ASTM E2448-05

(Test Method)Standard Test Method for Determining the Superplastic Properties of Metallic Sheet Materials

Standard Test Method for Determining the Superplastic Properties of Metallic Sheet Materials

SCOPE

1.1 This test method describes the procedure for determining the superplastic forming properties (SPF) of a metallic sheet material. It includes tests both for the basic SPF properties and also for derived SPF properties. The test for basic properties encompasses effects due to strain hardening or softening.

1.2 This test method covers sheet materials with thicknesses of at least 0.5 mm but not greater than 6 mm. It characterizes the material under a uni-axial tensile stress condition.

Note 1—Most industrial applications of superplastic forming involve a multi-axial stress condition in a sheet; however it is more convenient to characterize a material under a uni-axial tensile stress condition. Tests should be performed in different orientations to the rolling direction of the sheet to ascertain initial anisotropy.

1.3 This method has been used successfully between strain rates of 10-5 to 10-1 per second.

1.4 This method has been used successfully on Aluminum and Titanium alloys. The use of the method with other metals should be verified.

1.5 The values given in SI units are to be considered the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2448 – 05

Standard Test Method for

Determining the Superplastic Properties of Metallic Sheet

Materials

This standard is issued under the fixed designation E 2448; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 646 Test Method for Tensile Strain Hardening Exponents

(n-Values) of Metallic Materials

1.1 This test method describes the procedure for determin-

E 691 Practice for Conducting an Interlaboratory Study to

ing the superplastic forming properties (SPF) of a metallic

Determine the Precision of a Test Method

sheet material. It includes tests both for the basic SPF proper-

ties and also for derived SPF properties. The test for basic

3. Terminology

properties encompasses effects due to strain hardening or

3.1 Definitions—Definitions such as gage length (L and L ),

softening.

true stress (s), true strain (e), normal engineering stress (S),

1.2 This test method covers sheet materials with thicknesses

and engineering strain (e) are defined in Terminology E6.

of at least 0.5 mm but not greater than 6 mm. It characterizes

Thus,

the material under a uni-axial tensile stress condition.

e5 ln~L/L !

NOTE 1—Most industrial applications of superplastic forming involve a

s5 S~1 1 e!

multi-axial stress condition in a sheet; however it is more convenient to

characterize a material under a uni-axial tensile stress condition. Tests

NOTE 2—Engineering stress S and strain e are only valid up to the point

should be performed in different orientations to the rolling direction of the

ofneckingorinstabilityofcrosssection.Forsuperplasticdeformation,the

sheet to ascertain initial anisotropy.

coupon undergoes an essentially uniform and constant neck along its

1.3 This method has been used successfully between strain length, and S and e are assumed in this standard to be valid. However at

-5 -1

the junction to the clamp sections of the coupon the cross section reduces

rates of 10 to 10 per second.

from the original value to the final value, over a length of approximately

1.4 This method has been used successfully on Aluminum

4 % at each end. Also, there are local small instabilities of cross section

and Titanium alloys. The use of the method with other metals

over the gauge length.These contribute to an error in the calculated values

should be verified.

of e and s. In the absence of currently available extensometers that could

1.5 The values given in SI units are to be considered the

operate in the high temperature environment of an SPF test, e and s are

standard.

to be inferred from crosshead extension and force.

1.6 This standard does not purport to address all of the

3.2 Symbols Specific To This Standard:

safety concerns, if any, associated with its use. It is the

V = machine crosshead velocity, the velocity of the traveling

responsibility of the user of this standard to establish appro-

member of the test machine to which one of the coupon clamps

priate safety and health practices and determine the applica-

is attached

bility of regulatory limitations prior to use.

·

e = strain rate, measured as: V/@L ~1 1 e!#

2. Referenced Documents

NOTE 3—This is an operational definition of strain rate.

2.1 ASTM Standards:

·

m = strain rate sensitivity, defined as (ln Ds)/ (ln De). In

E4 Practices for Force verification of Testing Machines

· ·

E6 Terminology Relating to Methods of Mechanical Test-

practical terms, m = log (s /s )/log (e /e ) under stated test

2 1 2 1

ing

conditions, see 7.2.1.

E21 Test Methods for Elevated Temperature Tension Tests

NOTE 4—The derived term m is widely used to describe the SPF

of Metallic Materials

properties of a material. It should be used with caution, as it is dependent

on strain, strain rate and temperature. Many references in the literature do

not identify the strain condition at which the readings were taken, or allow

This test method is under the jurisdiction of ASTM Committee E28 on

multiple strains to be used in the determination of m.

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on

NOTE 5—Many superplastic alloys exhibit strain hardening. However

Ductility and Flexure Testing.

the conventional strain hardening exponent n as defined in Test Method

Current edition approved Dec. 1, 2005. Published January 2006.

E 646 is not valid for superplastic materials as strain hardening in the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

latter is usually a coefficient of strain, rather than an exponent. The

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2448–05

mechanism of strain hardening in superplastic flow is essentially due to

movement of the crosshead. Due to the low loads of these tests

grain growth, and although the stress/strain relationship is often linear, it

(typically 100 N maximum) compliance is likely to be small.

is not universal for all superplastic materials. Consequently there is no

5.4 The tensile test machine shall be computer controlled

simple definition of a strain hardening coefficient and this standard does

andcapableofvaryingthecrossheadspeedinordertomaintain

not define one. Consideration of strain hardening in superplastic defor-

a near constant strain rate. Step increases in crosshead speed

mation is discussed in Ghosh and Hamilton’s, “Influences of Material

are allowed, a variation of 1 % from nominal strain rate is

Parameters and Microstructure on Superplastic Forming.”

permitted.

3.2.1 The gage length (L) is defined as the instantaneous

5.5 The tensile test machine shall be provided with clamps

distance between the shoulders of the coupon during the test.

that hold the test coupon at and under the shoulders adjacent to

NOTE 6—It is assumed no local necking takes place and the cross

the gage section. The coupon is not to be compressed by the

section of the coupon is constant over the entire gage length. For some

clamps, as this will induce superplastic flow out of the clamp

materials, cavitation inside the material increases the volume of the gage

area during the test. Clamp design should follow that shown in

section as the test progresses, and the true cross-sectional area has to be

Fig. 2.

compensated for any strain. For other materials, the coupon can develop

5.6 The apparatus is provided with a furnace that shall

a ribbed or other local texture, and in this case, the minimum cross section

maintain the coupon at a constant temperature throughout the

has to be measured. During the test there is an increasingly non uniform

cross section at each end of the coupon where the gage section transitions

test. Test equipment shall meet the requirements of Test

to the original width at the clamp section. This effect is small and can

Methods E21 for temperature measuring, calibration, and

usually be ignored.

standardization.

4. Significance and Use

6. Procedure

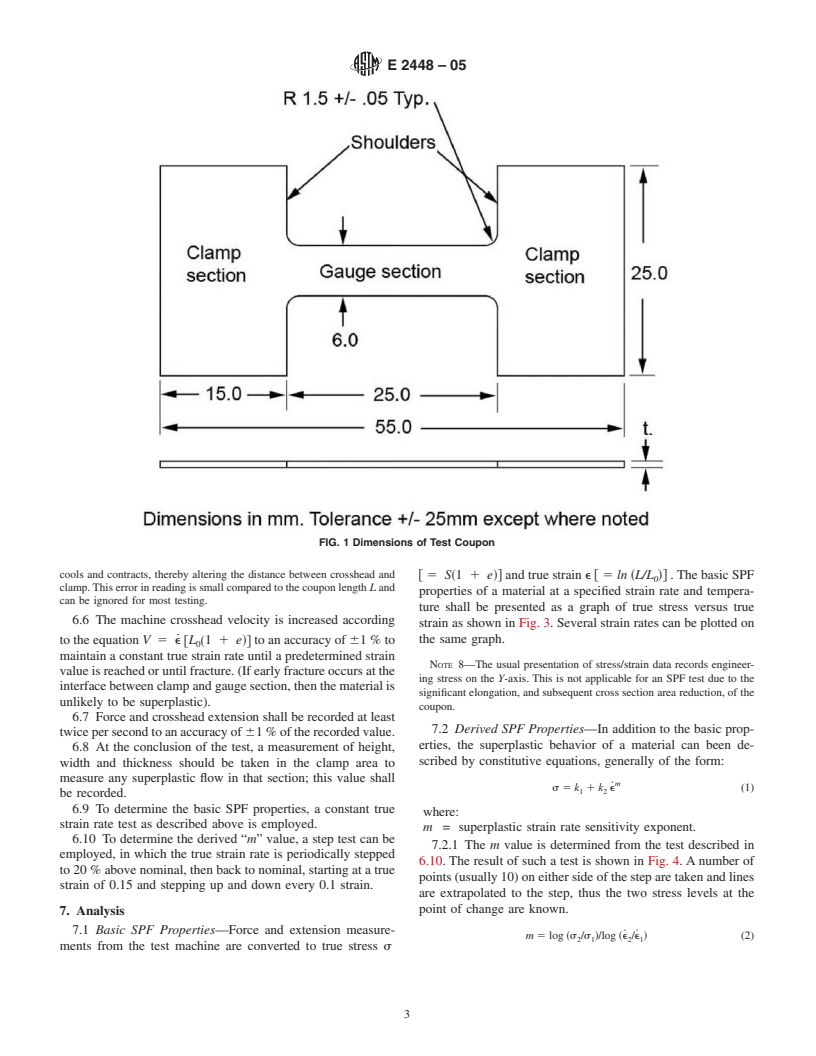

4.1 The determination of the superplastic properties of a

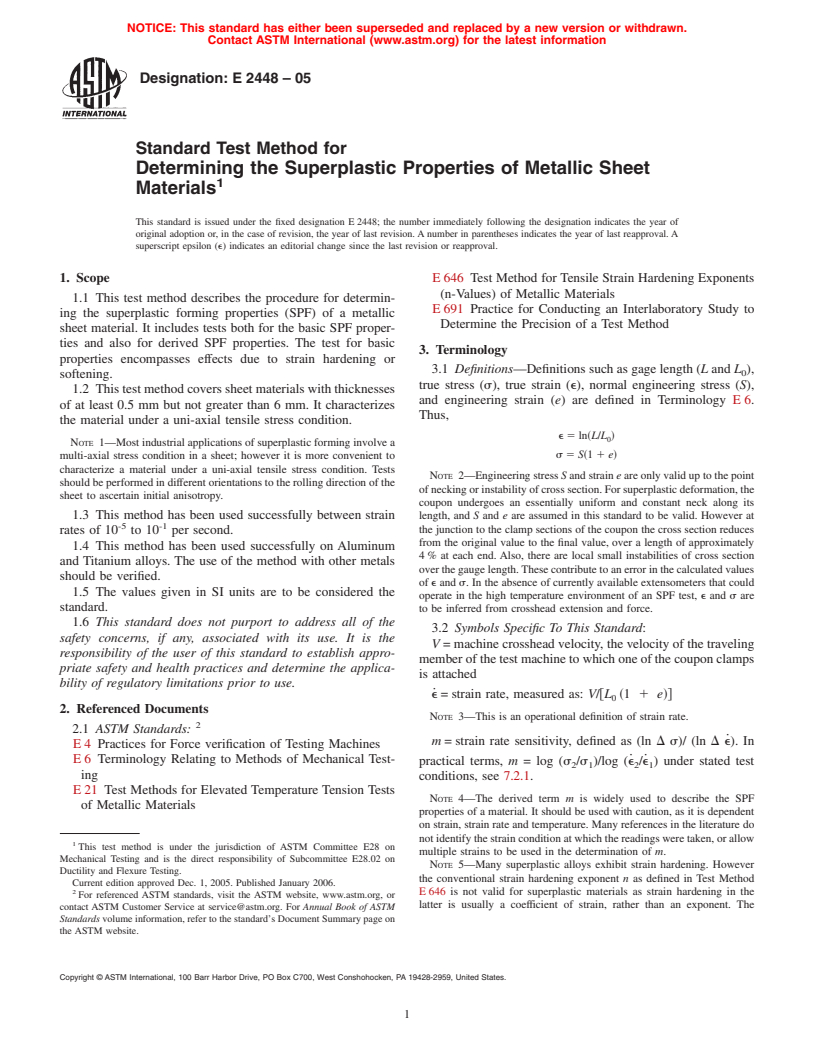

6.1 Test coupons shall be made to the dimensions shown in

metallic sheet material is important for the observation, devel-

Fig. 1. The coupon width and gage thickness t shall be

opment and comparison of superplastic materials. It is also

measuredandrecordedataminimumoffourplacesinthegage

necessary to predict the correct forming parameters during an

section, to a tolerance of 1 % of reading, or 12 µm, whichever

SPF process. SPF tensile testing has peculiar characteristics

is greater.

comparedtoconventionalmechanicaltesting,whichdistortthe

6.2 If material oxidation affects the superplastic behavior of

true values of stress, strain, strain hardening, and strain rate at

the material, the furnace can be flooded with argon or other

the very large elongations encountered in an SPF pull test,

inert gas to reduce the effects of oxidation.

consequently conventional mechanical test methods cannot be

6.3 Before starting the test, the furnace is bought up to the

used. This test method addresses those characteristics by

desired temperature and stabilized. The coupon is loaded into

optimizing the shape of the test coupon and specifying a new

the clamps. During the heat up of the coupon, it is important to

test procedure.

minimize external stress from the machine to the coupon.

4.2 The evaluation of a superplastic material can be divided

Many test machines incorporate a “protect specimen” or “load

into two parts. Firstly, the basic superplastic-forming (SPF)

control” option during the heating phase to accommodate the

properties of the material are measured using the four param-

thermal expansion of the coupon/grip assembly inside the

eters of stress, temperature, strain, and strain rate. These are

furnace and to prevent buckling of the coupon. This control

obtained using conversions from the raw data of a tensile test.

option ensures “almost” zero loading on the test specimen

Secondly, derived properties useful to define an SPF material

during heating through the movement of the cross-head beam.

are obtained from the basic properties using specific equations.

6.4 Ideally the test should not commence until the coupon

5. Apparatus

hasreachedthermalequilibrium.Thiswillbereachedwhenthe

cross-head beam ceases to move under the “protect specimen”

5.1 The accuracy of the testing machine shall be within the

control, indicating that no more thermal expansion is taking

permissible variation specified in PracticesE4.

place. However this time can be long enough to allow grain

5.2 The apparatus shall be calibrated according to appropri-

growthinthecoupon,whichdistortsthesuperplasticproperties

ate standards or manufacturer instructions.

being evaluated. Therefore the time taken for the thermo-

5.3 No extensometer is used in this test method, and the

couples to come within tolerance can be used instead if grain

extension of the test coupon is measured at the machine

growth is considered

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.