ASTM D1322-97

(Test Method)Standard Test Method for Smoke Point of Kerosine and Aviation Turbine Fuel

Standard Test Method for Smoke Point of Kerosine and Aviation Turbine Fuel

SCOPE

1.1 This test method covers a procedure for determination of the smoke point of kerosine and aviation turbine fuel.

Note 1- There is a good correlation between Luminometer number (Test Method D 1740) and smoke point which is represented in Appendix X1.

1.2 This standard does not purport to address all of the safety concerns, if any associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 1322 – 97

Designation: 57/95

Standard Test Method for

Smoke Point of Kerosine and Aviation Turbine Fuel

This standard is issued under the fixed designation D 1322; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 aviation turbine fuel—refined petroleum distillate,

generally used as a fuel for aviation gas turbines.

1.1 This test method covers a procedure for determination

3.1.1.1 Discussion—Different grades are characterized by

of the smoke point of kerosine and aviation turbine fuel.

volatility ranges, freeze point, and by flash point.

NOTE 1—There is good correlation between Luminometer number

3.1.2 kerosine—refined petroleum distillate, boiling be-

(Test Method D 1740) and smoke point which is represented in Appendix

tween 140 and 300°C, generally used in lighting and heating

X1.

applications.

1.2 This standard does not purport to address all of the

3.1.3 smoke point—the maximum height, in millimetres, of

safety concerns, if any, associated with its use. It is the

a smokeless flame of fuel burned in a wick-fed lamp of

responsibility of the user of this standard to establish appro-

specified design.

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 The sample is burned in an enclosed wick-fed lamp that

2. Referenced Documents

is calibrated daily against pure hydrocarbon blends of known

2.1 ASTM Standards:

smoke point. The maximum height of flame that can be

D 1740 Test Method for Luminometer Number of Aviation

achieved with the test fuel without smoking is determined to

Turbine Fuels

the nearest 0.5 mm.

D 4057 Practice for Manual Sampling of Petroleum and

5. Significance and Use

Petroleum Products

2.2 IP Standard:

5.1 This test method provides an indication of the relative

IP 57/95 Smoke Point

smoke producing properties of kerosines and aviation turbine

fuels in a diffusion flame. The smoke point is related to the

NOTE 2—Only IP 57/95 published in 1995 is equivalent to D1322;

hydrocarbon type composition of such fuels. Generally the

earlier versions of IP 57 were not equivalent.

more aromatic the fuel the smokier the flame. A high smoke

2.3 ISO Standard:

point indicates a fuel of low smoke producing tendency.

ISO 3014:1993(E) Petroleum Products—Determination of

5.2 The smoke point (and Luminometer number with which

the Smoke Point of Kerosine

it can be correlated) is quantitatively related to the potential

radiant heat transfer from the combustion products of the fuel.

3. Terminology

Because radiant heat transfer exerts a strong influence on the

3.1 Definitions of Terms Specific to This Standard:

metal temperature of combustor liners and other hot section

parts of gas turbines, the smoke point provides a basis for

correlation of fuel characteristics with the life of these com-

This test method is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

ponents.

D02.J0.07on Combustion Characteristics.

Current edition approved June 10, 1997. Published October 1997. Originally

6. Apparatus

published as D 1322 – 54T. Last previous edition D 1322 – 96.

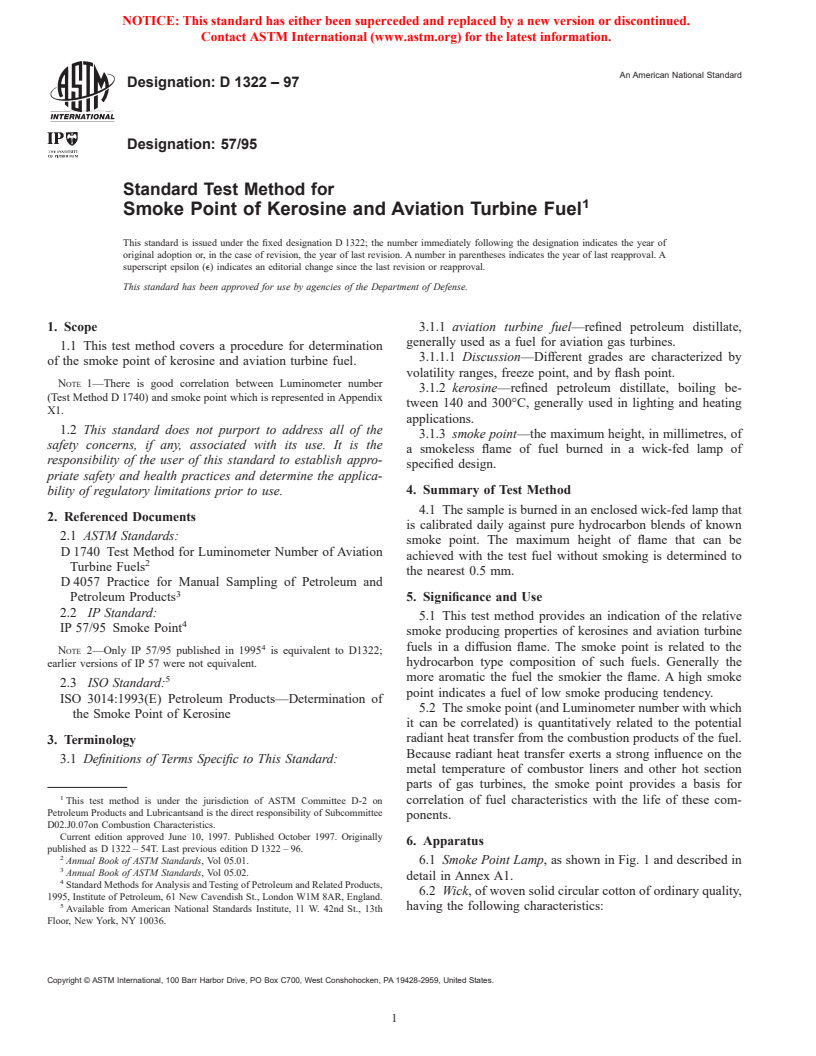

Annual Book of ASTM Standards, Vol 05.01. 6.1 Smoke Point Lamp, as shown in Fig. 1 and described in

Annual Book of ASTM Standards, Vol 05.02.

detail in Annex A1.

Standard Methods for Analysis and Testing of Petroleum and Related Products,

6.2 Wick, of woven solid circular cotton of ordinary quality,

1995, Institute of Petroleum, 61 New Cavendish St., London W1M 8AR, England.

having the following characteristics:

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D1322–97

TABLE 1 Reference Fuel Blends

Standard Smoke Point at

Toluene 2,2,4-trimethylpentane

101.3 kPa

mm %(v/v) % (v/v)

14.7 40 60

20.2 25 75

22.7 20 80

25.8 15 85

30.2 10 90

35.4 5 95

42.8 0 100

NOTE 6—Warning: Extremely flammable, vapor harmful if inhaled.

(See Annex A2.4.)

8. Sampling and Preparation of Samples

8.1 It is recommended samples shall be taken by the

procedures described in Practice D 4057. Use the sample as

received. Allow all samples to come to ambient temperature

(20 6 5°C), without artificial heating. If the sample is hazy or

appears to contain foreign material, filter through qualitative

filter paper.

9. Preparation of Apparatus

9.1 Place the lamp in a vertical position in a room where it

can be completely protected from drafts. Carefully inspect each

new lamp to ensure that the air holes in the gallery and the air

inlets to the candle holder are all clean, unrestricted and of

proper size. The gallery shall be so located that the air holes are

completely unobstructed.

NOTE 7—Slight variations in these items all have a marked effect on the

precision of the result obtained.

9.1.1 If the room is not completely draft-free, place the lamp

in a vertical position in a box constructed of heat-resistant

material (not containing asbestos), open at the front. The top of

FIG. 1 Smoke Point Lamp

the box shall be at least 150 mm above the top of the chimney

and the inside of the box painted dull black.

9.2 Extract all wicks, either new or from a previous deter-

Casing 17 ends, 66 tex by 3

Filling 9 ends, 100 tex by 4 mination, for at least 25 cycles in an extractor, using a mixture

Weft 40 tex by 2

of equal volumes of toluene and anhydrous methanol. Allow

Picks 6 per centimetre

the wicks to dry partially in a hood before placing in the oven,

6.3 Pipettes or Burettes, Class A.

or use a forced-draft and explosion-proof oven for drying

wicks, or both. Dry for 30 min at 100 to 110°C and store in a

7. Reagents and Materials

dessicator until used.

7.1 Toluene, ASTM Reference Fuel grade.

10. Calibration of Apparatus

NOTE 3—Warning: Flammable, vapor harmful. (See Annex A2.1.)

10.1 Calibrate the apparatus in accordance with 10.2. Reca-

7.2 2,2,4-trimethylpentane (isooctane), minimum purity

librate at regular intervals of not more than seven days or when

99.75 % (m/m).

there has been a change in the apparatus or operator, or when

NOTE 4—Warning: Flammable, vapor harmful. (See Annex A2.2.)

a change of more than 0.7 kPa occurs in the barometric

pressure reading.

7.3 Methanol (methyl alcohol), anhydrous.

10.2 Calibrate the apparatus by testing two of the reference

NOTE 5—Warning: Flammable, vapor harmful. (See Annex A2.3.)

fuel blends specified in 7.4, using the procedure specified in

7.4 Reference Fuel Blends, appropriate to the fuels under Section 11 and, if possible, bracketing the smoke point of the

test, made up accurately from toluene and 2,2,4- sample. If this is not possible, use the two test blends having

trimethylpentane, in accordance with the compositions given in their smoke points nearest to the smoke point of the sample.

Table 1, by means of calibrated burettes or pipettes. 10.2.1 Determine the correction factor f for the apparatus

7.5 Heptane, minimum purity 99.75 % (m/m). from the equation;

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D1322–97

~A / A ! 1 ~B / B !

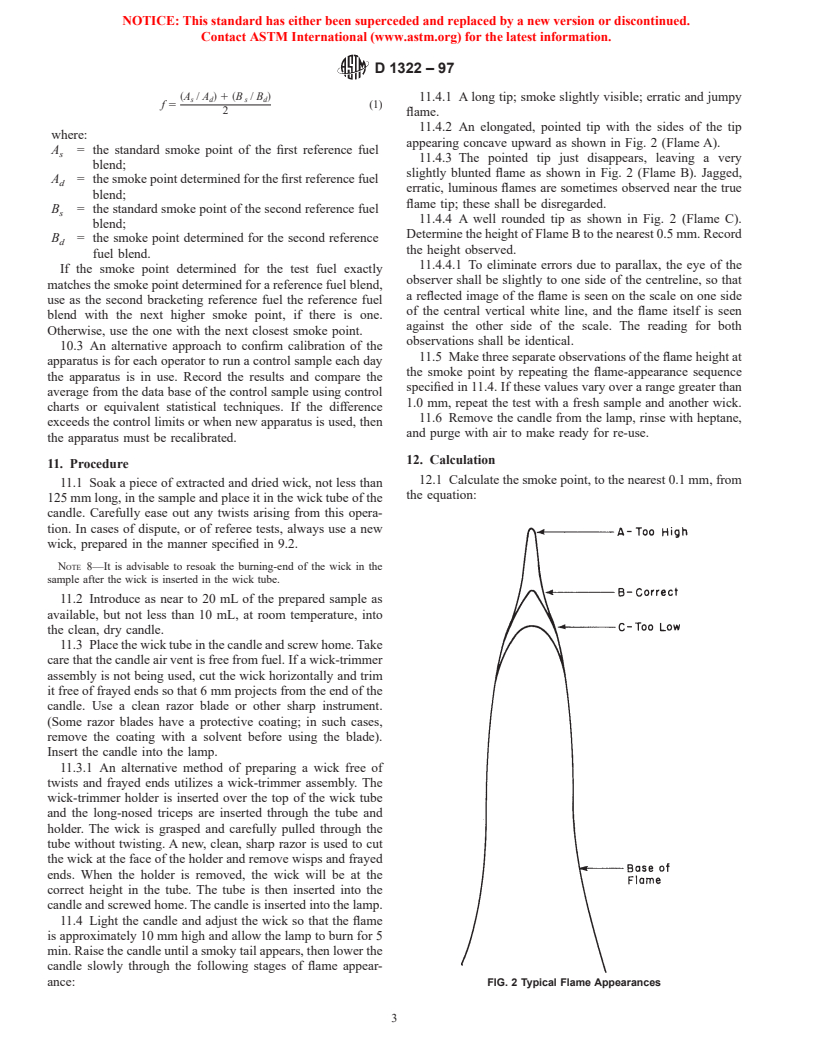

11.4.1 A long tip; smoke slightly visible; erratic and jumpy

s d s d

f 5 (1)

flame.

11.4.2 An elongated, pointed tip with the sides of the tip

where:

appearing concave upward as shown in Fig. 2 (Flame A).

A = the standard smoke point of the first reference fuel

s

11.4.3 The pointed tip just disappears, leaving a very

blend;

slightly blunted flame as shown in Fig. 2 (Flame B). Jagged,

A = the smoke point determined for the first reference fuel

d

erratic, luminous flames are sometimes observed near the true

blend;

flame tip; these shall be disregarded.

B = the standard smoke point of the second reference fuel

s

11.4.4 A well rounded tip as shown in Fig. 2 (Flame C).

blend;

Determine the height of Flame B to the nearest 0.5 mm. Record

B = the smoke point determined for the second reference

d

the height observed.

fuel blend.

11.4.4.1 To eliminate errors due to parallax, the eye of the

If the smoke point determined for the test fuel exactly

observer shall be slightly to one side of the centreline, so that

matches the smoke point determined for a reference fuel blend,

a reflected image of the flame is seen on the scale on one side

use as the second bracketing reference fuel the reference fuel

of the central vertical white line, and the flame itself is seen

blend with the next higher smoke point, if there is one.

against the other side of the scale. The reading for both

Otherwise, use the one with the next closest smoke point.

observations shall be identical.

10.3 An alternative approach to confirm calibration of the

11.5 Make three separate observations of the flame height at

apparatus is for each operator to run a control sample each day

the smoke point by repeating the flame-appearance sequence

the apparatus is in use. Record the results and compare the

specified in 11.4. If these values vary over a range greater than

average from the data base of the control sample using control

1.0 mm, repeat the test with a fresh sample and another wick.

charts or equivalent statistical techniques. If the difference

11.6 Remove the candle from the lamp, rinse with heptane,

exceeds the control limits or when new apparatus is used, then

and purge with air to make ready for re-use.

the apparatus must be recalibrated.

12. Calculation

11. Procedure

12.1 Calculate the smoke point, to the nearest 0.1 mm, from

11.1 Soak a piece of extracted and dried wick, not less than

the equation:

125 mm long, in the sample and place it in the wick tube of the

candle. Carefully ease out any twists arisin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.