ASTM D1343-95(2019)

(Test Method)Standard Test Method for Viscosity of Cellulose Derivatives by Ball-Drop Method

Standard Test Method for Viscosity of Cellulose Derivatives by Ball-Drop Method

SIGNIFICANCE AND USE

4.1 This test provides an easy method of determining the viscosity of cellulose derivatives in a given solvent. The answers are in units commonly used in industrial practice. Such information is needed for cellulose derivatives that are to be extruded, molded, sprayed, or brushed as is or in solution.

SCOPE

1.1 This test method describes the apparatus and general procedure for making ball-drop viscosity measurements on solutions of various cellulose derivatives. Instructions for sample preparation, solution concentration, and other details are discussed in the ASTM methods for the respective cellulose derivatives.

1.2 This test method is applicable to solutions of various cellulose derivatives having viscosities greater than 10 P, by using balls of various diameters and densities. Viscosity results are expressed preferably in poises.

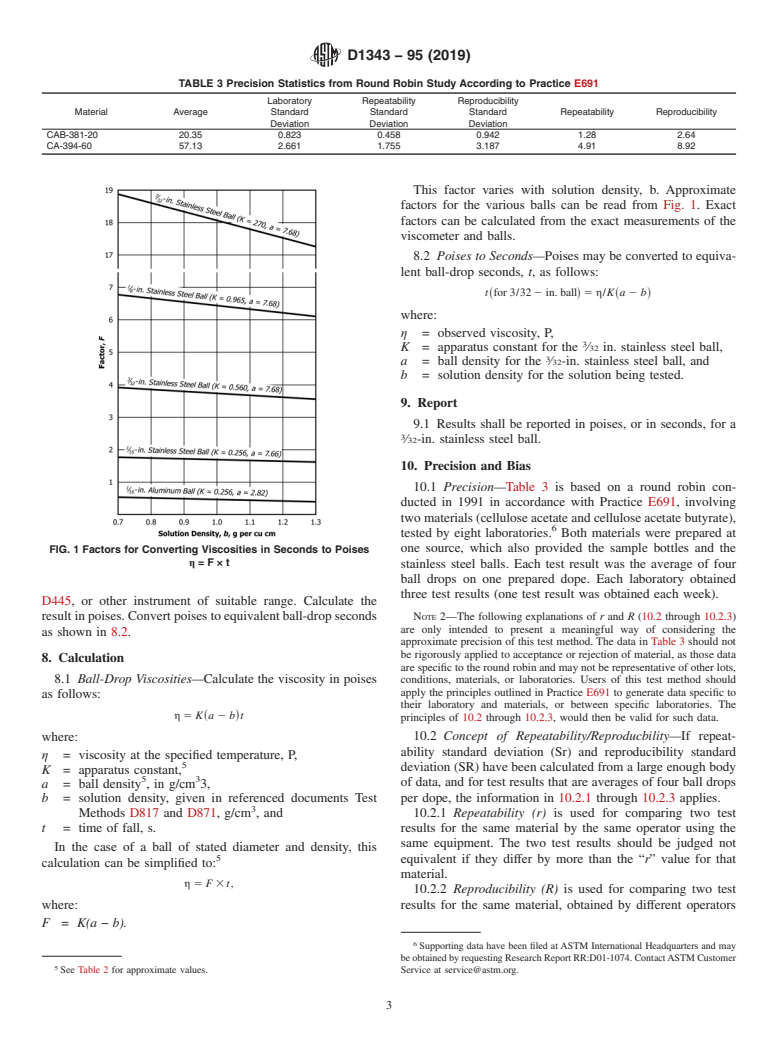

1.3 In commercial practice, viscosities are often expressed in seconds using 2.38-mm (3/32-in.) stainless steel balls.2 When the viscosity is outside the practical range for these balls (75 to 300 P), the measurement can be made using a calibrated pipet viscometer or a different ball and calculating the observed viscosity to the corresponding time for a 2.38-mm (3/32-in.) ball, even though it is a small fraction of a second.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1343 − 95 (Reapproved 2019)

Standard Test Method for

Viscosity of Cellulose Derivatives by Ball-Drop Method

This standard is issued under the fixed designation D1343; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

1.1 This test method describes the apparatus and general 2.1 ASTM Standards:

procedure for making ball-drop viscosity measurements on D301 Test Methods for Soluble Cellulose Nitrate (With-

solutions of various cellulose derivatives. Instructions for drawn 2011)

sample preparation, solution concentration, and other details D445 Test Method for Kinematic Viscosity of Transparent

arediscussedintheASTMmethodsfortherespectivecellulose and Opaque Liquids (and Calculation of Dynamic Viscos-

derivatives. ity)

D817 Test Methods of Testing Cellulose Acetate Propionate

1.2 This test method is applicable to solutions of various

and Cellulose Acetate Butyrate

cellulose derivatives having viscosities greater than 10 P, by

D871 Test Methods of Testing Cellulose Acetate

using balls of various diameters and densities.Viscosity results

E691 Practice for Conducting an Interlaboratory Study to

are expressed preferably in poises.

Determine the Precision of a Test Method

1.3 In commercial practice, viscosities are often expressed

in seconds using 2.38-mm ( ⁄32-in.) stainless steel balls. When

3. Summary of Test Method

the viscosity is outside the practical range for these balls (75 to

3.1 A solution of the cellulose derivative is made in a

300 P), the measurement can be made using a calibrated pipet

suitable solvent and allowed to equilibrate at a chosen tem-

viscometer or a different ball and calculating the observed

perature.Astainless steel or aluminum ball is dropped into the

viscosity to the corresponding time for a 2.38-mm ( ⁄32-in.)

solution, and the time required for it to cover a measured

ball, even though it is a small fraction of a second.

distance in its fall is recorded.The viscosity of the solution can

1.4 The values stated in SI units are to be regarded as the

then be calculated in poise or recorded in seconds.

standard. The values given in parentheses are for information

NOTE 1—The choice of solvent has significant influence on viscosity.

only.

1.5 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 This test provides an easy method of determining the

responsibility of the user of this standard to establish appro-

viscosity of cellulose derivatives in a given solvent. The

priate safety, health, and environmental practices and deter-

answers are in units commonly used in industrial practice.

mine the applicability of regulatory limitations prior to use.

Such information is needed for cellulose derivatives that are to

1.6 This international standard was developed in accor-

be extruded, molded, sprayed, or brushed as is or in solution.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Apparatus

Development of International Standards, Guides and Recom-

5.1 Constant-Temperature Water Bath, glass-walled.

mendations issued by the World Trade Organization Technical

5.1.1 For routine testing, an aquarium viscometer is recom-

Barriers to Trade (TBT) Committee.

mended. This viscometer is a rectangular glass enclosure with

front and rear walls that have etched horizontal parallel lines

This test method is under the jurisdiction of ASTM Committee D01 on Paint

50.8 mm (2.00 6 0.02 in.) apart. The bottles containing the

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved Dec. 1, 2019. Published December 2019. Originally

approved in 1954. Last previous edition approved in 2011 as D1343 – 95 (2011). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/D1343-95R19. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2 3

When a ⁄32-in. stainless steel ball is used, the viscosities in seconds should be Standards volume information, refer to the standard’s Document Summary page on

practically the same as those obtained using the apparatus described in Section 11 the ASTM website.

of Test Methods D871 – 48, and in Section 10 of Test Methods D301 – 50, which The last approved version of this historical standard is referenced on

last appeared in the 1952 Annual Book of ASTM Standards, Part 4. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1343 − 95 (2019)

TABLE 1 Bottles

6. Calibration

Bottle Round Square

6.1 Calculate the apparatus constant, K, using the following

Capacity, oz 16 16

equation and exact dimensions of the bottle and balls used:

Weight, oz 12 12

Height, in. 6.7 7

2 3

K 5 2gr 1 2 2.104 d/D 12.09 d/D /9L

@ ~ ! ~ ! #

Inside diameter, cm 6.4

Side to side, cm . 6.0

where:

Corner to corner, cm . 7.2

g = acceleration of gravity in cgs units

r = ball radius, cm,

d = ball diameter, cm,

D = bottle diameter, cm (in the case of square bottles the

samples solutions are set inside the viscometer at a level such

average of the side to side and corner to corner

that the upper etched line of the viscometer is at least 12.7 mm

diameters shall be used), and

( ⁄2 in.) below the upper surface of the solution in the bottle,

L = distance of ball drop, cm.

and the lower etched line of the viscometer is at least 12.7 mm

( ⁄2 in.) above the bottom of the sample bottle. Suitable lighting

7. Procedure

is provided to enable the observer to sight across the parallel

etched lines, through the sample bottle and solution, avoiding

7.1 Preparation of Solution—Dry the sample and prepare a

in this manner parallax errors. With this viscometer no timing

solution as specified for the particular material. Such instruc-

markers need to be provided on the bottles.

tions are given in the viscosity sections of Test Methods D301,

5.2 Bottles and Caps:

D871, and D817. Weigh into the bottle an appropriate amount

5.2.1 Bottles, round or square, conforming to the dimen-

of dry sample and specified solvent, accurate to 0.1 g, to make

sional requirements shown in Table 1, shall be used. Screw

about 350 mLof solution.The accurate and precise make up of

caps of metal or phenolic plastic in sizes to fit the bottles and

the solution is a necessity (example: 60.00 g of cellulose

having aluminum foil or cardboard and cellophane liners may

acetate and 240.00 g solvent). Close the bottle tightly.Allow to

be used to close the bottles. Alternatively, rubber stoppers

stand a short time for the solvent to penetrate the sample. Then

covered with aluminum or tin foil, may also be used as

tumble or shake until a uniform solution is obtained. For some

closures. In this latter case, solvent loss during measurement of

samples this may require several days. Transfer to the water

viscosity can be minimized by removing the stopper, leaving

bath at 25 6 0.1°C, and allow the solution to come to

the foil in place, and making a small hole in the center of the

temperature. A practical method to determine possible solvent

foil through which the balls may be dropped.

loss during this time involves weighing the bottle immediately

5.2.2 Timing marks sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.