ASTM D1043-16(2024)

(Test Method)Standard Test Method for Stiffness Properties of Plastics as a Function of Temperature by Means of a Torsion Test

Standard Test Method for Stiffness Properties of Plastics as a Function of Temperature by Means of a Torsion Test

SIGNIFICANCE AND USE

4.1 The property measured by this test is the apparent modulus of rigidity, G, sometimes called the apparent shear modulus of elasticity. It is important to note that this property is not the same as the modulus of elasticity, E, measured in tension, flexure, or compression. The relationship between these properties is shown in Annex A1.

4.2 The measured modulus of rigidity is termed “apparent” since it is the value obtained by measuring the angular deflection occurring when the specimen is subjected to an applied torque. Since it is possible that the specimen will be deflected beyond its elastic limit, the calculated value will not always represent the true modulus of rigidity within the elastic limit of the material. In addition, the value obtained by this test method will also be affected by the creep characteristics of the material, since the load application time is arbitrarily fixed. For many materials, it is possible that there is a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method. Table 1 in Classification D4000 lists the current ASTM material standards.

4.3 This test method is useful for determining the relative changes in stiffness over a wide range of temperatures.

SCOPE

1.1 This test method covers the determination of the stiffness characteristics of plastics over a wide temperature range by direct measurement of the apparent modulus of rigidity.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: This test method and ISO 458-1 and ISO 458-2 address the same subject matter, but differ in technical content.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1043 − 16 (Reapproved 2024)

Standard Test Method for

Stiffness Properties of Plastics as a Function of

Temperature by Means of a Torsion Test

This standard is issued under the fixed designation D1043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D4000 Classification System for Specifying Plastic Materi-

als

1.1 This test method covers the determination of the stiff-

D5947 Test Methods for Physical Dimensions of Solid

ness characteristics of plastics over a wide temperature range

Plastics Specimens

by direct measurement of the apparent modulus of rigidity.

E177 Practice for Use of the Terms Precision and Bias in

1.2 The values stated in SI units are to be regarded as the

ASTM Test Methods

standard. The values given in parentheses are for information 4

2.2 ISO Standards:

only.

ISO 458-1 Plastics—Determination of Stiffness in Torsion

1.3 This standard does not purport to address all of the

of Flexible Materials, Part 1: General Method

safety concerns, if any, associated with its use. It is the

ISO 458-2 Plastics—Determination of Stiffness in Torsion

responsibility of the user of this standard to establish appro-

of Flexible Materials, Part 2: Application to Plasticized

priate safety, health, and environmental practices and deter-

Compounds of Homopolymers and Copolymers of Vinyl

mine the applicability of regulatory limitations prior to use.

Chloride

NOTE 1—This test method and ISO 458-1 and ISO 458-2 address the

3. Terminology

same subject matter, but differ in technical content.

3.1 Definitions—For definitions of the technical terms per-

1.4 This international standard was developed in accor-

taining to plastics used in this test method, see Terminology

dance with internationally recognized principles on standard-

D883.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4. Significance and Use

mendations issued by the World Trade Organization Technical

4.1 The property measured by this test is the apparent

Barriers to Trade (TBT) Committee.

modulus of rigidity, G, sometimes called the apparent shear

2. Referenced Documents

modulus of elasticity. It is important to note that this property

is not the same as the modulus of elasticity, E, measured in

2.1 ASTM Standards:

tension, flexure, or compression. The relationship between

D618 Practice for Conditioning Plastics for Testing

these properties is shown in Annex A1.

D638 Test Method for Tensile Properties of Plastics

D747 Test Method for Apparent Bending Modulus of Plas-

4.2 The measured modulus of rigidity is termed “apparent”

tics by Means of a Cantilever Beam (Withdrawn 2019)

since it is the value obtained by measuring the angular

D883 Terminology Relating to Plastics

deflection occurring when the specimen is subjected to an

D1053 Test Methods for Rubber Property—Stiffening at

applied torque. Since it is possible that the specimen will be

Low Temperatures: Flexible Polymers and Coated Fabrics

deflected beyond its elastic limit, the calculated value will not

always represent the true modulus of rigidity within the elastic

1 limit of the material. In addition, the value obtained by this test

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties. method will also be affected by the creep characteristics of the

Current edition approved Feb. 1, 2024. Published February 2024. Originally

material, since the load application time is arbitrarily fixed. For

approved in 1949. Last previous edition approved in 2016 as D1043 - 16. DOI:

many materials, it is possible that there is a specification that

10.1520/D1043-16R24.

requires the use of this test method, but with some procedural

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from International Organization for Standardization (ISO), ISO

The last approved version of this historical standard is referenced on Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

www.astm.org. Geneva, Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1043 − 16 (2024)

modifications that take precedence when adhering to the 5.2.1 Flask—A Dewar flask of suitable dimensions.

specification. Therefore, it is advisable to refer to that material 5.2.2 Thermometer—A thermometer having the necessary

specification before using this test method. Table 1 in Classi- temperature range and having an accuracy of 61°C or better.

fication D4000 lists the current ASTM material standards. The bulb or sensing tip shall be located in proximity to the test

specimen.

4.3 This test method is useful for determining the relative

5.2.3 Timer, for controlling load application time.

changes in stiffness over a wide range of temperatures.

5.2.4 Heat-Transfer Medium—For normal laboratory

purposes, a substance that is liquid over the desired tempera-

5. Apparatus

ture range shall be used for the heat-transfer medium, provided

5.1 Testing Machine—A machine capable of exerting a

it has been shown that the liquid does not soften or otherwise

torque sufficient to deflect a test specimen in the range of 5 to

affect the test specimen.

100° of arc, depending on the stiffness of the specimen and its

span. A schematic diagram of a suitable machine is shown in NOTE 5—Among the liquids found useful are acetone, ethanol, butanol,

methanol, normal hexane, silicone oil, and a mixture of methyl phosphate

Fig. 1.

and water in the ratio of 87 to 13 by volume. For temperatures to −70°C

NOTE 2—Two machines of different torque capacities are being used: (−94°F), a mixture of 50 parts ethanol, 30 parts ethylene glycol, and 20

parts water is potentially useful.

one covers the range of approximately 0.0113 to 0.113 N·m (0.1 to 1.0

in.·lbf) and the other of approximately 0.113 to 1.81 N·m (1.0 to 16 in.·lbf)

5.2.5 Refrigeration—Means shall be provided for cooling

or higher. Some machines also allow varying the span, which is especially

the heat-transfer medium. This cooling can be by means of a

important if shearing failures can occur (as in laminates at a span/width of

refrigeration cooling coil built into the instrument and im-

6).

NOTE 3—It is acceptable to vary the amount of torque to suit the

mersed in the Dewar flask of heat transfer fluid or by means of

stiffness of the test specimen, and it is necessary to have various weights

a low temperature chamber in which Dewar flasks of heat

available for this purpose. Determine the actual amount of torque being

transfer liquid are placed to pre-cool before starting the test.

applied by any given combination of weights, torque wheel radii, and shaft

bearings by calibration. The accuracy of the apparatus can be subject to

NOTE 6—For time-efficient low-temperature use of the equipment,

change, and therefore periodic calibration is necessary to ensure reliable

space for cooling enough containers of the heat-transfer medium for a

test results. Testing machine calibration procedures are given in Annex A2

day’s work is desirable. Depending on the temperature ranges involved,

and Annex A3.

mechanical refrigeration or a dry-ice chest, or both, will be advantageous.

NOTE 4—For operation at low temperatures the shaft of the machine

5.2.6 Heater—A controlled electric immersion heater in the

must be provided with a heated collar next to the lower bearing to prevent

the formation of ice. Dewar flask shall be used in conjunction with an agitator to

vary the temperature.

5.2 Temperature Control:

5.3 Micrometer—A micrometer accurate to within 60.0025

mm (60.0001 in.) or better shall be used for measuring

specimen thickness and width.

5.4 Modifications to Testing Equipment—The modifications

described in Annex A4 will increase the accuracy and sensi-

tivity of the testing equipment. The modifications are readily

adaptable to several types of test equipment used for testing

plastics. Some of the modifications are desirable, but not

necessary, for obtaining meaningful data.

6. Test Specimens

6.1 Geometry—Test specimens shall be of the rectangular

geometry shown in Fig. 2. Cut test specimens from

compression-molded sheets, extruded sheet, or from parts of

uniform thickness having flat parallel surfaces, or prepare them

by injection molding. Care shall be taken to ensure that the test

specimens are isotropic. Where the testing machine permits

varying the span, use a span to width (L/a) ratio of 6 to 8. It is

recommended that spans of 38 to 100 mm (1.5 to 4 in.) be used.

These test specimens are acceptable for use for nonrigid

materials on the low-range machine which has a span (L) of 38

mm (1.5 in.).

FIG. 1 Torsion Tester FIG. 2 Test Specimen

D1043 − 16 (2024)

often desirable to reduce the torque slightly before taking successive

6.2 Thickness—The thickness of the specimen shall range

readings, particularly in the temperature range where the material is

between approximately 1 and 3 mm (0.040 and 0.125 in.). This

rapidly decreasing in rigidity.

range normally makes it possible to test materials of widely

NOTE 8—Better reproducibility is obtained if torques are chosen such

different stiffnesses.

that the deflection obtained at a given temperature is similar to or greater

than that obtained at the previous lower temperature.

6.3 Duplicate specimens of each material shall be tested.

8.9 After each suitable reading is obtained, repeat the steps

More replications are often needed, especially for nonhomo-

geneous materials. If the results from testing the first two indicated in 8.6 – 8.8 for the next desired temperature. If

desired, it is acceptable to lower the torque prior to each

specimens differ significantly, test a third specimen and discard

the outlier (the value that varies the most from the other two). reading (Note 7 and Note 8).

7. Conditioning

9. Calculation

7.1 Conditioning—Condition the test specimens in accor-

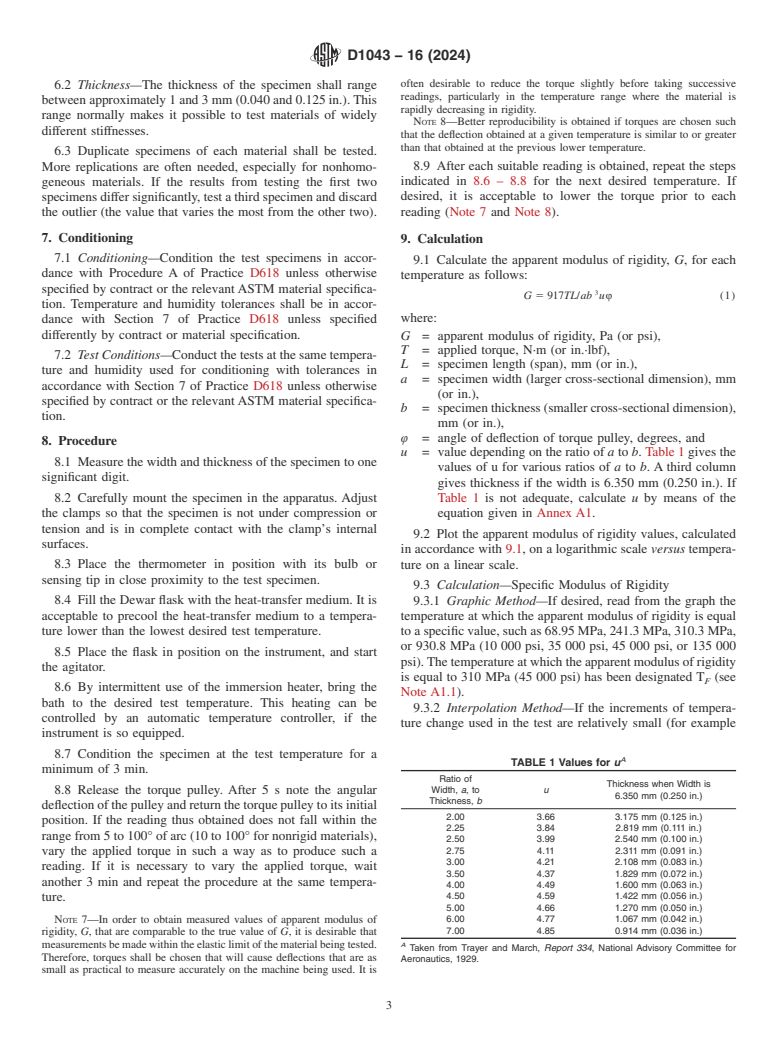

9.1 Calculate the apparent modulus of rigidity, G, for each

dance with Procedure A of Practice D618 unless otherwise

temperature as follows:

specified by contract or the relevant ASTM material specifica-

G 5 917TL/ab uφ (1)

tion. Temperature and humidity tolerances shall be in accor-

where:

dance with Section 7 of Practice D618 unless specified

differently by contract or material specification.

G = apparent modulus of rigidity, Pa (or psi),

T = applied torque, N·m (or in.·lbf),

7.2 Test Conditions—Conduct the tests at the same tempera-

L = specimen length (span), mm (or in.),

ture and humidity used for conditioning with tolerances in

a = specimen width (larger cross-sectional dimension), mm

accordance with Section 7 of Practice D618 unless otherwise

(or in.),

specified by contract or the relevant ASTM material specifica-

b = specimen thickness (smaller cross-sectional dimension),

tion.

mm (or in.),

φ = angle of deflection of torque pulley, degrees, and

8. Procedure

u = value depending on the ratio of a to b. Table 1 gives the

8.1 Measure the width and thickness of the specimen to one

values of u for various ratios of a to b. A third column

significant digit.

gives thickness if the width is 6.350 mm (0.250 in.). If

8.2 Carefully mount the specimen in the apparatus. Adjust Table 1 is not adequate, calculate u by means of the

the clamps so that the specimen is not under compression or equation given in Annex A1.

tension and is in complete contact with the clamp’s internal

9.2 Plot the apparent modulus of rigidity values, calculated

surfaces.

in accordance with 9.1, on a logarithmic scale versus tempera-

8.3 Place the thermometer in position with its bulb or

ture on a linear scale.

sensing tip in close proximity to the test specimen.

9.3 Calculation—Specific Modulus of Rigidity

8.4 Fill the Dewar flask with the heat-transfer medium. It is

9.3.1 Graphic Method—If desired, read from the graph the

acceptable to precool the heat-transfer medium to a tempera- temperature at which the apparent modulus of rigidity is equal

ture lower than the lowest desired test temperature. to a specific value, such as 68.95 MPa, 241.3 MPa, 310.3 MPa,

or 930.8 MPa (10 000 psi, 35 000 psi, 45 000 psi, or 135 000

8.5 Place the flask in position on the instrument, and start

psi). The temperature at which the apparent modulus of rigidity

the agitator.

is equal to 310 MPa (45 000 psi) has been designated T (see

F

8.6 By intermittent use of the immersion heater, bring the

Note A1.1).

bath to the desired test temperature. This heating can be

9.3.2 Interpolation Method—If the increments of tempera-

controlled by an automatic temperature controller, if the

ture change used in the test are relatively small (for example

instrument is so equipped.

8.7 Condition the specimen at the test temperature for a

A

TABLE 1 Values for u

minimum of 3 min.

Ratio of

Thickness when Width is

8.8 Release the torque pulley. After 5 s note the angular Width, a, to u

6.350 mm (0.250 in.)

Thickness, b

deflection of the pulley and return the torque pulley to its initial

2.00 3.66 3.175 mm (0.125 in.)

position. If the reading thus obtained does not fall within the

2.25 3.84 2.819 mm (0.111 in.)

range from 5 to 100° of arc (10 to 100° for nonrigid materials),

2.50 3.99 2.540 mm (0.100 in.)

vary the applied torque in such a way as to produce such a 2.75 4.11 2.311 mm (0.091 in.)

3.00 4.21 2.108 mm (0.083 in.)

reading. If it is necessary to vary the applied torque, wait

3.50 4.37 1.829 mm (0.072 in.)

another 3 min and repeat the procedure at the same tempera-

4.00 4.49 1.600 mm (0.063 in.)

4.50 4.59 1.422 mm (0.056 in.)

ture.

5.00 4.66 1.270 mm (0.050 in.)

NOTE 7—In order to obtain measured values of apparent modulus of 6.00 4.77 1.067 mm (0.042 in.)

7.00 4.85 0.914 mm (0.036 in.)

rigidity, G, that are comparable to the true value of G, it is desirable that

A

measurements be made within the elastic limit of the material being tested.

Taken from Trayer and March, Report 334, National Advisory Committee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.