ASTM E377-96(2002)

(Practice)Standard Practice for Internal Temperature Measurements in Low-Conductivity Materials

Standard Practice for Internal Temperature Measurements in Low-Conductivity Materials

SIGNIFICANCE AND USE

Internal temperature measurements are made on both in-flight vehicles and on-ground test specimens; and, because of the importance of the temperature measurements to the design of various missile and spacecraft heat shields, it is essential that care be taken to minimize the sources of error in obtaining these measurements.

Over the past several years, the problems of using thermocouples to obtain accurate temperature measurements in low-conductivity specimens have been studied by various people to isolate the sources of error and to establish improved temperature measurement techniques. The major sources of error are listed in this document and recommended solutions to the problems are given.

SCOPE

1.1 This practice covers methods for instrumenting low-conductivity specimens for testing in an environment subject to rapid thermal changes such as produced by rocket motors, atmospheric re-entry, electric-arc plasma heaters, etc. Specifically, practices for bare-wire thermocouple instrumentation applicable to sheath-type thermocouples are discussed.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E377–96 (Reapproved 2002)

Standard Practice for

Internal Temperature Measurements in Low-Conductivity

Materials

This standard is issued under the fixed designation E 377; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope and lead wires, (3) proper selection of thermocouple type and

size, corresponding to both the temperature range to be

1.1 This practice covers methods for instrumenting low-

measured and the chemical compatibility with the environ-

conductivityspecimensfortestinginanenvironmentsubjectto

ment, and (4) proper use of instrumentation for readout of

rapid thermal changes such as produced by rocket motors,

thermocouple emf.

atmospheric re-entry, electric-arc plasma heaters, and so forth.

Specifically, practices for bare-wire thermocouple instrumen-

NOTE 1—Reader is referred to ASTM MNL 12, and STP 492, as well

tation applicable to sheath-type thermocouples are discussed. as Kinzie, P.A., Thermocouple Temperature Measurement, for needed

information.

1.2 The values stated in inch-pound units are to be regarded

as the standard. The metric equivalents of inch-pound units

3.2 The most important sources of error beyond the above

may be approximate.

basic areas are the following:

1.3 This standard does not purport to address all of the

3.2.1 The thermal disturbance produced in the low-

safety concerns, if any, associated with its use. It is the

conductivitymaterialatthevicinityofthethermocouplesensor

responsibility of the user of this standard to establish appro-

hot junction due to the sensor size, configuration, and instal-

priate safety and health practices and determine the applica-

lation method.

bility of regulatory limitations prior to use.

3.2.2 Electrical shorting of lead wires due to the electrical

conductivity of the virgin or charred ablation material, and

2. Significance and Use

3.2.3 Thermocouple sensor hot junction location accuracy.

2.1 Internal temperature measurements are made on both

4. Thermal Disturbance at Vicinity of Thermocouple

in-flight vehicles and on-ground test specimens; and, because

of the importance of the temperature measurements to the Sensor Hot Junction

design of various missile and spacecraft heat shields, it is

4.1 General—Ideally, to measure the true internal tempera-

essential that care be taken to minimize the sources of error in

ture of a solid body, it would be desirable not to have any

obtaining these measurements.

foreign substance present that would create a disturbance

2.2 Over the past several years, the problems of using

affecting the natural flow of heat in the body. Since it is

thermocouplestoobtainaccuratetemperaturemeasurementsin

physically impossible to exclude the temperature sensor from

low-conductivity specimens have been studied by various

theinternalconfinesofthebody,itisnecessarythatthethermal

people to isolate the sources of error and to establish improved

disturbanceintroducedbythesensorbeminimizedforaccurate

temperature measurement techniques. The major sources of

temperature measurements.

error are listed in this document and recommended solutions to

4.2 Thermocouple Junction Bead Diameter:

the problems are given.

4.2.1 General—Excessively large junction beads result in

lower than true temperature measurements in low-conductivity

3. General

materials (conductivity of material less than conductivity of

3.1 Before proceeding to the major sources of error, it is

thermocouple wire) because of the heat sink effect of the bead.

assumed that the reader is familiar with basic methods of

4.2.2 Recommendations—To minimize this effect, the junc-

forming and using thermocouples , that is (1) electric welding

tion bead diameter should be no larger than 1.5 wire diameters

to form junctions, (2) maintaining cleanliness of junction area

for butt-welded junctions and 2 wire diameters for other types

of welds.

1 4.3 Thermocouple Wire in Isothermal Surface of Hot Junc-

This practice is under the jurisdiction of ASTM Committee E21 on Space

Simulation andApplications of Space Technology and is the direct responsibility of tion:

Subcommittee E21.08 on Thermal Protection.

4.3.1 General—Because many materials have low thermal

Current edition approved Oct. 10, 1996. Published December 1996. Originally

conductivity compared with those of thermocouple assemblies,

published as E 377 – 68. Last previous edition E 377 – 68 (1992).

it has been found that certain methods of installing sensors can

ANSI MC96.1-1975. Temperature Measurement Thermocouples (Sponsor

ISA).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E377

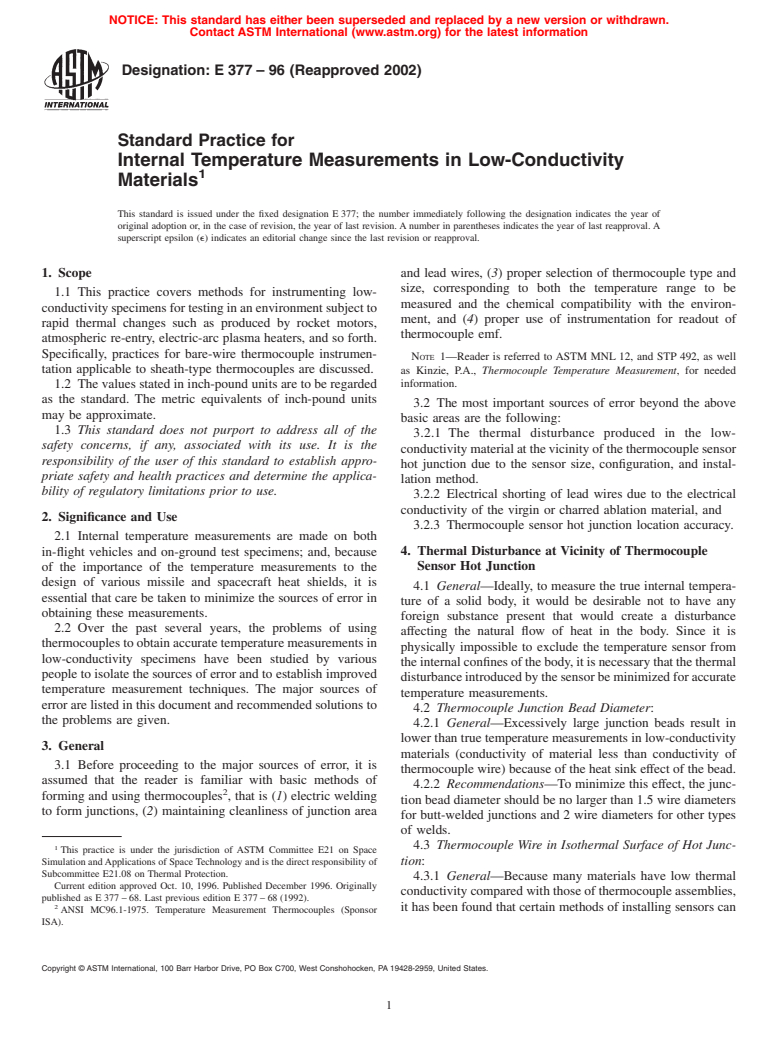

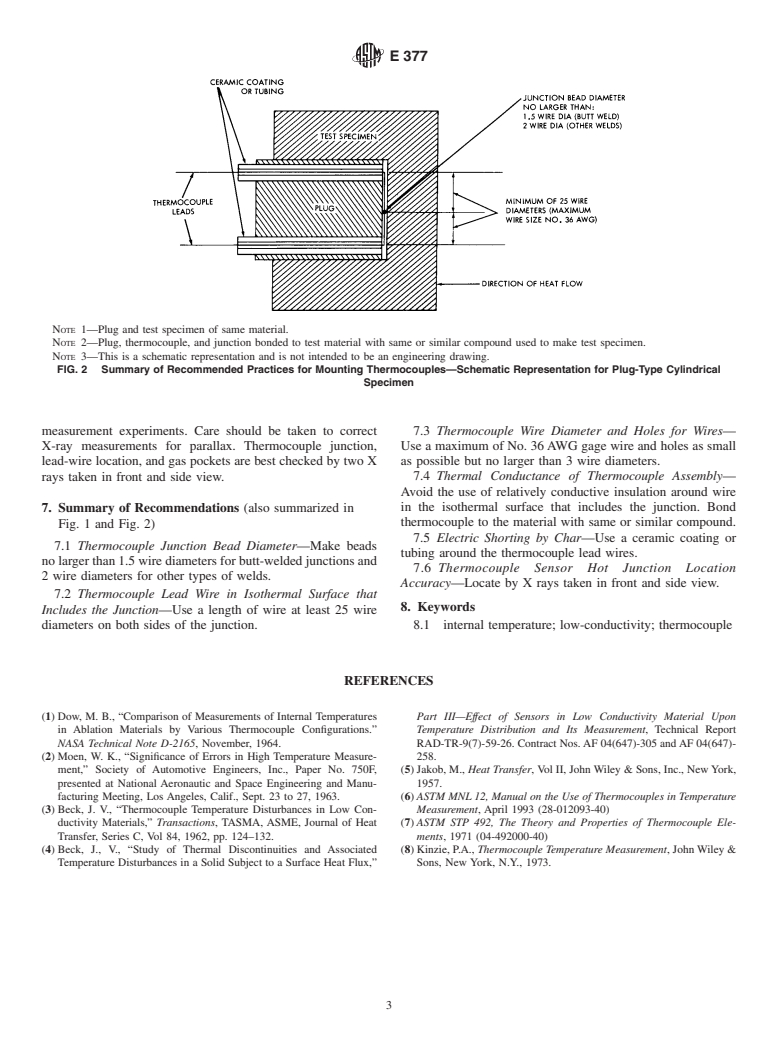

NOTE 1—If a number of thermocouples in depth are required, drill holes at varying locations on the circumference.

NOTE 2—Eliminate air pockets in junction plane by filling hole with same or similar compound as that used to make test specimen.

NOTE 3—This is a schematic representation and is not intended to be an engineering drawing.

FIG. 1 Summary of Recommended Practices for Mounting Thermocouples—Schematic Representation for “One-Piece” Cylindrical

Specimen

produce significant errors in internal temperature measurement conductivity material by bonding the thermocouple to the

(1-4). Errors of several hundred degrees are possible unless specimen (thus eliminating air pockets) with the same or

heat conduction away from the sensor hot junction, by the similar compound (such as an epoxy plastic) as that used to

sensor materials, is minimized. Test results show that a make the specimen.

thermocouple having a sufficient length of bare wire in the

5. Electrical Shorting by Conductive Char Layers

isothermal surface that includes the junction will minimize

these errors. 5.1 General—The char layer formed by most organic ma-

terials becomes highly conductive (electrically) as pyrolysis

4.3.2 Recommendations—It is therefore recommended that

the configuration of the thermocouple sensor be such that the progresses. Care should be taken to avoid the possibility of

electrical shorting of thermocouple lead wires not protected by

leads perpendicular to the heat flow have a length equivalent to

at least 25 wire diameters on both sides of the junction in the proper insulation methods. Studies (1) have shown that short-

ing can result in temperature errors of as much as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.