ASTM E959-83(2005)

(Test Method)Standard Test Method for Characterizing the Performance of Refuse Size-Reduction Equipment

Standard Test Method for Characterizing the Performance of Refuse Size-Reduction Equipment

SIGNIFICANCE AND USE

Throughput, power and energy requirements, and product size are key parameters that describe the operation and performance of solid waste size-reduction equipment.

This test method can be used to determine if the size-reduction equipment is operating within specifications and meeting performance criteria.

Having determined the parameters given in 5.1, the equipment that has been subjected to the test may be compared to other equipment similarly tested in order to establish relative levels of performance among equipment.

The basic test period is a continuous two to four h duration. The use of several test periods may be warranted to assess adequately the performance of size reduction equipment.

SCOPE

1.1 This test method covers measuring the performance of solid waste size reduction equipment.

1.2 This test method can be used to measure the flow (that is, throughput) of solid waste through the size-reduction equipment, energy usage of the size-reduction device, and particle size of the shredded product.

1.3 This test method includes instructions for measuring energy usage, solid waste throughput, net processing time, and particle size distribution.

1.4 This test method applies only to size reduction equipment that produces a shredded product with a size corresponding to 90 % cumulative passing in the range of 0.5 to 15 cm (0.2-6 in.) on an air-dry weight basis. For material with nominal sizes outside of this range, the precision and bias statements for particle size designation (Section ) may not apply.

1.5 This test method can be applied to size reduction equipment located anywhere within a processing line.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section for specific hazard information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E959–83 (Reapproved 2005)

Standard Test Method for

Characterizing the Performance of Refuse Size-Reduction

Equipment

This standard is issued under the fixed designation E959; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E828 Test Method for Designating the Size of RDF-3 From

its Sieve Analysis

1.1 This test method covers measuring the performance of

E929 Test Method for Measuring Electrical Energy Re-

solid waste size reduction equipment.

quirements of Processing Equipment

1.2 This test method can be used to measure the flow (that

is, throughput) of solid waste through the size-reduction

3. Terminology Definitions:

equipment, energy usage of the size-reduction device, and

3.1 characteristic product size—the screen size correspond-

particle size of the shredded product.

ing to 63.2 % cumulative passing by weight.

1.3 This test method includes instructions for measuring

3.2 discrete throughput method—the method whereby av-

energy usage, solid waste throughput, net processing time, and

erage throughput is calculated as the average of a number of

particle size distribution.

discrete throughput measurements conducted during a test

1.4 This test method applies only to size reduction equip-

period.

ment that produces a shredded product with a size correspond-

3.3 idling time—timeperiodsduringwhichasizereduction

ing to 90 % cumulative passing in the range of 0.5 to 15 cm

device is freewheeling, that is, not processing refuse.

(0.2–6 in.) on an air-dry weight basis. For material with

3.4 net processing time—the time during which refuse is

nominal sizes outside of this range, the precision and bias

processed through the size reduction device.

statements for particle size designation (Section 14) may not

3.5 nominal product size—the screen size corresponding to

apply.

90 % cumulative passing by weight.

1.5 This test method can be applied to size reduction

3.6 size reduction device or equipment—adevicewhichsize

equipment located anywhere within a processing line.

reduces (Synonyms: shredder, grinder, pulverizer, and mill).

1.6 The values stated in SI units are to be regarded as the

3.7 stationary belt method—a method of gross sample

standard. The values given in parentheses are for information

collectioninwhichtheconveyorbeltisstoppedandthesample

only.

of material is removed manually.

1.7 This standard does not purport to address all of the

3.8 time-averaged throughput method—the method

safety concerns, if any, associated with its use. It is the

whereby the average throughput is calculated by dividing the

responsibility of the user of this standard to establish appro-

total mass size reduced by the net processing time.

priate safety and health practices and determine the applica-

3.9 test interval— a test interval is equal to one-quarter of

bility of regulatory limitations prior to use. See Section 7 for

the test period.

specific hazard information.

3.10 test period— the test period is two to four continuous

2. Referenced Documents h of net-processing time.

2.1 ASTM Standards:

4. Summary of Test Method

4.1 The duration of the test period is established and refuse

is prepared for processing.

4.2 An energy measuring system is installed.

This test method is under the jurisdiction of ASTM Committee D34 on Waste

4.3 Solid waste is processed through the size reduction

Management and is the direct responsibility of Subcommittee D34.03 onTreatment,

Recovery and Reuse. equipment, energy usage and throughput is measured, and

Current edition approved Feb. 1, 2005. Published March 2005. Originally

samples for analysis of product particle size distribution are

approved in 1983. Last previous edition approved in 1999 as E959-83(1999). DOI:

collected.

10.1520/E0959-83R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E959–83 (2005)

4.4 Average throughput, power requirements, specific en- 9. Preparation for Test

ergy, and particle size of the shredded product are calculated.

9.1 Refuse Preparation and Establishment of Test

4.5 Two methods (Time-Averaged Throughput Method and

Intervals—The duration of the test period is to be a minimum

Discrete Throughput Method [Section 10]) for measuring the

of 2 h and a maximum of 4 of net-processing time. During the

performance of size reduction equipment are described. The

test period, collect four gross samples of shredded product

selection of a particular method is governed by the layout of

from which subsamples for particle size distribution analysis

the processing equipment, the location of the size-reduction

will be taken subsequently. The test period is divided into four

equipment relative to the other processing equipment, and the

equal test intervals (that is, test intervals 1, 2, 3, and 4).

preference of the parties conducting the test.

Calculate the approximate duration of the test intervals using

the following relation:

5. Significance and Use

t *

5.1 Throughput, power and energy requirements, and prod- p

t * . (1)

i

uct size are key parameters that describe the operation and

performance of solid waste size-reduction equipment.

where:

5.2 This test method can be used to determine if the

t * = estimate of the duration of the test interval (h), and

p

size-reduction equipment is operating within specifications and

t * = estimateddurationofthetestperiod(h),subjecttothe

p

meeting performance criteria.

condition 2 h# t *#4h.

p

5.3 Having determined the parameters given in 5.1, the

Weigh refuse, uniformly mixed as much as possible, and

equipment that has been subjected to the test may be compared

form into four discrete piles, each of which has an approximate

tootherequipmentsimilarlytestedinordertoestablishrelative

(nominal) weight as calculated by the following relation:

levels of performance among equipment.

m˙ *t *

5.4 The basic test period is a continuous two to four h i

M* . (2)

i

duration. The use of several test periods may be warranted to

assess adequately the performance of size reduction equip-

where:

ment.

M* = approximate weight of the refuse pile in Mg,

i

m˙* = nominal throughput value (Mg/h) established for the

6. Apparatus

test, and

6.1 Hand Broom.

t* = estimated duration of the test interval (h) derived

i

6.2 Dust Pan.

from Eq 1.

6.3 Wide-mouthed Shovel.

The measured weight of each pile (M) is to be within 65%

i

6.4 Clock or Stopwatch, accurate to 0.1 s.

of the nominal weight (M*). Record the weight of each pile on

i

6.5 Plastic Bags, large containers, or both.

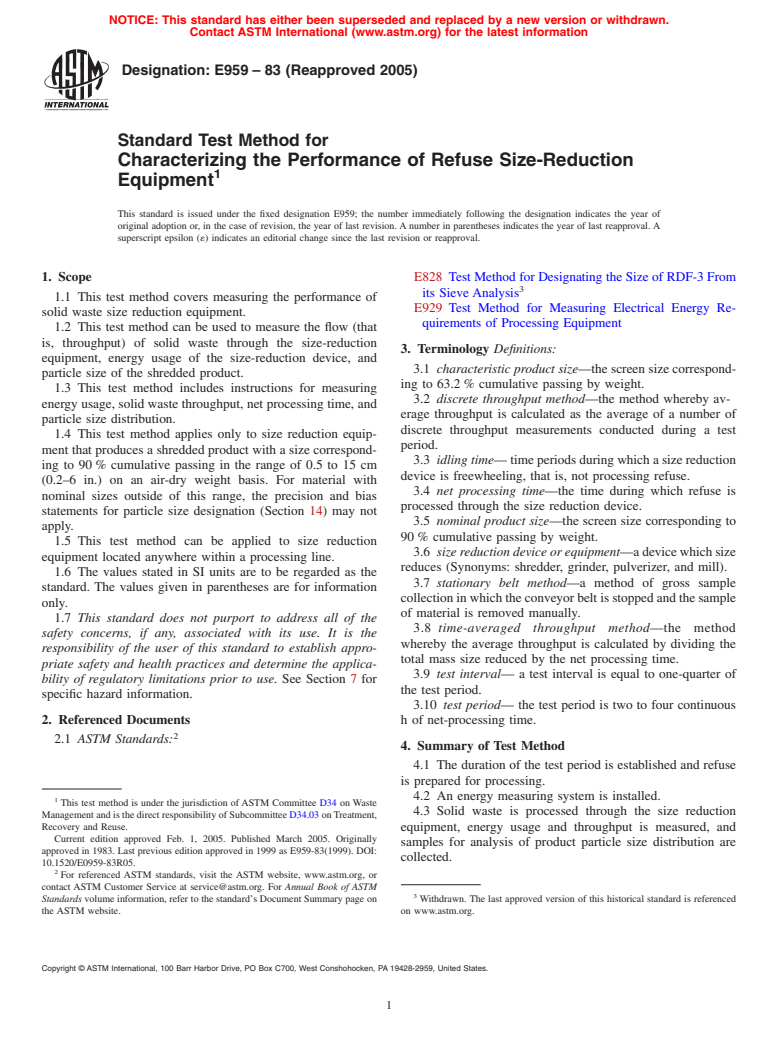

the sample data form shown in Fig. 1.

6.6 Push-broom.

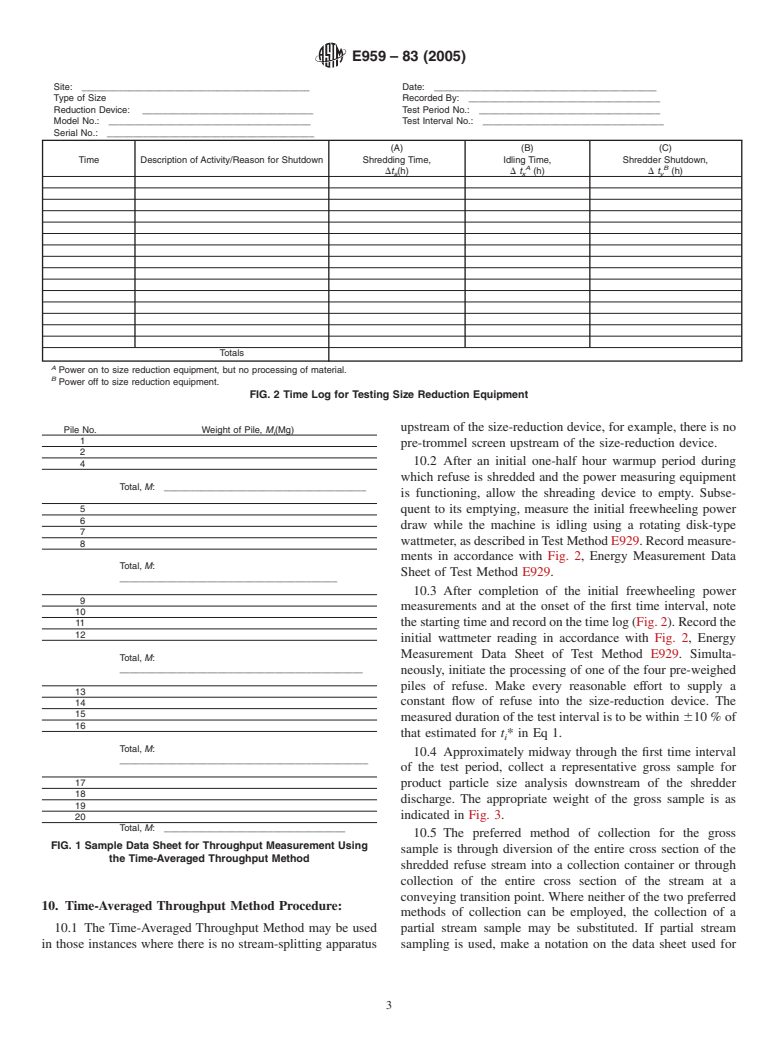

9.2 Time Measurements and Logbook—Keep a time log

6.7 Ties and Labels.

during the conduct of the test program, the primary purpose of

6.8 Electrical Metering System.

which is to allow the calculation of net-processing time. A

6.9 Sieving Equipment, manual or mechanical.

sample format for the log is shown in Fig. 2.

9.2.1 The key time recordings for each time interval are as

7. Hazards

follows:

7.1 The test procedure described in 11.4 requires the re-

9.2.1.1 Starting time of the time interval,

moval of shredded material from a stopped conveyor belt by

test personnel. Precautions should be taken to ensure that the

9.2.1.2 Starting time of idling periods in which the size

belt cannot be started while occupied. These precautions

reduction device is electrically energized but in which no size

consistoflockoutoftheelectricalpowertotheconveyor,ready

reduction of refuse is occurring,

access to a safety “stop” cord located on the conveyor, or both.

9.2.1.3 Starting time of any periods in which the size

7.2 This test method requires installation of electrical me-

reduction device is electrically shut down (de-energized), and

tering equipment. Consequently, the precautions described in

9.2.1.4 Finishing time of the test interval.

Test Method E929 should be observed.

9.2.2 In order to obtain representative test data, it is recom-

7.3 Gross samples should be collected sufficiently far from

mended that the net-processing time be a minimum of 75 % of

the size reduction equipment such that test personnel are

the duration of the test period. For example, if a four-h test

protected from potential explosions and flying objects from the

period is chosen, the net processing time should be equal to or

equipment.

greater than three h.

8. Equipment Calibration

9.3 Setup and Use of the Energy Measuring Equipment—

Measure energy usage of the size reduction device during the

8.1 All electrical metering equipment used for energy mea-

test period using Test Method E929. Use a rotating disk-type

surement shall be calibrated in accordance with Test Method

E929. wattmeter or equivalent as the measuring instrument. Install

and test the energy measuring equipment prior to initiating the

8.2 All weight-measuring equipment shall be calibrated

according to the manufacturer’s instructions. test period.

E959–83 (2005)

Site: ____________________________________________ Date: ___________________________________________

Type of Size Recorded By: _____________________________________

Reduction Device: _________________________________ Test Period No.: ___________________________________

Model No.: _______________________________________ Test Interval No.: ___________________________________

Serial No.: ________________________________________

(A) (B) (C)

Time Description of Activity/Reason for Shutdown Shredding Time, Idling Time, Shredder Shutdown,

A B

Dt (h) D t (h) D t (h)

s x y

Totals

A

Power on to size reduction equipment, but no processing of material.

B

Power off to size reduction equipment.

FIG. 2 Time Log for Testing Size Reduction Equipment

upstream of the size-reduction device, for example, there is no

Pile No. Weight of Pile, M(Mg)

i

pre-trommel screen upstream of the size-reduction device.

10.2 After an initial one-half hour warmup period during

which refuse is shredded and the power measuring equipment

Total, M: _______________________________________

is functioning, allow the shreading device to empty. Subse-

quent to its emptying, measure the initial freewheeling power

draw while the machine is idling using a rotating disk-type

wattmeter,asdescribedinTestMethodE929.Recordmeasure-

ments in accordance with Fig. 2, Energy Measurement Data

Total, M:

Sheet of Test Method E929.

__________________________________________

10.3 After completion of the initial freewheeling power

measurements and at the onset of the first time interval, note

11 thestartingtimeandrecordonthetimelog(Fig.2).Recordthe

initial wattmeter reading in accordance with Fig. 2, Energy

Measurement Data Sheet of Test Method E929. Simulta-

Total, M:

_______________________________________________

neously, initiate the processing of one of the four pre-weighed

piles of refuse. Make every reasonable effort to supply a

constant flow of refuse into the size-reduction device. The

measured duration of the test interval is to be within 610 % of

that estimated for t*inEq1.

i

Total, M:

10.4 Approximately midway through the first time interval

________________________________________________

of the test period, collect a representative gross sample for

17 product particle size analysis downstream of the shredder

discharge. The appropriate weight of the gross sample is as

indicated in Fig. 3.

Total, M: ___________________________________

10.5 The preferred method of collection for the gross

FIG. 1 Sample Data Sheet for Throughput Measurement Using

sample is through diversion of the entire cross section of the

the Time-Averaged Throughput Method

shredded refuse stream into a collection container or through

collection of the entire cross section of the stream at a

conveying transition point. Where neither of the two preferred

10. Time-Averaged Throughput Method Procedure:

methods of collection can be employed, the collection of a

10.1 The Time-Averaged Throughput Method may be used partial stream sample may be substituted. If partial stream

in those instances where there is no stream-splitting apparatus sampling is used, make a notation on the data sheet used for

E959–83 (2005)

Nominal Product Size, X , (cm)

FIG. 3 Weight Requirements for Gross and Lab Samples as a Function of Nominal Product Size

recording the weights of gross and laboratory samples (Fig. 4) been noted, measure the final freewheeling power draw and

and the data sheets used to record particle size distribution data record the data in Fig. 2, Energy Measurement Data Sheet of

(Fig. 5).

Test Method E929.

10.6 Weigh the gross sample and store in a waterproof

container or bag until the representative laboratory samples are

11. Discrete Throughput Method Procedure

chosen. Record weight data on the data sheet shown in Fig. 4.

11.1 The Discrete Throughput Method is used in those

10.7 At the conclusion of the time interval, note the time

instances where splitting of the raw refuse stream occurs prior

and record the reading on the time log.

to its entering the size-reduction device, for example, in those

10.8 Collect the second, third, and fourth gross samples for

systems where a pre-trommel screen is located upstream of the

product particle size analysis approximately midway into the

size-reduction device.

second, third, and fourth test intervals, respectively, of the test

11.2 Follow the procedures in 10.2 through 10.4 . The

period, following the procedures in 10.4 through 10.7 . Note

preferred method of collection of the gross sample is by

and record on the time logs the starting times of the subsequent

diversion of the entire cross section of the shredded refuse

test intervals.

stream into a collection container or through collection of the

10.9 Following the fourth time interval and immediately

entire cross section of the stream in free fall at a conveying

upon size reducing the remainder of the fourth pile of refuse,

note the time and record the final wattmeter reading on Table transition point. Use a stopwatch to measure the time during

which the throughput sample is being collected.

X4 of Test Method E929.After the final wattm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.