ASTM A27/A27M-08

(Specification)Standard Specification for Steel Castings, Carbon, for General Application

Standard Specification for Steel Castings, Carbon, for General Application

ABSTRACT

This specification covers carbon steel castings for general applications. The grades of steels covered here are: Grade N-1, Grade N-2, Grade U-60-30 [415-205], Grade 60-30 [415-205], Grade 65-35 [450-240], Grade 70-36 [485-250] and Grade 70-40 [485-275]. Except for Grades N-1 and U-60-30, all steel castings shall be heat-treated by full annealing, normalizing, normalizing and tempering, or quenching and tempering. Heat treatments shall be performed after castings have been allowed to cool. Heat and product analyses shall be performed wherein specimens shall conform to required chemical composition of carbon, manganese, silicon, sulfur and phosphorus. Except for Grades N-1 and N-2, all steels shall undergo tension test, and shall conform to the following mechanical requirements: tensile strength, yield point, elongation, and reduction of area.

SCOPE

1.1 This specification covers carbon steel castings for general applications that require up to 70 ksi (485 MPa) minimum tensile strength.

Note 1—The grades covered by this specification represent materials that are suitable for assembly with other steel castings or wrought steel parts by fusion welding. It is not intended to imply that all these grades possess the same degree of weldability or that the same welding techniques can be used on all castings. It is the responsibility of the purchaser to establish for himself a suitable welding technique.

1.2 Several grades and two classes of steel castings are covered, as indicated below. The grade and class desired shall be specified by the purchaser.

1.2.1 Grade N-1—Chemical analysis only.

1.2.2 Grade N-2—Heat-treated but not mechanically tested.

1.2.3 Grade U-60-30 [415-205]—Mechanically tested but not heat-treated.

1.2.4 Grades 60-30 [415-205], 65-35 [450-240], 70-36 [485-250], and 70-40 [485-275]—Heat-treated and mechanically tested.

1.2.5 Class 1 and Class 2 steel castings shall be specified in accordance with 9.2.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A27/A27M – 08

Standard Specification for

1

Steel Castings, Carbon, for General Application

This standard is issued under the fixed designation A27/A27M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

1.1 This specification covers carbon steel castings for gen-

A732/A732M Specification for Castings, Investment, Car-

eral applications that require up to 70 ksi (485 MPa) minimum

bon and Low Alloy Steel for General Application, and

tensile strength.

Cobalt Alloy for High Strength at Elevated Temperatures

NOTE 1—The grades covered by this specification represent materials

A781/A781M Specification for Castings, Steel and Alloy,

that are suitable for assembly with other steel castings or wrought steel

Common Requirements, for General Industrial Use

parts by fusion welding. It is not intended to imply that all these grades

A957/A957M Specification for Investment Castings, Steel

possess the same degree of weldability or that the same welding

and Alloy, Common Requirements, for General Industrial

techniques can be used on all castings. It is the responsibility of the

Use

purchaser to establish for himself a suitable welding technique.

1.2 Several grades and two classes of steel castings are

3. General Conditions for Delivery

covered, as indicated below. The grade and class desired shall

3.1 Except for steel investment castings, material furnished

be specified by the purchaser.

to this specification shall conform to the requirements of

1.2.1 Grade N-1—Chemical analysis only.

Specification A781/A781M, including any supplementary re-

1.2.2 Grade N-2—Heat-treated but not mechanically tested.

quirements that are indicated in the purchase order. Failure to

1.2.3 Grade U-60-30 [415-205]—Mechanically tested but

comply with the general requirements of Specification A781/

not heat-treated.

A781M constitutes nonconformance with the specification. In

1.2.4 Grades 60-30 [415-205], 65-35 [450-240], 70-36

caseofaconflictbetweentherequirementsofthisspecification

[485-250], and 70-40 [485-275]—Heat-treated and mechani-

and Specification A781/A781M, this specification shall pre-

cally tested.

vail.

1.2.5 Class 1 and Class 2 steel castings shall be specified in

3.2 Steel investment castings furnished to this specification

accordance with 9.2.

shall conform to the requirements of Specification A957/

1.3 The values stated in either SI units or inch-pound units

A957M, including any supplementary requirements that are

are to be regarded separately as standard. The values stated in

indicated in the purchase order. Failure to comply with the

each system may not be exact equivalents; therefore, each

common requirements of Specification A957/A957M consti-

system shall be used independently of the other. Combining

tutes nonconformance with this specification. In case of con-

values from the two systems may result in non-conformance

flict between the requirements of this specification and Speci-

with the standard.

fication A957/A957M, Specification A957/A957M shall

prevail.

2. Referenced Documents

2

2.1 ASTM Standards:

4. Ordering Information

4.1 Orders for material under this specification should

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

include the following information in proper sequence.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

4.1.1 Quantity,

A01.18 on Castings.

4.1.2 Specification, grade (1.2), and class (9.2),

Current edition approved Oct. 1, 2008. Published November 2008. Originally

4.1.3 Description of the casting by pattern number or

approved in 1901. Last previous edition approved in 2005 asA27/A27M – 05. DOI:

10.1520/A0027_A0027M-08.

drawing,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1.4 Options in the specification, and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A27/A27M – 08

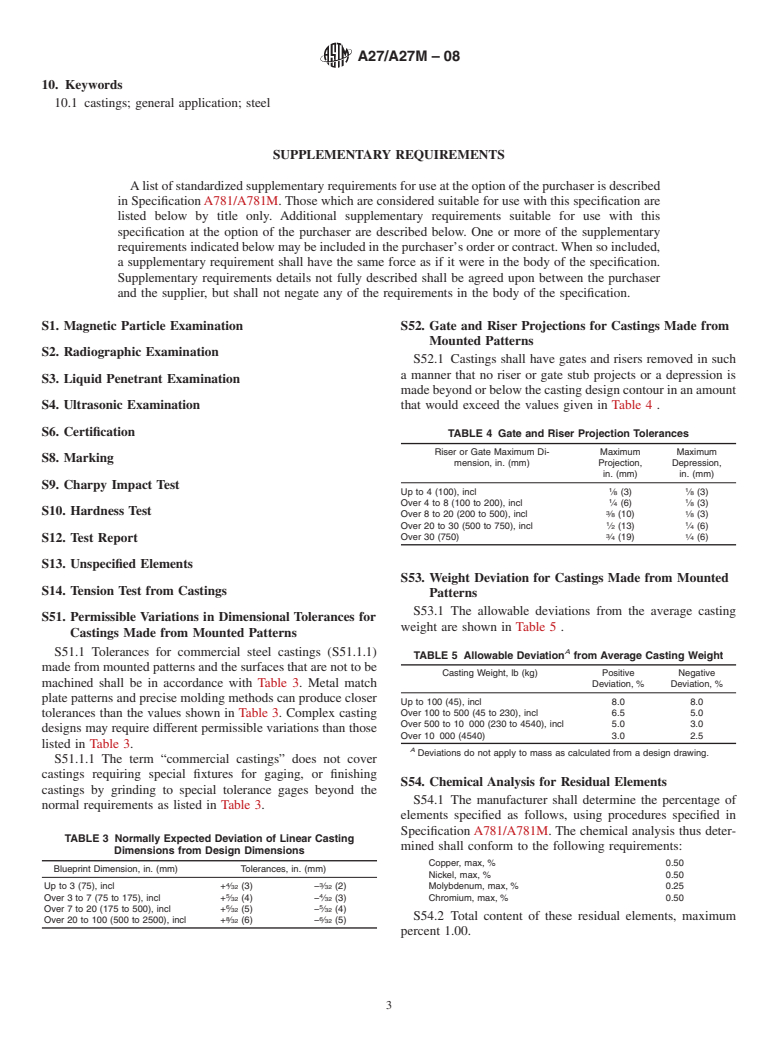

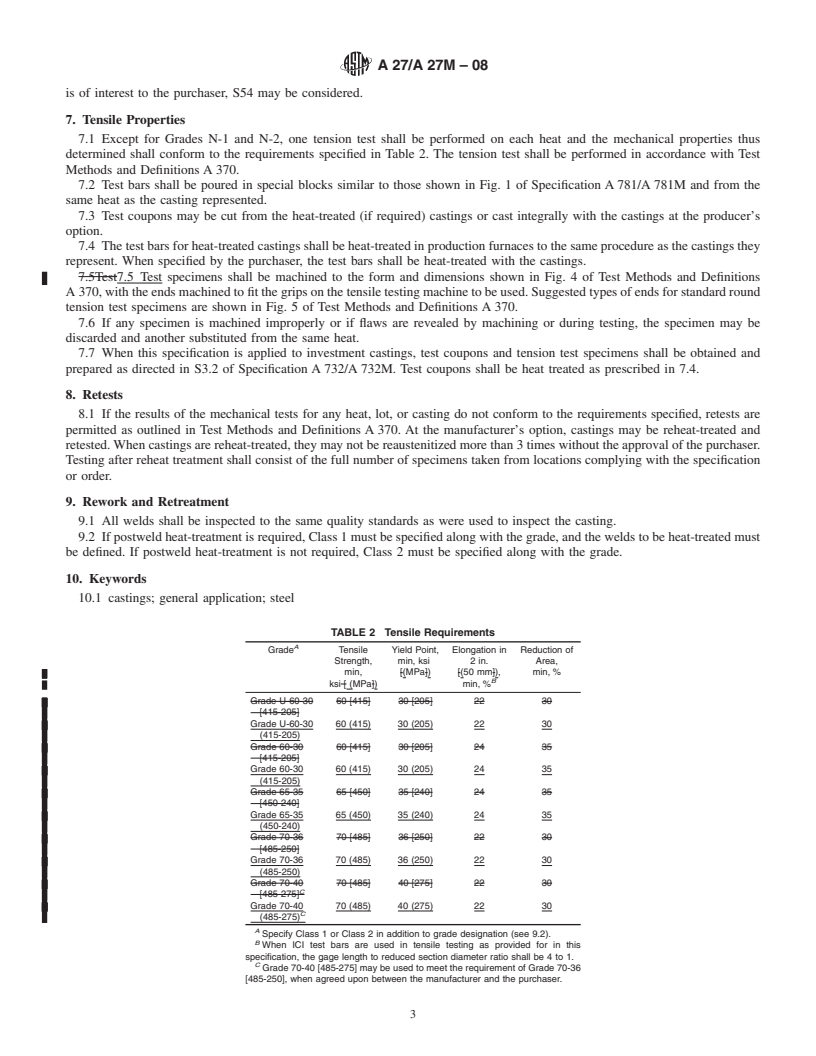

TABLE 2 Tensile Requirements

4.1.5 Supplementary requirements desired, including stan-

A

dards of acceptance. Grade Tensile Yield Point, Elongation in Reduction of

Strength, min, ksi 2in. Area,

min, (MPa) (50 mm), min, %

5. H

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A27/A27M–05 Designation: A 27/A 27M – 08

Standard Specification for

1

Steel Castings, Carbon, for General Application

This standard is issued under the fixed designation A 27/A 27M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers carbon steel castings for general applications that require up to 70 ksi [485 MPa](485 MPa)

minimum tensile strength.

NOTE 1—The grades covered by this specification represent materials that are suitable for assembly with other steel castings or wrought steel parts by

fusion welding. It is not intended to imply that all these grades possess the same degree of weldability or that the same welding techniques can be used

on all castings. It is the responsibility of the purchaser to establish for himself a suitable welding technique.

1.2 Several grades and two classes of steel castings are covered, as indicated below. The grade and class desired shall be

specified by the purchaser.

1.2.1 Grade N-1—Chemical analysis only.

1.2.2 Grade N-2—Heat-treated but not mechanically tested.

1.2.3 Grade U-60-30 [415-205]—Mechanically tested but not heat-treated.

1.2.4 Grades60-30 [415-205],65-35[450-240],70-36[485-250],and70-40[485-275]—Heat-treatedandmechanicallytested.

1.2.5 Class 1 and Class 2 steel castings shall be specified in accordance with 9.2.

1.3The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

Inch-pound units are applicable for material ordered to SpecificationA27 and SI units for material ordered to SpecificationA27M.

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.18

on Castings.

Current edition approved March 1, 2005. Published March 2005. Originally approved in 1901 as A27-01. Last previous edition approved in 2003 as A27/A27M–03.

Current edition approved Oct. 1, 2008. Published November 2008. Originally approved in 1901. Last previous edition approved in 2005 as A 27/A 27M – 05.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 27/A 27M – 08

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

A 732/A 732M Specification for Castings, Investment, Carbon and LowAlloy Steel for GeneralApplication, and CobaltAlloy

for High Strength at Elevated Temperatures

A 781/A 781M Specification for Castings, Steel and Alloy, Common Requirements, for General Industrial Use Specification

for Castings, Steel and Alloy, Common Requirements, for General Industrial Use

A 957/A 957M Specification for Investment Castings, Steel and Alloy, Common Requirements, for General Industrial Use

3. General Conditions for Delivery

3.1Material furnished to this specification shall conform to the requirements of Specification A781/A781M

3.1 Except for steel investment castings, material furnished to this specification shall conform to the requirements of

SpecificationA 781/A 781M,includinganysupplementaryrequirementsthatareindicatedinthepurchaseorder.Failuretocomply

with the general requirements of Specification A 781/A 781M constitutes nonconformance with thisthe specification. In case of a

conflict between the requirements of this specification and Specification A 781/A 781M, this specification shall prevail.

3.2 Steel investment castings furnished to this specification shall conform to the requirements of SpecificationA 957/A 957

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.