ASTM D4142-89(2001)

(Guide)Standard Guide for Testing Epoxy Resins

Standard Guide for Testing Epoxy Resins

SIGNIFICANCE AND USE

This guide directs the user to test methods that determine properties generally accepted as standard test items for classification of epoxy resins.

SCOPE

1.1 This guide covers methods for testing epoxy resins as listed in Table 1. All of the methods were tested by interlaboratory participation in accordance with usual ASTM guidelines. Each method specifies a recommended amount of sample for starting a separate analysis, but several of the procedures can be conducted on the same starting material if so desired. For example, viscosity, color, and density could be run on the same specimen.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D4142–89 (Reapproved2001)

Standard Guide for

1

Testing Epoxy Resins

This standard is issued under the fixed designation D4142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

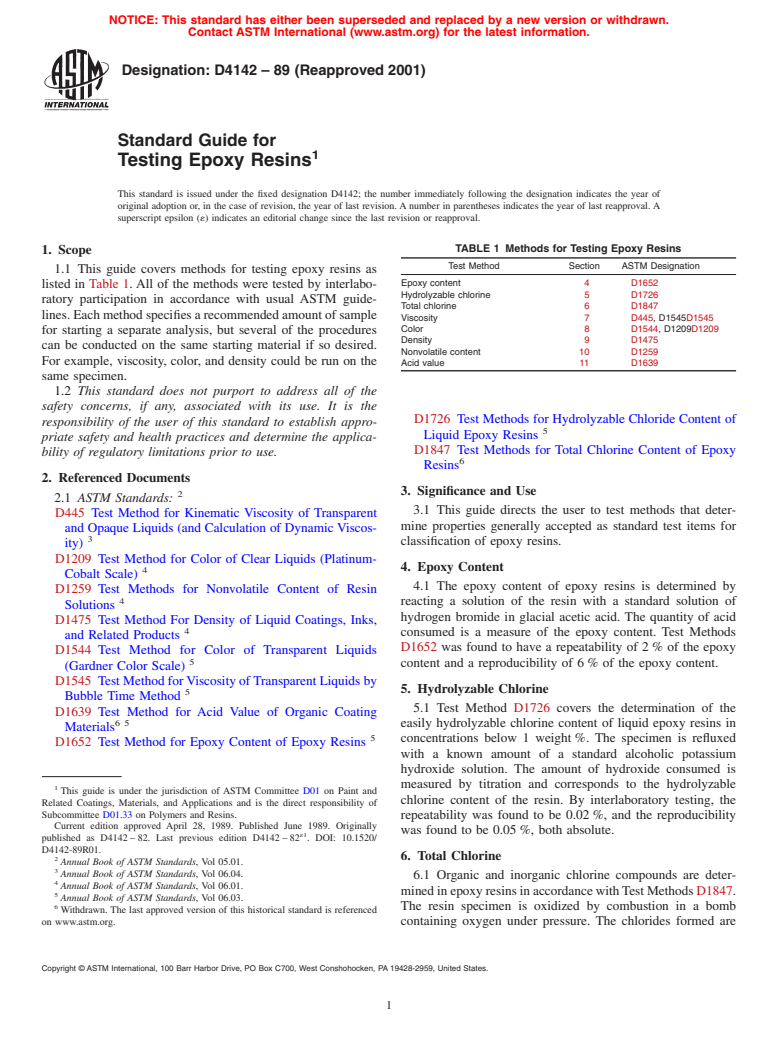

TABLE 1 Methods for Testing Epoxy Resins

1. Scope

Test Method Section ASTM Designation

1.1 This guide covers methods for testing epoxy resins as

Epoxy content 4 D1652

listed in Table 1. All of the methods were tested by interlabo-

Hydrolyzable chlorine 5 D1726

ratory participation in accordance with usual ASTM guide-

Total chlorine 6 D1847

lines.Eachmethodspecifiesarecommendedamountofsample

Viscosity 7 D445, D1545D1545

Color 8 D1544, D1209D1209

for starting a separate analysis, but several of the procedures

Density 9 D1475

can be conducted on the same starting material if so desired.

Nonvolatile content 10 D1259

For example, viscosity, color, and density could be run on the

Acid value 11 D1639

same specimen.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

D1726 Test Methods for Hydrolyzable Chloride Content of

responsibility of the user of this standard to establish appro-

5

Liquid Epoxy Resins

priate safety and health practices and determine the applica-

D1847 Test Methods for Total Chlorine Content of Epoxy

bility of regulatory limitations prior to use.

6

Resins

2. Referenced Documents

3. Significance and Use

2

2.1 ASTM Standards:

3.1 This guide directs the user to test methods that deter-

D445 Test Method for Kinematic Viscosity of Transparent

mine properties generally accepted as standard test items for

and Opaque Liquids (and Calculation of Dynamic Viscos-

3

classification of epoxy resins.

ity)

D1209 Test Method for Color of Clear Liquids (Platinum-

4. Epoxy Content

4

Cobalt Scale)

4.1 The epoxy content of epoxy resins is determined by

D1259 Test Methods for Nonvolatile Content of Resin

4

reacting a solution of the resin with a standard solution of

Solutions

hydrogen bromide in glacial acetic acid. The quantity of acid

D1475 Test Method For Density of Liquid Coatings, Inks,

4

consumed is a measure of the epoxy content. Test Methods

and Related Products

D1652 was found to have a repeatability of 2 % of the epoxy

D1544 Test Method for Color of Transparent Liquids

5

content and a reproducibility of 6 % of the epoxy content.

(Gardner Color Scale)

D1545 Test Method forViscosity ofTransparent Liquids by

5. Hydrolyzable Chlorine

5

Bubble Time Method

5.1 Test Method D1726 covers the determination of the

D1639 Test Method for Acid Value of Organic Coating

65 easily hydrolyzable chlorine content of liquid epoxy resins in

Materials

5

concentrations below 1 weight %. The specimen is refluxed

D1652 Test Method for Epoxy Content of Epoxy Resins

with a known amount of a standard alcoholic potassium

hydroxide solution. The amount of hydroxide consumed is

measured by titration and corresponds to the hydrolyzable

1

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

chlorine content of the resin. By interlaboratory testing, the

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.33 on Polymers and Resins.

repeatability was found to be 0.02 %, and the reproducibility

Current edition approved April 28, 1989. Published June 1989. Originally

was found to be 0.05 %, both absolute.

´1

published as D4142 – 82. Last previous edition D4142 – 82 . DOI: 10.1520/

D4142-89R01.

6. Total Chlorine

2

Annual Book of ASTM Standards, Vol 05.01.

3

Annual Book of ASTM Standards, Vol 06.04.

6.1 Organic and inorganic chlorine compounds are deter-

4

Annual Book of ASTM Standards, Vol 06.01.

minedinepoxyresinsinaccordancewithTestMethodsD1847.

5

Annual Book of ASTM Standards, Vol 06.03.

6

The resin specimen is oxidized by combustion in a bomb

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org. containing oxygen under pressure. The chlorides formed are

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4142–89 (2001)

dissolved in a sodium carbonate solution and then either different laboratories should be considered suspect if they

titrated or determined gravimetrically. The absolute repeatabil- differ by more than four thirds of a color number.

ity and reproducibility for the titration method are 0.02 and 8.2 The color of epoxy resins having light absorption

0.05 weight %, respectively. For the gravimetric method, the characteristics nearly identical with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.