ASTM G38-01(2007)

(Practice)Standard Practice for Making and Using C-Ring Stress-Corrosion Test Specimens

Standard Practice for Making and Using C-Ring Stress-Corrosion Test Specimens

SIGNIFICANCE AND USE

The C-ring is a versatile, economical specimen for quantitatively determining the susceptibility to stress-corrosion cracking of all types of alloys in a wide variety of product forms. It is particularly suitable for making transverse tests of tubing and rod and for making short-transverse tests of various products as illustrated for plate in Fig. 1.

FIG. 1 Sampling Procedure for Testing Various Products

SCOPE

1.1 This practice covers the essential features of the design and machining, and procedures for stressing, exposing, and inspecting C-ring type of stress-corrosion test specimens. An analysis is given of the state and distribution of stress in the C-ring.

1.2 Specific considerations relating to the sampling process and to the selection of appropriate test environments are outside the scope of this practice.

1.3 The values stated in SI units are to be regarded as the standard; The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G38 − 01(Reapproved 2007)

Standard Practice for

Making and Using C-Ring Stress-Corrosion Test Specimens

ThisstandardisissuedunderthefixeddesignationG38;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope cracking of all types of alloys in a wide variety of product

forms. It is particularly suitable for making transverse tests of

1.1 This practice covers the essential features of the design

tubingandrodandformakingshort-transversetestsofvarious

and machining, and procedures for stressing, exposing, and

products as illustrated for plate in Fig. 1.

inspecting C-ring type of stress-corrosion test specimens. An

analysis is given of the state and distribution of stress in the

5. Sampling

C-ring.

5.1 Test specimens shall be taken from a location and with

1.2 Specific considerations relating to the sampling process

an orientation so that they adequately represent the material to

and to the selection of appropriate test environments are

be tested.

outside the scope of this practice.

5.2 In testing thick sections that have a directional grain

1.3 The values stated in SI units are to be regarded as

structure, it is essential that the C-ring be oriented in the

standard. The values given in parentheses are for information

section so that the direction of principal stress (parallel to the

only.

stressing bolt) is in the direction of minimum resistance to

1.4 This standard does not purport to address all of the

stress-corrosion cracking. For example, in the case of alumi-

safety concerns, if any, associated with its use. It is the

numalloys (1), thisistheshort-transversedirectionrelativeto

responsibility of the user of this standard to establish appro-

the grain structure. If the ring is not so oriented it will tend to

priate safety and health practices and determine the applica-

crack off-center at a location where the stress is unknown.

bility of regulatory limitations prior to use.

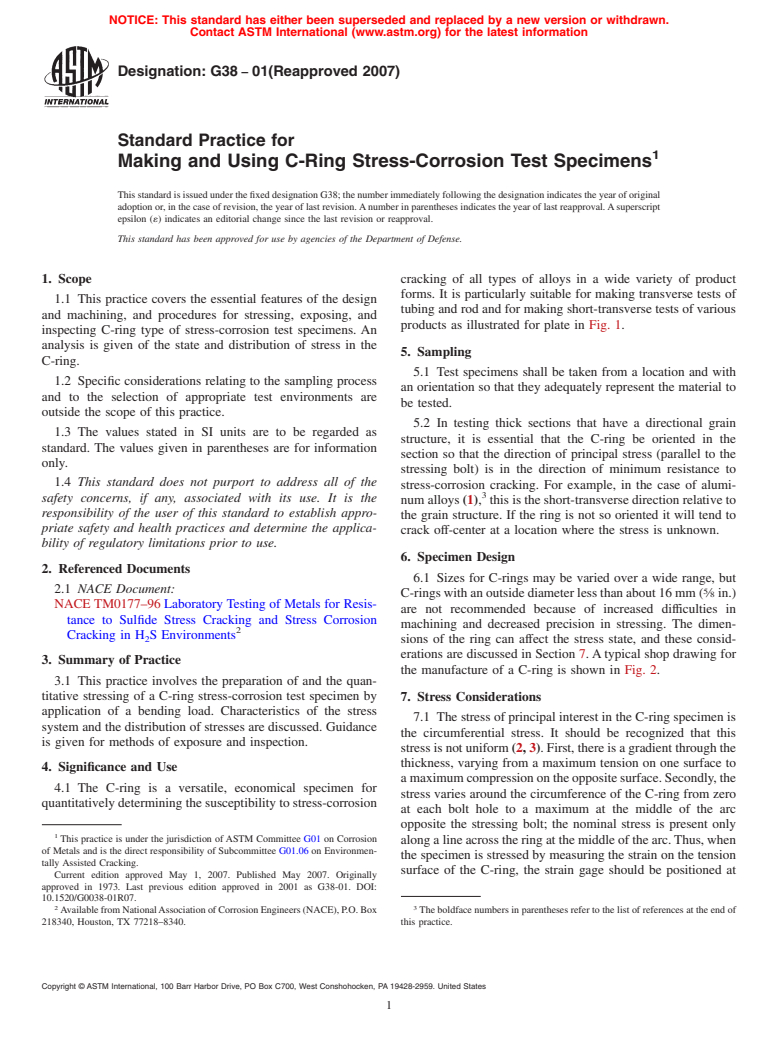

6. Specimen Design

2. Referenced Documents

6.1 Sizes for C-rings may be varied over a wide range, but

2.1 NACE Document: 5

C-ringswithanoutsidediameterlessthanabout16mm( ⁄8in.)

NACE TM0177–96Laboratory Testing of Metals for Resis-

are not recommended because of increased difficulties in

tance to Sulfide Stress Cracking and Stress Corrosion

machining and decreased precision in stressing. The dimen-

Cracking in H S Environments

2 sions of the ring can affect the stress state, and these consid-

erations are discussed in Section 7.Atypical shop drawing for

3. Summary of Practice

the manufacture of a C-ring is shown in Fig. 2.

3.1 This practice involves the preparation of and the quan-

titative stressing of a C-ring stress-corrosion test specimen by

7. Stress Considerations

application of a bending load. Characteristics of the stress

7.1 The stress of principal interest in the C-ring specimen is

system and the distribution of stresses are discussed. Guidance

the circumferential stress. It should be recognized that this

is given for methods of exposure and inspection.

stressisnotuniform (2, 3).First,thereisagradientthroughthe

thickness, varying from a maximum tension on one surface to

4. Significance and Use

amaximumcompressionontheoppositesurface.Secondly,the

4.1 The C-ring is a versatile, economical specimen for

stress varies around the circumference of the C-ring from zero

quantitativelydeterminingthesusceptibilitytostress-corrosion

at each bolt hole to a maximum at the middle of the arc

opposite the stressing bolt; the nominal stress is present only

This practice is under the jurisdiction ofASTM Committee G01 on Corrosion

alongalineacrosstheringatthemiddleofthearc.Thus,when

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen-

the specimen is stressed by measuring the strain on the tension

tally Assisted Cracking.

surface of the C-ring, the strain gage should be positioned at

Current edition approved May 1, 2007. Published May 2007. Originally

approved in 1973. Last previous edition approved in 2001 as G38-01. DOI:

10.1520/G0038-01R07.

AvailablefromNationalAssociationofCorrosionEngineers(NACE),P.O.Box Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

218340, Houston, TX 77218–8340. this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G38 − 01 (2007)

be greater than the nominal stress and generally may be

expected to be in the plastic range.

7.4 The possibility of residual stress should always be

considered, especially when C-rings are machined from prod-

ucts that contain appreciable residual stress or when C-rings

over about 6.35 mm ( ⁄4 in.) thick are heat treated after being

machined. It is generally not advisable to heat treat finish-

machined C-rings because of the likelihood of developing

residual stresses in the ring.

NOTE 1—When specimens are exposed to corrosive media at elevated

temperatures, the possibility of relaxation of stress during the exposure

period should be investigated. Relaxation can be estimated from known

creep data for both the ring and the stressing bolt.

7.5 AnadvantageoftheC-ringisthatitcanbestressedwith

high precision and bias by application of a measured deflec-

tion.Thesourcesoferrorinstressingarethosethatareinherent

with the use of measuring instruments (micrometers, strain

gages, etc.) as discussed in 7.2-7.4 and Annex A1.

7.6 The calculated stress applies only to the state of stress

before initiation of cracks. Once cracking has initiated the

stress at the tip of the crack, as well as in uncracked areas, has

changed.

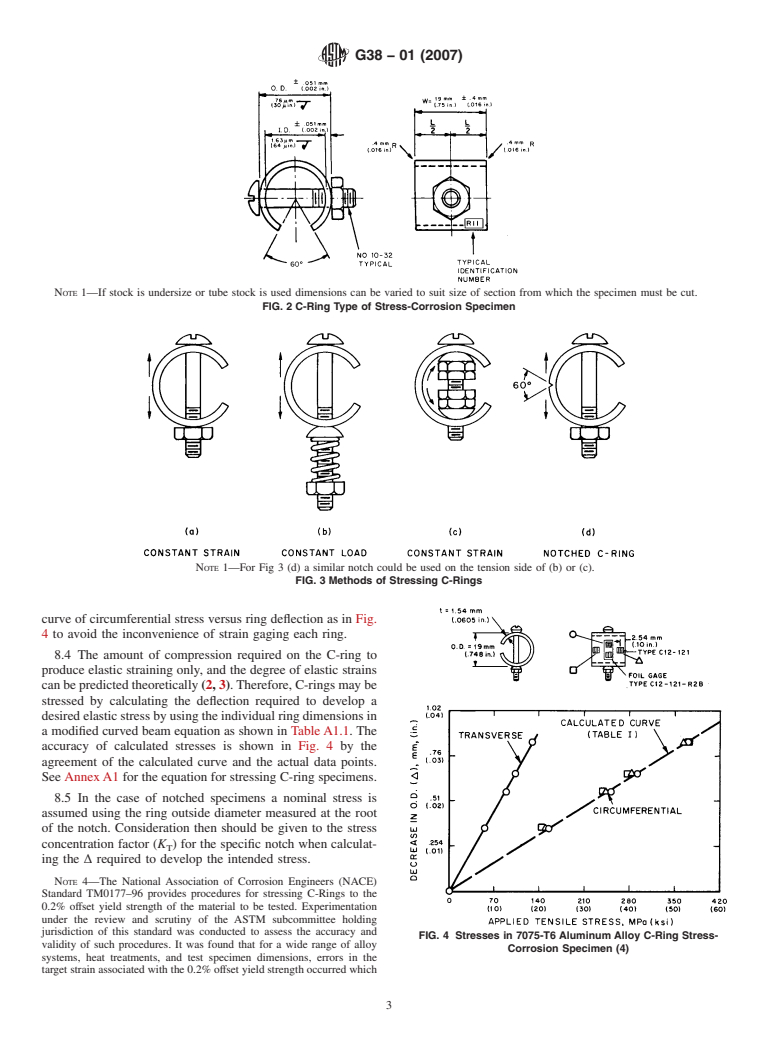

8. Stressing Methods

8.1 The C-ring, as generally used, is a constant-strain

specimen with tensile stress produced on the exterior of the

ring by tightening a bolt centered on the diameter of the ring.

FIG. 1 Sampling Procedure for Testing Various Products However,anearlyconstantloadcanbedevelopedbytheuseof

a calibrated spring placed on the loading bolt. C-rings also can

be stressed in the reverse direction by spreading the ring and

the middle of the arc in order to indicate the maximum strain.

creatingatensilestressontheinsidesurface.Thesemethodsof

Thirdly,thecircumferentialstressmayvaryacrossthewidthof

stressing are illustrated in Fig. 3. Proper choice of a minimum

the ring, the extent of the variation depending on the width-

bolt diameter or a spring constant is, of course, required to

to-thickness and diameter-to-thickness ratios of the C-ring. In

assure achieving true constant strain or constant load stressing.

general,whenloadedasshowninFig.3(a,b),thetensilestress

on the outer surface will be greater at the extreme edge than at

8.2 The most accurate stressing procedure is to attach

thecenter,whilewhenloadedasshowninFig.3(c),thetensile

circumferential and transverse electrical strain gages to the

stress on the inner surface will be less at the edge than at the

surfacestressedintensionandtotightentheboltuntilthestrain

4).

center (

measurements indicate the desired circumferential stress. The

7.2 Another characteristic of the stress system in the C-ring circumferential (σ ) and transverse (σ ), stresses are calcu-

C T

is the presence of biaxial stresses; that is, transverse as well as

lated as follows:

circumferential stresses are developed on the critical test

σ 5 E/~1 2 µ !·~ϵ 1µϵ !, and

C C T

section.The transverse stress will vary from a maximum at the

σ 5 E/~1 2 µ !·~ϵ 1µϵ !

T T C

mid-widthtozeroattheedges,andwillbethesamesignasthe

where:

circumferential stress. In general, the transverse stress may be

E = Young’s modulus of elasticity,

expected to decrease with decreasing width to thickness and

µ = Poisson’s ratio,

increasingdiametertothicknessratios.Anexampleisshownin

´ = circumferential strain, and

Fig. 4 where the transverse tensile stress at the mid-width of a C

´ = transverse strain.

T

19.00 mm (0.748 in.) outside diameter by 1.537 mm (0.0605

NOTE2—Whenusingelectricalstraingageswiththin-walledC-rings,a

in.)thickby19.0mm(0.75in.)wideC-ringofaluminumalloy

correction should be allowed for the displacement of the gage from the

7075-T6 was equal to about one third of the circumferential

surface of the ring. All traces of the gage and the adhesive must be

tensile stress. In this example the circumferential stress was

removed from the C-ring before it is exposed.

uniform over most of the width of the C-ring; measurements

NOTE 3—Stresses may be calculated from measured strains using the

were not made at the extreme edge.

modulus of elasticity, provided the stresses and strains do not exceed the

proportional limit.

7.3 In the case of the notched C-ring (Fig. 3(d)) a triaxial

stress state is present adjacent to the root of the notch (5).In 8.3 When several rings of the same alloy and dimensions

addition, the circumferential stress at the root of the notch will are to be loaded, it is convenient to determine a calibration

G38 − 01 (2007)

NOTE 1—If stock is undersize or tube stock is used dimensions can be varied to suit size of section from which the specimen must be cut.

FIG. 2 C-Ring Type of Stress-Corrosion Specimen

NOTE 1—For Fig 3 (d) a similar notch could be used on the tension side of (b) or (c).

FIG. 3 Methods of Stressing C-Rings

curve of circumferential stress versus ring deflection as in Fig.

4 to avoid the inconvenience of strain gaging each ring.

8.4 The amount of compression required on the C-ring to

produce elastic straining only, and the degree of elastic strains

canbepredictedtheoretically (2, 3).Therefore,C-ringsmaybe

stressed by calculating the deflection required to develop a

desiredelasticstressbyusingtheindividualringdimensionsin

a modified curved beam equation as shown in TableA1.1.The

accuracy of calculated stresses is shown in Fig. 4 by the

agreement of the calculated curve and the actual data points.

See AnnexA1 for the equation for stressing C-ring specimens.

8.5 In the case of notched specimens a nominal stress is

assumed using the ring outside diameter measured at the root

of the notch. Consideration then should be given to the stress

concentration factor (K ) for the specific notch when calculat-

T

ing the ∆ required to develop the intended stress.

NOTE 4—The National Association of Corrosion Engineers (NACE)

Standard TM0177–96 provides procedures for stressing C-Rings to the

0.2% offset yield strength of the material to be tested. Experimentation

under the review and scrutiny of the ASTM subcommittee holding

jurisdiction of this standard was conducted to assess the accuracy and

FIG. 4 Stresses in 7075-T6 Aluminum Alloy C-Ring Stress-

validity of such procedures. It was found that for a wide range of alloy

Corrosion Specimen (4)

systems, heat treatments, and test specimen dimensions, errors in the

target strain associated with the 0.2% offset yield strength occurred which

G38 − 01 (2007)

FIG. 5 Protection Against Galvanic Effects

wouldbeofsignificance.However,itwasalsodeterminedthatinallcases

corrosiveenvironment (6).Thespecimensshouldbesupported

the actual strain realized following the procedures exceeded that associ-

insuchawaythatnothingexceptthecorrosivemediumcomes

ated with the 0.2% offset yield stress, rendering results following such

in contact with the critically stressed area. No part of an

procedures conservative from an engineering analysis standpoint.

exposure rack should be allowed to touch the surface or the

9. Machining

edges of the critically stressed region.

9.1 When rings are machined from solid stock, precautions

12.2 Care must be exercised to avoid galvanic effects

should be taken to avoid practices that overheat, plastically

betweentheC-ring,thestressingbolt,andexposureracks.Itis

deform, or develop residual stress in the metal surface.

essential also to prevent crevice corrosion that could develop

Machining should be done in stages so that the final cut leaves

corrosion products between ring and bolt and alter the stress in

theprincipalsurfacewithacleanfinishof0.7µm(30µin.)rms

the C-ring. Protection can readily be applied by means of

or better. Necessary machining sequences, type of tool, feed

suitable coatings or by insulating bushing as shown in Fig. 5.

rate, etc., depend upon the alloy and temper of the test piece.

Consideration must be given to the selection of coatings or

Lapping, mechanical polishing, and similar operations that

insulators that will neither contaminate the corroding medium

produce flow of the metal should be avoided.

nor be deteriorated by it. An insulating bushing, for example,

that would deteriorate or creep, and thus allow the stress in the

10. Surface Preparation

specimen to decrease, would be unsatisfactory.

10.1 A high-quality machined surface is the most desirable

NOTE 5—Specimens should be placed in the intended corrosive

for corrosion test purposes unless one wants to test the

environment as soon as possible after being stressed, as some alloys may

as-fabricated surface of a tube or bar; it should, of course, be

crack in moderately humid air.

degreased before exposing the specimen. In order to remove

NOTE 6—Hemispheric glazed ceramic insulators (S-151 Steatite) are

excellentforuseoutdoorsandinneutralaqueoussolutions. Beeswax,and

heat treat films or thin layers of surface metal that may have

other adherent wax-type coatings, are suitable for room temperature tests

become distorted during machining, chemical or electrochemi-

in aqueous solutions. For tests in acidic or alkaline solutions, fast drying

cal etches may be used. The choice of such a treatment will

vinyl-type lacquers have been used successfully; an example is an

depend upon the alloy of the test piece. Care should be

electroplaters stop-off.

exercised to choose an etchant that will not selectively attack

12.3 Determination of cracking time is a subjective proce-

constituents in the metal or will not deposit undesirable

dure involving visual examination that under some conditions

residues on the surface. Etching or pickling should not be used

canbeverydifficult,asnotedinSection13,anddependsonthe

for alloys that may undergo hydrogen embrittlement.

skill and experience of the inspector.

10.2 It is generally the best procedure to complete the

surface preparation before the C-ring is stressed except for a

13. Inspection

possible final degreasing of the critically stressed area.

13.1 Highly stressed C-rings of alloys that are appreciably

10.3 Every precaution should be taken to maint

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.