ASTM C1173-97

(Specification)Standard Specification for Flexible Transition Couplings for Underground Piping Systems

Standard Specification for Flexible Transition Couplings for Underground Piping Systems

SCOPE

1.1 These specifications describe the properties of devices or assemblies suitable for use as flexible transition couplings, hereinafter referred to as couplings, for underground drainage and sewer piping systems.

1.2 Couplings that may include bushings or inserts and that meet the requirements of this standard are suitable for joining plain end pipe or fittings. The pipe to be joined shall be of similar or dissimilar materials, size, or both.

1.3 The values stated in inch-pound units shall be regarded as standard.

1.4 The ASTM standards referenced herein shall be considered mandatory.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1173 – 97

Standard Specification for

Flexible Transition Couplings for Underground Piping

Systems

This standard is issued under the fixed designation C 1173; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope dard, see Terminology C 717.

3.2 Definitions of Terms Specific to This Standard:

1.1 These specifications describe the properties of devices

3.2.1 center stop—an integral part of the gasket centered on

or assemblies suitable for use as flexible transition couplings,

its axial length intended to limit the insertion depth of the pipe

hereinafter referred to as couplings, for underground drainage

to be coupled.

and sewer piping systems.

3.2.2 fitting—parts of a pipeline other than the straight pipe

1.2 Couplings that may include bushings or inserts and that

couplings, or valves.

meet the requirements of this standard are suitable for joining

3.2.3 flexible transition couplings—devices used to form a

plain end pipe or fittings. The pipe to be joined shall be of

leakproof joint between sections of plain end pipe or fittings of

similar or dissimilar materials, size, or both.

the same or different materials, of the same or different size, or

1.3 The values stated in inch-pound units shall be regarded

any combination of materials or pipe sizes.

as standard.

3.2.4 free torque—the torque value expressed in lbf·in./Nm

1.4 The ASTM standards referenced herein shall be consid-

when the clamp is tightened four revolutions of the screw nut;

ered mandatory.

while in the free state, this value does not include any

2. Referenced Documents

breakaway effects due to staking or passage of the band ends

beyond the screw heads.

2.1 ASTM Standards:

3.2.5 inserts—a bushing or ring placed into the coupling

C 717 Terminology of Building Seals and Sealants

socket to accommodate pipe materials of differing outside

D 412 Test Methods for Vulcanized Rubber and Thermo-

diameters.

plastic Rubbers and Thermoplastic Elastomers—Tension

3.2.6 joint—the completed assembly of parts consisting of

D 471 Test Method for Rubber Property—Effect of Liq-

the flexible transition coupling and the joined pipes, or fittings,

uids

or both.

D 518 Test Method for Rubber Deterioration—Surface

3.2.7 lot—a specific quantity of similar material or collec-

Cracking

tion of similar units from a common source; the quantity

D 543 Practice for Evaluating Resistance of Plastics to

offered for inspection and acceptance at any one time. A lot

Chemical Reagents

might comprise a shipment, batch, or similar quantity.

D 573 Test Method for Rubber—Deterioration in an Air

3.2.8 plain end pipe—any pipe that does not include any

Oven

bell, hub, threaded area, or other means of joining.

D 638 Test Method for Tensile Properties of Plastics

3.2.9 shear ring—an interior or exterior element which is

D 1149 Test Method for Rubber Deterioration Surface

used to span the distance between the pipe ends within a

Ozone Cracking in a Chamber

coupling so as to provide increased resistance to axial displace-

D 2240 Test Method for Rubber Property—Durometer

ment.

Hardness

D 3045 Practice for Heat Aging of Plastics Without Load

4. Classification

3. Terminology

4.1 The couplings shall be permitted to have a center stop.

The components shall be designed so that the elastomeric

3.1 Definitions—For definitions of terms used in this stan-

material is compressed to form a hydrostatic seal when the

joint is assembled. The couplings shall be of the types

These specifications are under the jurisdiction of ASTM Committee C-24 on

described in 4.1.1-4.1.3.

Building Seals and Sealants and are the direct responsibility of Subcommittee

C24.75on Gaskets and Couplings for Plumbing and Sewer Piping. 4.1.1 Type A—A coupling consisting of an elastomeric

Current edition approved Dec. 10, 1997. Published April 1998. Originally

sleeve incorporating corrosion resistance tension bands and a

published as C 1173 – 91. Last previous edition C 1173 – 95.

2 tightening mechanism. Couplings shall be fabricated with or

Annual Book of ASTM Standards, Vol 04.07.

Annual Book of ASTM Standards, Vol 09.01. without shear rings, and with or without a center stop.

Annual Book of ASTM Standards, Vol 08.01.

4.1.2 Type B—A coupling consisting of an elastomeric or

Annual Book of ASTM Standards, Vol 08.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1173

rubber sleeve incorporating a corrosion resistant outer sleeve 8. Sampling, Tests, and Retests

and tension bands, or tightening mechanism, or both (Note 1).

8.1 Test specimens representative of the couplings to be

4.1.3 Type C—A coupling fabricated with elastomeric com-

used shall be randomly selected from the manufactured lot for

pression seals.

testing.

NOTE 1—The provisions of this standard are not intended to prevent the

8.2 No less than two couplings for each size or type shall be

use of any alternate material or method of construction, provided any such

tested, unless otherwise specified or waived by the purchaser.

alternate meets the requirements of this standard.

8.3 Where there is a failure in the original test, the entire test

shall be rerun with twice the number of samples and any failure

5. Materials and Manufacture

shall be cause for rejection.

5.1 Elastomeric materials used in the manufacturing of

couplings and inserts shall comply with the requirements set

9. Test Methods

forth in Table 1.

9.1 Elastomeric Materials:

5.2 Stainless steel tension bands shall be of the 300 series

9.1.1 Hardness—Hardness shall be measured on either a

stainless steel.

finished surface, a squarely cut end, or a flat sliced or buffed

5.3 Couplings or bushings/inserts, or both, of multi-piece

surface, depending on the size and shape of the specimen. See

construction or with splices shall show no separation, peeling,

Test Method D 2240.

or other defects when tested in accordance with Section 9.

9.1.2 Tensile Strength and Elongation— The dumbbells

5.4 The coupling shall be free from porosity and air pockets.

Its surface shall be smooth and free from pitting, cracks, shall be prepared from sections of the finished material. See

blisters, air marks, or any other imperfections that affect its Test Methods D 412.

performance in service. The flash extension shall not exceed 1

9.1.3 Heat Aging, for hardness, tensile and elongation shall

mm at any point where the presence of flash affects perfor-

be performed in accordance with Test Method D 573. Speci-

mance.

mens shall be oven-aged for 96 h at 158 6 3.6°F (70 6 2°C).

9.1.4 Ozone Resistance—Test specimens shall be used as

6. Requirements

described in Test Method D 518, Procedure A, stretched 20 %

6.1 The physical and chemical properties of the coupling

and exposed to an ozone concentration of 50 parts per 100

materials shall conform to the requirements specified in Table

million for 100 h at 104 6 3.6°F (40 6 2°C). See Test Method

1.

D 1149.

7. Dimensions 9.1.5 Water Absorption—Size and time determinatio

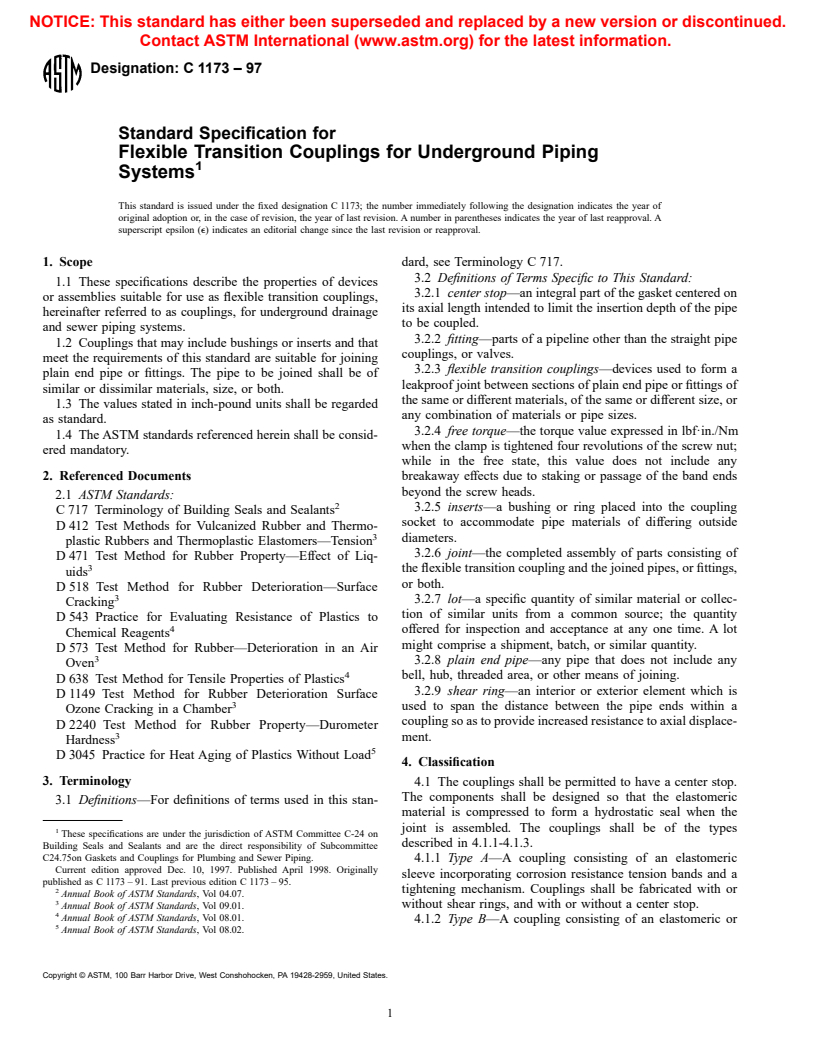

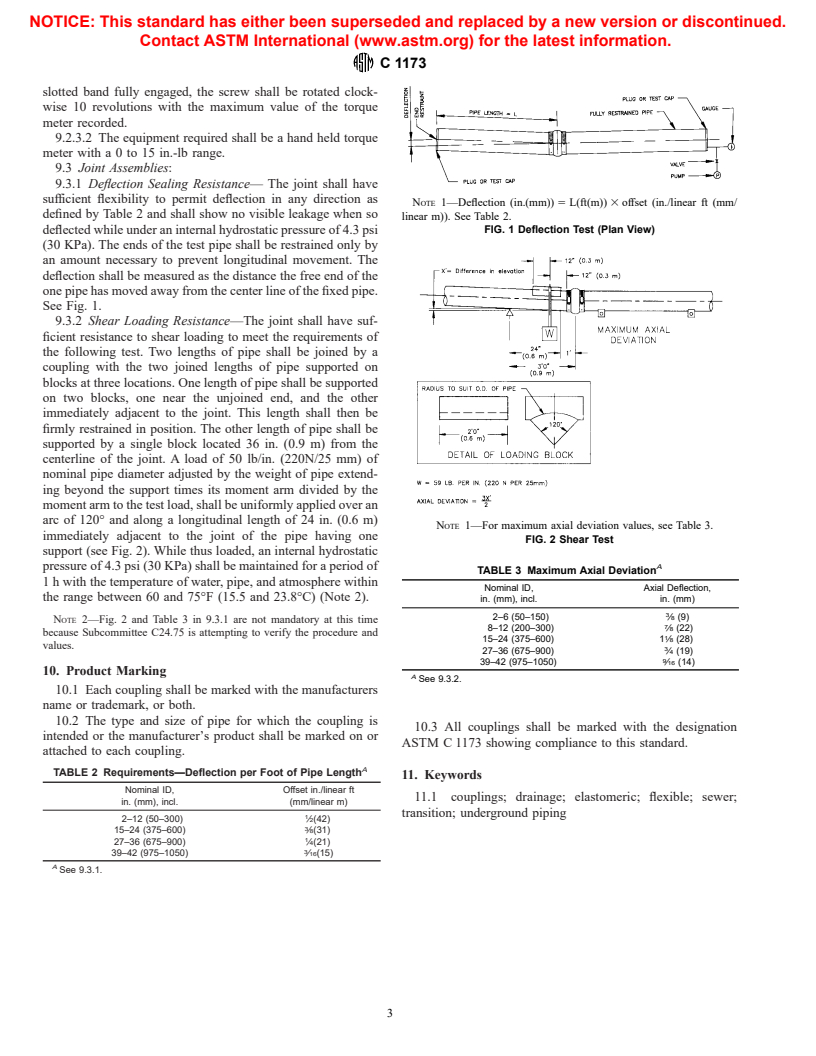

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.