) as they were

nearest 0.1 g (0.002 lb). After weighing, the test specimen shall

previous to placing them in the furnace.

be placed in a tight fitting five-sided sheet metal box covered

11.4.6.3 Weigh the specimens when they have cooled to

with a No. 16-mesh wire screen tightly stretched and firmly

ambient temperature. The percent binder is the average of the

attached to the box over the open side. The specimen shall be

following calculation for the three specimens:

in intimate contact with the screen and five sides of the box.

The method of attachment shall be in accordance with MIL-

W 2 W

I F

B,% 5 3 100

STD-167-1, allowing the test specimen to have the exposed

W

I

face down and in a horizontal position. A pan shall be installed

where:

below the test specimen to catch all material particles that fall

B 5 percent binder,

from the test specimen during the test. The test shall be

W 5 initial weight, and

I

conducted with the specimen in the horizontal position only.

W 5 final weight after 1 h.

F

The vibration excitation shall be in the horizontal position only.

C 1139

11.9.6.3 At the completion of the 100 h of vibration, remove room shall be constructed from a suitable ceramic insulation

the test specimen from its mounting attachments and sheet board and shall form an airtight box having a ceiling and four

metal box. Weigh the specimen again to the nearest 0.002 lb sides. The box shall sit on a floor fabricated with the same

(0.1 g) and calculate the percent weight loss. Also measure the material. The interior dimensions of the fully lined quarter-

specimen’s thickness again in 5 places to the nearest 0.1 in. scale room

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.