ASTM D4145-83(1996)e1

(Test Method)Standard Test Method for Coating Flexibility of Prepainted Sheet

Standard Test Method for Coating Flexibility of Prepainted Sheet

SCOPE

1.1 This test method describes a procedure for determining the flexibility and adhesion of organic coatings (paints) on metallic substrates that are deformed by bending when the sheet is fabricated into building panels or other products.

1.2 The metal substrate must be capable of passing this test without fracturing and with no excessive grain development.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 4145 – 83 (Reapproved 1996)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Coating Flexibility of Prepainted Sheet

This standard is issued under the fixed designation D 4145; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords and the unit of measurement statement were added editorially in January 1996.

1. Scope

1.1 This test method describes a procedure for determining

the flexibility and adhesion of organic coatings (paints) on

metallic substrates that are deformed by bending when the

sheet is fabricated into building panels or other products.

1.2 The metal substrate must be capable of passing this test

without fracturing and with no excessive grain development.

1.3 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

information only.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Terminology

2.1 Definitions of Terms Specific to This Standard:

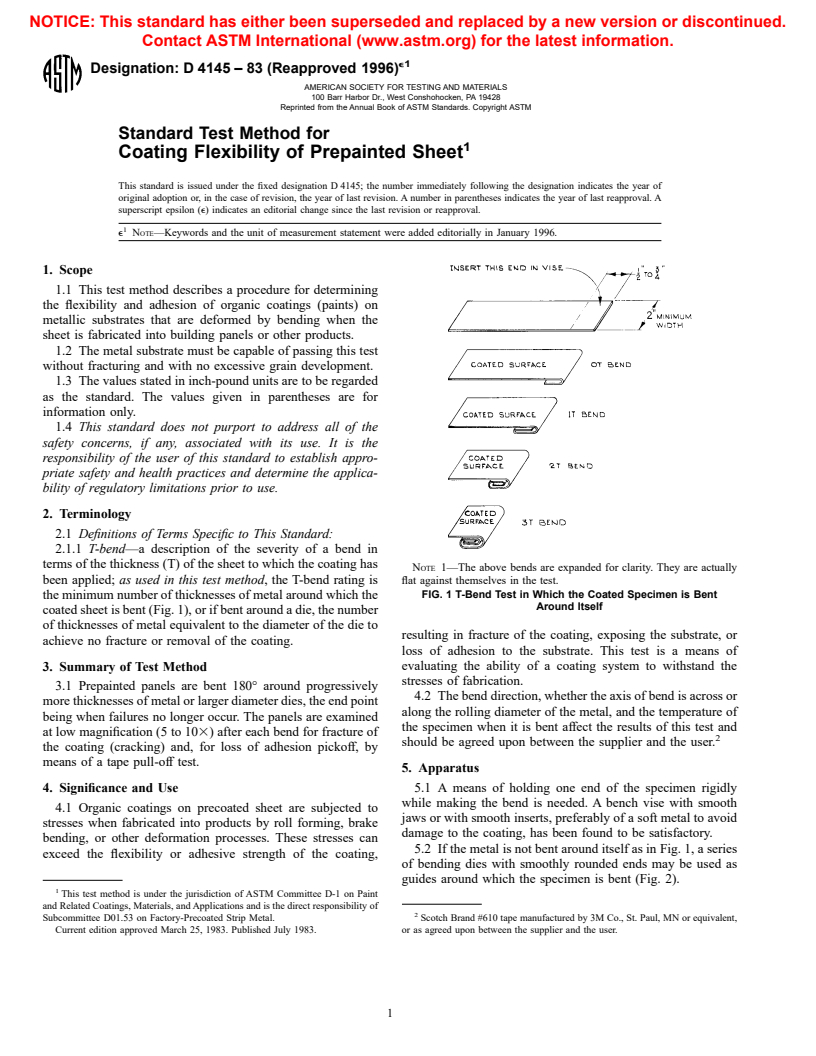

2.1.1 T-bend—a description of the severity of a bend in

terms of the thickness (T) of the sheet to which the coating has

NOTE 1—The above bends are expanded for clarity. They are actually

been applied; as used in this test method, the T-bend rating is flat against themselves in the test.

FIG. 1 T-Bend Test in Which the Coated Specimen is Bent

the minimum number of thicknesses of metal around which the

Around Itself

coated sheet is bent (Fig. 1), or if bent around a die, the number

of thicknesses of metal equivalent to the diameter of the die to

resulting in fracture of the coating, exposing the substrate, or

achieve no fracture or removal of the coating.

loss of adhesion to the substrate. This test is a means of

evaluating the ability of a coating system to withstand the

3. Summary of Test Method

stresses of fabrication.

3.1 Prepainted panels are bent 180° around progressively

4.2 The bend direction, whether the axis of bend is across or

more thicknesses of metal or larger diameter dies, the end point

along the rolling diameter of the metal, and the temperature of

being when failures no longer occur. The panels are examined

the specimen when it is bent affect the results of this test and

at low magnification (5 to 103) after each bend for fracture of

should be agreed upon between the supplier and the user.

the coating (cracking) and, for loss of adhesion pickoff, by

means of a tape pull-off test.

5. Apparatus

5.1 A means of holding one end of the specimen rigidly

4. Significance and Use

while making the bend is needed. A bench vise with smooth

4.1 Organic coatings on precoated sheet are subjected to

jaws or with smooth inserts, preferably of a soft metal to avoid

stresses when fabricated into products by roll forming, brake

damage to the coating, has been found to be satisfactory.

bending, or other deformation processes. These stresses can

5.2 If the metal is not bent around itself as in Fig. 1, a series

exceed the flexibility or adhesive strength of the coating,

of bending dies with smoothly rounded ends may be used as

guides around which the specimen is bent (Fig. 2).

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.53 on Factory-Precoated Strip Metal. Scotch Brand #610 tape manufactured by 3M Co., St. Paul, MN or equivalent,

Current edition approved March 25, 1983. Published July 1983. or as agreed upon between the supplier and the user.

D 4145

6.1.3 Continue to bend the specimen until the bent end can

be inserted in the jaws of the vise. Tighten the vise to complete

the 180° bend, which is called an OT bend. Take care to tighten

the vise sufficiently so that the apex of the bend is as flat as can

be reasonably achieved.

6.1.4 Examine the bend using a hand lens or low-power

microscope for cracks in the coating.

6.1.5 Apply pressure-sensitive tape along the bend. Rub

the tape flat; then, holding the specimen firmly, remove the tape

with a rapid movement at an angle of 180° to the bend surface.

Examine the tape for coating removed from the surface of the

specimen (that is, pickoff). In the case of a coated steel

specimen (for example,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.