ASTM B430-97

(Test Method)Standard Test Method for Particle Size Distribution of Refractory Metal Powders and Related Compounds by Turbidimetry

Standard Test Method for Particle Size Distribution of Refractory Metal Powders and Related Compounds by Turbidimetry

SCOPE

1.1 This test method covers the determination of particle size distribution of refractory metal powders with a turbidimeter (1). Experience has shown that this test method is satisfactory for the analysis of elemental tungsten, molybdenum, rhenium, tantalum metal powders, and tungsten carbide powders. Other refractory metal powders, for example, elemental metals, carbides, and nitrides, may be analyzed using this test method with caution as to significance until actual satisfactory experience is developed. The procedure covers the determination of particle size distribution of the powder in two conditions:

1.1.1 As the powder is supplied (as-supplied), and

1.1.2 After the powder has been de-agglomerated by rod milling (laboratory milled) according to Practice B859.

1.2 Where dual units are given, inch-pound units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 430 – 97

Standard Test Method for

Particle Size Distribution of Refractory Metal Powders and

Related Compounds by Turbidimetry

This standard is issued under the fixed designation B 430; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the determination of particle

size distribution of refractory metal powders with a turbidime-

3. Summary of Test Method

ter (1). Experience has shown that this test method is

3.1 A uniform dispersion of the powder in a liquid medium

satisfactory for the analysis of elemental tungsten, molybde-

is allowed to settle in a glass cell. A beam of light is passed

num, rhenium, tantalum metal powders, and tungsten carbide

through the cell at a level having a known vertical distance

powders. Other refractory metal powders, for example, el-

from the liquid level. The intensity of the light beam is

emental metals, carbides, and nitrides, may be analyzed using

determined using a photo cell. This intensity increases with

this test method with caution as to significance until actual

time as sedimentation of the dispersion takes place.

satisfactory experience is developed. The procedure covers the

3.2 The times at which all particles of a given size have

determination of particle size distribution of the powder in two

settled below the level of the transmitted light beam are

conditions:

calculated from Stokes’ law for the series of sizes chosen for

1.1.1 As the powder is supplied (as-supplied), and

the particle size analysis.

1.1.2 After the powder has been de-agglomerated by rod

3.3 The intensity of the light beam at these times is

milling (laboratory milled) according to Practice B 859.

measured as percent of the light transmitted through the cell

1.2 Where dual units are given, inch-pound units are to be

with the clear liquid medium. The size distribution in the

regarded as standard.

powder can be calculated from these relative intensities using

1.3 This standard does not purport to address all of the

the Lambert-Beer law in the modified form (also see Refs 2, 3,

safety concerns, if any, associated with its use. It is the

4).

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- DW 5 d ~log I 2 log I ! (1)

1–2 m d1 d2

bility of regulatory limitations prior to use.

where I and I are the intensities measured at the times

d1 d2

when all particles having diameters larger than d and d

1 2

2. Referenced Documents

respectively have settled below the level of the light beam, d

m

2.1 ASTM Standards:

is the arithmetic mean of particle sizes d and d , and DW

1 2 1-2

B 330 Test Method for Average Particle Size of Powders of

refers to the relative weight for the particle size range between

Refractory Metals and Their Compounds by the Fisher

d and d . Values of DW are determined for each of the particle

1 2

Sub-Sieve Sizer

size ranges chosen. The sum of these values is (DW. The

B 821 Guide for Liquid Dispersion of Metal Powders and

weight percent of particles in the size range from d to d can

1 2

Related Compounds for Particle Size Analysis

then be calculated as:

B 859 Practice for De-Agglomeration of Refractory Metal

Weight, % 5 ~DW /(DW! 3 100 (2)

Powders and Their Compounds Prior to Particle Size

Analysis

4. Significance and Use

E 456 Terminology Relating to Quality and Statistics

4.1 Knowledge of the particle size distribution of refractory

metal powders is useful in predicting powder-processing be-

This test method is under the jurisdiction of ASTM Committee B09 on Metal

havior, and ultimate performance of powder metallurgy parts.

Powders and Metal Powder Products and is the direct responsibility of Subcom-

Particle size distribution is closely related to the flowability,

mittee B09.03 on Refractory Metal Powders.

compressibility, and die-filling characteristics of a powder, as

Current edition approved Sept. 10, 1997. Published February 1998. Originally

published as B 430 – 65 T. Last previous edition B 430 – 95. well as to the final structure and properties of the finished parts.

The boldface numbers in parenthesis refer to the references listed at the end of

However, the degree of correlation between the results of this

this test method.

test method and the quality of powders in use has not been fully

Annual Book of ASTM Standards, Vol 02.05.

determined quantitatively.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 430

4.2 This test method is suitable for manufacturing control 7. Preparation of Apparatus

and research and development in the production and use of

7.1 Warm up equipment by turning on the light source and

refractory metal-type powders, as indicated in 1.1.

recorder for a minimum of 1 h prior to use.

4.3 Reported particle size measurement is a function of both

7.2 Fill the cell with sedimentation medium to a height

the actual particle dimension and shape factor, as well as the

sufficient to cover the light beam path by at least 10 mm and

particular physical or chemical properties being measured.

place the cell in the turbidimeter (Note 3). If a microammeter

Caution is required when comparing data from instruments

is used to measure light intensity, adjust the light transmission

operating on different physical or chemical parameters or with

to 100 % using the diaphragm. If a millivolt recorder is used,

different particle size measurement ranges. Sample acquisition,

adjust the potentiometer so that the photovoltaic cell output is

handling, and preparation also can affect reported particle size

10 mV or 100 %. In this case, the diaphragm is not adjusted

results.

and is completely open.

5. Apparatus

NOTE 3—For convenience in filling the cell to the proper height,

inscribe a line on each face of the cell at the desired liquid-level height.

5.1 Turbidimeter (5)—The recommended instrument is one

The height of fall is usually 25 mm. To determine the location of the line,

using a cell rectangular in cross section, approximately 50 mm

the center of the light beam path must be established and 25 mm added to

high, 40 mm wide, and 10-mm sedimentation medium thick-

this value.

ness, and having optically parallel faces.

7.3 After the instrument is adjusted to 100 % light transmis-

5.2 Millivolt Recorder, 0 to 10-mV range, 10-in. (254-mm)

sion through the sedimentation cell and medium, move the cell

wide strip chart, 0 to 100 graduations, 120 in./h (50 mm/min)

carriage until light is passing through a reference glass held in

chart speed, or microammeter with 0 to 100 graduations,

another slot of the cell carriage. Read and record the percent of

15-μA full scale, 4.5-mV full scale.

reference light transmission. Having been selected to have

NOTE 1—While a 120-in./h (50-mm/min) chart speed is recommended,

approximately 70 to 95 % of the transmission of the sedimen-

other speeds may be satisfactory.

tation cell and medium, the reference glass will indicate 100 %

5.3 Ultrasonic Cleaning Tank, with tank dimensions ap-

light transmission through the sedimentation cell when the

proximately 5 by 5 by 3 in. (127 by 127 by 76 mm) deep and

recorder reads this value through the reference cell.

1 1 5

an output of 50 W, or approximately 3 ⁄2 by 3 ⁄2 by 2 ⁄8 in. (89

by 89 by 67 mm) deep and an output of 25 W. 8. Calculation of Times at Which Light Intensity is

5.4 Glass Vial, nominal 2-dram, flat-bottom, with a tight-

Measured

fitting cap. The vial shall be approximately 2 in. (51 mm) in

8.1 The times at which the light transmission values should

height with a ⁄8-in. (16-mm) outside diameter and approxi-

be read are calculated from Stokes’ law. A uniform 1-μm

mately a ⁄32-in. (0.8-mm) wall.

interval should be used in making measurements through the

10-μm size and, depending upon the particular powder, either

6. Reagents

1-μm or 5-μm intervals thereafter. The form of Stokes’ law

6.1 Sedimentation Medium:

used is as follows:

6.1.1 Base Medium, distilled or deionized water (see Note

8 2

4).

t 5 ~18 3 10 Nh!/d ~r 2r !g (3)

x m

6.1.2 Use either one of the following as recommended in

where:

Guide B 821:

t = time, s,

6.1.2.1 Daxad (No. 11) —Dissolve 25 mg in 1 L of base

N = viscosity of settling medium at ambient temperature,

medium.

P (Note 4),

6.1.2.2 Sodium Hexametaphosphate—Dissolve 0.1 g in 1 L

h = height of fall, cm (distance from liquid level height

of base medium.

to midpoint of light beam),

NOTE 2—Use water that is pure. Do not store the sedimentation

d = diameter of particle, μm (d , d , et al),

1 2

medium longer than a week, and do not use rubber tubing in any storage

r = theoretical density of the powder being tested (for

x

container. Clean thoroughly all sedimentation medium containers every

tungsten, use 19.3 g/cm ),

week.

r = density of settling medium at ambient temperature

m

(Note 4), and

The recommended instrument is a Cenco Photelometer (not made anymore) of

g = gravitational constant (980 cm/s ).

original or modified designs or any proven equivalent instrument. A schematic

diagram of the Photelometer is shown in the papers referenced at the end of this test

NOTE 4—The viscosity and density values at different temperatures that

method. Copies of detailed drawings of an acceptable instrument are available from

are used for the sedimentation medium in this procedure are the same as

ASTM Headquarters. Order ADJA0430. A fabricated instrument can be secured

for pure water. Some viscosity (from the Handbook of Chemistry and

from WAB Instruments Co., 5171 Hickory Dr., Cleveland, OH 44124.

Physics, 65th Edition, CRC Press, 1984) and density (from Metrological

The 69800-Q1, Model S, Type G, Speedomax W, or XL630 Series recorder as

Handbook 145, NIST, 1990) values are given as follows:

made by the Leeds and Northrup Co., have been found satisfactory.

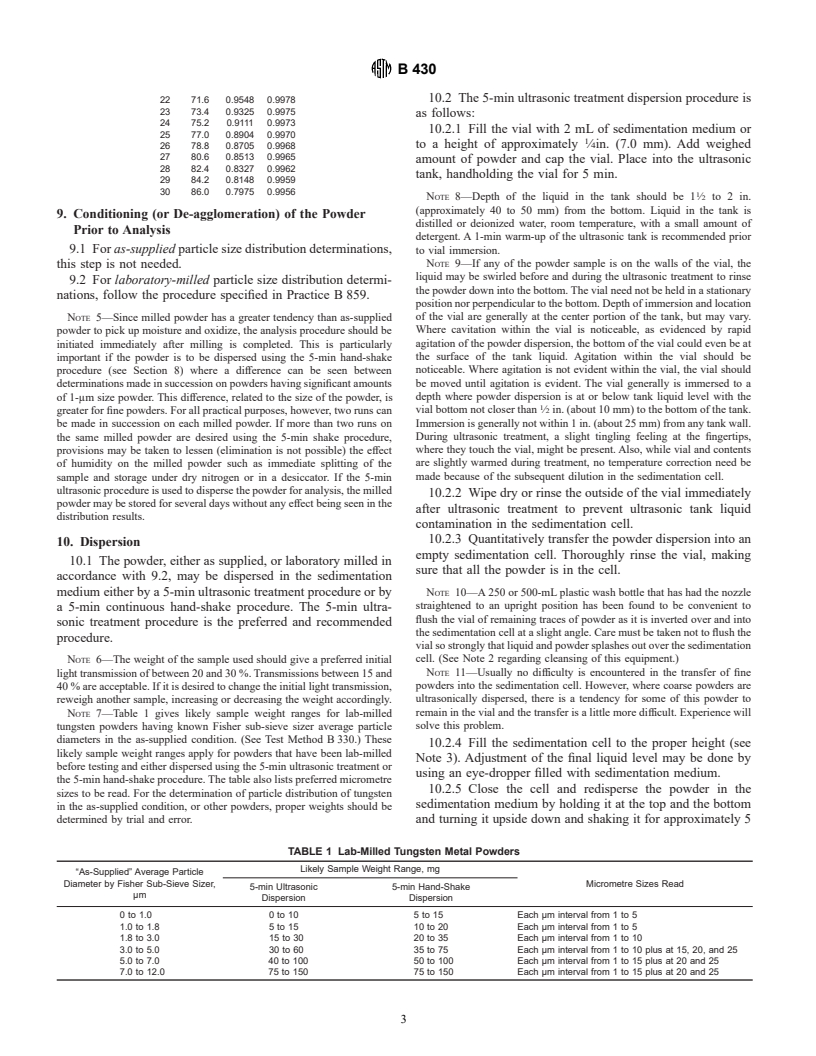

Temperature, Viscosity, Density,

Ultrasonic tank Model Nos. 2 or 12 as made by Bransonic Instrument Co.,

°C °F cP g/cm

Stamford, CT, have been found satisfactory.

Two-dram Titeseal vials, as made by Chemical Rubber Co., Cleveland, OH,

18 64.4 1.0530 0.9986

have been found satisfactory.

19 66.2 1.0270 0.9984

Daxad No. 11 powder as made by the W. R. Grace and Co., Polymers and

20 68.0 1.0020 0.9982

Chemicals Div., 62 Whittemore Ave., Cambridge, MA 02140, has been found

21 69.8 0.9779 0.9980

satisfactory.

B 430

10.2 The 5-min ultrasonic treatment dispersion procedure is

22 71.6 0.9548 0.9978

23 73.4 0.9325 0.9975

as follows:

24 75.2 0.9111 0.9973

10.2.1 Fill the vial with 2 mL of sedimentation medium or

25 77.0 0.8904 0.9970

to a height of approximately ⁄4in. (7.0 mm). Add weighed

26 78.8 0.8705 0.9968

27 80.6 0.8513 0.9965

amount of powder and cap the vial. Place into the ultrasonic

28 82.4 0.8327 0.9962

tank, handholding the vial for 5 min.

29 84.2 0.8148 0.9959

30 86.0 0.7975 0.9956

NOTE 8—Depth of the liquid in the tank should be 1 ⁄2 to 2 in.

(approximately 40 to 50 mm) from the bottom. Liquid in the tank is

9. Conditioning (or De-agglomeration) of the Powder

distilled or deionized water, room temperature, with a small amount of

Prior to Analysis

detergent. A 1-min warm-up of the ultrasonic tank is recommended prior

9.1 For as-supplied particle size distribution determinations,

to vial immersion.

NOTE 9—If any of the powder sample is on the walls of the vial, the

this step is not needed.

liquid may be swirled before and during the ultrasonic treatment to rinse

9.2 For laboratory-milled particle size distribution determi-

the powder down into the bottom. The vial need not be held in a stationary

nations, follow the procedure specified in Practice B 859.

position nor perpendicular to the bottom. Depth of immersion and location

NOTE 5—Since milled powder has a greater tendency than as-supplied of the vial are generally at the center portion of the tank, but may vary.

powder to pick up moisture and oxidize, the analysis procedure should be Where cavitation within the vial is noticeable, as evidenced by rapid

initiated immediately after milling is completed. This is particularly agitation of the powder dispersion, the bottom of the vial could even be at

important if the powder is to be dispersed using the 5-min hand-shake the surface of the tank liquid. Agitation within the vial should be

procedure (see Section 8) where a difference can be seen between noticeable. Where agitation is not evident within the vial, the vial should

be moved until agitation is evident. The vial generally is immersed to a

determinations made in succession on powders having significant amounts

depth where powder dispersion is at or below tank liquid level with the

of 1-μm size powder. This difference, related to the size of the powder, is

vial bottom not closer than ⁄2 in. (about 10 mm) to the bottom of the tank.

greater for fine powders. For all practical purposes, however, two runs can

Immersion is generally not within 1 in. (about 25 mm) from any tank wall.

be made in succession on each milled powder. If more than two runs on

During ultrasonic treatment, a slight tingling feeling at the fingertips,

the same milled powder are desired using the 5-min shake procedure,

where they touch the vial, might be present. Also, while vial and contents

provisions may be taken to lessen (elimination is not possible) the effect

are slightly warmed during treatment, no temperature correction need be

of humidity on the milled powder such as immediate splitting of the

made because of the subsequent dilution in the sedimentation cell.

sample and storage under dry nitrogen or in a desiccator. If the 5-min

ultrasonic procedure is used to disperse the powder for analysis, the milled

10.2.2 Wipe dry or rinse the outside of the vial immediately

powder may be stored for several days without any effect being seen in the

after ultrasonic treatment to prevent ultrasonic tank liquid

distribution results.

contamination in the sedimentation cell.

10.2.3 Quantitatively transfer the powder dispersion into an

10. Dispersion

empty sedimentation cell. Thoroughly rinse the vial, making

10.1 The powder, either as supplied, or laboratory milled in

sure that all the powder is in the cell.

accordance with 9.2, may be dispersed in the sedimentation

medium either by a 5-min ultra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.