ASTM D3516-89(2011)

(Test Method)Standard Test Methods for Ashing Cellulose

Standard Test Methods for Ashing Cellulose

SIGNIFICANCE AND USE

Ash content gives an estimation of the inorganic content of cellulose samples. The presence of high levels of ash can be expected to be detrimental to the process of making cellulose derivatives. It also provides a rough estimate of silica content which can have a significant effect on the performance of filters in cellulose derivative manufacturing facilities.

SCOPE

1.1 These test methods cover four ashing methods for cellulose. These are intended for use on unbleached and bleached cellulose in sheeted or bulk fiber form. Each one of the test methods has advantages, so that preference applications exist for all four.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3516 − 89 (Reapproved 2011)

Standard Test Methods for

1

Ashing Cellulose

This standard is issued under the fixed designation D3516; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and it should not be considered as a standard preparative

procedure for elemental analysis.

1.1 These test methods cover four ashing methods for

cellulose. These are intended for use on unbleached and

NOTE 1—The ash content at this ignition temperature is a reasonable

bleached cellulose in sheeted or bulk fiber form. Each one of

measure of the mineral salts and inorganic foreign matter in the cellulose.

the test methods has advantages, so that preference applica- The weight of ash obtained varies with the temperature of ignition. Higher

temperatures(850°C)willconvertcalciumcarbonateandothercarbonates

tions exist for all four.

to the oxides and thus give lower values for ash. The composition of ash

1.2 The test methods appear as follows:

may vary with the pulping process employed for manufacture, which

limits the significance of the ash determination in absolute terms.

Sections

Test Method A—Ash in Cellulose at 575°C 6 to 11

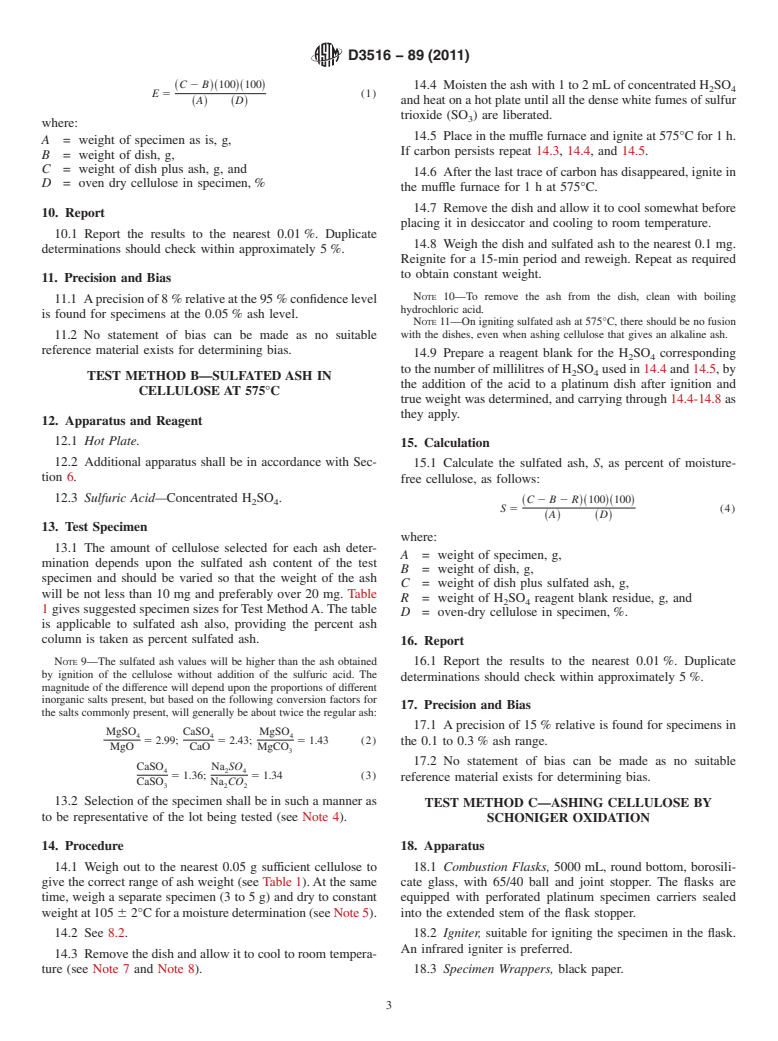

3.2 Test Method B, Sulfated Ash in Cellulose at 575°C—In

Test Method B—Sulfated Ash in Cellulose at 575°C 12 to 17

Test Method C—Ashing Cellulose by Schoniger Oxidation 18 to 22

this ashing procedure the metal salts are converted to sulfates

Test Method D—Wet Ashing of Cellulose for Inorganics 23 to 29

by treatment with sulfuric acid and ignition at 575 6 25°C to

1.3 The values stated in SI units are to be regarded as the

overcome limitations of Test Method A. It should not be

standard. The values given in parentheses are for information

considered as a standard preparative test method for elemental

only.

analysis.

1.4 This standard does not purport to address all of the

NOTE 2—Conventional dry ashing at high temperature (over 850°C)

safety concerns, if any, associated with its use. It is the

results in loss of carbon dioxide from metal carbonates, decomposition of

responsibility of the user of this standard to establish appro-

magnesiumsulfate,andlossofsodiumsalts.Ashingatlowertemperatures

priate safety and health practices and determine the applica-

(575°C) gives a better estimate of the inorganic impurities, but has the

disadvantage of requiring a long ignition time and also the heat produced

bility of regulatory limitations prior to use. For a specific

by the burning pulp can raise the temperature far above 575°C for a short

hazard statement, see 20.6.1.

period of time, converting calcium carbonate to the oxide in varying

amounts. The sulfated ash method overcomes these objectionable features

2. Referenced Documents

and has additional advantages. It is relatively insensitive to ignition time.

2

Ash weight remains constant during weighing, and because the ash does

2.1 ASTM Standards:

not melt it will not attack the crucible.

D1193 Specification for Reagent Water

D1348 Test Methods for Moisture in Cellulose 3.3 Test Method C, Ashing Cellulose by Schoniger

Oxidation—This test method is generally applicable to ashing

3. Summary of Test Methods

cellulose for subsequent analysis of inorganic constituents.The

procedure utilizes the Schoniger technique in which the cellu-

3.1 Test Method A, Ash in Cellulose at 575°C—This test

lose is burned in a combustion flask and all combustion

method measures the ash content of cellulose, which is defined

products are dissolved in an aqueous medium, thus avoiding

for this test as the residue remaining after ignition at 575 6

the possibility of physical loss of sample such as can occur in

25°C until all carbon has been burned off. It is the simplest of

dry ashing (Test Methods A and B). A limitation is the

the four test methods for the determination of ash content only,

relatively small sample of 1 g, which can be ashed without

excessively large apparatus in which to carry out the oxidation

step. Small specimens may not be adequately representative

1

These test methods are under the jurisdiction of ASTM Committee D01 on

where a particulate contaminate is involved.

Paint and Related Coatings, Materials, and Applications and are the direct

responsibility of Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

3.4 Test Method D, Wet Ashing of Cellulose for Inorganics—

Current edition approved June 1, 2011. Published June 2011. Originally

This test method is recommended for ashing cellulose for

approved in 1976. Last previous edition approved in 2006 as D3516 – 89 (2006).

DOI: 10.1520/D3516-89R11.

subsequent analysis of inorganic constituents. The pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.