ASTM C1019-00b

(Test Method)Standard Test Method for Sampling and Testing Grout

Standard Test Method for Sampling and Testing Grout

SCOPE

1.1 This test method covers procedures for both field and laboratory sampling and compression testing of grout used in masonry construction.

Note 1—The testing agency performing this test method should be evaluated in accordance with Practice C1093.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1019 – 00b

Standard Test Method for

Sampling and Testing Grout

This standard is issued under the fixed designation C 1019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * grout specimens in order to provide compressive strength test

results more nearly indicative of the grout strength in the wall.

1.1 This test method covers procedures for both field and

In this test method, molds are made from masonry units having

laboratory sampling and compression testing of grout used in

the same absorption and moisture content characteristics as

masonry construction.

those being used in the construction.

NOTE 1—The testing agency performing this test method should be

3.2 This test method is used to either help select grout

evaluated in accordance with Practice C 1093.

proportions by comparing test values or as a quality control test

1.2 The values stated in inch-pound units are to be regarded

for uniformity of grout preparation during construction.

as the standard.

3.3 The physical exposure condition and curing of the grout

1.3 This standard does not purport to address all of the

are not exactly reproduced, but this test method does subject

safety problems, if any, associated with its use. It is the

the grout specimens to absorption conditions similar to those

responsibility of the user of this standard to establish appro-

experienced by grout in the wall.

priate safety and health practices and determine the applica-

NOTE 2—Test results of grout specimens taken from a wall should not

bility of regulatory limitations prior to use.

be compared to test results obtained with this test method.

2. Referenced Documents

4. Apparatus

2.1 ASTM Standards:

4.1 Maximum-Minimum Thermometer.

C 39 Test Method for Compressive Strength of Cylindrical

4.2 Straightedge, a steel straightedge not less than 6 in.

Concrete Specimens

(152.4 mm) long and not less than ⁄16 in. (1.6 mm) in

C 143 Test Method for Slump of Hydraulic Cement Con-

thickness.

crete

4.3 Tamping Rod, a nonabsorbent rod, either round or

C 511 Specification for Moist Cabinets, Moist Rooms, and

square in cross section nominally ⁄8 in. (15.9 mm) in dimen-

Water Storage Tanks Used in the Testing of Hydraulic

sion with ends rounded to hemispherical tips of the same

Cements and Concretes

diameter. The rod shall be a minimum length of 12 in. (304.8

C 617 Practice for Capping Cylindrical Concrete Speci-

mm).

mens

4.4 Nonabsorbent Blocks, nonabsorbent, rigid squares with

C 1064 Test Method for Temperature of Freshly Mixed

side dimensions equal to one half the desired grout specimen

Portland Cement Concrete

height, within a tolerance of 5 %, and of sufficient quantity or

C 1093 Practice for Accreditation of Testing Agencies for

thickness to yield the desired grout specimen height, as shown

Unit Masonry

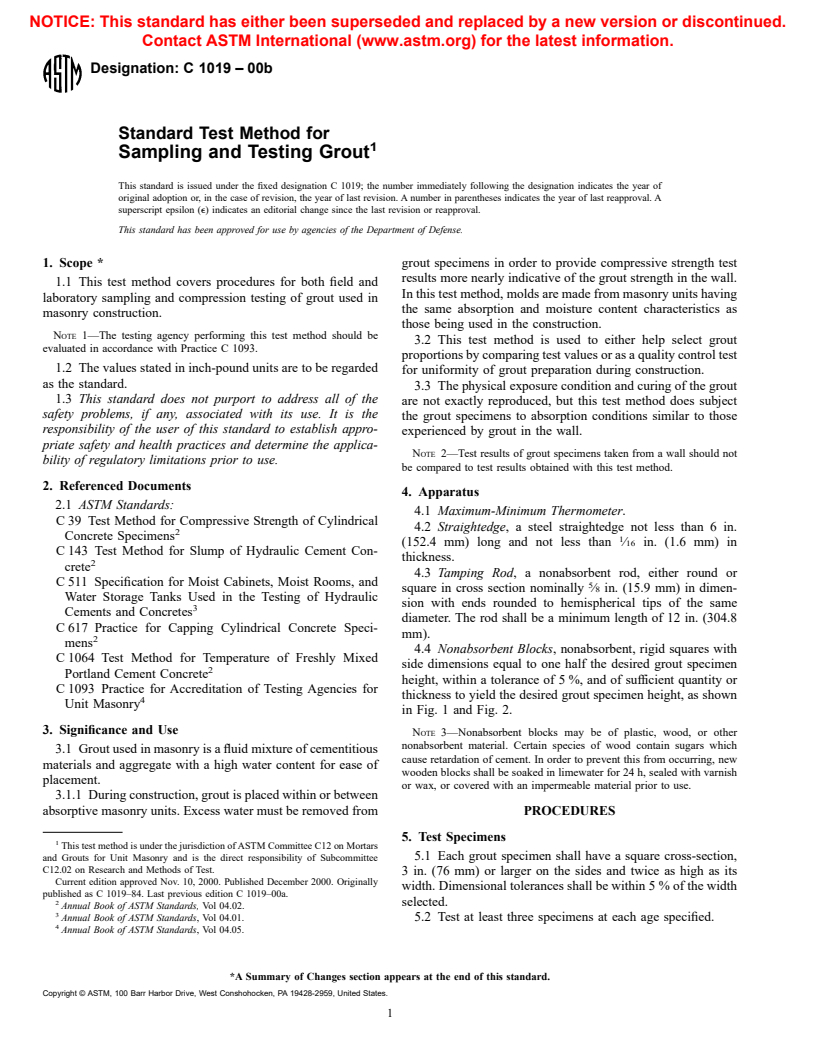

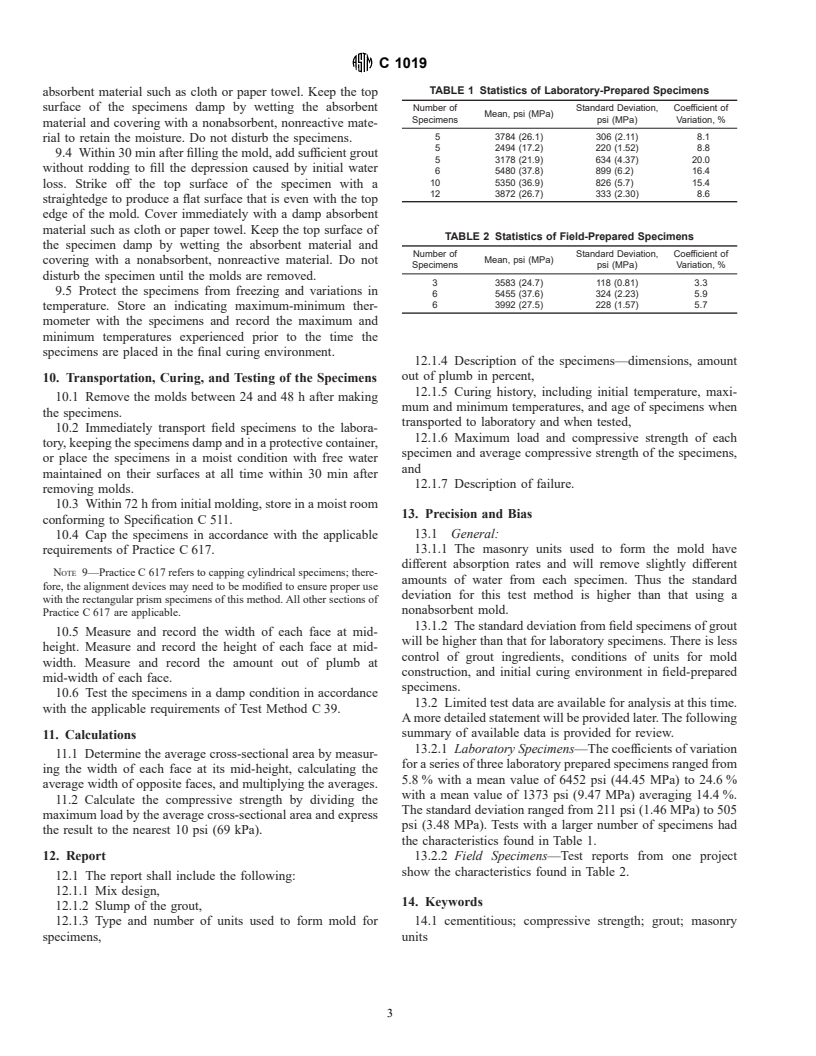

in Fig. 1 and Fig. 2.

3. Significance and Use

NOTE 3—Nonabsorbent blocks may be of plastic, wood, or other

nonabsorbent material. Certain species of wood contain sugars which

3.1 Grout used in masonry is a fluid mixture of cementitious

cause retardation of cement. In order to prevent this from occurring, new

materials and aggregate with a high water content for ease of

wooden blocks shall be soaked in limewater for 24 h, sealed with varnish

placement.

or wax, or covered with an impermeable material prior to use.

3.1.1 During construction, grout is placed within or between

absorptive masonry units. Excess water must be removed from PROCEDURES

5. Test Specimens

This test method is under the jurisdiction of ASTM Committee C12 on Mortars

5.1 Each grout specimen shall have a square cross-section,

and Grouts for Unit Masonry and is the direct responsibility of Subcommittee

C12.02 on Research and Methods of Test.

3 in. (76 mm) or larger on the sides and twice as high as its

Current edition approved Nov. 10, 2000. Published December 2000. Originally

width. Dimensional tolerances shall be within 5 % of the width

published as C 1019–84. Last previous edition C 1019–00a.

selected.

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 04.01. 5.2 Test at least three specimens at each age specified.

Annual Book of ASTM Standards, Vol 04.05.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 1019

6.4 Line the masonry surfaces that will be in contact with

the grout specimen with a thin, permeable material to prevent

bond to the masonry units.

NOTE 7—The lining, such as paper towel, is used to aid in stripping the

grout specimen from the mold. Proper installation of the lining prevents

irregularly sized specimens and varying test results.

6.5 Brace units to prevent displacement during grouting and

NOTE—Front masonry unit stack not shown to allow view of specimen.

curing.

FIG. 1 Grout Mold (Units 6 in. (152.4 mm) or Less in Height, 2 ⁄4

in. (57.2 mm) High Brick Shown)

7. Sampling Grout

7.1 Size of Sample—Grout samples to be used for slump and

compressive strength tests shall be a minimum of ⁄2 ft (0.014

3 3

m ). Sample size retained at ⁄2 ft .

7.2 Procedure—The procedures used in sampling shall

include the use of precautions that will assist in obtaining

samples that are representative of the nature and condition of

the grout. After the final slump adjustment has been made,

sample grout as the grout is being placed.

7.2.1 Field Sampling—Collect two or more portions taken

NOTE—Front masonry unit not shown to allow view of specimen.

at regularly spaced intervals during the discharge of the middle

FIG. 2 Grout Mold (Units Greater than 6 in. (152.4 mm) High, 8 in.

portion of the batch. The elapsed time between obtaining the

(203.2 mm) High Concrete Masonry Unit Shown)

first and final portions of the sample shall be as short as

possible, but not more than 15 min.

NOTE 4—Frequency of sampling and age of test is to be determined by 7.2.2 Laboratory Sampling—The entire mixed batch of

the specifier of this test method and is usually found in the construction

grout is the sample.

documents.

NOTE 8—The field technician sampling, making, and curing specimens

for acceptance testing should be certified (American Concrete Institute

6. Mold Construction

Field Testing Technician—Grade I, National Concrete Masonry Associa-

6.1 Select a level location where the molds remain undis-

tion Masonry Testing Technician, or equivalent). Equivalent certification

turbed for 48 h.

programs should include both written and performance examinations.

NOTE 5—The location of specimen construction should be protected

7.3 Transport the grout sample to the mold location. Protect

and as free from perceptible vibration as possible.

the sample from the sun, wind, and other sources of rapid

evaporation and from contamination. Remix the sample with a

6.2 The construction of the mold shall simulate the in-situ

construction. If the grout is placed between two different types shovel or trowel to ensure uniformity.

of masonry units, both types shall be used to construct the

8. Temperature and Slump Test

mold.

6.3 Form a space with a square cross-section, 3 in. (76 mm) 8.1 Measure and record the temperature of the grout sample

or larger on each side and twice as high as its width, by in accordance with Test Method C 1064.

stacking masonry units of the same type and moisture condi- 8.2 Begin filling the slump cone within 5 min of obtaining

tion as those being used in the construction. The surface of the the final portion of the sample.

unit in contact with the grout specimen shall not have been 8.3 Measure and record the slump in accordance with the

previously used to mold specimens. Place nonabsorbent requirements of Test Method C 143.

blocks, cut to proper size and of the proper thickness or

9. Compressive Test Specimen

quantity, at the bottom of the space to achieve the necessary

height of speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.