ASTM F765-93(2022)

(Specification)Standard Specification for Wildcats, Ship Anchor Chain

Standard Specification for Wildcats, Ship Anchor Chain

ABSTRACT

This specification covers wildcats as used in windlasses to haul in and pay out anchor chain on board ships. Wildcats shall be classified based on materials and manufacture. Wildcats shall be fabricated from structural steel plate, medium-strength carbon steel castings, or high-strength steel castings, joined by electric welding. Wildcats shall conform to specified dimensions, depending on chain size. Wildcats shall be tested to fit sample chain. Workmanship, finish, appearance, packaging, and making shall conform to the requirements of this specification.

SCOPE

1.1 This specification covers wildcats as used in windlasses to haul in and pay out anchor chain on board ships. An associated chain stopper is used to secure the chain while the ship is anchored, or the anchor is housed.

1.2 Wildcats are of the five whelp type for use with stud link anchor chain conforming to the American Bureau of Shipping Grades 1, 2, and 3. Wildcat dimensions are provided for chains in integral 1/8-in. (3-mm) steps, ranging in size from 3/4 to 41/8 in. (19 to 104 mm). Wildcat dimensions for chains in intermediate 1/16-in. (1.5-mm) steps are not provided, but wildcats in these sizes are permitted within the scope of this specification.

1.3 Wildcats are configured to pass detachable links oriented parallel or perpendicular to the wildcat shaft centerline.

1.4 The values stated in inch-pound units are to be regarded as the standard. This specification is for use with anchor chain that is measured in inch-pound units.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F765 −93 (Reapproved 2022) An American National Standard

Standard Specification for

Wildcats, Ship Anchor Chain

ThisstandardisissuedunderthefixeddesignationF765;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.2 Other Documents:

American Bureau of Shipping Rules for Building and

1.1 This specification covers wildcats as used in windlasses

Classing Steel Vessels, Section, 2.2.2 Anchor Chain

to haul in and pay out anchor chain on board ships. An

AmericanWeldingSocietyStructuralWeldingCodeChapter

associated chain stopper is used to secure the chain while the

D1.1

ship is anchored, or the anchor is housed.

1.2 Wildcatsareofthefivewhelptypeforusewithstudlink

3. Classification

anchor chain conforming to theAmerican Bureau of Shipping

3.1 The size of the wildcat is identified by the chain size.

Grades1,2,and3.Wildcatdimensionsareprovidedforchains

1 3 1

3.2 Wildcats are furnished in four types as follows:

in integral ⁄8-in. (3-mm) steps, ranging in size from ⁄4 to 4 ⁄8

3.2.1 Type I—Fabricated from structural steel plate for

in. (19 to 104 mm). Wildcat dimensions for chains in interme-

flanges, hubs, whelps, and chain pockets, joined by electric

diate ⁄16-in. (1.5-mm) steps are not provided, but wildcats in

welding. Surface hardness is approximately 150 HB.

these sizes are permitted within the scope of this specification.

3.2.2 Type II—Fabricated from structural steel plate for

1.3 Wildcats are configured to pass detachable links ori-

flanges, hubs, and chain pockets; and high-strength steel

ented parallel or perpendicular to the wildcat shaft centerline.

castings for whelps, joined by electric welding. Surface hard-

1.4 The values stated in inch-pound units are to be regarded

nessisapproximately150HBforflangesandhubsand300HB

as the standard. This specification is for use with anchor chain

for whelps.

that is measured in inch-pound units.

3.2.3 Type III—Cast from medium-strength carbon steel

castings to provide a surface hardness of approximately 150

1.5 This international standard was developed in accor-

HB.

dance with internationally recognized principles on standard-

3.2.4 Type IV—Cast from high-strength steel castings to

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- provide a surface hardness of approximately 300 HB.

mendations issued by the World Trade Organization Technical

4. Descriptions of Terms

Barriers to Trade (TBT) Committee.

4.1 chain groove—circumferential groove at the chain cen-

2. Referenced Documents

terline to provide clearance for links passing normal to the

2.1 ASTM Standards:

wildcat shaft centerline.

A27/A27MSpecification for Steel Castings, Carbon, for

4.2 chain pockets—recessesbetweentheflangesandwhelps

General Application

into which links with flat side orientated parallel to the wildcat

A36/A36MSpecification for Carbon Structural Steel

shaft centerling lay.

A148/A148M Specification for Steel Castings, High

4.3 detachable link—a “C” shaped link, closed by means of

Strength, for Structural Purposes

apairofclosingpiecesandataperpin,andusedtojoinanchor

E10Test Method for Brinell Hardness of Metallic Materials

chain lengths and appendages into a continuous length aboard

ship.

This specification is under the jurisdiction of ASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on 4.4 flanges—circumferential rims on the outside of the

Outfitting and Deck Machinery.

whelps, chain pockets, and chain groove.

CurrenteditionapprovedJuly1,2022.PublishedJuly2022.Originallyapproved

in 1982. Last previous edition approved in 2017 as F765–93 (2017). DOI:

10.1520/F0765-93R22.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Bureau of Shipping (ABS), ABS Plaza, 16855

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Northchase Dr., Houston, TX 77060, http://www.eagle.org.

Standards volume information, refer to the standard’s Document Summary page on Available from American Welding Society (AWS), 8669 NW 36 St., #130,

the ASTM website. Miami, FL 33166-6672, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F765−93 (2022)

4.5 link grip—the inside dimension of a chain link repre- shall conform to Specification A36/A36M for flanges and

senting the effective length of a chain link in an assembled hubs, and chain pockets, and Specification A148/A148M for

chain. Generally four times the nominal size of a stud link whelps, joined by electric welding in accordance with AWS,

anchor chain, see Fig. 1. Structural Welding Code, Chapter D1.1, stress-relieved and

heat-treated. Material for Type III wildcats shall conform to

4.6 whelps—protrusions on the inside of the flanges of the

Specification A27/A27M, Grade 70–40, quenched and tem-

wildcat that resemble gear teeth and of such shape and

pered. Material for Type IV wildcats shall conform to Speci-

dimensionssoastofollowthepathofthechain,asitentersand

fication A148/A148M, Grade 150–125, quenched and tem-

leaves the wildcat. Faces of protrusions are separated by the

pered.

chain groove to permit links with the flat side normal to the

wildcat shaft centerline to pass, but blocking links with the flat 6.2 The manufacturer’s name or identification mark, chain

side oriented parallel to the wildcat shaft centerline. size,andpatternordrawingnumbershallbecastorstampedon

the wildcat, using minimum ⁄4-in. (19-mm) size characters.

4.7 wildcat—a rotating member specially contoured to re-

Themarkingshallnotappearonawearingsurfaceandshallbe

ceive assembled chain links and connecting links around the

visible on an assembled windlass.

circumferenceofthememberandofsuitablestrengthtoimpart

motion to the chain when rotated.

7. Dimensions

5. Ordering Information

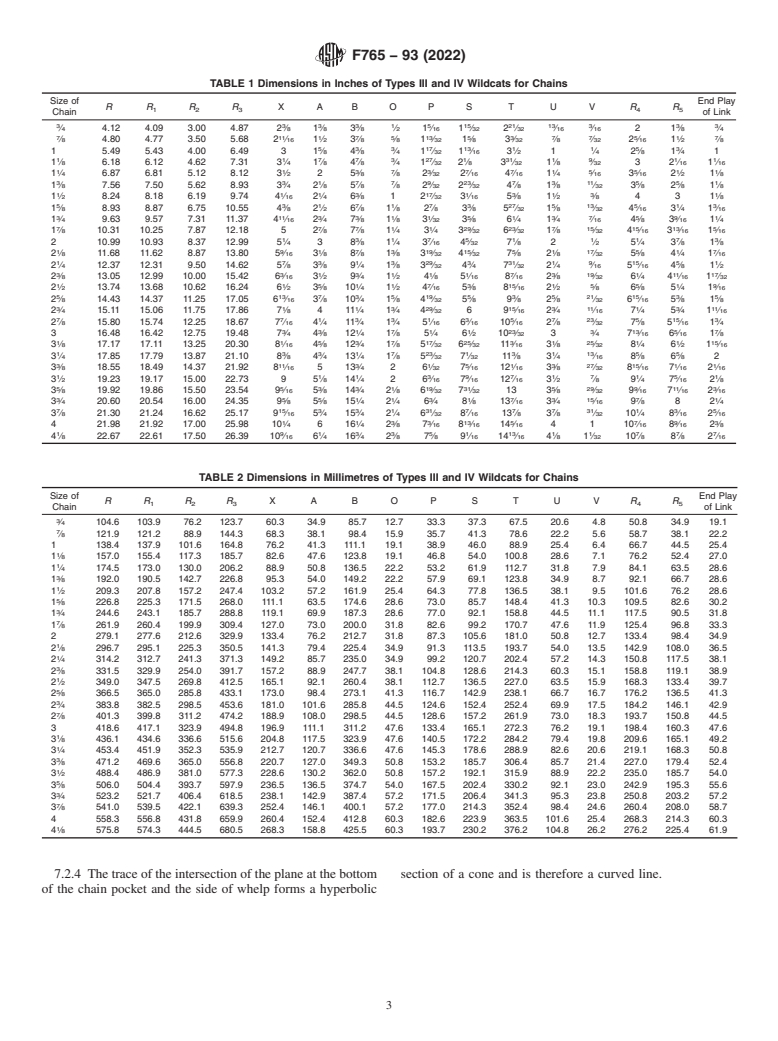

7.1 Wildcat must be fitted to the sample chain, and detach-

ablelink(seeSection9).PrincipaldimensionsofTypesIIIand

5.1 Ordersforwildcatsunderthisspecificationshallinclude

IV wildcats for chains in steps of ⁄8in. (3 mm) are shown for

the following:

information only in Table 1 and Table 2.

5.1.1 Quantity (number),

5.1.2 Size (chain size),

7.2 Dimensions in Table 1 and Table 2 are developed in

5.1.3 ASTM designation and date of issue,

accordance with the following (see also Fig. 2 and Fig. 3):

5.1.4 Type (I, II, III, or IV),

7.2.1 Bottom of chain pockets are relieved to clear enlarge-

5.1.5 Size, grade, and type of chain,

ments occurring at centers of chain links as manufactured.

5.1.6 Availability of assembled chain and detachable link to

7.2.2 Each face of the whelp is a partial frustrum of a cone

be furnished by the purchaser for test (see Section 9),

developed so that each link whose plane is parallel to the

5.1.7 As-cast or machined dimensions for wildcat bore, hub

wildcat shaft centerline will have end play as noted in Table 1

width, and outside boss diameter, and

and Table 2. This end play provides clearance between

5.1.8 Marking (shipping).

nonbearing side of whelp and the end of the next following

link, the centerline plane of which is parallel to the axis of

6. Materials and Manufacture

shaft.

6.1 Material for Type I wildcats shall conform to Specifi- 7.2.3 The inner surfaces of the chain pockets, that form the

cationA36/A36Mforflanges,hubs,whelps,andchainpockets, flanges of the wildcat, are flat surfaces together forming the

joined by electric welding in accordance withAWS, structural frustrums of pentagonal pyramids. The traces of the intersec-

welding code Chapter D1.1. Type I wildcats in sizes 2 in. and tions of these flat surfaces or sides of the frustrums coincide

larger shall be stress-relieved. Material for Type II wildcats with the centerline of the whelps.

FIG. 1 Chain Wrap Test

F765−93 (2022)

TABLE 1 Dimensions in Inches of Types III and IV Wildcats for Chains

Size of End Play

RR R R XA B O P S T U V R R

1 2 3 4 5

Chain of Link

3 3 3 3 1 5 15 21 13 3 3 3

⁄4 4.12 4.09 3.00 4.87 2 ⁄8 1 ⁄8 3 ⁄8 ⁄2 1 ⁄16 1 ⁄32 2 ⁄32 ⁄16 ⁄16 21 ⁄8 ⁄4

7 11 1 7 5 13 5 3 7 7 5 1 7

⁄8 4.80 4.77 3.50 5.68 2 ⁄16 1 ⁄2 3 ⁄8 ⁄8 1 ⁄32 1 ⁄8 3 ⁄32 ⁄8 ⁄32 2 ⁄16 1 ⁄2 ⁄8

5 3 3 17 13 1 1 5 3

1 5.49 5.43 4.00 6.49 3 1 ⁄8 4 ⁄8 ⁄4 1 ⁄32 1 ⁄16 3 ⁄2 1 ⁄4 2 ⁄8 1 ⁄4 1

1 1 7 7 3 27 1 31 1 9 1 1

1 ⁄8 6.18 6.12 4.62 7.31 3 ⁄4 1 ⁄8 4 ⁄8 ⁄4 1 ⁄32 2 ⁄8 3 ⁄32 1 ⁄8 ⁄32 32 ⁄16 1 ⁄16

1 1 3 7 3 7 7 1 5 5 1 1

1 ⁄4 6.87 6.81 5.12 8.12 3 ⁄2 25 ⁄8 ⁄8 2 ⁄32 2 ⁄16 4 ⁄16 1 ⁄4 ⁄16 3 ⁄16 2 ⁄2 1 ⁄8

3 3 1 7 7 9 23 7 3 11 5 5 1

1 ⁄8 7.56 7.50 5.62 8.93 3 ⁄4 2 ⁄8 5 ⁄8 ⁄8 2 ⁄32 2 ⁄32 4 ⁄8 1 ⁄8 ⁄32 3 ⁄8 2 ⁄8 1 ⁄8

1 1 1 3 17 1 3 1 3 1

1 ⁄2 8.24 8.18 6.19 9.74 4 ⁄16 2 ⁄4 6 ⁄8 12 ⁄32 3 ⁄16 5 ⁄8 1 ⁄2 ⁄8 43 1 ⁄8

5 3 1 7 1 7 3 27 5 13 5 1 3

1 ⁄8 8.93 8.87 6.75 10.55 4 ⁄8 2 ⁄2 6 ⁄8 1 ⁄8 2 ⁄8 3 ⁄8 5 ⁄32 1 ⁄8 ⁄32 4 ⁄16 3 ⁄4 1 ⁄16

3 11 3 3 1 1 5 1 3 7 5 9 1

1 ⁄4 9.63 9.57 7.31 11.37 4 ⁄16 2 ⁄4 7 ⁄8 1 ⁄8 3 ⁄32 3 ⁄8 6 ⁄4 1 ⁄4 ⁄16 4 ⁄8 3 ⁄16 1 ⁄4

7 7 7 1 1 29 23 7 15 15 13 5

1 ⁄8 10.31 10.25 7.87 12.18 5 2 ⁄8 7 ⁄8 1 ⁄4 3 ⁄4 3 ⁄32 6 ⁄32 1 ⁄8 ⁄32 4 ⁄16 3 ⁄16 1 ⁄16

1 3 1 7 5 1 1 1 7 3

2 10.99 10.93 8.37 12.99 5 ⁄4 38 ⁄8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.