ASTM D1742-94(2000)e1

(Test Method)Standard Test Method for Oil Separation from Lubricating Grease During Storage

Standard Test Method for Oil Separation from Lubricating Grease During Storage

SCOPE

1.1 This test method covers the determination of the tendency of a lubricating grease to separate oil during storage in both normally filled and partially filled containers.

1.2 This test method is not suitable for greases softer than NLGI No. 1 grade.

1.3 Values stated in acceptable SI units are to be regarded as the standard except for the dimensions in Fig. 2 where inch-pound units are standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see 7.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D1742–94 (Reapproved 2000)

Standard Test Method for

Oil Separation from Lubricating Grease During Storage

This standard is issued under the fixed designation D 1742; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Warning notes were placed in text editorially in June 2000.

1. Scope

1.1 This test method covers the determination of the ten-

dency of a lubricating grease to separate oil during storage in

both normally filled and partially filled containers.

1.2 This test method is not suitable for greases softer than

NLGI No. 1 grade.

1.3 Values stated in acceptable SI units are to be regarded as

the standard except for the dimensions in Fig. 2 where

inch-pound units are standard.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For a specific

hazard statement, see 7.1.

2. Referenced Documents

2.1 ASTM Standards:

D 235 Specification for Mineral Spirits (Petroleum Spirits)

(Hydrocarbon Drycleaning Solvent)

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

poses

2.2 Other Standard:

NLGI Grease Consistency Classification

3. Terminology

3.1 Definitions:

3.1.1 lubricating grease, n—a semi-fluid to solid product of

a thickener in a liquid lubricant.

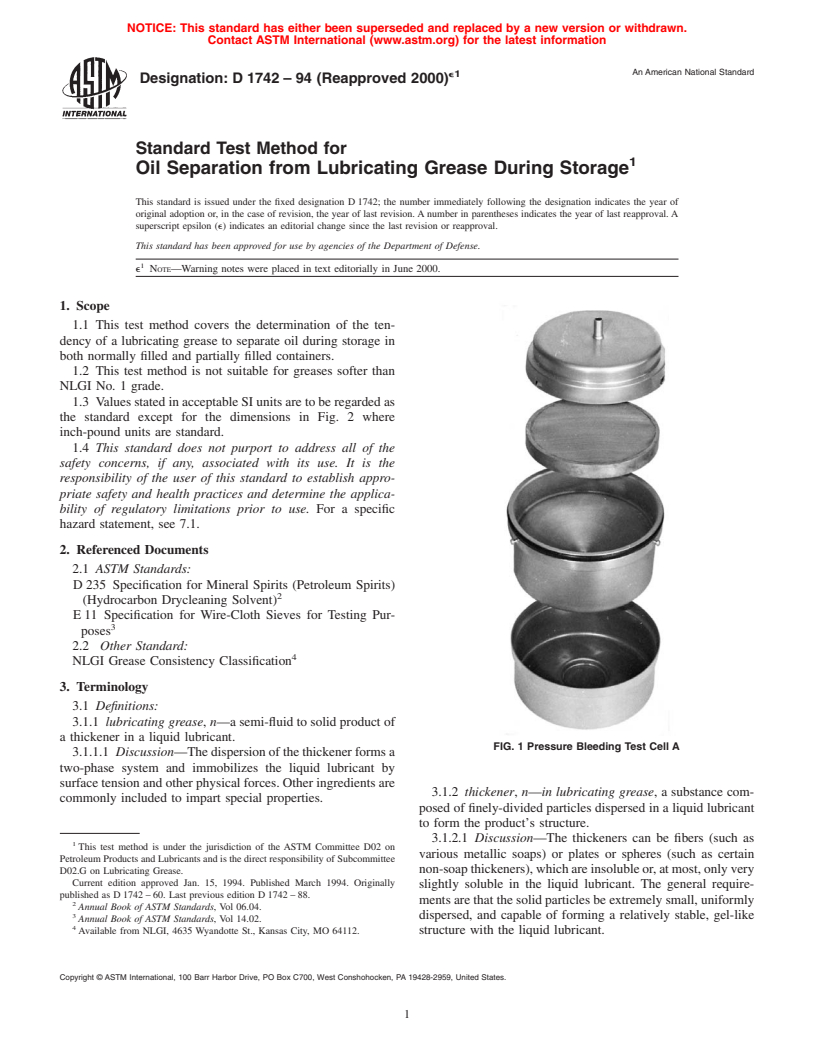

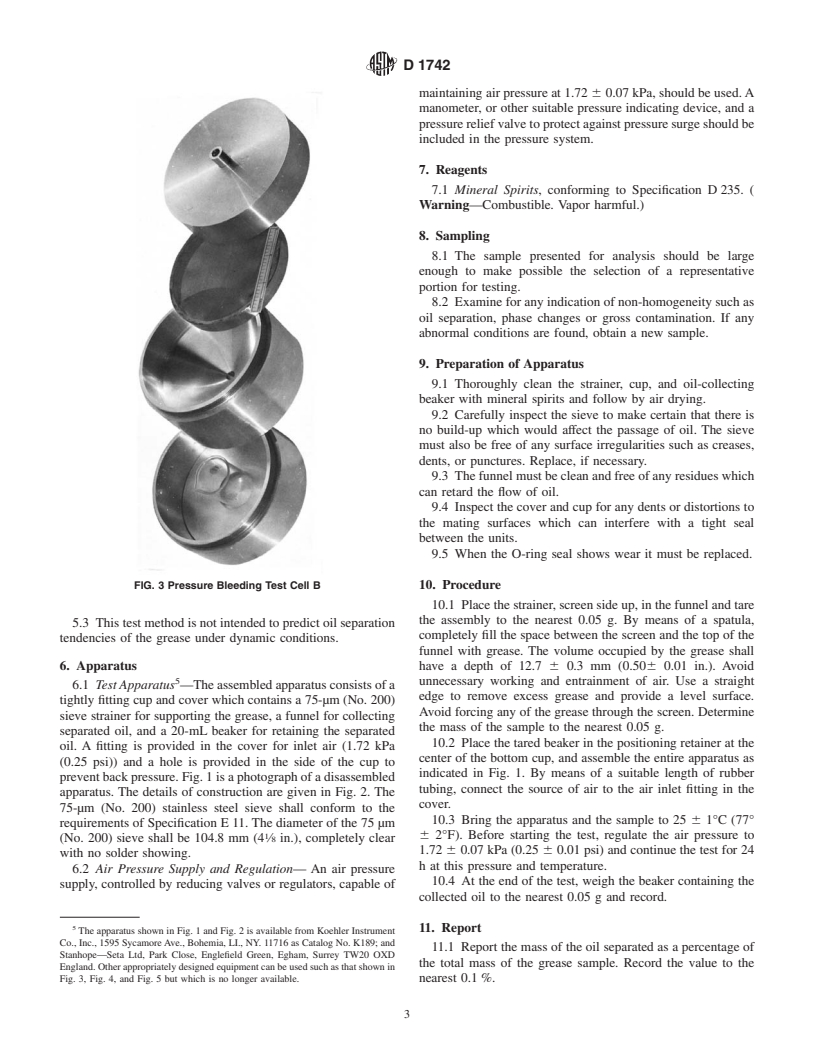

FIG. 1 Pressure Bleeding Test Cell A

3.1.1.1 Discussion—Thedispersionofthethickenerformsa

two-phase system and immobilizes the liquid lubricant by

surface tension and other physical forces. Other ingredients are

3.1.2 thickener, n—in lubricating grease, a substance com-

commonly included to impart special properties.

posed of finely-divided particles dispersed in a liquid lubricant

to form the product’s structure.

3.1.2.1 Discussion—The thickeners can be fibers (such as

This test method is under the jurisdiction of the ASTM Committee D02 on

various metallic soaps) or plates or spheres (such as certain

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

non-soapthickeners),whichareinsolubleor,atmost,onlyvery

D02.G on Lubricating Grease.

Current edition approved Jan. 15, 1994. Published March 1994. Originally

slightly soluble in the liquid lubricant. The general require-

published as D 1742 – 60. Last previous edition D 1742 – 88.

ments are that the solid particles be extremely small, uniformly

Annual Book of ASTM Standards, Vol 06.04.

dispersed, and capable of forming a relatively stable, gel-like

Annual Book of ASTM Standards, Vol 14.02.

Available from NLGI, 4635 Wyandotte St., Kansas City, MO 64112. structure with the liquid lubricant.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1742

in. mm in. mm in. mm in. mm

5 7

0.0021 0.053 1 ⁄8 41.3 0.500 12.70 4 ⁄16 112.7

3 1

0.0029 0.074 1 ⁄4 44.4 0.510 12.95 4 ⁄2 114.3

0.010 0.25 2 50.8 0.520 13.20 4 ⁄16 119.1

1 1 5 3

⁄16 1.59 2 ⁄2 63.5 ⁄8 15.87 4 ⁄4 120.6

1 11 3 26

⁄8 3.17 3 ⁄16 93.7 ⁄4 19.05 4 ⁄32 123.03

3 1 1

⁄16 4.76 4 ⁄8 104.8 1 25.4 5 ⁄4 133.3

1 1

⁄4 6.35 4.360 110.74 1 ⁄4 31.8 6 152.4

5 3 1

⁄16 7.94 4.365 110.87 1 ⁄8 34.9 6 ⁄2 165.1

3 3

⁄8 9.52 4 ⁄8 111.1 3 76.2

FIG. 2 Detailed Drawing of Pressure Bleeding Test Cell A

3.1.3 oil separation, n—the appearance of a liquid fraction 5. Significance and Use

from an otherwise homogeneous lubricating composition.

5.1 When a lubricating grease separates oil, the remaining

compositionincreasesinconsistency.Thiscanaffecttheability

4. Summary of Test Method

of the product to function as designed.

4.1 The sample of grease, supported on a 75-µm (No. 200)

5.2 It has been found that the results of this test correlate

sieve, is subjected to 1.72 kPa (0.25 psi) air pressure for 24 h

directly with the oil separation that occurs in 35-lb pails of

at25°C(77°F).Anyoilseepagethatoccursdrainsintoabeaker

and is weighed. grease during storage.

D1742

maintaining air pressure at 1.72 6 0.07 kPa, should be used.A

manometer, or other suitable pressure indicating device, and a

pressurereliefvalvetoprotectagainstpressuresurgeshouldbe

included in the pressure system.

7. Reagents

7.1 Mineral Spirits, conforming to Specification D 235. (

Warning—Combustible. Vapor harmful.)

8. Sampling

8.1 The sample presented for analysis should be large

enough to make possible the selection of a representative

portion for testing.

8.2 Examine for any indication of non-homogeneity such as

oil separation, phase changes or gross contamination. If any

abnormal conditions are found, obtain a new sample.

9. Preparation of Apparatus

9.1 Thoroughly clean the strainer, cup, and oil-collecting

beaker with mineral spirits and follow by air drying.

9.2 Carefully inspect the sieve to make certain that there is

no build-up which would affect the passage of oil. The sieve

must also be free of any surface irregularities such as creases,

dents, or punctures. Replace, if necessary.

9.3 The funnel must be clean and free of any residues which

can retard the flow of oil.

9.4 Inspect the cover and cup for any dents or distortions to

the mating surfaces which can interfere with a tight seal

between the units.

9.5 When the O-ring seal shows wear it m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.