ASTM G38-01

(Practice)Standard Practice for Making and Using C-Ring Stress-Corrosion Test Specimens

Standard Practice for Making and Using C-Ring Stress-Corrosion Test Specimens

SCOPE

1.1 This practice describes the essential features of the design and machining, and procedures for stressing, exposing, and inspecting C-ring type of stress-corrosion test speci- mens. An analysis is given of the state and distribution of stress in the C-ring.

1.2 Specific considerations relating to the sampling process and to the selection of appropriate test environments are outside the scope of this practice.

1.3 The values stated in SI units are to be regarded as standard. The inch-pound units are provided for information.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 38 – 01

Standard Practice for

1

Making and Using C-Ring Stress-Corrosion Test Specimens

ThisstandardisissuedunderthefixeddesignationG38;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope tubingandrodandformakingshort-transversetestsofvarious

products as illustrated for plate in Fig. 1.

1.1 This practice describes the essential features of the

design and machining, and procedures for stressing, exposing,

5. Sampling

and inspecting C-ring type of stress-corrosion test specimens.

5.1 Test specimens shall be taken from a location and with

Ananalysisisgivenofthestateanddistributionofstressinthe

an orientation so that they adequately represent the material to

C-ring.

be tested.

1.2 Specific considerations relating to the sampling process

5.2 In testing thick sections that have a directional grain

and to the selection of appropriate test environments are

structure, it is essential that the C-ring be oriented in the

outside the scope of this practice.

section so that the direction of principal stress (parallel to the

1.3 The values stated in SI units are to be regarded as

stressing bolt) is in the direction of minimum resistance to

standard. The inch-pound units are provided for information.

stress-corrosion cracking. For example, in the case of alumi-

1.4 This standard does not purport to address all of the

3

numalloys (1), thisistheshort-transversedirectionrelativeto

safety concerns, if any, associated with its use. It is the

the grain structure. If the ring is not so oriented it will tend to

responsibility of the user of this standard to establish appro-

crack off-center at a location where the stress is unknown.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

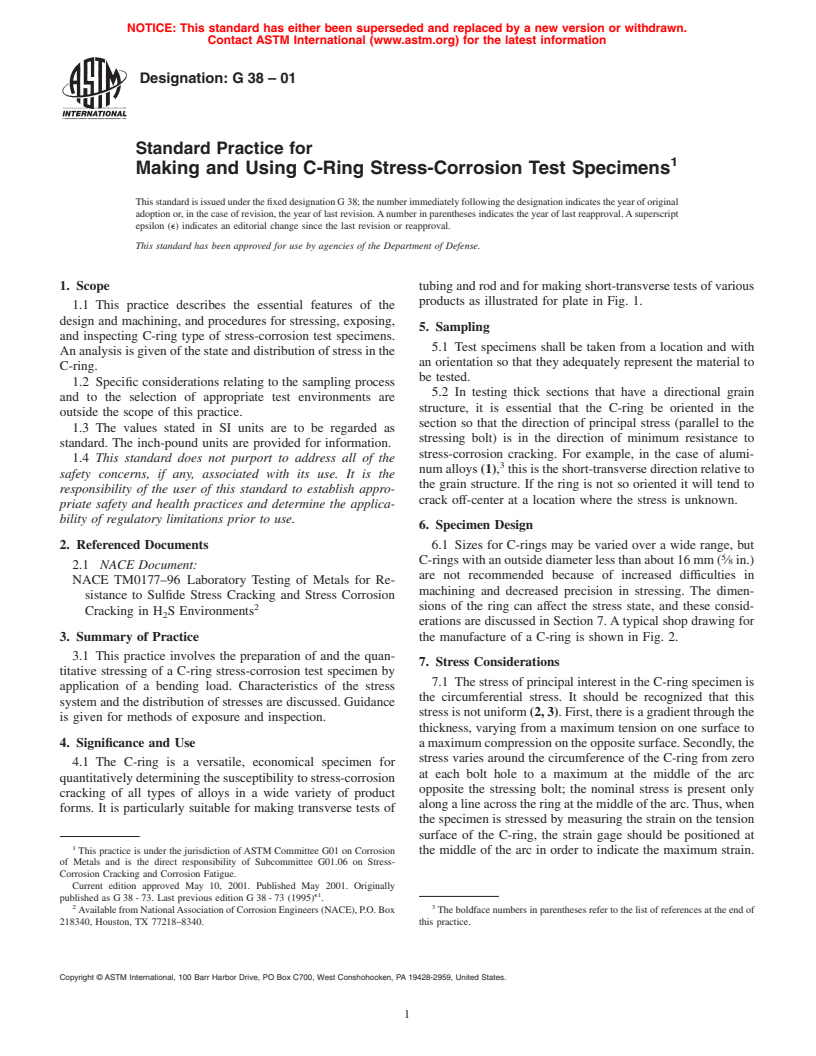

6. Specimen Design

6.1 Sizes for C-rings may be varied over a wide range, but

2. Referenced Documents

5

C-ringswithanoutsidediameterlessthanabout16mm( ⁄8in.)

2.1 NACE Document:

are not recommended because of increased difficulties in

NACE TM0177–96 Laboratory Testing of Metals for Re-

machining and decreased precision in stressing. The dimen-

sistance to Sulfide Stress Cracking and Stress Corrosion

2 sions of the ring can affect the stress state, and these consid-

Cracking in H S Environments

2

erations are discussed in Section 7.Atypical shop drawing for

3. Summary of Practice the manufacture of a C-ring is shown in Fig. 2.

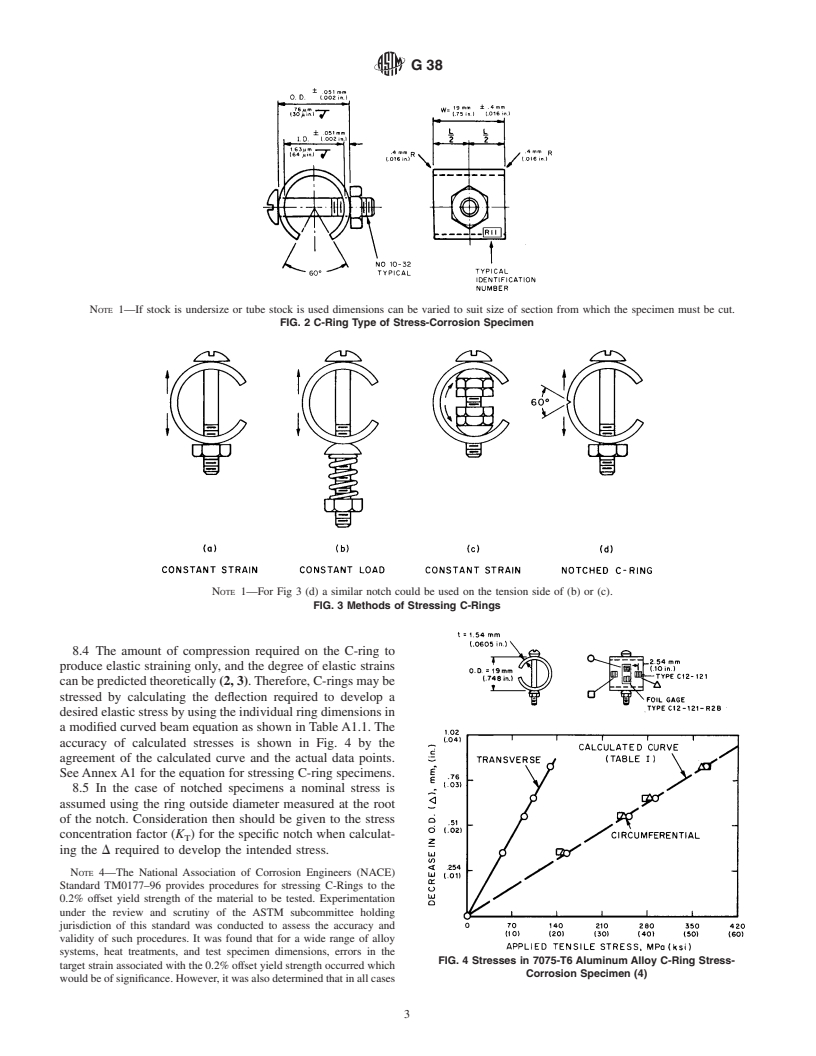

3.1 This practice involves the preparation of and the quan-

7. Stress Considerations

titative stressing of a C-ring stress-corrosion test specimen by

7.1 The stress of principal interest in the C-ring specimen is

application of a bending load. Characteristics of the stress

the circumferential stress. It should be recognized that this

system and the distribution of stresses are discussed. Guidance

stressisnotuniform(2,3).First,thereisagradientthroughthe

is given for methods of exposure and inspection.

thickness, varying from a maximum tension on one surface to

4. Significance and Use amaximumcompressionontheoppositesurface.Secondly,the

stress varies around the circumference of the C-ring from zero

4.1 The C-ring is a versatile, economical specimen for

at each bolt hole to a maximum at the middle of the arc

quantitativelydeterminingthesusceptibilitytostress-corrosion

opposite the stressing bolt; the nominal stress is present only

cracking of all types of alloys in a wide variety of product

alongalineacrosstheringatthemiddleofthearc.Thus,when

forms. It is particularly suitable for making transverse tests of

the specimen is stressed by measuring the strain on the tension

surface of the C-ring, the strain gage should be positioned at

1

This practice is under the jurisdiction ofASTM Committee G01 on Corrosion the middle of the arc in order to indicate the maximum strain.

of Metals and is the direct responsibility of Subcommittee G01.06 on Stress-

Corrosion Cracking and Corrosion Fatigue.

Current edition approved May 10, 2001. Published May 2001. Originally

e1

published as G38-73. Last previous edition G38-73 (1995) .

2 3

AvailablefromNationalAssociationofCorrosionEngineers(NACE),P.O.Box Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

218340, Houston, TX 77218–8340. this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

G38

7.4 The possibility of residual stress should always be

considered, especially when C-rings are machined from prod-

ucts that contai

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.