ASTM C1648-06

(Guide)Standard Guide for Choosing a Method for Determining the Index of Refraction and Dispersion of Glass

Standard Guide for Choosing a Method for Determining the Index of Refraction and Dispersion of Glass

SCOPE

1.1 This guide identifies and describes seven test methods for measuring the index of refraction of glass, with comments relevant to their uses such that an appropriate choice of method can be made. Four additional methods are mentioned by name, and brief descriptive information is given in Annex A1. The choice of a test method will depend upon the accuracy required, the nature of the test specimen that can be provided, the instrumentation available, and (perhaps) the time required for, or the cost of, the analysis. Refractive index is a function of the wavelength of light; therefore, its measurement is made with narrow-bandwidth light. Dispersion is the physical phenomenon of the variation of refractive index with wavelength. The nature of the test-specimen refers to its size, form, and quality of finish, as described in each of the methods herein. The test methods described are mostly for the visible range of wavelengths (approximately 400 to 780m); however, some methods can be extended to the ultraviolet and near infrared, using radiation detectors other than the human eye.

1.1.1 List of test methods included in this guide:

Becke line (method of central illumination),

Apparent depth of microscope focus (the method of the Duc de Chaulnes),

Critical Angle Refractometers (Abbe type and Pulfrich type),

Metricon system,

Vee-block refractometers,

Prism spectrometer, and

Specular reflectance.

1.1.2 Test methods presented by name only (see Annex A1):

Immersion refractometers,

Interferometry,

Ellipsometry, and

Method of oblique illumination.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.2 Warning-Refractive index liquids are used in several of the following test methods. Cleaning with organic liquid solvents also is specified. Degrees of hazard associated with the use of these materials vary with the chemical nature, volatility, and quantity used. See manufacturer's literature and general information on hazardous chemicals.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1648 − 06

StandardGuide for

Choosing a Method for Determining the Index of Refraction

and Dispersion of Glass

This standard is issued under the fixed designation C1648; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This guide identifies and describes seven test methods

responsibility of the user of this standard to establish appro-

for measuring the index of refraction of glass, with comments

priate safety and health practices and determine the applica-

relevanttotheirusessuchthatanappropriatechoiceofmethod

bility of regulatory limitations prior to use.

canbemade.Fouradditionalmethodsarementionedbyname,

1.3 Warning—Refractive index liquids are used in several

and brief descriptive information is given in Annex A1. The

of the following test methods. Cleaning with organic liquid

choice of a test method will depend upon the accuracy

solvents also is specified. Degrees of hazard associated with

required, the nature of the test specimen that can be provided,

the use of these materials vary with the chemical nature,

the instrumentation available, and (perhaps) the time required

volatility, and quantity used. See manufacturer’s literature and

for, or the cost of, the analysis. Refractive index is a function

general information on hazardous chemicals.

of the wavelength of light; therefore, its measurement is made

with narrow-bandwidth light. Dispersion is the physical phe-

2. Referenced Documents

nomenon of the variation of refractive index with wavelength.

2.1 ASTM Standards:

The nature of the test-specimen refers to its size, form, and

E167Practice for Goniophotometry of Objects and Materi-

quality of finish, as described in each of the methods herein.

als (Withdrawn 2005)

The test methods described are mostly for the visible range of

E456Terminology Relating to Quality and Statistics

wavelengths (approximately 400 to 780µm); however, some

methods can be extended to the ultraviolet and near infrared,

3. Terminology

using radiation detectors other than the human eye.

3.1 Definitions:

1.1.1 List of test methods included in this guide:

3.1.1 dispersion, n—the physical phenomenon of the varia-

1.1.1.1 Becke line (method of central illumination),

tion of refractive index with wavelength.

1.1.1.2 Apparent depth of microscope focus (the method of

3.1.1.1 Discussion—The term, “dispersion,” is commonly

the Duc de Chaulnes),

used in lieu of the more complete expression, “reciprocal

1.1.1.3 Critical Angle Refractometers (Abbe type and Pul-

relative partial dispersion.” A dispersion-number can be de-

frich type),

fined to represent the refractive index as a function of wave-

1.1.1.4 Metricon system,

length over a selected wavelength-range; that is, it is a

1.1.1.5 Vee-block refractometers,

combined measure of both the amount that the index changes

1.1.1.6 Prism spectrometer, and

and the non-linearity of the index versus wavelength relation-

1.1.1.7 Specular reflectance.

ship.

1.1.2 Testmethodspresentedbynameonly(seeAnnexA1):

3.1.2 resolution, n—as expressed in power of 10, a com-

1.1.2.1 Immersion refractometers,

monly used term used to express the accuracy of a test method

1.1.2.2 Interferometry,

intermsofthedecimalplaceofthelastreliablymeasureddigit

1.1.2.3 Ellipsometry, and

of the refractive index which is expressed as the negative

1.1.2.4 Method of oblique illumination.

power of 10.As an example, if the last reliably measured digit

is in the fifth decimal place, the method would be designated a

-5

10 method.

This guide is under the jurisdiction of ASTM Committee C14 on Glass and

Glass Products and is the direct responsibility of Subcommittee C14.11 on Optical For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Properties. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Oct. 1, 2006. Published February 2007. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

C1648-06. the ASTM website.

Metricon is a trademark of Metricon Corporation 12 North Main Street, P.O. The last approved version of this historical standard is referenced on

Box 63, Pennington, New Jersey 08534. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1648 − 06

A

TABLE 1 Spectral Lines for Measurement of Refractive Index

Fraunhofer Line A’ C C’ D d e F F’ g G’ h

Element K H Cd Na He Hg H Cd Hg H Hg

B C D D

Wavelength Nanometers 786.2 656.3 643.8 589.3 587.6 546.1 486.1 480.0 435.8 434.0 404.7

A

From Ref (4).

B

A later reference (identification not available) lists 789.9 nm for the potassium A’ line, although referring to Ref (4). The Handbook of Chemistry and Physics lists 789.9

nm as a very strong line, and it does not list a line at 786.2 nm at all.

C

The wavelength of the corresponding deuterium line is 656.0 nm.

D

The two cadmium lines have been recognized for refractometry since Ref (4) was published.

ν 5 n 21 / n 2 n (1)

3.2 Symbols: ~ ! ~ !

D D F C

n=index of refraction

4.2.1 Some modern usage specifies the use of the mercury

ν=Abbe-number; a representation of particular relative

e-line, and the cadmium C' and F' lines. These three lines are

partial dispersions

obtained with a single spectral lamp.

ν =Abbe-number determined with spectral lines D, C,

D

ν 5 ~n 21!/~n 2 n ! (2)

and F

e e F' C'

ν =Abbe-number determined with spectral lines e, C',

e

4.2.2 Aconsequence of the defining equations (Eq 1 and 2)

and F'

is that smaller ν-values correspond to larger dispersions. For

D=the spectral emission line of the sodium doublet at

ν-values accurate to 1 to 4%, index measurements must be

nominally589.3nm(whichisthemid-pointofthedoubletthat

-4

accurateto1×10 ;therefore,citingν-valuesfromlessaccurate

has lines at 589.0 nm and 589.6 nm)

test methods might not be useful.

C=the spectral emission line of hydrogen at 656.3 nm

F=the spectral emission line of hydrogen at 486.1 nm NOTE 1—For lens-design, some computer ray-tracing programs use

data directly from the tabulation of refractive indices over the full

e=the spectral emission line of mercury at 546.1 nm

wavelength range of measurement.

C'=the spectral emission line of cadmium at 643.8 nm

NOTE 2—Because smaller ν-values represent larger physical disper-

F'=the spectral emission line of cadmium at 480.0 nm

sions, the term constringence is used in some texts instead of dispersion.

4. Significance and Use

5. Precision, Bias, and Accuracy (see Terminology E456)

4.1 Measurement—The refractive index at any wavelength

5.1 Precision—The precision of a method is affected by

of a piece of homogeneous glass is a function, primarily, of its

several of its aspects which vary among methods. One aspect

composition, and secondarily, of its state of annealing. The

is the ability of the operator to repeat a setting on the observed

index of a glass can be altered over a range of up to

-4

optical indicator that is characteristic of the method. Another

1×10 (that is, 1 in the fourth decimal place) by the changing

aspect is the repeatability of the coincidence of the measure-

of an annealing schedule. This is a critical consideration for

ment scale of the instrument and the optical indicator (magni-

optical glasses, that is, glasses intended for use in high

tude of dead-band or backlash); this, too, varies among

performanceopticalinstrumentswheretherequiredvalueofan

-6

methods. A third aspect is the repeatability of the operator’s

index can be as exact as 1×10 . Compensation for minor

reading of the measurement scale. Usually, determinations for

variations of composition are made by controlled rates of

a single test specimen and for the reference piece should be

annealing for such optical glasses; therefore, the ability to

repeated several times and the resulting scale readings aver-

measure index to six decimal places can be a necessity;

aged after discarding any obvious outliers.

however, for most commercial and experimental glasses,

standard annealing schedules appropriate to each are used to

5.2 Bias (Systematic Error):

limit internal stress and less rigorous methods of test for

5.2.1 Absolute Methods—Two of the test methods are abso-

refractive index are usually adequate.The refractive indices of

lute;theothersarecomparisonmethods.Theabsolutemethods

-4

glass ophthalmic lens pressings are held to 5×10 because the

are the prism spectrometer and the apparent depth of micro-

tools used for generating the figures of ophthalmic lenses are

scope focus. These yield measures of refractive index of the

made to produce curvatures that are related to specific indices

specimen in air. In the case of the prism spectrometer, when

of refraction of the lens materials. -6

used for determinations of 1×10 , correction to the index in

4.2 Dispersion—Dispersion-values aid optical designers in vacuum (the intrinsic property of the material) can be calcu-

their selection of glasses (Note 1). Each relative partial lated from the known index of air, given its temperature,

dispersion-number is calculated for a particular set of three pressure, and relative humidity. The accuracy of the apparent

wavelengths, and several such numbers, representing different depth method is too poor for correction to vacuum to be

parts of the spectrum might be used when designing more meaningful. Bias of the prism spectrometer depends upon the

complex optical systems. For most glasses, dispersion in- accuracy of its divided circle. The bias of an index determina-

creases with increasing refractive index. For the purposes of tion must not be greater than one-half of the least count of

this standard, it is sufficient to describe only two reciprocal reading the scale of the divided circle. For a spectrometer

-6

relative partial dispersions that are commonly used for char- capable of yielding index values accurate to 1×10 , the bias

-7

acterizing glasses.The longest established practice has been to must be not greater than 5×10 . Bias of the apparent depth

cite the Abbe-number (or Abbe ν-value), calculated by: method depends on the accuracy of the device for measuring

C1648 − 06

the displacement of the microscope stage; it is usually appre- andtheothersideappearsdarkerthantheaveragebrightnessof

ciable smaller than the precision of the measurement, as the field. When the focus is above the plane of the glass

explained in 7.6. particle, a bright line next to the boundary appears in the

5.2.2 Comparison Methods—All of the comparison meth- medium of higher index. This is the “Becke line”; conversely,

ods rely upon using a reference material, the index of which is whenthefocusisbelowtheplaneoftheparticle,thebrightline

knowntoanaccuracythatisgreaterthanwhatcanbeachieved appears in the medium of lower index. Successive changes of

by the measurements of the given method itself; therefore, the oil, using new glass particles, lead by trial and error to a

bias of these methods is the uncertainty of the specified bracketing of the index of the particle between the pair of oils

refractive index of the reference material, provided that the that match most closely (or to an exact match). Visual

instrument’s scale is linear over the range within which the interpolation can provide resolution to about one fourth of the

test-specimen and the reference are measured. The bias intro- difference between the indices of the two oils. The physical

duced by non-linearity of the scale can be compensated by principle underlying the method is that of total internal

calibratingthescaleoveritsrangewithreferencepieceshaving reflection at the boundary, within the medium of higher index.

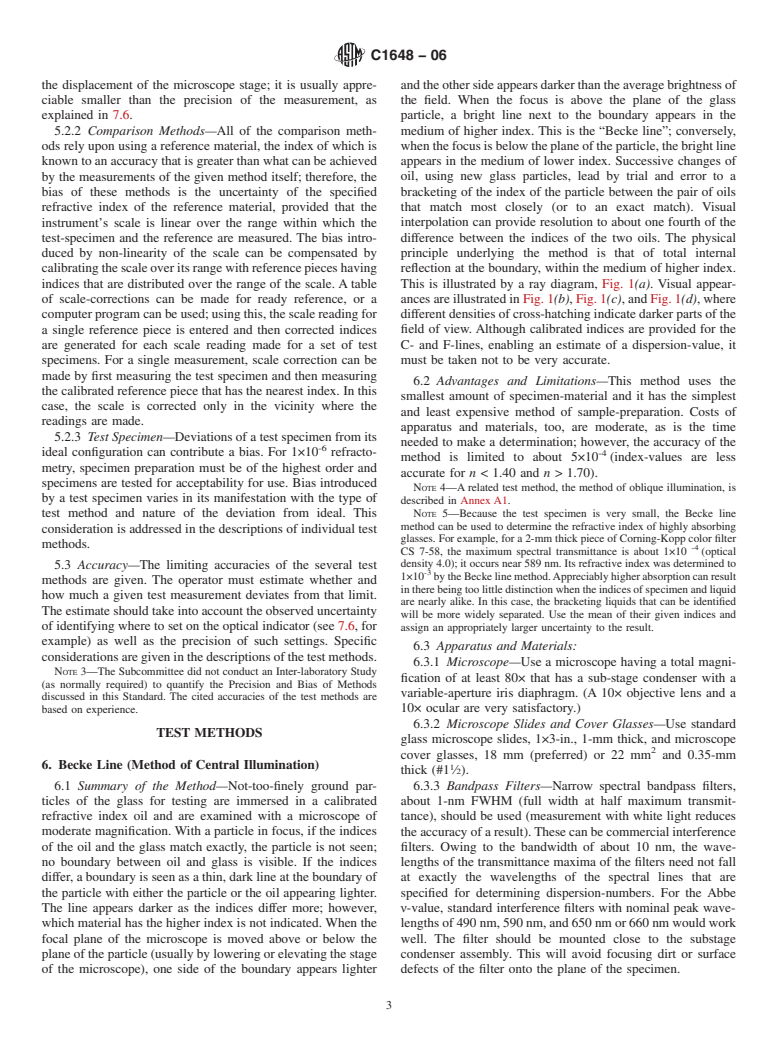

indices that are distributed over the range of the scale.Atable This is illustrated by a ray diagram, Fig. 1(a). Visual appear-

of scale-corrections can be made for ready reference, or a ancesareillustratedinFig.1(b),Fig.1(c),andFig.1(d),where

differentdensitiesofcross-hatchingindicatedarkerpartsofthe

computerprogramcanbeused;usingthis,thescalereadingfor

a single reference piece is entered and then corrected indices field of view.Although calibrated indices are provided for the

C- and F-lines, enabling an estimate of a dispersion-value, it

are generated for each scale reading made for a set of test

specimens. For a single measurement, scale correction can be must be taken not to be very accurate.

made by first measuring the test specimen and then measuring

6.2 Advantages and Limitations—This method uses the

thecalibratedreferencepiecethathasthenearestindex.Inthis

smallest amount of specimen-material and it has the simplest

case, the scale is corrected only in the vicinity where the

and least expensive method of sample-preparation. Costs of

readings are made.

apparatus and materials, too, are moderate, as is the time

5.2.3 Test Specimen—Deviationsofatestspecimenfromits

needed to make a determination; however, the accuracy of the

-6

ideal configuration can contribute a bias. For 1×10 refracto- -4

method is limited to about 5×10 (index-values are less

metry, specimen preparation must be of the highest order and

accurate for n < 1.40 and n > 1.70).

specimens are tested for acceptability for use. Bias introduced

NOTE 4—Arelated test method, the method of oblique illumination, is

by a test specimen varies in its manifestation with the type of

described in Annex A1.

test method and nature of the deviation from ideal. This NOTE 5—Because the test specimen is very small, the Becke line

method can be used to determine the refractive index of highly absorbing

consideration is addressed in the descriptions of individual test

glasses.Forexample,fora2-mmthickpieceofCorning-Koppcolorfilter

methods.

-4

CS 7-58, the maximum spectral transmittance is about 1×10 (optical

density4.0);itoccursnear589nm.Itsrefractiveindexwasdeterminedto

5.3 Accuracy—The limiting accuracies of the several test

-3

1×10 bytheBeckelinemethod.Appreciablyhigherabsorptioncanresult

methods are given. The operator must estimate whether and

intherebeingtoolittledistinctionwhentheindicesofspecimenandliquid

how much a given test measurement deviates from that limit.

are nearly alike. In this case, the bracketing liquids that can be identified

Theestimateshouldtakeintoaccounttheobserveduncertainty

will be more widely separated. Use the mean of their given indices and

of identifying where to set on the optical indicator (see7.6, fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.