ASTM E1545-00

(Test Method)Standard Test Method for Assignment of the Glass Transition Temperature by Thermomechanical Analysis

Standard Test Method for Assignment of the Glass Transition Temperature by Thermomechanical Analysis

SCOPE

1.1 This test method covers procedures for the assignment of the glass transition temperature of materials on heating using thermomechanical measurements under prescribed experimental conditions.

1.2 This test method is applicable to amorphous or to partially crystalline materials that are sufficiently rigid below the glass transition to inhibit indentation by the sensing probe.

1.3 The normal operating temperature range is from -100 to 600°C. This temperature range may be extended depending upon the instrumentation used.

1.4 Computer- or electronic-based instruments, techniques, or data treatment equivalent to this test method may also be used. Users of this test method are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user of this test method to determine the necessary equivalency prior to use. In the case of dispute, only the manual procedures are to be considered valid.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1545–00

Standard Test Method for

Assignment of the Glass Transition Temperature by

Thermomechanical Analysis

This standard is issued under the fixed designation E1545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E473 Terminology Relating to Thermal Analysis

E691 Practice for Conducting an Interlaboratory Study to

1.1 This test method covers procedures for the assignment

Determine the Precision of a Test Method

oftheglasstransitiontemperatureofmaterialsonheatingusing

E831 Test Method for Linear Thermal Expansion of Solid

thermomechanical measurements under prescribed experimen-

Materials by Thermomechanical Analysis

tal conditions.

E1142 Terminology Relating to Thermophysical Proper-

1.2 This test method is applicable to amorphous or to

ties

partially crystalline materials that are sufficiently rigid below

E1356 Test Method for Glass Transition Temperatures by

the glass transition to inhibit indentation by the sensing probe.

Differential Scanning Calorimetry or Differential Thermal

1.3 The normal operating temperature range is from−100

Analysis

to 600°C. This temperature range may be extended depending

E 1363 Test Method for Calibration of Thermomechanical

upon the instrumentation used.

Analyzers

1.4 Computer- or electronic-based instruments, techniques,

2.2 IIPEC Standard:

or data treatment equivalent to this test method may also be

Test Method 2.4.24, Glass Transition Temperature TMA

used.

Method

NOTE 1—Usersofthistestmethodareadvisedthatallsuchinstruments

ISO11359-2 Plastics—ThermomechanicalAnalysis(TMA)

or techniques may not be equivalent. It is the responsibility of the user of

– Part 2: Determination of Coefficient of Linear Thermal

this test method to verify equivalency prior to use.

Expansion and Glass Transition Temperature

1.5 The values stated in SI units are to be regarded as the

standard. 3. Terminology

1.6 ThistestmethodisrelatedtoISO11359-2.ISO11359-2

3.1 Definitions—The following terms are applicable to this

additionally covers the determination of coefficient of linear

test method and can be found in Terminologies E473 and

thermal expansion not covered by this test method.

E1142: thermomechanical analysis(TMA), thermomechanical

1.7 This standard does not purport to address all of the

measurement, thermodilatometry, glass transition, glass tran-

safety concerns, if any, associated with its use. It is the

sition temperature, and linear thermal expansion.

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

4.1 Thistestmethodusesthermomechanicalanalysisequip-

tionary statements are given in Section 7.

ment (thermomechanical analyzer, dilatometer, or similar de-

vice)toassignthechangeindimensionofaspecimenobserved

2. Referenced Documents

when the material is subjected to a constant heating rate

2.1 ASTM Standards:

through its glass transition. This change in dimension associ-

D 832 Practice for Rubber Conditioning for Low-

atedwiththechangefromvitreoussolidtoamorphousliquidis

Temperature Testing

observed as movement of the sensing probe in direct contact

withthespecimenandisrecordedasafunctionoftemperature.

The intersection of the extrapolation of the slope of the probe

This test method is under the jurisdiction of ASTM Committee E-37 on

Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on Annual Book of ASTM Standards, Vol 14.02.

Test Methods and Recommended Practices. Available from The Institute for Interconnecting and Packaging Electronic

Current edition approved March 10, 2000. Published June 2000. Originally Circuits, 7380 N. Lincoln Ave., Lincolnwood, IL 60646-1705.

published as E1545–93. Last previous edition E1545–95a. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 09.01. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1545

displacement curve before and after the transition is used to 7. Hazards

determine the glass transition temperature.

7.1 This test method may be used for amorphous and

semicrystalline materials having a glass transition that is at or

5. Significance and Use

below room temperature providing care is taken to avoid

contacting the specimen with a loaded probe prior to cooling

5.1 The glass transition is dependent on the thermal history

the specimen below its glass transition. Applying a loaded

ofthematerialtobetested.Foramorphousandsemicrystalline

probetoaspecimenthatisaboveitsglasstransitionmaycause

materials the assignment of the glass transition temperature

partial penetration by the probe which can lead to probe

may lead to important information about thermal history,

stickinguponcoolingbelowtheglasstransition.Thiscondition

processingconditions,stability,progressofchemicalreactions,

has been known to yield erroneous results during the heating

and mechanical and electrical behavior.

cycle.

5.2 Thermomechanical analysis provides a rapid means of

7.2 With some materials a transient may be observed

detecting changes in hardness or linear expansion associated

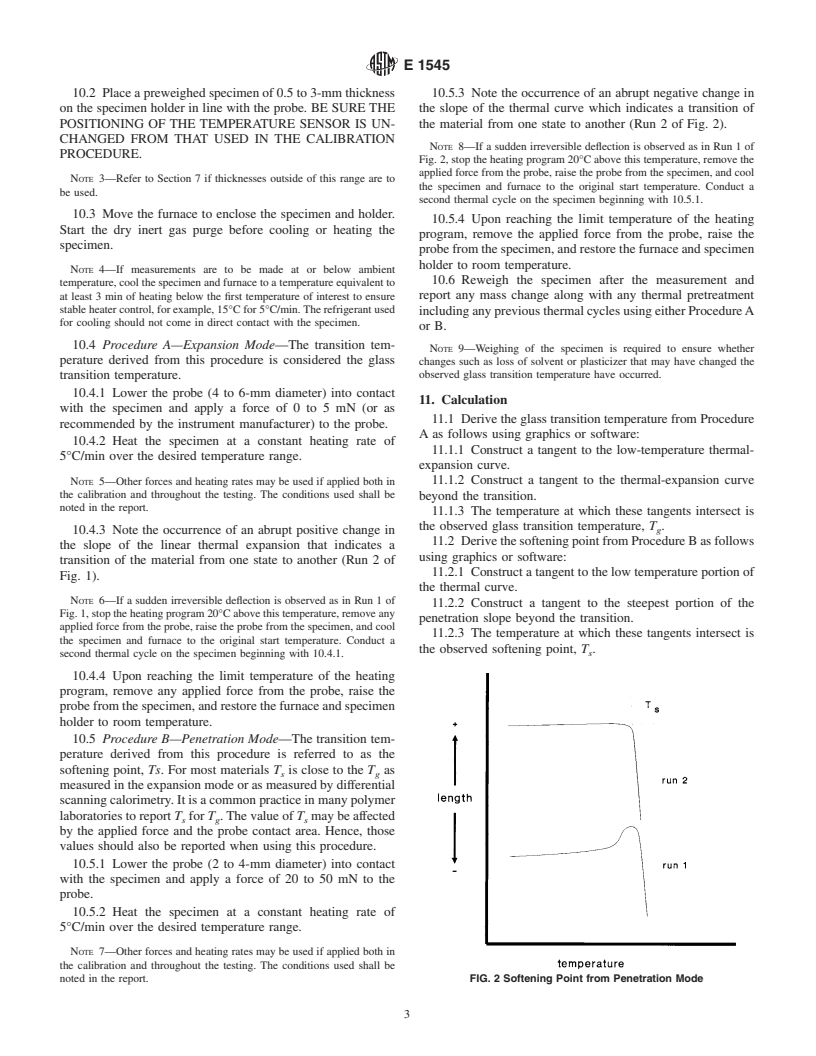

between the pre-transition slope and the final slope (Run 1 of

with the glass transition.

Fig. 1).This may occur due to settling, residual stresses within

5.3 Thistestmethodisusefulforresearchanddevelopment,

the specimen, or alteration of the specimen morphology. Refer

quality control, and specification acceptance.

to Note 6 for directions when this is encountered.

7.3 Specimens of thickness less than 0.2 mm may be very

6. Apparatus

difficult to handle. Thin films (50 to 200 µm) on a substrate

6.1 Thermomechanical Analyzer (TMA)—The essential in-

may be considered for this test method providing the substrate

strumentation required to provide the minimum thermome-

is mechanically stable in the temperature region of the film

chanical analytical capability for this test method includes the

glass transition.

following:

7.4 Forspecimensofthicknessgreaterthan5mm,tempera-

6.1.1 A rigid specimen holder, composed of inert low

turenonuniformitiesofsufficientextentcandevelopwithinthe

–1 –1

expansivity material#1µmm °C , to center the specimen

specimen as to yield erroneously high values of the glass

in the furnace and to fix the specimen to mechanical ground.

transition temperature using this test method.

6.1.2 A rigid circular expansion probe, 2 to 6 mm in

8. Sampling

diameter, composed of inert low expansivity material#1µm

–1 –1

m °C , that contacts the specimen with an applied compres-

8.1 Analyze samples as received or after pretreatment. If

sive force.

some treatment is applied to a specimen prior to analysis, note

6.1.3 Asensingelementlinearoveraminimum2-mmrange

this treatment and any resulting change in mass in the report.

to measure the displacement in length of the specimen.

9. Calibration

6.1.4 A weight or force transducer to generate a constant

9.1 Perform calibration in accordance with Test Method

force of 0 to 50 mN that is applied through the rigid

E1363.

compression probe to the specimen.

6.1.5 A furnace capable of providing uniform controlled

10. Procedure

heating (cooling) of a specimen to a constant temperature or at

10.1 Calibrate the thermomechanical analyzer in accor-

a constant rate over the temperature range of –100 to 600°C.

dance with Test Method E1363.

6.1.6 A temperature controller capable of executing a spe-

cific temperature program by operating the furnace between

selected temperature limits at a rate of temperature change of

5 6 0.5°C/minute.

6.1.7 A temperature sensor that can be attached to, in

contact with, or reproducibly placed in close proximity to the

specimen to provide an indication of the specimen/furnace

temperature to 6 0.1°C.

6.1.8 A means of sustaining an environment around the

specimen of a dry inert purge gas of 45 to 55 mL/minute.

NOTE 2—Typically, 99.9+% pure nitrogen, argon or helium is used.

Unlesseffectsofmoisturearetobestudied,drypurgegasisrecommended

and is essential for operation at subambient temperatures.

6.1.9 Arecordingdevice,eitherdigitaloranalog,capableof

recording and displaying any fraction of the specimen dimen-

sion sign

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.