ASTM D5494-93(2006)

(Test Method)Standard Test Method for the Determination of Pyramid Puncture Resistance of Unprotected and Protected Geomembranes

Standard Test Method for the Determination of Pyramid Puncture Resistance of Unprotected and Protected Geomembranes

SIGNIFICANCE AND USE

The pyramid method of puncture resistance is an index test for the determination of the puncture resistance of unprotected geomembranes or geomembranes protected with non-woven geotextiles and other puncture protective geosynthetics.

5.1.1 The purpose of this test method is to establish an index value of puncture resistance by providing standard criteria and a basis for uniform reporting.

This test method may be used for acceptance testing of commercial shipments of geomembranes and geomembranes protected with non-woven geotextiles; however, caution is advised since information about between laboratory precision is incomplete.

SCOPE

1.1 The test method is to be used as an index test to determine the pyramid puncture resistance of geomembranes and, or both, geomembranes protected by non-woven geotextiles and other puncture protective geosynthetics.

1.2 The test method measures the increase of the pyramid puncture resistance due to the use of protective non-woven geotextiles with geomembranes.

1.3 The values stated in SI units are to be regarded as the standard value. The values stated in parentheses are provided for information only.

This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5494 – 93 (Reapproved 2006)

Standard Test Method for the

Determination of Pyramid Puncture Resistance of

Unprotected and Protected Geomembranes

This standard is issued under the fixed designation D5494; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2.1 Discussion—In geotechnical engineering, essen-

tially impermeable means that no measurable liquid flows

1.1 The test method is to be used as an index test to

through a geosynthetic when tested in accordance with Test

determine the pyramid puncture resistance of geomembranes

Method D4491.

and, or both, geomembranes protected by non-woven geotex-

3.1.3 geotextile, n—a permeable geosynthetic comprised

tiles and other puncture protective geosynthetics.

solely of textiles.

1.2 The test method measures the increase of the pyramid

3.1.3.1 Discussion—Current manufacturing techniques pro-

puncture resistance due to the use of protective non-woven

duce non-woven fabrics, knitted (non-tubular) fabrics, and

geotextiles with geomembranes.

woven fabrics.

1.3 The values stated in SI units are to be regarded as the

3.1.4 For other terms, see Terminology D4439.

standard value. The values stated in parentheses are provided

for information only.

4. Summary of Test Method

1.4 This standard does not purport to address all of the

4.1 A test specimen is clamped without tension between

safety problems, if any, associated with its use. It is the

circular plates of a ring clamp attachment secured in a

responsibility of the user of this standard to establish appro-

compressionpressortensiletestingmachine.Aforceisexerted

priate safety and health practices and determine the applica-

against the center of the unsupported or supported portion of

bility of regulatory limitations prior to use.

the test specimen by a solid steel pyramid attached to a load

2. Referenced Documents indicator until rupture of the specimen occurs. The maximum

load and elongation recorded is the value of the puncture

2.1 ASTM Standards:

resistance of the specimen.

D76 Specification for Tensile Testing Machines for Textiles

D4354 Practice for Sampling of Geosynthetics for Testing

5. Significance and Use

D4439 Terminology for Geosynthetics

5.1 The pyramid method of puncture resistance is an index

D4491 Test Methods for Water Permeability of Geotextiles

test for the determination of the puncture resistance of unpro-

by Permittivity

tected geomembranes or geomembranes protected with non-

3. Terminology woven geotextiles and other puncture protective geosynthetics.

5.1.1 Thepurposeofthistestmethodistoestablishanindex

3.1 Definitions:

value of puncture resistance by providing standard criteria and

3.1.1 atmosphere for testing geosynthetics, n—air main-

a basis for uniform reporting.

tained at a relative humidity between 50 to 70 % and a

5.2 This test method may be used for acceptance testing of

temperature of 21 6 2°C (70 6 4°F).

commercial shipments of geomembranes and geomembranes

3.1.2 geomembrane, n—an essentially impermeable geo-

protected with non-woven geotextiles; however, caution is

synthetic composed of one or more synthetic sheets.

advised since information about between laboratory precision

is incomplete.

This test method is under the jurisdiction of ASTM Committee D35 on 6. Apparatus

Geosynthetics and is the direct responsibility of D35.10 on Geomembranes.

6.1 Test Set Up—A compression press with a reading force

Current edition approved July 1, 2006. Published September 2006. Originally

e1

accuracy of at least 2 N (0.5 lb) is necessary. The press must

approved in 1993. Last previous edition approved in 1999 as D5494–93(1999) .

DOI: 10.1520/D5494-93R06.

maintain a constant test speed and should be provided with an

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

automaticchartrecorderfortheforcevs.deformationbehavior.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A clamping device for the test sample, a special piston and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. electrical signal equipment for determining the puncture load

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5494 – 93 (2006)

are the additional pieces of test equipment needed. Also, a shallberoundedoffwitharadiusof0.1mm 60.01mm(0.004

tensile testing machine conforming to the requirements of in. 6 0.0004 in.). The transitional edge from the base of the

Specification D76 can be utilized in a compression mode for pyramidtothecylindershallhavearadius(R)of3.0mm 60.1

this test method. The equipment set up shall provide a constant mm (0.12 in.6 0.004 in.).

rate of speed, reading accuracy of at least 2 N (0.5 lb) and be 6.6 Electrical Equipment for the Determination of the Punc-

provided with an automatic chart recorder for load vs. defor- ture Load—An electrical circuit is to be employed between the

mation. Additional equipment required by this test method is loading piston and the underlying medium (water or aluminum

described below. plate) such that puncture resistance load at failure can be

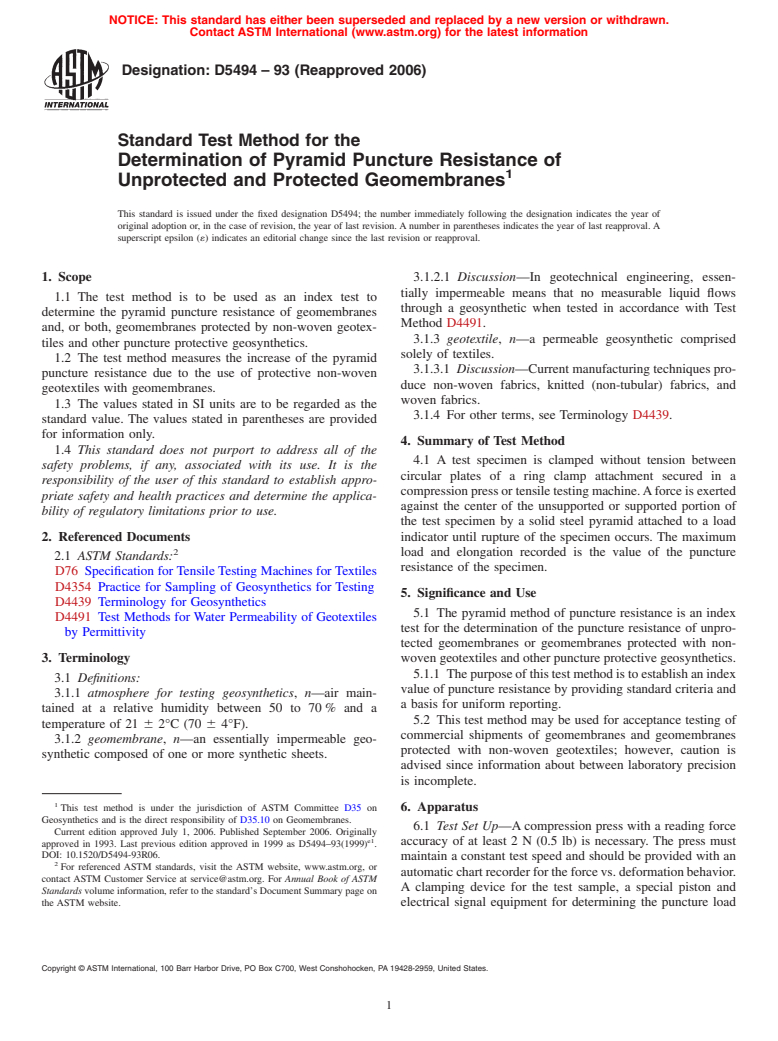

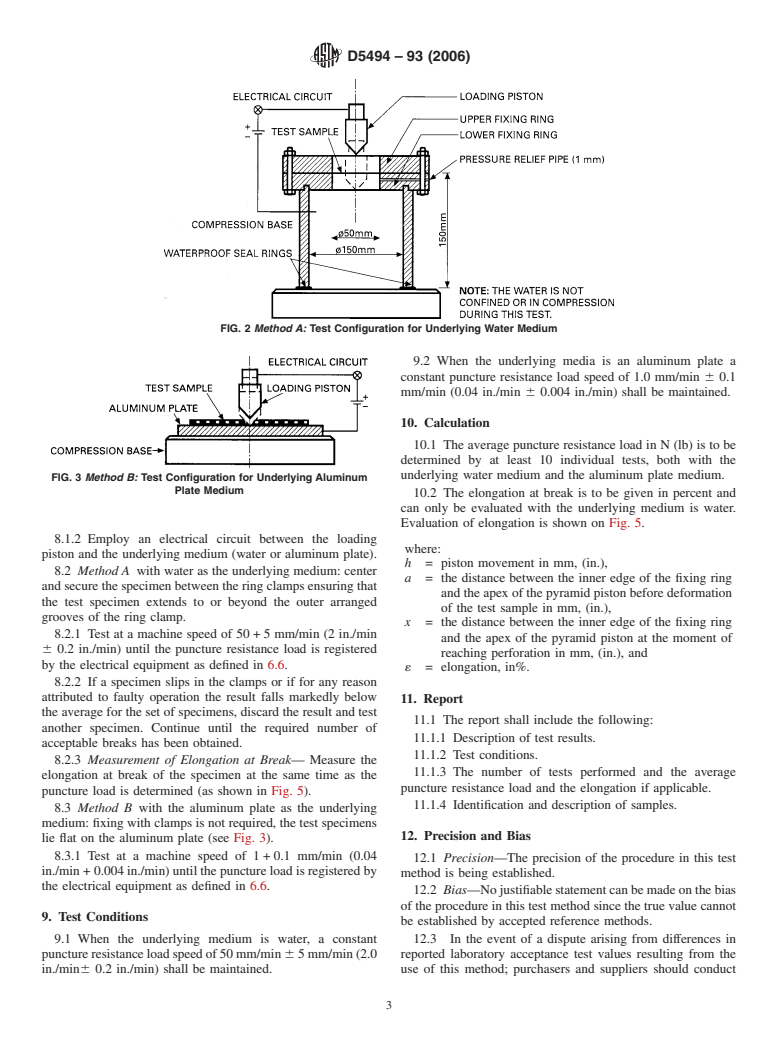

6.2 Clamping Device—The upper and lower fixing ring determined. The electrical circuit, which is closed at the

clamp, dimensions of which are shown on Fig. 1a and 1b. The moment of puncture, can be connected to a signal lamp and the

lower fixing ring shall be provided with a circular recess with puncture resistance load can be recorded at failure.

a diameter corresponding to the external diameter of the

7. Sampling

compression base. This will facilitate mounting of the lower

fixing ring to the compression base as illustrated on Fig. 2. 7.1 Lot Sample—Divide the product into lots and take the

Concentrically arranged grooves shall be located on the lower lot sample as directed in Practice D4354.

face of the upper ring and upper face of the lower ring to 7.2 Laboratory Sample—For the laboratory sample take a

facilitate non-slip clamping of the test specimen(s). swatch extending the full width of the geosynthetic, of suffi-

6.3 Compression Base (Fig. 2)—CBR type test presses are cient length from each sample roll so that the requirements of

normally equipped with a CBR-cylinder compression base Sections 7.3 and 9 can be met. Take a sample that will exclude

having a diameter of 150 mm (6.0 in.) as shown on Fig. 2. material from the outer wrap and inner wrap around the core

Additionally, the compression base must be deep enough to unless the sample is taken at the production site, in which case

allow the loading piston to plunge at least 100 mm (4.0 in.). inner and outer wrap material may be used.

The compression base should be manufactured of rust resistant 7.3 Test for underlying water medium: The test specimen

high-grade steel. shall be cut out with a punch with a diameter greater than 80

6.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.