ASTM F1357-99(2009)

(Specification)Standard Specification for Articulating Total Wrist Implants

Standard Specification for Articulating Total Wrist Implants

ABSTRACT

This specification covers total wrist implants that provide articulation function through radial carpal components. However, this specification does not include implants with ceramic coated or porous coated surfaces, one-piece elastomeric implants, and those used for custom applications. Implants covered by this specification are of the constrained, partially constrained, or unconstrained joint prosthesis type. The implants shall be manufactured from biocompatible materials made of unalloyed titanium, cobalt-28chromium-6molybdenum alloy, wrought cobalt-20chromium-15tungsten-10nickel alloy, wrought titanium-6aluminum-4vanadium extra low interstitial alloy, wrought 35cobalt-35nickel-20chromium-10molybdenum alloy, wrought cobalt-20nickel-20chromium-3.5molybdenum-3.5tungsten-5iron alloy, cobalt-28chromium-6molybdenum alloy, titanium-6aluminum-4vanadium alloy, or wrought cobalt-28chromium-6molybdenum alloy with dimensions in conformity to the requirements specified. Tests for polymeric creep (cold flow), wear, and range of motion of the device as well as in vitro laboratory testing shall be performed and shall conform to the requirements specified. Per service requirement, metallic implants shall undergo fluorescent penetrant inspection, while cast metallic implants shall undergo radiography.

SCOPE

1.1 This specification describes total wrist implants, including solid ceramic implants, used to provide functioning articulation by employing radial carpal components.

1.2 This specification excludes those implants with ceramic-coated or porous-coated surfaces, one piece elastomeric implants (with or without grommets), and those devices used for custom applications.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1357 – 99 (Reapproved 2009)

Standard Specification for

Articulating Total Wrist Implants

This standard is issued under the fixed designation F 1357; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Applications (UNS R30035)

F 563 Specification for Wrought Cobalt-20Nickel-

1.1 This specification describes total wrist implants, includ-

20Chromium-3.5Molybdenum-3.5Tungsten-5Iron Alloy

ing solid ceramic implants, used to provide functioning articu-

for Surgical Implant Applications (UNS R30563)

lation by employing radial carpal components.

F 601 Practice for Fluorescent Penetrant Inspection of Me-

1.2 Thisspecificationexcludesthoseimplantswithceramic-

tallic Surgical Implants

coated or porous-coated surfaces, one piece elastomeric im-

F 603 Specification for High-Purity Dense Aluminum Ox-

plants (with or without grommets), and those devices used for

ide for Medical Application

custom applications.

F 629 Practice for Radiography of Cast Metallic Surgical

1.3 The values stated in SI units are to be regarded as

Implants

standard. No other units of measurement are included in this

F 648 Specification for Ultra-High-Molecular-Weight Poly-

standard.

ethylene Powder and Fabricated Form for Surgical Im-

1.4 This standard does not purport to address all of the

plants

safety concerns, if any, associated with its use. It is the

F 748 Practice for Selecting Generic Biological Test Meth-

responsibility of the user of this standard to establish appro-

ods for Materials and Devices

priate safety and health practices and determine the applica-

F 799 SpecificationforCobalt-28Chromium-6Molybdenum

bility of regulatory limitations prior to use.

Alloy Forgings for Surgical Implants (UNS R31537,

2. Referenced Documents R31538, R31539)

F 981 Practice for Assessment of Compatibility of Bioma-

2.1 ASTM Standards:

terials for Surgical Implants with Respect to Effect of

F67 Specification for Unalloyed Titanium, for Surgical

Materials on Muscle and Bone

Implant Applications (UNS R50250, UNS R50400, UNS

F 983 Practice for Permanent Marking of Orthopaedic Im-

R50550, UNS R50700)

plant Components

F75 Specification for Cobalt-28 Chromium-6 Molybdenum

F 1108 Specification for Titanium-6Aluminum-4Vanadium

Alloy Castings and Casting Alloy for Surgical Implants

Alloy Castings for Surgical Implants (UNS R56406)

(UNS R30075)

F 1537 Specification for Wrought Cobalt-28Chromium-

F86 Practice for Surface Preparation and Marking of Me-

6MolybdenumAlloysforSurgicalImplants(UNSR31537,

tallic Surgical Implants

UNS R31538, and UNS R31539)

F90 Specification for Wrought Cobalt-20Chromium-

15Tungsten-10Nickel Alloy for Surgical Implant Applica-

3. Terminology

tions (UNS R30605)

3.1 Definitions:

F 136 Specification for Wrought Titanium-6Aluminum-

3.1.1 carpal component—articulating member inserted into

4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical

or through the carpal bones.

Implant Applications (UNS R56401)

3.1.2 radial component—articulating member inserted into

F 562 Specification for Wrought 35Cobalt-35Nickel-

the radius for articulation with the carpal component.

20Chromium-10Molybdenum Alloy for Surgical Implant

3.1.3 total wrist replacement—prosthetic parts substituted

for the native opposing radial and carpal articulating surfaces.

This specification is under the jurisdiction of ASTM Committee F04 on 4. Classification

Medical and Surgical Materials and Devices and is the direct responsibility of

4.1 Constrained—A constrained joint prosthesis is used for

Subcommittee F04.22 on Arthroplasty.

joint replacement and prevents dislocation of the prosthesis in

Current edition approved June 15, 2009. Published July 2009. Originally

approved in 1991. Last previous edition approved in 2004 as F 1357 - 99 (2004).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1357 – 99 (2009)

more than one anatomical plane and consists of either a single, tion possible before subluxation occurs or the motion is

flexible, across-the-joint component, or more than one compo- arrested by the implant. These results shall be reported in the

nent linked together or affined. product labeling.

6.4 Guidelines for In-Vitro Laboratory Testing—No ASTM

4.2 Partially Constrained—A semi-constrained joint pros-

standards for testing articulating wrist implants have not been

thesis is used for partial or total joint replacement and limits

developed. Laboratory testing that simulates the conditions of

translation and rotation of the prosthesis in one or more planes

use is desirable to compare materials and designs and to

via the geometry of its articulating surfaces. It has no across-

provide an indication of clinical performance. Implant testing

the-joint linkages.

shall be done in keeping with the implants intended function,

4.3 Unconstrained—An unconstrained joint prosthesis is

that is, implants intended to partially stabilize or stabilize a

used for partial or total joint replacement and restricts mini-

joint shall be subjected to the maximum destabilizing force

mally prosthesis movement in one or more planes. Its compo-

anticipated in clinical application during flexural testing.

nents have no across-the-joint linkages.

7. Dimensions

5. Materials and Manufacture

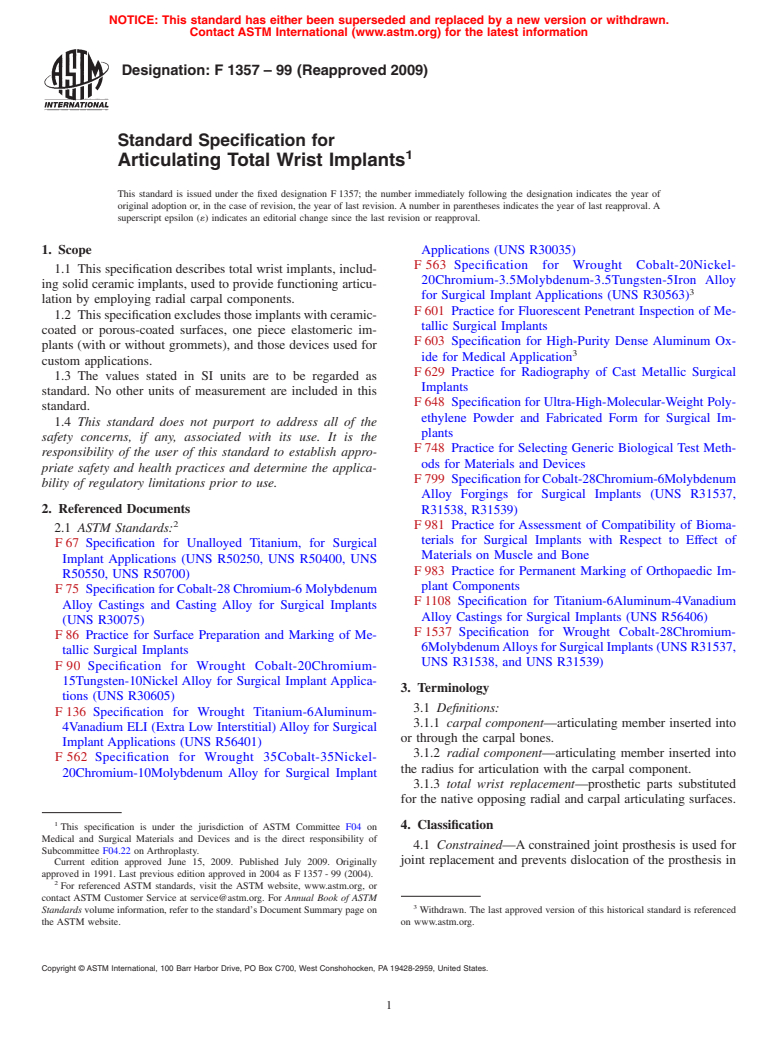

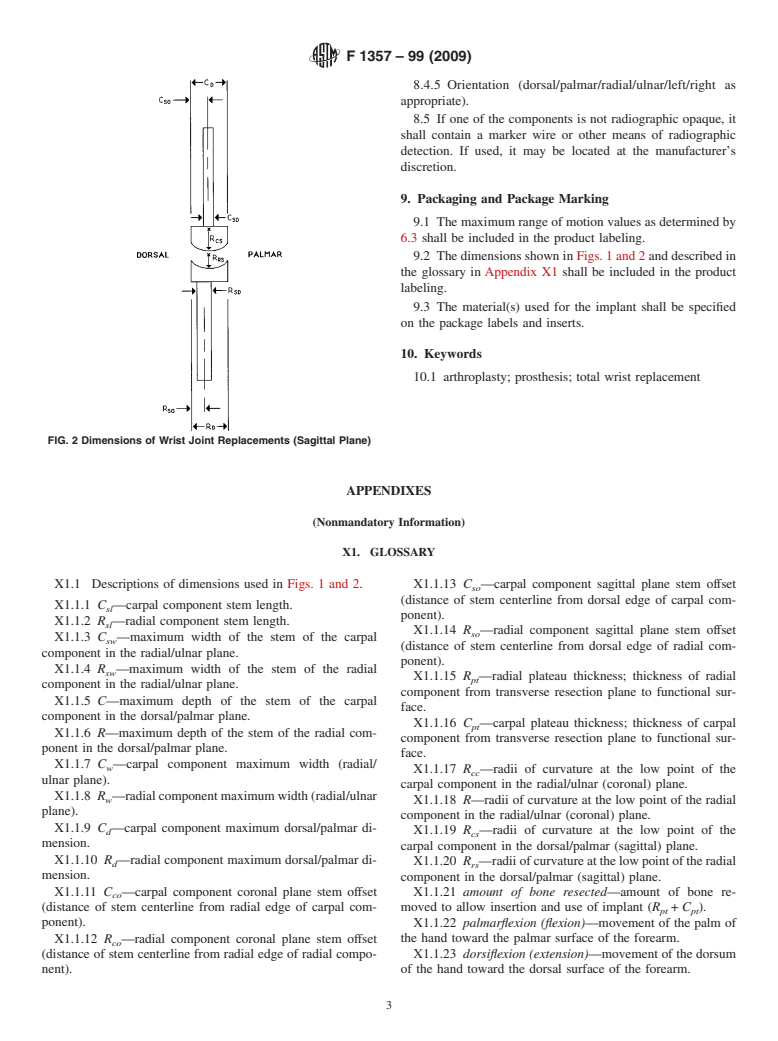

7.1 Dimensions of wrist joint replacement components shall

5.1 Proper material selection is necessary, but insufficient to

be as designated in Figs. 1 and 2.

ensure suitable function of a device.

5.2 All metal implant components shall conform to one of

8. Finish and Marking

the following specifications for implant materials: Specifica-

8.1 Items conforming to this specification shall be finished

tion F67, F75, F90, F 136, F 562, F 563 (nonbearing use

andmarkedinaccordancewithPracticeF86whereapplicable.

only), F 799, F 1108,or F 1537.

8.2 Metallic Bearing Surface—Articulate surfaces shall be

5.3 All polymeric components shall conform to the follow-

finished to an average roughness of 0.125 µm.

ing specification for implant materials: Specification F 648.

8.3 Polymeric Bearing Surface Finish— shall conform to

5.4 All solid ceramic components shall conform to Specifi-

manufacturer’s documented standards concerning concentric-

cation F 603 for implant materials.

ity, sphericity, and surface roughness, when applicable.

5.5 Biocompatibility—Articulating implants shall be manu-

8.4 Items conforming to this specification shall be marked

factured from the materials listed in 5.2-5.4. Before implants

in accordance with PracticesF86 and F 983. Radial and carpal

can be manufactured from other materials, their biocompatibil-

component marking shall include, as possible, the items below

ity will be considered suitable only if they produce an

in the following order of importance:

acceptable response after testing in accordance with Practice

8.4.1 Manufacturer,

F 981.

8.4.2 Size,

5.6 When required for metallic implants, fluorescent pen- 8.4.3 Catalog Number,

etrant inspection shall be performed in accordance with Prac- 8.4.4 Lot Number, and

tice F 601.

5.7 When required for cast metallic implants, radiography

shall be performed in accordance with Practice F 629.

6. Performance Requirements

6.1 Polymeric Creep (Cold Flow)—Ultra-high molecular

weight polyethylene in implant form must conform to the

requirements detailed in Specification F 648. When creep

occurs, it must not impair the function or stability of the

interface.

6.2 Wear of Alternative Materials—It is important to under-

stand the wear performance for articulating surfaces.Any new

or different material couple should not exceed the wear rates of

the following material couple when tested under physiological

conditions. The current wear couple is CoCrMo alloy (Speci-

fication F75) against ultra high molecular weight polyethyl-

ene. This is an industry wide referenced wear couple and is

considered by some to be the minimum. It has been proven to

provide clinically acceptable results.

NOTE 1—In situations where the pin-on-flat test may not be considered

appropriate, other test methods may be considered.

6.3 Range of Motion of the Device Before Implantation—

The implant shall be evaluated to determine t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.