ASTM E1832-08(2012)

(Practice)Standard Practice for Describing and Specifying a Direct Current Plasma Atomic Emission Spectrometer

Standard Practice for Describing and Specifying a Direct Current Plasma Atomic Emission Spectrometer

SIGNIFICANCE AND USE

4.1 This practice describes the essential components of the DCP spectrometer. This description allows the user or potential user to gain a basic understanding of this system. It also provides a means of comparing and evaluating this system with similar systems, as well as understanding the capabilities and limitations of each instrument.

SCOPE

1.1 This practice describes the components of a direct current plasma (DCP) atomic emission spectrometer. This practice does not attempt to specify component tolerances or performance criteria. This practice does, however, attempt to identify critical factors affecting bias, precision, and sensitivity. A prospective user should consult with the vendor before placing an order to design a testing protocol for demonstrating that the instrument meets all anticipated needs.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are give in Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1832 − 08 (Reapproved 2012)

Standard Practice for

Describing and Specifying a Direct Current Plasma Atomic

Emission Spectrometer

This standard is issued under the fixed designation E1832; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E520 Practice for Describing Photomultiplier Detectors in

Emission and Absorption Spectrometry

1.1 This practice describes the components of a direct

E528 Practice for Grounding Basic Optical Emission Spec-

current plasma (DCP) atomic emission spectrometer. This

trochemical Equipment (Withdrawn 1998)

practice does not attempt to specify component tolerances or

E1097 Guide for Determination of Various Elements by

performance criteria. This practice does, however, attempt to

Direct Current Plasma Atomic Emission Spectrometry

identifycriticalfactorsaffectingbias,precision,andsensitivity.

A prospective user should consult with the vendor before

3. Terminology

placing an order to design a testing protocol for demonstrating

3.1 For terminology relating to emission spectrometry, refer

that the instrument meets all anticipated needs.

to Terminology E135.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4.1 This practice describes the essential components of the

bility of regulatory limitations prior to use. Specific hazards DCPspectrometer.This description allows the user or potential

statements are give in Section 9. user to gain a basic understanding of this system. It also

providesameansofcomparingandevaluatingthissystemwith

2. Referenced Documents similar systems, as well as understanding the capabilities and

2 limitations of each instrument.

2.1 ASTM Standards:

E135 Terminology Relating to Analytical Chemistry for

5. Overview

Metals, Ores, and Related Materials

5.1 A DCP spectrometer is an instrument for determining

E158 Practice for Fundamental Calculations to Convert

Intensities into Concentrations in Optical Emission Spec- concentration of elements in solution. It typically is comprised

of several assemblies including a direct current (dc) electrical

trochemical Analysis (Withdrawn 2004)

E172 Practice for Describing and Specifying the Excitation source, a sample introduction system, components to form and

contain the plasma, an entrance slit, elements to disperse

SourceinEmissionSpectrochemicalAnalysis(Withdrawn

2001) radiation emitted from the plasma, one or more exit slits, one

or more photomultipliers for converting the emitted radiation

E406 Practice for Using Controlled Atmospheres in Spec-

trochemical Analysis into electrical current, one or more electrical capacitors for

storing this current as electrical charge, electrical circuitry for

E416 Practice for Planning and Safe Operation of a Spec-

trochemical Laboratory (Withdrawn 2005) measuring the voltage on each storage device, and a dedicated

computer with printer. The liquid sample is introduced into a

spray chamber at a right angle to a stream of argon gas. The

sampleisbrokenupintoafineaerosolbythisargonstreamand

This practice is under the jurisdiction of ASTM Committee E01 on Analytical

carriedintotheplasmaproducedbyadc-arcdischargebetween

Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.20 on Fundamental Practices.

a tungsten electrode and two or more graphite electrodes.

Current edition approved Dec. 1, 2012. Published December 2012. Originally

When the sample passes through the plasma, it is vaporized

approvedin1996.Lastpreviouseditionapprovedin2003asE1832 – 03,whichwas

and atomized, and many elements are ionized. Free atoms and

withdrawn October 2004 and reinstated in May 2008. DOI: 10.1520/E1832-08R12.

ions are excited from their ground states. When electrons of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

excited atoms and ions fall to a lower-energy state, photons of

Standards volume information, refer to the standard’s Document Summary page on

specific wavelengths unique to each emitting species are

the ASTM website.

emitted.Thisradiation,focussedbyalensontotheentranceslit

The last approved version of this historical standard is referenced on

www.astm.org. of the spectrometer and directed to an echelle grating and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1832 − 08 (2012)

quartz prism, is dispersed into higher orders of diffraction.

Control on the diffraction order is accomplished by the

low-dispersion echelle grating. Radiation of specific wave-

lengthorwavelengthspassesthroughexitslitsandimpingeson

a photomultiplier or photomultipliers. The current outputs

charge high-quality capacitors, and the voltages thus generated

are measured and directed to the computer. Using calibration

solutions, a calibration curve is generated for each element of

interest. The computer compares the signals arising from the

many elements in the sample to the appropriate calibration

curve and then calculates the concentration of each element.

Over seventy elements may be determined. Detection limits in

a simple aqueous solution are less than 1 mg/L for most of

these elements. Mineral acids or organic liquids also may be

used as solvents, and detection limits are usually within an

order of magnitude of those obtained with water. Detection

limits may be improved by using preconcentration procedures.

Solid samples are dissolved before analysis.

6. Description of Equipment

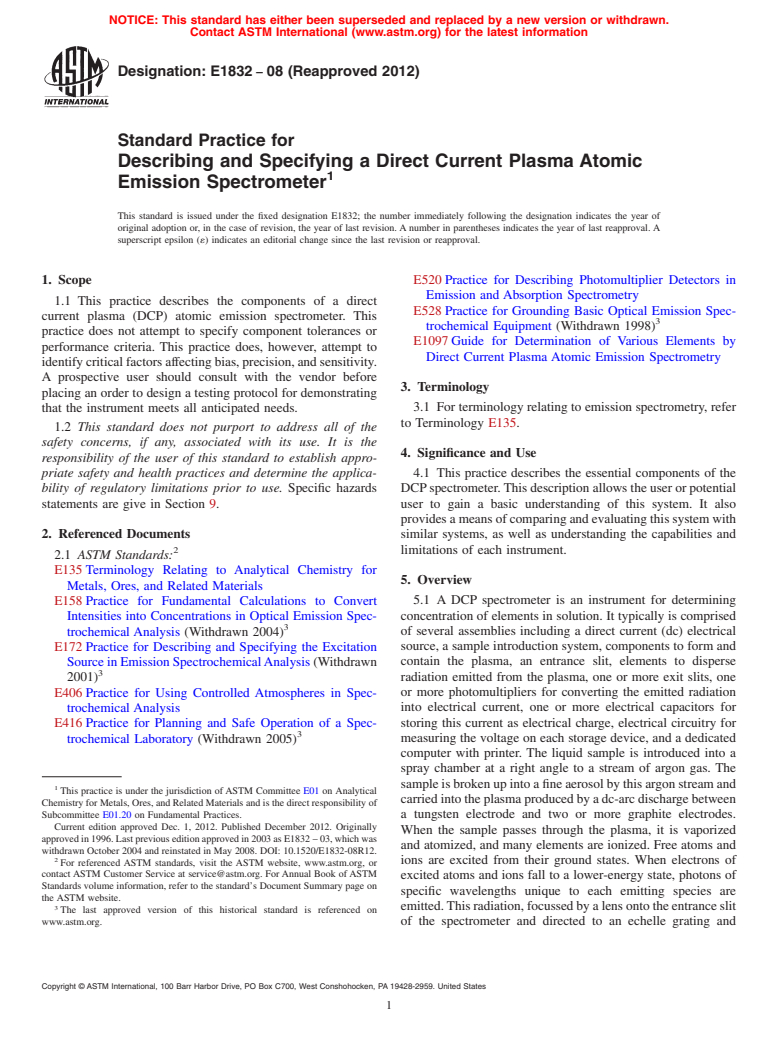

6.1 Echelle Spectrometer—Components of the equipment

shown in Fig. 1 and described in this section are typical of a

commercially available spectrometer.Although a specific spec-

trometer is described herein, other spectrometers having equal

or better performance may be satisfactory. The spectrometer is

FIG. 1 Echelle Grating Spectrometer

a Czerny-Turner mount and consists of a condensing lens in

front of an entrance slit, a collimating mirror, combined

dispersingelements(gratingandprism),focusmirror,exitslits,

corresponding photomultiplier. For single element capability,

photomultipliers, control panel, and wavelength selector

energy for one wavelength usually passes through its exit slit

mechanism.

directlytothephotomultiplierwithouttheneedforaperiscope.

6.1.1 CondensingLens, placed between the DCPsource and

Select the specific exit slit width before installation. Provide a

the entrance slit. It should have a focal length capable of

single channel cassette with one exit slit variable from 0.025

focusing an image of the source on the entrance slit and with

mm to 0.200 mm in width and from 0.100 mm to 0.500 mm in

sufficient diameter to fill the aperture of the spectrometer with

length.

radiant energy.

6.1.7 Photomultipliers, up to twenty end-on tubes, are

6.1.2 Entrance Slit, although available with fixed width and

mounted behind the focal plane in a fixed pattern. Consider

height, a slit variable in both width and height provides greater

sensitivity at specific wavelength and dark current in the

flexibility. Typical values are 0.025 mm to 0.500 mm in width

selection of appropriate photomultipliers. Provide variable

and 0.100 mm to 0.500 mm in height. Adjustable slit widths

voltage to each photomultiplier to change its response as

and heights are useful in obtaining optimal spectral band width

required by the specific application. A typical range is from

and radiant energy entering the spectrometer for the require-

550 V to 1000 V in 50-V steps. A survey of the properties of

ments of the analytical method.

photomultipliers is given in Practice E520.

6.1.3 Collimating Mirror, renders all rays parallel after

6.1.8 Control Panels, are provided to perform several func-

entering the spectrometer. These parallel rays illuminate the

tions and serve as input to microprocessors to control the

combined dispersing elements. The focal length and f number

operation of the spectrometer. Provide a numeric keyboard to

should be specified. Typical focal length and f number are 750

enter high and low concentrations of reference materials for

mm and f/13.

calibration and standardization of each channel and to display

6.1.4 Combined Dispersing Components, positioned so that

entered values for verification. Provide a switch on this panel

the radiant energy from the collimating mirror passes through

tosetthemodeeithertointegrateduringanalysisortomeasure

the prism, is refracted and reflected by a plane grating and back

instantaneous intensity. The latter mode is required to obtain

through the prism. Specify the ruling on the grating (for

the peak position for a specific channel by seeking maximum

example, 79 grooves/mm).

intensity by wavelength adjustment and verifying by wave-

6.1.5 Focus Mirror, placed to focus the radiant energy from

length scanning. Conduct interference and background inves-

the combined dispersing elements on a flat two-dimensional

tigations with this mode. Scanning is required if automatic

focal plane where the exit slits are located.

background correction is to be performed. Provide other

6.1.6 FixedExitSlits, mounted in a removable fixture called necessary switches for the following purposes: to calibrate or

an optical cassette for multielement capability. A two-mirror standardize the spectrometer, start analysis, interrupt the func-

periscope behind each exit slit directs the radiant energy to a tion being performed, set integration time and the number of

E1832 − 08 (2012)

replicate analyses, and direct the output to a printer, display, or

storage medium. Impose a fixed time delay of 10 s before

integration can begin to ensure that the solution being analyzed

is aspirated into the DCPdischarge. Provide digital and analog

voltmeters for displaying the instantaneous or integrated inten-

sities during peaking, scanning, or analysis. If a computer is an

integral part of the spectrometer, most of the control functions

are accomplished with software.

6.1.9 Wavelength Adjustment, provided to adjust the wave-

length range and diffraction order for peaking the spectrometer

because a two-dimensional spectrum is produced. Both coarse

and final control of these adjustments are required.To maintain

optical alignment, the spectrometer should be thermally iso-

lated from the DCP source or heated. A heated base on which

the spectrometer rests has been satisfactory for this purpose.

6.1.10 Dispersion and Spectral Band Pass—Typical disper-

sion and spectral band pass with a 0.025-mm slit width vary

from 0.061 nm/mm and 0.0015 nm at 200 nm to 0.244 nm/mm

and 0.0060 nm at 800 nm, respectively.

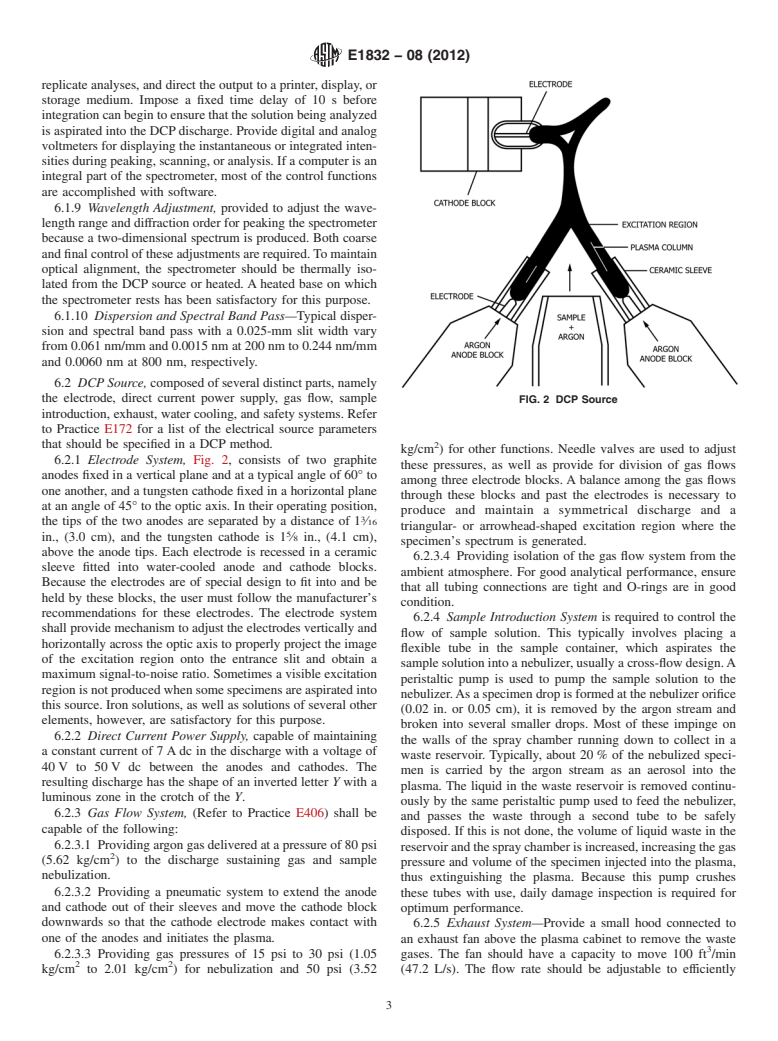

6.2 DCPSource, composed of several distinct parts, namely

the electrode, direct current power supply, gas flow, sample FIG. 2 DCP Source

introduction, exhaust, water cooling, and safety systems. Refer

to Practice E172 for a list of the electrical source parameters

that should be specified in a DCP method. 2

kg/cm ) for other functions. Needle valves are used to adjust

6.2.1 Electrode System, Fig. 2, consists of two graphite

these pressures, as well as provide for division of gas flows

anodes fixed in a vertical plane and at a typical angle of 60° to

among three electrode blocks. A balance among the gas flows

one another, and a tungsten cathode fixed in a horizontal plane

through these blocks and past the electrodes is necessary to

at an angle of 45° to the optic axis. In their operating position,

produce and maintain a symmetrical discharge and a

the tips of the two anodes are separated by a distance of 1 ⁄16

triangular- or arrowhead-shaped excitation region where the

in., (3.0 cm), and the tungsten cathode is 1 ⁄8 in., (4.1 cm),

specimen’s spectrum is generated.

above the anode tips. Each electrode is recessed in a ceramic

6.2.3.4 Providing isolation of the gas flow system from the

sleeve fitted into water-cooled anode and cathode blocks.

ambient atmosphere. For good analytical performance, ensure

Because the electrodes are of special design to fit into and be

that all tubing connections are tight and O-rings are in good

held by these blocks, the user must follow the manufacturer’s

condition.

recommendations for these electrodes. The electrode system

6.2.4 Sample Introduction System is required to control the

shall provide mechanism to adjust the electrodes vertically and

flow of sample solution. This typically involves placing a

horizontally across the optic axis to properly project the image

flexible tube in the sample container, which aspirates the

of the excitation region onto the entrance slit and obtain a

sample solution into a nebulizer, usually a cross-flow design.A

maximum signal-to-noise ratio. Sometimes a visible excitation

peristaltic pump is used to pump the sample solution to the

region is not produced when some specimens are aspirated into

nebulizer.As a specimen drop is formed at the nebulizer orifice

this source. Iron solutions, as well as solutions of several other

(0.02 in. or 0.05 cm), it is removed by the argon stream and

elements, however, are satisfactory for this purpose.

broken into several smaller drops. Most of these impinge on

6.2.2 Direct Current Power Supply, capable of maintaining

the walls of the spray chamber running down to collect in a

a constant current of 7 A dc in the discharge with a voltage of

waste reservoir. Typically, about 20 % of the nebulized speci-

40 V to 50 V dc between the anodes and cathodes. The

men is carried by the argon stream as an aerosol into the

resulting discharge has the shape of an inverted letter Y with a

plasma. The liquid in the waste reservoir is removed continu-

luminous zone in the crotch of the Y.

ously by the same peristaltic pump used to feed the nebulizer,

6.2.3 Gas Flow System, (Refer to Practice E406) shall be

and passes the waste through a second tube to be safely

capable of the following:

disposed. If this is not done, the volume of liquid waste in the

6.2.3.1 Providing argon gas delivered at a pressure of 80 psi

reservoirandthespraychamberisincreased,increasingthegas

(5.62 kg/cm ) to the discharge sustaining gas and sample

pressure and volume of the specimen injected into the plasma,

nebulization.

thus extinguishing the plasma. Because this pump crushes

6.2.3.2 Providing a pneumatic system to extend the anode

these tubes with use, daily damag

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.