ASTM D621-64(1988)e1

(Test Method)Test Methods for Deformation of Plastics Under Load

Test Methods for Deformation of Plastics Under Load

General Information

Standards Content (Sample)

An American National Standard

~~ Designation: D 621- 64 (Reapproved 1988)E1

AMERICAN SOCIETY FOR TESTING AND MATERIALS

19t6 Aace St., Philadelphia. Pa. t9103

Standard Test Methods for

Reprlnled from the Annual Book at ASTM Standards, Copyright ASTM

If not listed In the current combined Index, will eppear In the next edlllon.

Deformation of Plastics Under Load

This standard is issued under the fixed designation D 621; tbe number immediately following the designation indicates tbe year of

original adoption or, in the case of revision, the year oflast revision. A number in parentheses indicates the year oflast reapproval. A

superscript epsilon (ol indicates an editorial change since the last revision or reapproval.

These test methods Irave been approved for rISe by agencies ofthe Departmem ofDefense to replace Method 1101 of Federal Test

Method Standard 406. andfor Listing in the DoD Index ofSpecifications and Standards.

o. NOTE-The safety hazards caveat and the Precision and Bias section were added editorially in March 1988. The Referenced

Documents section was also added, causing the renumbering of subsequent sections.

D-618 Methods of Conditioning Plastics and Electrical

1. Scope

Insulating Materials for Testing

1.1 These test methods cover the determination of the

deformation under compression of nonmetallic sheet and

3. Significance and Use

molded plastic materials, of all classes and all commercial

3.1 Data obtained by Test Method A give a measure of

thicknesses, intended for structural and insulating purposes.

the ability of a rigid plastic in assemblies of conductors and

Two test methods are included, as follows:

insulators that are held together by bolts, rivets, or similar

Test Method A-For rigid plastics.

fastening devices, to withstand compression without yielding

Test Method B-For nonrigid plastics.

and loosening the assembly with time. Test Method A also

1.2 The word deformation is used herein in the broad

gives a measure of the rigidity of plastics at service tempera

sense to cover(1) dimensional change due almost entirely to

tures and consequently can be used as an identification test

flow, and (2) dimensional change due to a combination of

for procurement purposes.

flow and shrihkage caused by loss of water or other volatile

3.2 Data obtained by Test Method B give a measure ofthe

matter. The word flow as used in these test methods may

ability of a nonrigid plastic to return to its original dimen

describe either plastic or elastic defonnation or combinations

sions with time after having been deformed. Test Method B

thereof.

determines the extent to which the plastic will follow

associated parts in applications requiring elastic properties.

NOTIl I-The values slated in Sl units are to be regarded as the

standard.

TEST METHOD A-RIGID PLASTICS

NOTIl 2-Methyl methacrylate and polystyrene are examples of

materials that deform almost entirely by flow. Cellulose acetate,

cellulose acetate butyrate, phenolic laminated fiber, and vulcanized fiber

4. Nature of Test

are examples of materials that deform by a combination of flow and

4.1 The principle of Test Method A is essentially that of

shrinkage.

the parallel plate plastometer, namely, a constant-force

system whereby a test specimen is conditioned, if necessary,

1.3 This standard may involve hazardous materials, oper

of a constant

and is then placed between the parallel plates

alions, and eqllipmellt. Thi-s standard does not purport to

force device and the thickness observed over a required

address all ofthe safety problems associated with its use. It is

period at the stipulated temperature or temperatures.

the responsibility of the IIser of this standard to establish

appropriate sqfety and health practices and determine the

5. Apparatus

applicability ofreglilatory limitations prior to use.

5.1 Testing Machine-A machine capable of exerting a

constant force of 113 kg (250 Ib), 227 kg (500 Ib), and 454 kg

2. Referenced Documents

(1000 Ib) ±l % between the parallel anvils of the machine,

which shall be arranged so that they can be brought into

2.1 ASTM Standards:

contact with the test specimen before the load is applied. A

D 374 Test Methods for Thickness of Solid Electrical

machine suitable for this test is shown in Fig. 1. A recom

Insulation

mended method for calibrating such a device is given in the

D 575 Tc:st Methods for Rubber Properties in Com

Appendix. One of the anvils of the machine shall preferably

pression

be self-aligning and shall, in order that the load may be

applied evenly over the face of the specimen, be arranged so

that the specimen is accurately centered and the resultant of

I These lest methods are under the jurisdiction of ASTM Committee D·20 on

the load is through its center. The machine shall also be

Plastics and are tbe direct responsibility of Subcommittee D20.30 on Thermal

Properties (Section D20.30.07).

equipped with a dial gage or the equivalent capable of

Current edition approved Aug. 31, 1964. Published October 1964. OriginallY

measuring the relative movement of the faces to 0.025 mm

published as D 621 - 41. Last previous edition D 621 - 59.

(0.001 in.) or less. A thermometer of the total immersion

2 Anllual Book ofASTM Standards. Vol 08.01.

3 Annual Book ofASTM Stolldards. Vol 09.01. type shall be suspended in such a manner that the bulb is

4B1b 0621

HYf/rDlllic JacJc for

Raising Wtighl

El

.

~

Metric Equivalents

In. 5 20 25

mm 127 508 635

FIG. 1 Deformation Testing Machine

approximately level with the specimen and not more than 76 bearing that number, a second strip shall be cut adjacent to

the first one, cut into pieces, and the required number of

mm (3 in.) therefrom.

5.2 Test Chamber-A test chamber of suitable size and squares taken from the appropriate pieces. The number of

construction to enclose the testing machine and maintain it squares to be cut from each piece is prescribed in Table 1.

during the test within ± 1°C (2°F) of the specified test

NOTE 3-Substantial variations in test values may occur, particularly

temperature, except for the short period at the beginning

with composite specimens, if tlie opposite faces of the specimens are not

when opening the door may cause a drop in temperature.

plane and parallel or if sink marks or other similar imperfections are

present. To minimize such variations, the squares used to form the

composite specimens, if necessary, shall be rendered plane and parallel

6. Test Specimens

and their adjoining surfaces shall be freed of sink marks and other

imperfections by milling, grinding, or other appropriate means. If solid

6.1 The test specimen shall be a 12.7-mm (1/2-in.) cube,

cubes are used, their opposite faces in contact with the anvils of the

either solid or composite. Materials over 12.7 mm (1f2 in.) in

testing machine, if necessary, shall be milled plane and parallel and shall

thickness shall be reduced to 12.7 mm (1f2 in.), and thinner

be smooth and free of imperfections.

materials shall be piled up with the total height as near to

12.7 mm (1/2 in.) as possible. The squares of the composite

7. Conditioning

specimen shall be accurately aligned in all cases. Surfaces of

7.1 Where deformation under average room conditions is

the test specimens shall be plane and parallel.

required, condition and test specimens in accordance with

6.2 The specimens for materials made in large sheets,

7.1.1 and 7.1.2.

such as phenolic laminated fiber, where moisture absorption

7.1.1 Conditioning-Condition the test specimens at 23 ±

characteristics may vary over the entire surface, shall be

2°C (73.4 ± 3.6°F) and 50 ± 5 % relative humidity for not

prepared, unless otherwise specified, in accordance with the

less than 40 h prior to test in accordance with Procedure A of

sampling method described in 6.3, which averages the effect

Methods D 618 for those tests where conditioning is re-

over the sheet by selecting squares comprising the specimen

in such a manner that each square represents the same

TABLE 1 Number of Squares to be Cut from Each Piece

proportional part of the entire area of the sheet.

NOTE-In case of material of thicknesses not inclUded in the table, the squares

6.3 Specimen /rom Sheet Materials-The specimen shall

used In the composite test specimen shall be selected In accordance with the

be selected from the whole sheet by cutting a strip 12.7 mm

method for nearest thickness given In the tabla. In case the thickness Is midway

(1/2 in.) in width from the sheet, parallel to the two long edges between two adjacent values In the table, the squares used in the composite test

specimen shall be selected In accordance with the Instructions for the thinner

if the sheet is not square or parallel to any two ifit is square,

material.

midway between them, and extending from the edge to the

Thickness of Total Number

Number of Piece

center of the sheet. If quarter sheets are used, the strip shall

Material, of Squares ------------

be taken from the edge corresponding to the center-to-edge

mm(ln.) Required 2 3 4 6 6 7 8

section of the original whole sheet. The strip shall be divided

0.40 (11••) 32 B 6 6 4 3 3 2

into eight equal parts numbered from 1 to 8, beginning with

0.79 (1io2) 16 4 3 3 2 2 1 1

1.19(%.) 11 2

the piece corresponding to the edge of the sheet. The squares 2 2 2 1 1 1

1.59 (11,.) 8 2 1 1 1 1 1

used to form the composite test specimen shall be taken from

2.38 (0/32) 5 1 1 1 1 1

these pieces. If the whole piece is not used, the squares cut

3.2 (Yo) 4 1 1 1

from it shall be taken from the end which was originally 4.8 (3;;.) 3 1

9.5(%) 1 1

nearest the edge of the sheet. If any piece is insufficient for

12.7 (V2) 1 1

the number of squares required to be cut from a piece

~t 0621

c

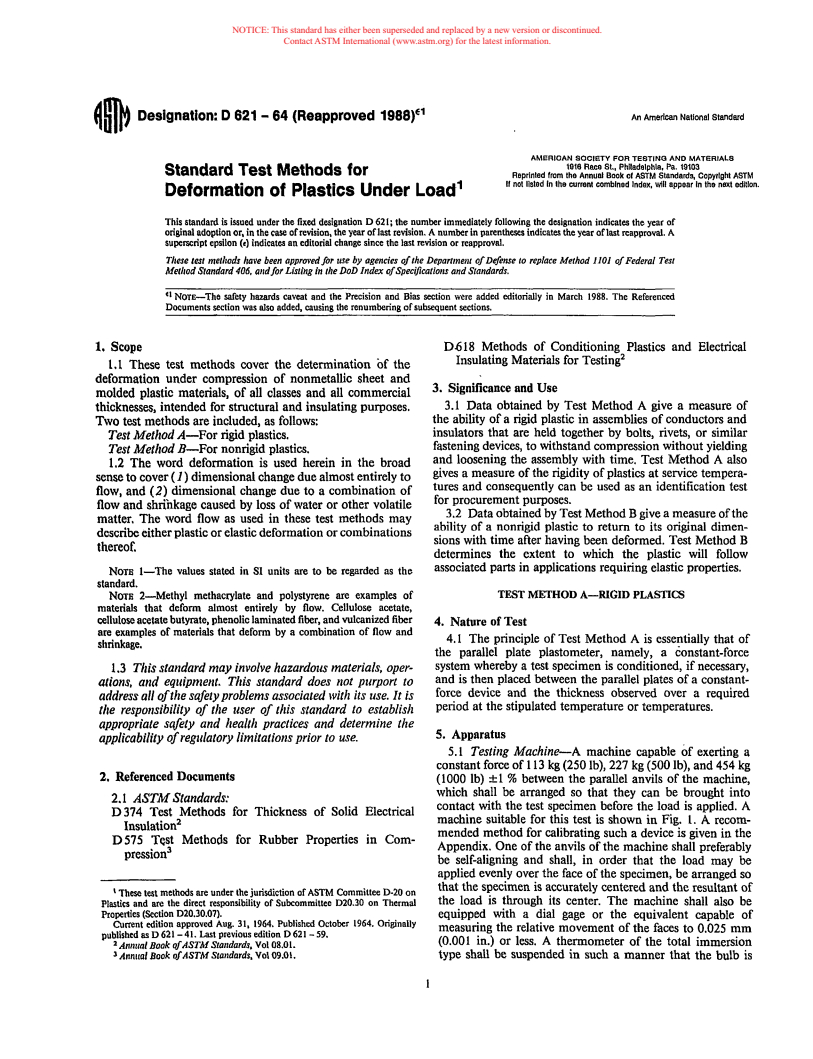

FIG. 2 Jig for Composite SpecImen

quired. In caseS ofdisagreement, the tolerances shall be ± I·C

(±1.8·F) and ±2 % relative humidity.

7.1.2 Test Conditions-Conduct tests in the Standard

Laboratory Atmosphere of23 ± 2·C (73.4 ± 3.6·F) and 50 ±

I--t--£

S % relative humidity, unless othenvise specified in the test

F

methods or in these test methods. In cases of disagreement,

the tolerances shall be ±1°C (±l.S·F) and ±2 % relative

humidity.

7.2 In those materials where shrinkage is a large part of

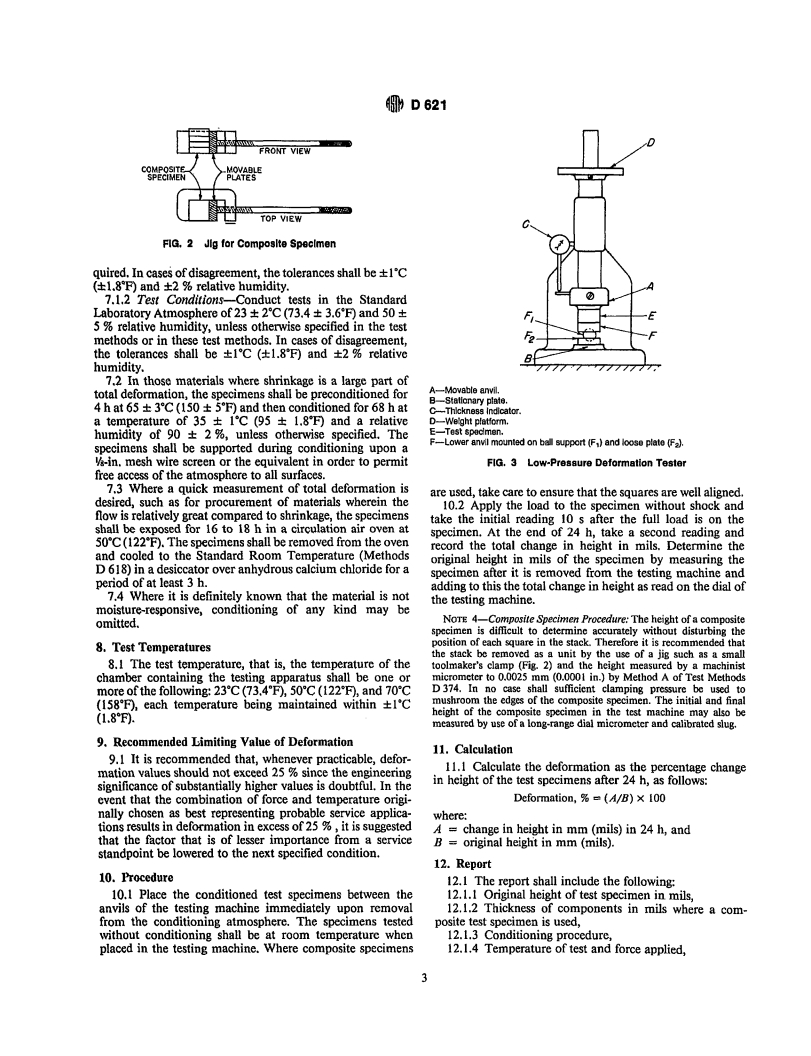

A-Movabla anvil.

total deformation, the specimens shall be preconditioned for

B-Statlonary plate.

4 h at 65 ± 3°e (150 ± SOF) and then conditioned for 68 hat

C-Thickness Indicator.

D-Welght platform.

a temperature of 35 ± 1°C (95 ± 1.8°F) and a relative

E-Test specimen.

humidity of 90 ± 2 %, unless otherwise specified. The

F-Lower anvil mounted on ball support (F,) and loose plate (F,v.

specimens shall be supported during conditioning upon a

'Is-in. mesh wire screen or the equivalent in order to permit

FIG. 3 Low-Pressure Deformation Tester

free access of the atmosphere to all surfaces.

7.3 Where a quick measurement of total deformation is

are used, take care to ensure that the squares are well aligned.

desired, such as for procurement of materials wherein the

10.2 Apply the load to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.